Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > Custom PCB and PCB Assembly: From Design to Prototyping

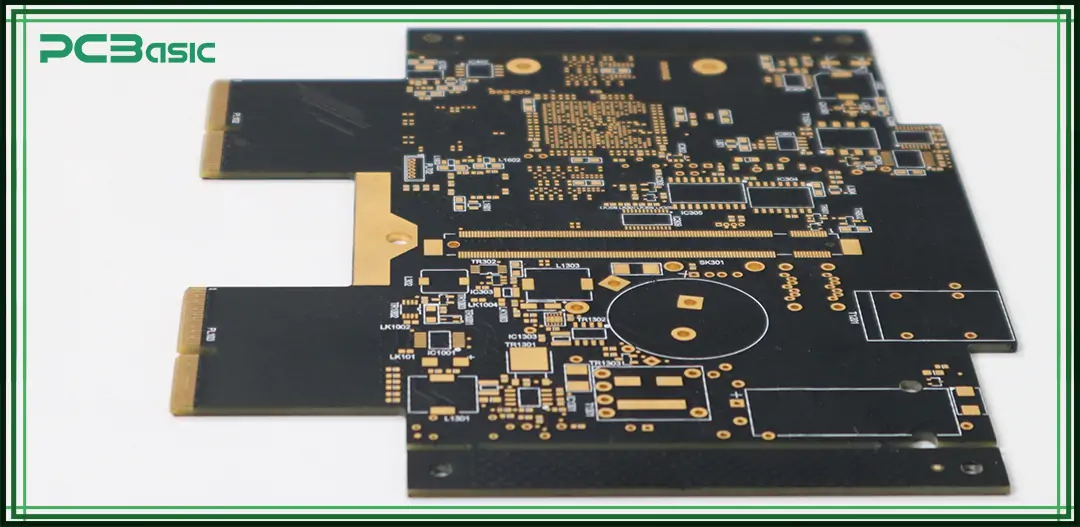

With the rapid development of the electronics industry, custom PCB and PCB assembly are no longer technologies that only large enterprises are able to use. Nowadays, more and more startups need custom circuit boards to develop smart wearable devices, and engineers are relying on them to build various automation control systems. The demand for custom circuit boards has permeated multiple industries and has become an important foundation for promoting the innovation and implementation of electronic products.

This article will take you through the entire process simply and clearly - from custom PCB design to custom prototyping and assembly. Whether you are looking for a reliable custom PCB manufacturer or want to figure out the cost of custom PCBs or PCB assembly, this article will provide practical information.

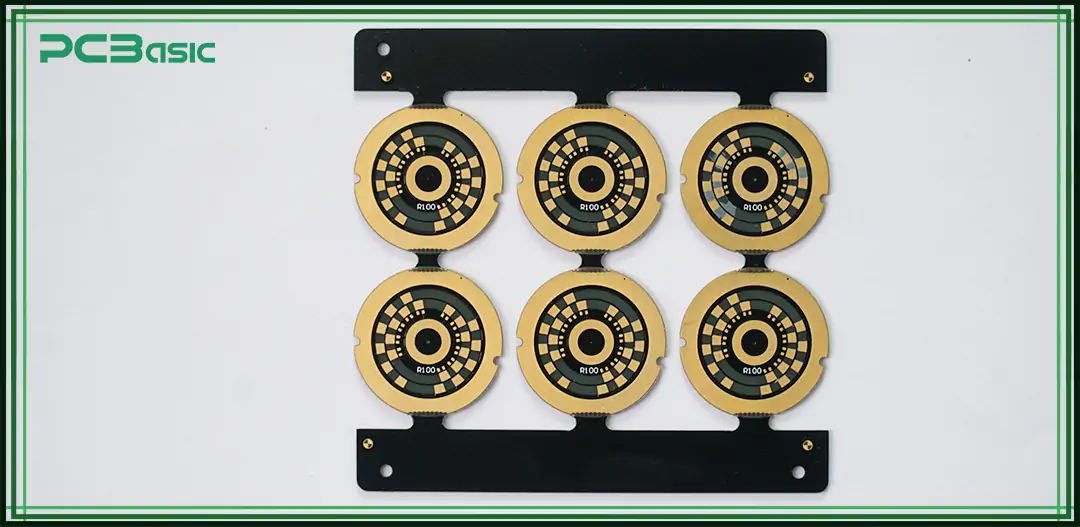

The custom printed circuit board refers to a circuit board that is tailor-made according to the actual requirements of your product. It is different from the standard general-purpose circuit board. The custom circuit board can be flexibly designed according to the specific uses, structures and performance requirements of the project. This means that engineers can have full control over all the key parameters of the circuit board, including:

• Unique board shapes and dimensions

It can be designed into any shape according to the product shell or installation space, such as circular, curved corners, and ultra-small size.

• Specific layer counts and material types

You can choose double-layer, 4-layer or multi-layer structures. In terms of materials, you can also select the conventional FR4, or the Rogers material which is more suitable for high-frequency applications, or even the aluminum substrate used for heat dissipation.

• Customized trace routing, via placements, and copper thickness

It can precisely control the thickness, spacing and routing mode of the circuit board trace, meeting the design requirements such as high-density wiring and impedance control.

• Electrical and thermal performance:

It can be designed for signal integrity, power consumption control and heat distribution to ensure the stability and reliability of the product in actual use.

• Integration with special components or mechanical interfaces

Mounting holes, pads, connectors, and vias can be customized to accommodate specific chips, sensors, or mechanical features, ensuring seamless integration into your overall product design.

Whether you are designing a high-frequency communication module or need to develop a core control board for a small IoT device, custom PCB design can help you achieve the optimal layout and functional combination.

Learning about the cost of custom PCB is a very crucial step in the early stage of product development, especially when conducting budget assessment and project planning. Although the specific custom PCB cost may vary depending on the product design, it is usually composed of the following core factors:

Main cost factors:

• Board complexity:

This includes the number of layers of the circuit board, the width and spacing of the traces, and the type of vias (such as through vias, blind vias, buried vias, micro-vias). The more complex the design is, the more refined the required craftsmanship will be, the higher the processing difficulty will be, and the cost will naturally increase.

• Board size:

The larger the custom circuit board size is, the more materials are used, the longer the processing time will be, and the cost will also increase accordingly.

• Material selection:

Standard FR4 is the most commonly used and economical material. However, if the project requires high-frequency signals or stronger heat dissipation performance, high-performance materials such as Rogers and aluminum-based materials may need to be used, and the cost will also increase accordingly.

• Order quantity

The unit price of custom prototyping or small-batch production is relatively high because separate material cutting, debugging, and process flow setting are required. Mass production orders can spread out these fixed costs, significantly reduce the price of individual pieces, and improve the overall cost performance.

• Testing requirements

If quality control, such as flying probe testing, AOI, X-ray, and functional testing, is required for your custom PCBs, certain testing costs will increase.

• Assembly complexity:

The number of components, package types (such as BGA, QFN, plug-ins), and whether double-sided mounting is required, will also directly affect the labor and equipment costs of custom PCB assembly.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

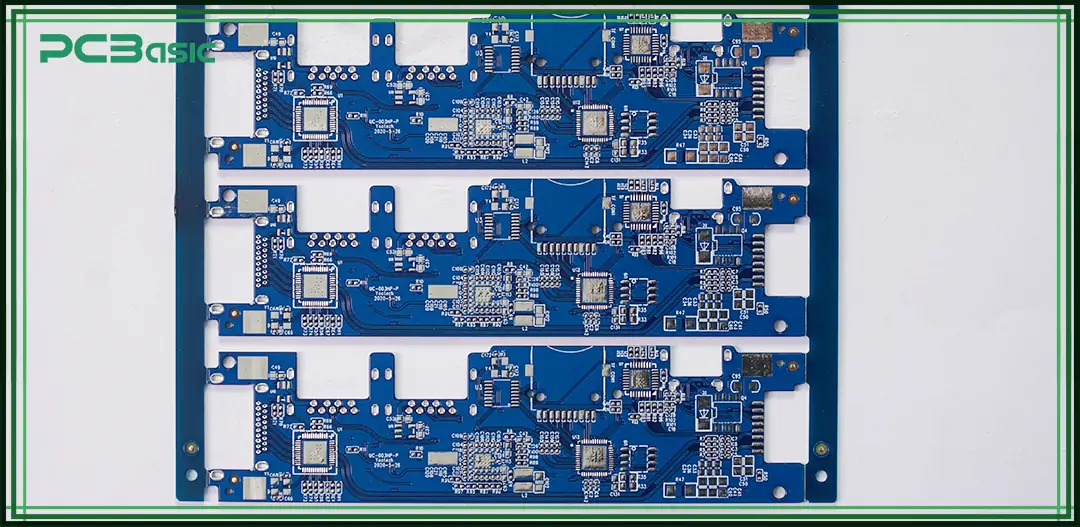

When the custom printed circuit board is completed, the next step is to assemble and solder various electronic components onto the circuit board. This process is called PCB assembly. The step determines whether the entire circuit board can work normally and is a very crucial part in the production of electronic products.

Core assembly services include:

SMT (Surface Mount Technology):

By using a pick-and-place machine to precisely attach tiny components to the surface of a PCB and then completing the soldering through reflow soldering. This is currently the most mainstream assembly method and is applicable to most modern electronic products, such as mobile phones, smart wearables, industrial control boards, etc.

Through-hole Assembly:

Insert the component pins into the vias on the PCB and fix them using wave soldering or manual soldering. It is suitable for occasions with large power or high structural requirements, such as transformers, power sockets, connectors and so on.

Hybrid Assembly (SMT + Through-hole):

Some circuit boards contain both surface mount components and through-hole components, requiring a combination of both techniques. This approach is more common in industrial and custom products.

Functional Testing and Inspection:

This includes automated optical inspection (AOI), X-ray inspection, flying probe testing, in-circuit testing, ensuring that each circuit board can work normally and has no soldering defects.

PCBasic provides one-stop PCB solutions from custom PCB design services, manufacturing to custom circuit board assembly. Whether it's single-chip prototyping or mass production, it can meet your needs.

1. Custom PCB Design Services

2. PCB Fabrication

3. Custom PCB Assembly

PCBasic is a one-stop custom PCB manufacturer that brings together quality, speed, and affordability. You don’t need to juggle multiple vendors—we do it all.

Ordering a custom PCB and custom PCB assembly from PCBasic is straightforward:

Step 1: Submit Your Files

Upload your Gerber files, BOM, and assembly drawings.

Step 2: Instant Quotation

Use our platform to get a fast quote based on specs, quantity, and lead time.

Step 3: DFM & Engineering Review

Our engineers review your files for manufacturability and assembly readiness.

Step 4: Prototyping or Mass Production

Whether it’s custom prototyping or a production run, we deliver as per your schedule.

Step 5: Delivery

Receive your fully assembled and tested custom circuit boards, which are ready for integration.

With PCBasic, it's never been easier to order custom PCBs and get full-service custom PCB assembly in one seamless workflow.

Choosing PCBasic as your custom PCB manufacturer and assembly partner provides the following advantages:

• Experienced Engineers: Over 15 years in custom PCB design and manufacturing

• End-to-End Services: From custom prototyping to large-scale custom circuit board assembly

• Smart Manufacturing: 9+ SMT lines, AOI, X-ray, and flying probe testing

• Certifications: ISO 9001, IATF 16949, and ISO 13485

• Global Support: Serving customers in over 50 countries

• Instant Quotation: Upload files and order custom PCBs online

With a proven track record and dedicated service team, PCBasic is a trusted choice for engineers, startups, and OEMs alike.

In this era when electronic products are increasingly intelligent and miniaturized, it is crucial to find the right partners for custom PCB and custom PCB assembly. From precise custom PCB design to highly reliable custom circuit board assembly, PCBasic guarantees every step for you.

Whether you need custom prototyping or medium- and large-scale production, PCBasic can serve as your core custom PCB manufacturer and provide a reliable solution.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.