Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > High Tg PCB: A Comprehensive Guide

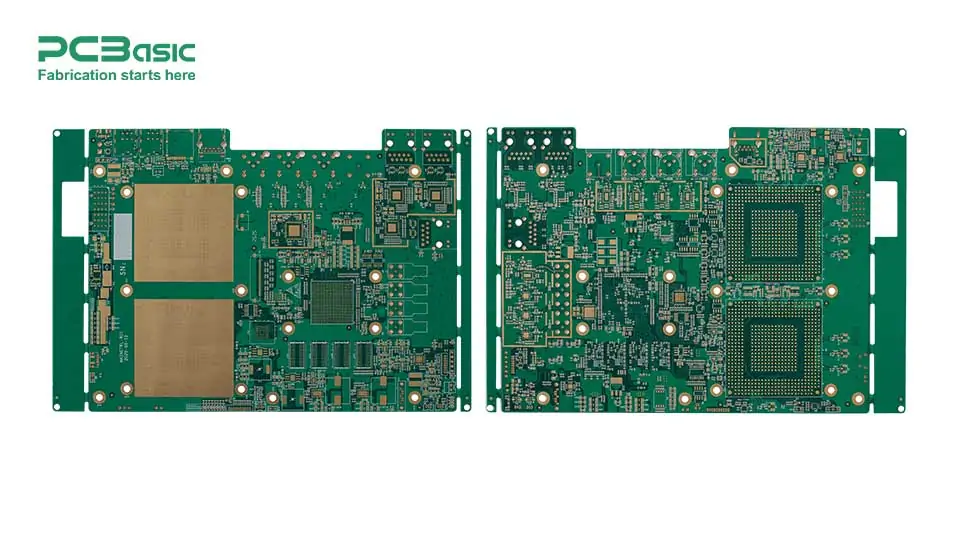

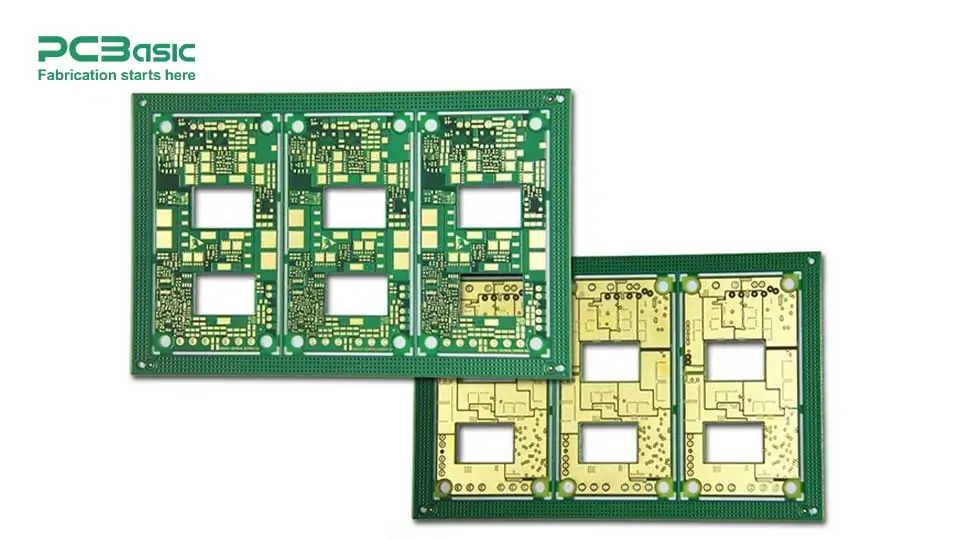

Do you know what high Tg PCB is? In the modern electronics industry, with the increased demand for high power density and high-temperature operating environments, high Tg PCBs have become a key choice to ensure the reliability and heat resistance of the circuit board. High Tg PCBs are designed to operate under high-temperature and mechanical stress conditions, and their thermal stability, mechanical strength, and electrical properties are better than ordinary PCBs.

Next, in this article, we will take you to explore the characteristics, advantages, application scenarios of high Tg PCB materials, and how to choose the right Tg board to ensure the best performance and reliability for electronic devices. First, let's have a look at definition of high Tg PCB.

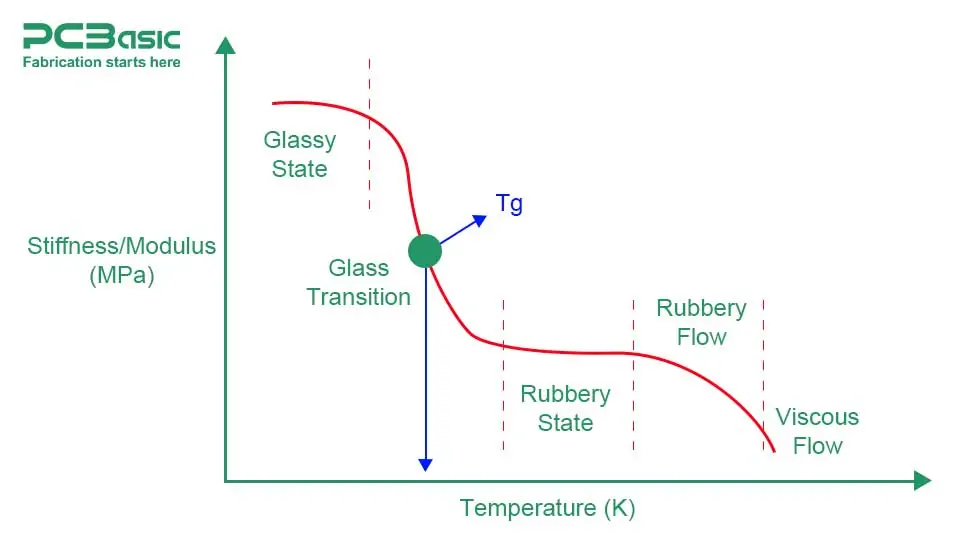

A high Tg PCB is a printed circuit board made using a material with a high glass transition temperature (Tg). The Tg value represents the temperature at which the PCB substrate material changes from a hard glass state to a soft rubber state. For standard FR4 materials, Tg values typically range from 130℃ to 140℃, while Tg values for high Tg PCBs reach 170℃ or higher, and ultra-high Tg materials can even exceed 180℃. High Tg PCBs are designed to maintain their mechanical and electrical properties at high temperatures without softening or failure. This makes them ideal for applications that operate in high-temperature environments or require lead-free welding processes.

FR4 is the most commonly used PCB substrate material and is usually composed of epoxy resin and glass fiber. High Tg FR4 is a specific type of high Tg PCB, mainly by changing the combination of resin formulation and glass fiber to improve its Tg value, high Tg FR4 indicates that this FR4 material has a higher glass transition temperature (usually greater than 170°C), more suitable for applications requiring high-temperature stability.

|

Metric |

Standard FR4 PCB |

High Tg FR4 PCB |

|

Tg Value |

130°C – 140°C |

≥170°C (High Tg), some >180°C |

|

Thermal Stability |

Moderate |

Excellent for continuous high-temperature use |

|

Thermal Shock Resistance |

Prone to delamination or warping during cycles |

Resistant to thermal cycling and extreme conditions |

|

Plated Through Hole Reliability |

May crack under thermal stress |

Maintains PTH integrity at high temperatures |

|

Suitable Layer Count |

Ideal for single/double-layer or low-layer PCBs |

Optimized for multilayer and HDI PCBs (8+ layers) |

|

Target Applications |

Consumer electronics (e.g., appliances, toys) |

Automotive, industrial control, medical, aerospace, 5G |

|

Cost |

Lower; ideal for cost-sensitive projects |

Slightly higher; justified by performance and reliability |

Glass transition temperature (Tg) is a key characteristic of PCB materials, especially substrate materials such as FR4. As mentioned earlier, Tg refers to the temperature at which a material changes from a rigid glass state to a flexible rubber state. Below Tg values, the material remains hard and stable, providing the necessary mechanical strength for the PCB. When the temperature exceeds the Tg value, the material becomes softer and more prone to deformation, which can lead to problems such as plate warping, delamination or plating through hole (PTH) failure.

Because the high Tg material can improve the reliability of the PCB in extreme environments, this makes it very suitable for multilayer circuit boards and high power density applications. Here are its advantages:

The first is its dimensional stability; the expansion rate of high Tg PCB materials at high temperatures is lower, and the probability of inter-layer dislocation and structural deformation will be reduced.

Secondly, its reliability of plated through holes, which can prevent PTH from cracking or delamination at high-temperatures and ensure the stability of the long-term use of the circuit board.

Third, its thermal stress resistance. This feature of Tg boards can effectively reduce thermal damage in applications that experience frequent temperature cycles, such as automotive and industrial equipment.

There is also its low coefficient of thermal expansion: the coefficient of thermal expansion of high Tg PCB is lower, and it can still maintain good dimensional stability in a high-temperature environment.

High Tg PCBs are often used in electronic applications that need to withstand high temperatures, high power densities or harsh environments. In this environment, circuit boards such as high Tg PCBs with excellent thermal performance and mechanical strength are needed to ensure the stable operation of the circuit boards. The application of High Tg PCB is also very extensive. The following are several typical application examples:

1. Aerospace Industry: Electronic components in aviation systems often operate in environments with extreme temperatures and high pressures. For instance, the aircraft engine control unit (ECU) needs to withstand the sharp temperature differences at high altitudes. At this time, the high Tg FR4 PCB has a glass transition temperature (Tg) of FR4 that can reach above 170℃. It can maintain mechanical and electrical properties even in extreme environments and is an ideal choice for ensuring flight safety.

2. Automotive Industry: such as electric vehicles, power systems, and RF circuits generate a large amount of heat, which puts forward higher requirements for the high-temperature resistance performance of the boards. The use of FR4 boards with a high Tg value can effectively reduce the coefficient of thermal expansion (CTE) and improve the pad reliability of multilayer boards.

3. Medical Industry: such as CT and MRI, biological detection instruments, and surgical monitoring equipment require extremely high reliability and stability, and must meet the design requirements of high-density interconnect (HDI). They need high Tg PCB.

4. Communication and 5G Infrastructure: 5G base stations, optical communication transceivers and high-frequency antennas need to operate at high frequencies and high power, resulting in significant internal heat generation. These applications are more inclined to use high Tg FR4 PCBs to reduce dielectric loss and maintain the rigidity of the circuit board.

5. Industrial Industry: Industrial automation, such as factory automation control systems, robot control units, power inverters and other equipment, need to operate stably for long periods under high-temperature and high-current conditions. They need to adopt high Tg FR4 plates to improve the thermal cycle life and dimensional stability of the products, and avoid pad cracking or multilayer plate failure.

|

Tg Value |

Application Range |

|

130-140℃ |

Consumer electronics |

|

170-180℃ |

Industrial, automotive, medical applications |

|

200℃+ |

Aerospace, military, extreme environments |

The data in the above table is for your reference.

|

Common High Tg FR4 Materials |

|

|

Material |

Properties |

|

Epoxy Resin-Based FR4 |

High thermal stability, Tg > 170°C |

|

Polyimide (PI) |

Excellent thermal stability, high dielectric properties |

|

PTFE (Polytetrafluoroethylene) |

Low dielectric loss, thermally stable at high frequencies |

|

Ceramic-Filled Epoxy |

Increased thermal conductivity and stability, good for high-power applications |

|

Hybrid Materials (PTFE/FR4) |

Combines PTFE and FR4 for cost-effective solutions with stability at high-temperature |

|

Polyester Resin-Based |

Heat resistance but less common than epoxy-based materials |

|

Bismaleimide-Triazine (BT) |

Excellent mechanical properties, high thermal stability |

High Tg PCBs are ideal for high-temperature, high power density electronic systems. The use of high Tg PCB materials can ensure stable operation of the board in extreme environments.

Electronic products are constantly evolving, and the correct selection of Tg Board and PCB Tg grades is increasingly important for automotive, medical, aerospace, telecommunications and industrial electronics. Whether you are designing high power systems or lead-free welding applications, investing in high Tg PCBs will ensure that your products meet high reliability standards.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

1. Does my project need to use high Tg materials? Are there any suggestions for model selection?

If your application involves: ①continuous operation temperature exceeding 130°C ②lead-free soldering (such as RoHS requirements) ③multi-layer or HDI design (≥6 layers) ④high-reliability scenarios such as automotive, industrial, power supply, and military industries.

Then you need to consider using high Tg PCB materials. Then select the appropriate grade and plate type based on the project's temperature budget. Here is a table about FR4 Tg materials’ categories:

Standard Tg PCB (130°C-140°C)

High Tg PCB (170°C-180°C)

Ultra High Tg PCB (200°C+)

2. What are some common high Tg materials available for selection?

Common high Tg FR4 PCB materials include: ITEQ IT-180A, Shengyi S1000H, Isola 370HR, Panasonic R-1755V, etc. Suitable materials can be selected according to performance requirements and budget.

3. Where can high Tg PCBs be sampled or purchased in bulk?

You can contact professional high Tg PCB factories or suppliers. For instance, PCBasic offers a complete range of services from prototyping, small batch production to mass production, supporting the manufacturing of high Tg PCB prototypes and rapid delivery, as well as multiple FR4 Tg grades and structural customization.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.