Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Mechanical Keyboard PCB – A Complete Guide

In the world of keyboard enthusiasts, programmers and gamers, a mechanical keyboard has become an indispensable tool. It is popular not only because of its crisp tactile feedback and long lifespan, but also for its extremely high playability and customization options. The core component that supports all of this is precisely the mechanical keyboard PCB.

Just like the motherboard in a computer, the keyboard PCB is the foundation of the entire system. Then, how does a mechanical keyboard work and how to choose the solution that suits you from a variety of keyboard PCB designs and layouts?

This article will take you through an in-depth analysis of the function and structure of PCBs for keyboards, introduce in detail different types and layouts of keyboard PCBs, and compare the advantages and disadvantages of soldered PCBs and hot-swap PCBs. After reading this, you will clearly understand what gives life to a mechanical keyboard board and how to make rational choices when purchasing or building your own keyboard.

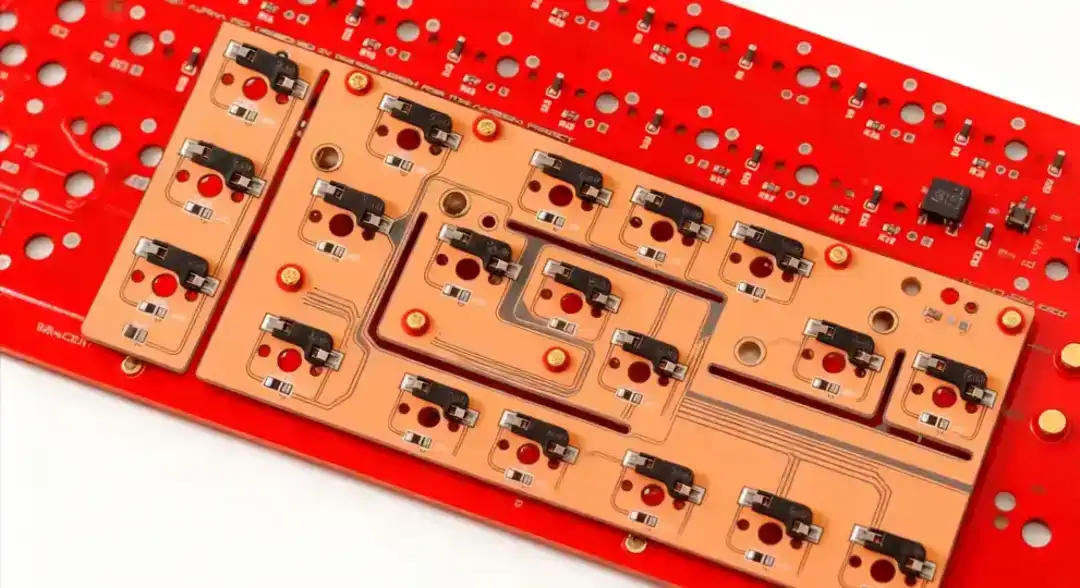

A mechanical keyboard PCB (Printed Circuit Board) is the core part of the mechanical keyboard. It is a thin circuit board, usually made of FR4 fiberglass, with copper traces on the surface. These traces are like "invisible wires", connecting all the mechanical keyboard components such as switches, stabilizers, diodes and microcontrollers to form a complete keyboard circuit.

Without a keyboard PCB, keycaps and witches are just useless plastic parts. It is the PCB that enables each keystroke to have a signal transmission, which is sent to the microcontroller and then recognized and input by the computer.

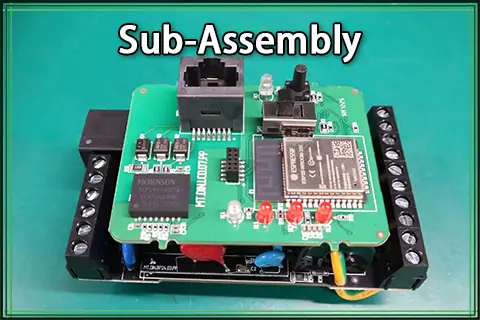

The difference between the mechanical keyboard PCB and PCBA:

These two concepts are often used interchangeably, but they are actually different:

• PCB (Printed Circuit Board): Just a bare keyboard circuit board without any electronic components.

• PCBA (Printed Circuit Board Assembly): A keyboard circuit board with components already assembled, such as switches, resistors, diodes, capacitors, LEDs and microcontrollers, etc.

Simple understanding, PCB for keyboard is an "empty board", while PCBA is a finished board that can be used directly. Strictly speaking, the mechanical keyboard PCB only refers to the bare boards.

The mechanical keyboard PCB is important because it determines the basic design of the keyboard. Whether it's the minimalist 40% keyboard PCB, the popular 60% PCB, or the full-size keyboard PCB, all rely on this circuit board to determine the layout, firmware support and long-term stability of the custom keyboard PCB design.

The keyboard circuit board is like a communication hub, responsible for converting your keystrokes into signals and transmitting them to the computer.

On the mechanical keyboard PCB, each key corresponds to a switch. Switches can be fixed by soldering or installed in hot-swap PCB sockets. When the key is pressed, the switch is triggered and the circuit is closed.

Once the circuit is closed, the electrical signal is transmitted along the copper traces on the keyboard circuit board to the microcontroller. The microcontroller is the "brain" of the keyboard hardware, interpreting signals into digital data that the computer can recognize.

Early keyboards used PS/2 connectors with unshielded twisted pair (UTP). Modern PCB keyboards mainly rely on USB interfaces and often use shielded twisted pair (STP) to ensure the stability of data transmission.

A well-designed PCB not only transmits signals but also receives feedback from the computer. For example, turning on or off RGB lighting, executing macros or responding to key combination inputs.

These instructions will be sent back from the computer to the mechanical keyboard PCB to achieve two-way interaction.

A standard mechanical keyboard PCB typically includes:

• Switches: the core of a mechanical keyboard, providing tactile, linear, or clicky feedback.

• Matrix circuit: rows and columns of traces that reduce the required number of microcontroller pins while enabling anti-ghosting.

• Microcontroller: common models include ATmega32U4 and STM32, which interpret input signals.

• Firmware: such as QMK or VIA, allowing advanced programming and macros.

• Supporting parts: diodes (for anti-ghosting), resistors, capacitors, stabilizers, and RGB LEDs.

The combination of these mechanical keyboard components determines the overall experience of the PCB keyboard, including typing feel, input speed and customization potential.

When analyzing or designing a custom keyboard PCB, several key technical factors need to be given priority consideration:

Common thicknesses include 1.2mm and 1.5mm. Thicker PCBs feel stiffer and more stable when in use, while thinner PCBs are more flexible and can give a slight "bouncy" typing feel. Thickness not only affects the typing experience but also relates to the strength and durability of the circuit board.

The thickness of the copper layer directly determines the stability and wear resistance of signal transmission. The thicker the copper, the more reliable the electrical signal transmission will be, and at the same time, the service life of the PCB will be longer. For keyboard PCBs with high-frequency input or long-term durability, a thicker copper layer can reduce resistance and heat generation.

Most keyboards use 2-layer PCBs, which are sufficient to meet the daily keyboard functions. However, in some high-end mechanical keyboard PCBs, a 4–5-layer structure is used to route more efficiently, enhance shielding performance and reduce signal interference. This is particularly important in keyboards with RGB lighting effects or complex functions.

There are mainly two types: plate-mounted and PCB-mounted. The plate-mounted switch uses a 3-pin design, which is more common and suitable for most keyboards. The PCB-mounted switch uses a 5-pin switch, with two additional positioning pins added, which can make the switch more stable and is particularly suitable for designs in plateless build.

An excellent keyboard PCB design must be compatible with mainstream firmware, such as QMK or VIA. Only in this way can users freely program through the software, define macro commands, modify key functions, and even customize lighting effects. This is one of the core selling points of modern PCB keyboards.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

When choosing or customizing mechanical keyboard PCBs, different types of circuit boards can bring completely different experiences. Whether it is the traditional soldered PCB, the convenient hot-swap PCB, or the RGB gaming PCB that emphasizes lighting effects and performance, each has its own advantages and disadvantages.

The following comparison table will visually present several aspects such as features, advantages, disadvantages and applicable scenarios, helping you quickly find the most suitable solution.

|

Type |

Features |

Advantages |

Disadvantages |

Best Use Cases |

|

Soldered PCBs |

Switches are soldered directly onto the keyboard circuit board |

Lower cost, strong connections, better electrical reliability |

Hard to replace switches, requires soldering tools |

Budget builds, users prioritizing stability and long-term durability |

|

Hot-Swappable PCBs |

Switches are installed in sockets, no soldering required |

Easy customization, convenient for switch testing, and simple repairs |

Higher cost, limited socket lifespan (500–50,000 cycles) |

Keyboard enthusiasts, DIY users, switch testers |

|

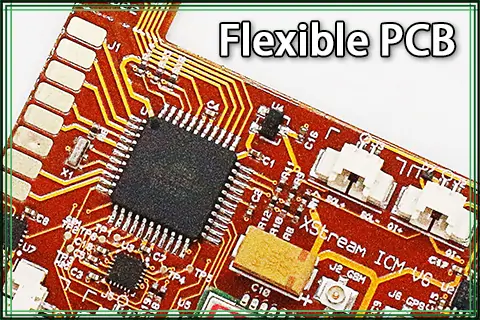

Flexible PCBs |

Built on flexible substrates, foldable or rollable |

Portable, space-saving, and enables unique keyboard designs |

Less common, not as stable as rigid PCBs |

Portable devices, ultra-thin or foldable keyboards |

|

Gaming & RGB PCBs |

Equipped with RGB lighting, optical or Hall-effect switches |

Faster response, strong durability, visually appealing |

Higher cost, more complex design |

Gamers, users who value lighting effects and performance |

|

Laptop Keyboard PCBs |

Compact PCB for keyboard, optimized for space |

Includes extra functions like brightness and volume control |

Limited customization, fixed layout |

Laptops, slim portable devices |

|

Wired PCB Keyboards |

Connect via USB |

Stable connection, lower latency |

Restricted by cables, less portable |

Gaming, professional office use |

|

Wireless PCB Keyboards |

Bluetooth or 2.4GHz connection |

Portable, supports multi-device switching |

Slightly higher latency, requires charging or batteries |

Mobile work, casual daily use |

For keyboard enthusiasts, choosing between a hot-swap PCB or a soldered keyboard circuit board has always been one of the core issues.

Hot-swap PCB vs Soldered PCB Comparison

|

Dimension |

Soldered PCB |

Hot-swap PCB |

|

Assembly |

Requires soldering 100+ switches, time-consuming |

Push-in switches, no tools required |

|

Customization |

Fixed switches, limited modding options |

Easy to swap or mix different switches |

|

Durability |

Solder joints are solid and can last indefinitely |

Sockets wear out over time with repeated use |

|

Cost |

Lower cost, around $20–30 |

Higher cost, usually $50–100+ |

|

Best For |

Users who want stability and long-term durability |

Enthusiasts who enjoy switch testing and DIY convenience |

Overall, both soldered PCBs and hot-swap PCBs have their own advantages. Soldered PCBs are lower in cost and more durable, making them suitable for users who pursue stability and long-term use. Hot-swap PCBs, on the other hand, offer greater convenience and playability, making them highly suitable for enthusiasts who enjoy trying out different components and making personalized modifications.

The layout determines the physical arrangement of keys, and the mechanical keyboard PCB determines which layouts it can support.

• 40% keyboard PCB: Ultra-minimalist and portable, with no function row or arrow keys.

• 60% PCB: A compact design that removes the numpad and function row, highly popular among enthusiasts.

• 65%: Builds on the 60% layout by adding arrow keys, striking a balance between portability and functionality.

• 75%: A compact layout that includes the F-row.

• TKL (Tenkeyless, ~80%): An 80% layout without a numpad.

• Full-size keyboard PCB (100%): Includes all keys, ideal for professionals and gamers who need a numpad.

Choosing the right keyboard PCB design depends on your workflow, desktop space and typing habits.

The mechanical keyboard PCB is not just a circuit board; it determines the input experience of the entire keyboard. From keyboard PCB design, material quality, to the choice between a hot-swap PCB or a soldered PCB, every step will affect performance, feel and service life.

Whether you want to build a minimalist 40% keyboard PCB, try different switches on a 60% PCB, or choose a high-end full-size keyboard PCB, understanding the function of the keyboard circuit board will help you make the right choice.

Q1: What’s the difference between PCB and PCBA?

A1: A PCB is just the bare keyboard circuit board. A PCBA is a complete assembly with switches, diodes, and microcontrollers installed.

Q2: Do hot-swap sockets reduce performance?

A2: Technically, there may be microsecond-level latency and a slightly less crisp feel. For most users, the difference is negligible.

Q3: Can I convert a soldered PCB into a hot-swap?

A3: Yes, with Mill-Max sockets or DIY mods. However, it’s time-consuming and requires soldering skills.

Q4: How long does a hot-swap socket last?

A4: Depends on brand and quality. Kailh sockets: ~1,000 cycles. Mill-Max: ~10,000. Zeal sockets: up to 50,000 cycles.

Q5: Are all switches compatible with hot-swap PCBs?

A5: Most MX-style switches fit, but very thick or non-standard pins may not. Always check specifications before use.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.