Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > FR-1 PCBs: Comparison with FR-2, FR-3, and FR-4 PCBs

When manufacturing PCBs, the first thing engineers need to do in the early design stage is to determine the substrate of the circuit board. Different materials will directly affect the heat dissipation capacity, mechanical strength, solderability and final production cost. Therefore, choosing the right materials is not only related to performance but also to whether the entire project can be mass-produced smoothly. For many cost-efficient applications, FR-1 PCBs are widely used in various simple consumer electronic devices due to their low price and flexible processing methods.

Although the industry has a very high recognition of FR-4, in fact, within the FR material system, there are various paper-based and resin-based materials suitable for different scenarios, such as FR-1, FR-2, and FR-3. Many people are not clear about the differences, applications and performance positioning of these materials, and are also prone to confusion when choosing materials.

This article will start from a practical, user-focused approach to help you understand the role FR-1 plays in the entire material lineup, and help you gain a more intuitive understanding of the characteristics of FR-1, what uniqueness it has in the manufacturing end, and what balance it achieves between cost and performance. Through this article, you will have a clearer concept of FR-1. After a thorough comparison with FR-2, FR-3, and FR-4, you will also be able to quickly determine which material is more suitable for your product direction.

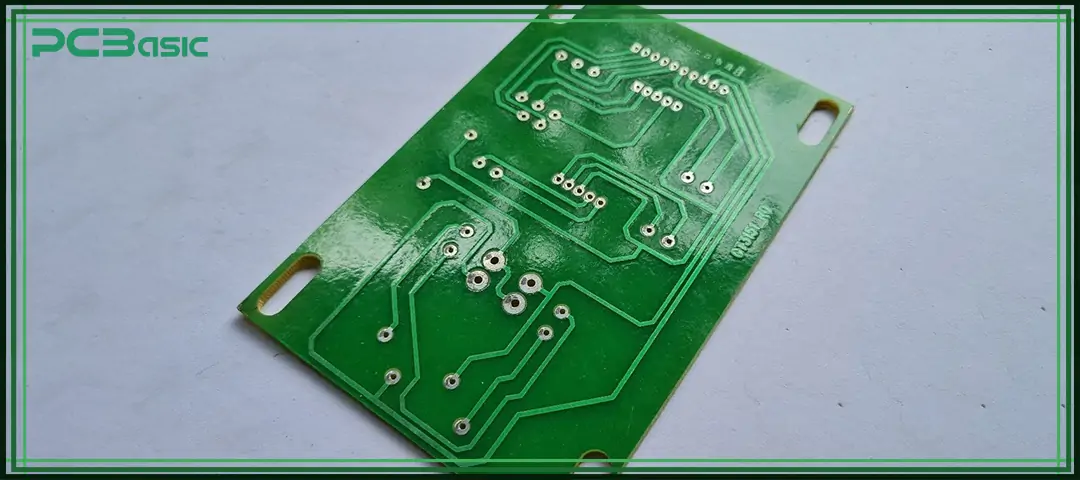

FR-1 is a rigid circuit board material made from cellulose paper (also known as phenolic paper) as the base material that is reinforced and cured with a phenolic resin system. The term FR stands for Flame Retardant, and the number "1" indicates its thermal performance level in the IPC/IEC classification system.

Compared with the common FR-4 fiberglass board, the core of the FR-1 PCB is entirely composed of paper-based material, so the cost is very low and it is suitable for mass production of simple-structured electronic products. Due to its lightweight and uncomplicated process requirements, it is widely used in various single-layer circuit boards and is one of the most common choices in entry-level PCBs.

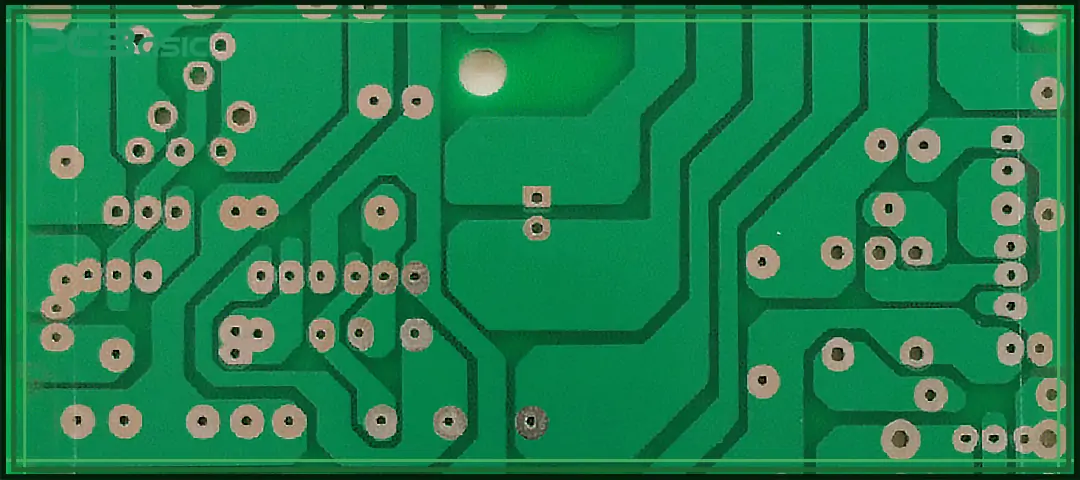

A typical FR-1 PCB is composed of the following layers:

• Copper Foil (18–70 μm) — The copper layer is relatively thin to reduce cost, yet still sufficient for simple circuit conduction needs.

• Phenolic Paper Core — Made from cellulose paper impregnated with phenolic resin, providing basic mechanical strength and flame-retardant performance.

• Adhesive Layer — Bonds the copper foil firmly to the paper substrate and is essential for maintaining structural stability.

• Solder Mask (Optional) — Many low-cost FR-1 products omit the solder mask to further reduce manufacturing expenses.

• Silkscreen Layer — Used for markings, text, and reference indicators, forming part of the standard mass-production process.

Because the core of FR-1 is paper-based, it is relatively soft and has limited heat resistance. This can lead to burrs during drilling, and the board has weaker thermal shock resistance compared with fiberglass materials. These characteristics also determine the applicable assembly processes — FR-1 is not suitable for lead-free reflow soldering and can only be processed under gentler thermal conditions.

|

Property |

Typical Value |

Notes |

|

Dielectric constant (1 MHz) |

~5.0–5.1 |

Stable enough for low-frequency circuits |

|

Dissipation factor |

~0.03 |

Acceptable for power and simple analog |

|

Volume resistivity |

10⁸–10⁹ Ω·cm |

Lower than fiberglass laminates |

|

Insulation resistance |

Moderate |

Sensitive to humidity |

Compared with FR-2, FR-3, and FR-4, the electrical performance is adequate but not ideal for high-speed or high-frequency designs.

|

Parameter |

FR-1 PCB Typical Range |

|

Tg |

125–135°C |

|

Td |

< 260°C |

|

Max reflow capability |

Not suitable for Pb-free reflow |

|

Heat resistance |

Low |

|

Thermal conductivity |

Weak |

The low Tg is a key reason FR-1 PCB is not recommended for SMT assembly using lead-free soldering. Wave soldering is possible only under controlled conditions.

|

Property |

Notes |

|

Punchability |

Excellent — ideal for mass stamping |

|

Bending strength |

Lower than FR-2 or FR-4 |

|

Drill quality |

Lower hole-wall integrity |

|

Warpage resistance |

Limited |

|

Density |

Light; suitable for cost-sensitive products |

The excellent punchability is why FR-1 PCB dominates in low-cost power adapters, toys, and simple consumer electronics.

• Complies with basic flame-retardant requirements

• ROHS-compliant variants are available

• Lower moisture resistance than FR-3 or FR-4

• Not suitable for harsh environments or outdoor electronics

Paper-based laminates absorb moisture more easily and degrade faster under thermal cycling.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Among all rigid circuit board materials, the price of FR-1 is almost the lowest, making it highly suitable for products that pursue cost advantages. For large-scale consumer electronics, using FR-1 can significantly reduce the overall manufacturing cost.

The paper-based structure of FR-1 makes it perform very well during mechanical punching, allowing for rapid batch molding and saving more time than drilling and milling methods. This feature is particularly suitable for single-layer boards with simple shapes and high volumes.

Although the dielectric performance of FR-1 is not as good as that of FR-4, it is more than sufficient in low-frequency and low-voltage small circuits. For instance, AC-DC mini power supplies, buzzer circuits, indicator light drivers, simple switch circuits, and other basic applications.

The FR-1 PCB is lightweight and very convenient for cutting and punching. It is an ideal choice for compact, simple consumer appliances, toys and control modules and other low-cost products.

Almost all PCB factories are equipped with FR-1 PCBs as standard single-sided material, and their supply chains are mature with short delivery times, making them highly suitable for customers who have high requirements for delivery speed.

The Tg of FR-1 is relatively low (125-135°C), and it cannot withstand the high temperature of lead-free reflow soldering. Even for wave soldering, the temperature must be strictly controlled; otherwise, blistering, delamination or deformation is likely to occur.

Because it is a paper-based material, the drilling strength of FR-1 is significantly weaker than that of FR-2, FR-3 or FR-4. The hole walls are prone to burrs and damages, and are not suitable for processing a large number of plated-through holes or precision drilling.

The paper-based structure of FR-1 determines that it cannot withstand the high temperature and high pressure required for multilayer lamination, and the reliability of the through-holes is also insufficient. Therefore, it can only be used for single-sided boards.

FR-1 has a high moisture absorption rate. Once the environmental humidity changes greatly, it is easy to cause a decline in insulation, warping of the board or unstable performance. It is not recommended for use in products that require long-term stability.

FR-1 is suitable for simple, low-speed and low-voltage circuits. It is not suitable for high-frequency and high-density wiring, nor for applications carrying high power or large current. All these require the use of higher-grade materials such as FR-4.

FR-1 PCB is ideal for:

• Power adapters and small chargers

• Toys and simple LED circuits

• Timers, buzzers, beepers

• Household electronics (coffee makers, kettles, irons)

• Small control modules

• Calculators and clocks

• Disposable or semi-disposable electronic products

• Low-cost consumer goods sold in millions of units

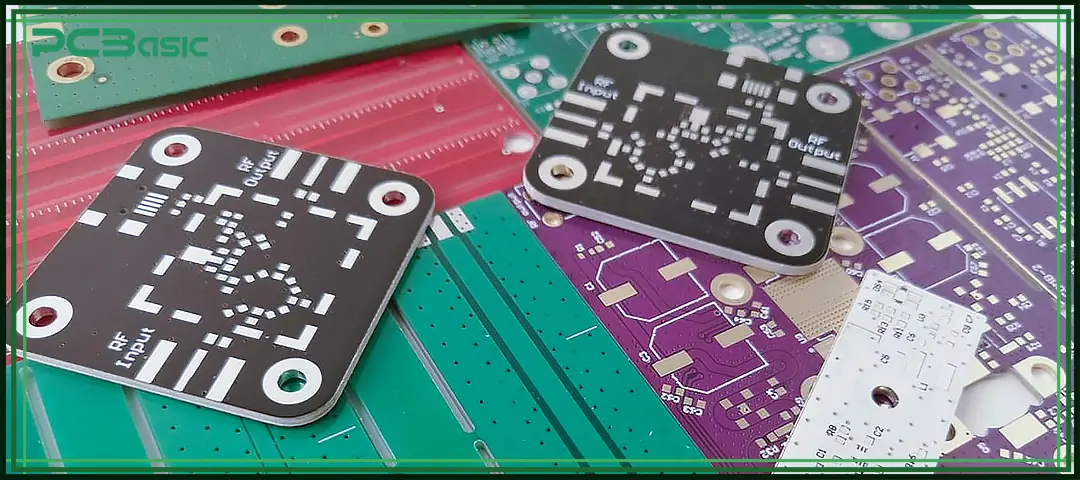

This section provides a detailed comparison to help you understand where FR-1 PCB stands relative to other common laminates.

• FR-1 PCB – paper + phenolic resin

• FR-1 – FR-2 also uses paper, but with epoxy resin instead of phenolic

• FR-3 – paper core with epoxy resin + better thermal resistance

• FR-4 – woven fiberglass + epoxy resin (industry standard)

|

Material |

Tg |

Heat Endurance |

Reflow Capability |

|

FR-1 PCB |

125–135°C |

Low |

No |

|

FR-1 vs FR-2 |

FR-2 has slightly better heat endurance |

Better |

Not for reflow |

|

FR-3 |

~150°C |

Medium |

Limited |

|

FR-4 |

135–170°C |

High |

Fully suitable |

FR-4 clearly dominates in all thermal performance categories.

• FR-1 PCB → weakest mechanical stability

• FR-2 → moderate

• FR-3 → stronger due to epoxy system

• FR-4 → extremely strong and rigid; ideal for drilling and multilayers

• FR-1 PCB: adequate for low-frequency only

• FR-2: FR-2 slightly better

• FR-3: stable dielectric characteristics

• FR-4: industry leader for impedance control and high-speed signals

|

Process |

FR-1 PCB |

FR-2 |

FR-3 |

FR-4 |

|

Punching |

Excellent |

Good |

Poor |

Not suitable |

|

Drilling |

Poor |

Medium |

Medium |

Excellent |

|

Plating |

Limited |

Good |

Good |

Excellent |

|

Lead-free SMT |

Not supported |

Not supported |

Partial |

Fully supported |

1. FR-1 PCB

2. FR-2

3. FR-3

4. FR-4 (highest, but most versatile)

When choosing FR-1, FR-2, FR-3, and FR-4 PCBs, it is necessary to determine the most suitable material based on the design requirements of the product.

The FR-1 PCB is more suitable for applications where cost is the top priority, the structure is simple, a single-panel design is required, only wave soldering is needed, and the product life cycle is relatively short.

If you need better mechanical strength, a medium operating temperature of the equipment, and hope to use epoxy resin as the material to enhance reliability, then FR-2 would be a more reliable choice.

When you want to continue using paper-based materials but require higher heat resistance and more stable electrical performance than FR-1, and there is a small amount of SMT process in the design, FR-3 can be chosen.

For products that require multilayer structures, high-speed or high-power circuits, high-density wiring, and have higher demands for heat resistance, reliability, and shock resistance, FR-4 is the industry standard and the most universal and reliable option, especially suitable for lead-free reflow soldering and long-term usage scenarios.

For single-layer consumer electronic products that pursue cost and output and have a simple circuit structure, FR-1 PCB remains one of the most cost-effective substrates. Although it cannot be compared with FR-2, FR-3 or FR-4 in terms of heat resistance, mechanical strength and electrical performance, it still has an irreplaceable cost advantage in low-power and low-complexity circuits.

When comparing FR-1 with FR-2, FR-3 and FR-4, the final choice depends on the product's requirements for temperature resistance, mechanical strength, signal integrity and overall reliability. If electronic products require high stability, support for lead-free reflow soldering, and have stricter performance standards, then FR-4 remains the mainstream in the industry. However, for application scenarios that pursue the ultimate cost and carry out large-scale mass production, the FR-1 PCB still has its undeniable value.

1. Is FR-1 PCB suitable for lead-free reflow soldering?

No. FR-1 PCB cannot withstand the high temperatures of lead-free reflow.

2. What is the biggest difference in FR-1 vs FR-2?

FR-1 uses phenolic resin, while FR-2 uses epoxy resin, resulting in better mechanical and thermal performance for FR-2.

3. Is FR-1 better than FR-3?

No. FR-3 offers higher Tg, improved stability, and better electrical performance.

4. Why is FR-4 more expensive than FR-1 PCB?

FR-4 uses fiberglass epoxy, supports multilayers, and works with high-speed electronics and lead-free processes.

5. Is FR-1 a good choice for high-frequency PCB design?

No. The dielectric performance of FR-1 PCB is not stable enough for high-frequency circuits.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.