Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Trustworthy Industrial Control PCB Assembly Service Providers

Robots, PLC control systems, motor drivers, industrial sensors, energy equipment, and various highly reliable production machinery - the electronic components behind these industrial systems all rely on the support of industrial control PCBs. Unlike conventional PCB assembly, industrial control PCB assembly has higher requirements for materials, quality control, long-term reliability, wide temperature range, and production consistency. Therefore, choosing the right industrial control PCBA supplier is very important for the manufacturing of these products.

Next, in this article, we will provide you with a guide to help you determine how to select a reliable industrial control PCB assembly partner. We will also introduce 5 trustworthy and reliable industrial control PCBA service providers for you.

Industrial control PCBA refers to circuit boards specifically designed for industrial environments. These assembled circuit boards must be capable of withstanding vibrations, dust, electrical noise, high temperatures, temperature fluctuations, and continuous operation for 24 hours. Since they are usually the "brains" of industrial equipment, responsible for processing data, controlling motors, managing input/output signals, and executing real-time logic, ensuring the safety and stability of the production process is crucial. Therefore, the quality requirements are very strict. Common typical applications of industrial control PCB assembly include:

PLC controller

Industrial automation modules

Motor drivers and servo controllers

Frequency converters (VFD)

Industrial sensors and transmitters

Power modules

Intelligent factory communication systems

Robot control board

Industrial monitoring and measurement equipment

These devices all rely on PCBA to achieve accurate signal processing, logical control, and device operation execution. As mentioned earlier, industrial control PCBA must operate in an industrial environment, so such PCBA must meet higher technical requirements, such as:

Long lifecycle (typically lasting for 5-15 years)

Wide temperature range reliability (-40℃ to +85℃, higher in some scenarios)

Damping and resistance to mechanical shock performance

Outstanding EMC/EMI immunity

Using industrial-grade components to ensure stability

Strict traceability and reliability testing

Long-term availability of key materials for supply

Only when these requirements are met can the industrial control PCBA operate properly in the industrial environment.

This is because in the field of industrial automation, circuit boards are not "auxiliary components", but rather the core components for control, safety and operation. If there is a problem with the industrial control PCBA, it will cause the entire production line to stop, and it may even damage expensive equipment, resulting in huge losses. Therefore, professional manufacturers are needed to produce industrial control PCBA. In addition, there are the following reasons:

1. The demand for reliability in the industrial sector is much higher than that in consumer electronics. Consumer electronics are used intermittently and in a mild environment; however, industrial equipment is completely different. Industrial PCBAs usually need to operate continuously 24/7, and their designed lifespan is often 5–15 years. Moreover, a single failure does not merely cause "inconvenience", but directly leads to production losses. Therefore, industrial control PCBAs must meet even stricter reliability standards. Choose a professional factory, and they will:

Control the entire production process with the aim of achieving long-term stability

Carry out thermal cycles, vibrations, and accelerated life tests

Use SPI, AOI, and X-ray to detect soldering defects

Establish a complete traceability system for each board

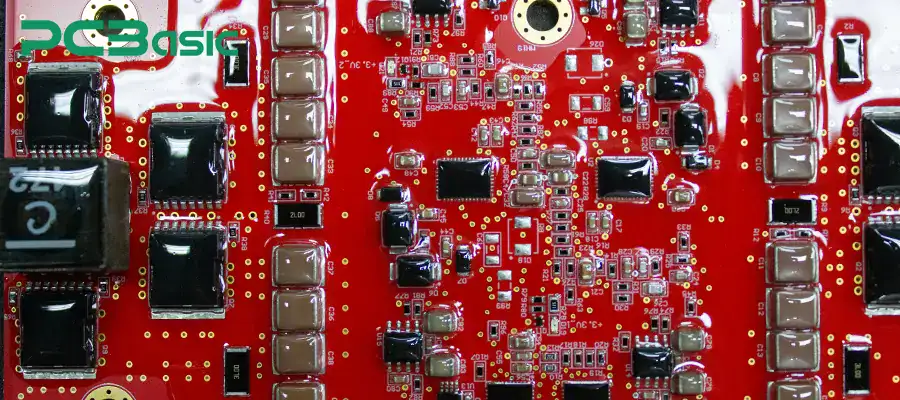

2. The industrial environment is harsh. To survive in such conditions, industrial control PCBA must possess:

Appropriate materials (high TG, thick copper, high-temperature components)

Soldering points capable of withstanding temperature changes and vibrations

Correctly designed creepage distance and electrical clearance

Environmental protection treatments such as anti-corrosion paint and encapsulation

This requires a professional industrial control PCBA supplier to produce PCBA that meets the requirements.

3. Industrial applications require an industrial-grade, traceable supply chain for components. Industrial products cannot use generic brands, gray-market channels, or components with unstable lifecycles. Typically, professional industrial PCBA suppliers can provide:

Components purchased only from authorized distributors or the original manufacturer

Industrial-grade devices (wide temperature range, long lifespan)

Monitoring of component lifecycle (End of Life)

Suggestions for substitute materials/second sources

Retention of batch and date codes for traceability

This is of great significance for industrial customers.

4. Industrial control PCBA often involves high power, current and voltage. Many industrial boards not only perform low-power control but also incorporate power supply and power modules, for example:

MOSFET and IGBT drive

2–6 oz thick copper plate

High-voltage and high-energy circuits

Isolation design and safety gap

Thermal management and heat dissipation structure

Professional industrial control PCB assembly factory:

Understand the thermal non-uniformity issues and soldering challenges caused by large-area copper foil

Ensure electrical clearance, insulation and safety standards

Control the reflow soldering temperature curve to avoid cracking of power device solder joints

Be capable of reliably producing boards that combine a logic-control section with a power-stage section.

These are all measures to ensure the production of industrial control PCBA.

5. Industrial products must meet strict standards and auditing requirements. Industrial products often have to undergo internal and external quality audits, safety certifications, and regulatory compliance. Professional industrial control PCBA suppliers must be able to support these. They typically possess:

ISO 9001

ISO 14001

IPC-A-610 Class II or Class III

Experience in obtaining UL, CE, etc. certifications

Complete process documents, test reports, and traceable records

6. Industrial applications require specific processes, such as:

Three-layer anti-corrosion coating

Encapsulation/sealing (for shock resistance and insulation)

Selective wave soldering (for large THT components)

Thick-silver soldering of high-power devices

High-mix small-batch production

Special fixtures and process control

These also need to be addressed by professional industrial control PCBA service providers.

7. The cost of malfunctioning industrial products is too high and it is not worth taking the risk. The cost of a single on-site malfunction may exceed the annual procurement expenses. Therefore, it is best to choose a professional industrial control PCB assembly partner. This is not only a technical choice but also a risk management strategy.

Industrial control PCB assembly must be long-term stable and capable of withstanding harsh environments, so the evaluation process must be more rigorous than choosing an ordinary electronics manufacturer. Below, we have listed several criteria that can be used to determine whether the supplier is reliable.

1. Qualified partners must possess the equipment and process control capabilities to handle complex and highly reliable assembly, including:

Fully automatic SMT production line

Stable processing of thick copper boards and high-power devices' reflow soldering curves

Selective wave soldering and reliable THT process

Adaptable to high-mix, low-volume production demands

Double-sided reflow capability

Process experience with BGA, QFN, LGA, and fine-pitch devices

2. The selected suppliers should have strict quality control and traceability. As industrial products typically require traceability for 5 to 10 years or even longer, reliable suppliers should provide:

IQC incoming material inspection and complete batch traceability

Automatic optical inspection and soldering verification

FCT functional test / ICT test

Reliability tests

Single board level traceability system based on MES or barcode

Clear and standardized quality process documents

3. Industrial-grade component management capability. The supply of components is also crucial for the manufacturing of industrial control PCBA. A qualified supplier must:

Procure components only from authorized channels.

Provide life cycle reports for ICs and key materials.

Maintain alternative materials and second source strategies.

Ensure no counterfeit or gray market components enter production.

Manage the long-term supply of materials for long-cycle products.

4. Industrial electronics require more engineering intervention than consumer electronics. An excellent supplier should be able to provide:

DFM (Design for Manufacturability)

DFA (Design for Assemblability)

DFT (Design for Testability)

Thermal design, EMC, creepage distance / electrical clearance review

BOM optimization and cost improvement suggestions

Failure analysis (FA) and 8D/CAPA reports

5. A reliable industrial control PCBA supplier must possess the capabilities of compliance, certification and auditing:

ISO 9001 (Quality System)

ISO 14001 (Environmental System)

ISO 45001 (Occupational Safety System)

IPC-A-610 Class II/III manufacturing capability

UL, CE and safety certification experience

Complete document, record and audit support capabilities

6. Specialized manufacturing capabilities for adapting to harsh environments. Industrial circuit boards typically require additional process support, including:

Three-layer anti-corrosion coating

Encapsulation and packaging

High-temperature solder paste

Handling of large connectors and THT components

Strengthened soldering (for shock resistance)

Surface protection treatment

In the previous section, we listed several criteria for choosing reliable industrial control PCBA manufacturers. Now, we present five leading and trustworthy industrial control PCBA suppliers. Let's start with the first one. (The rankings are not in any particular order.)

Jabil is one of the world's largest EMS manufacturers and a mature supplier of industrial control PCBA. It has extensive experience in areas such as automation, industrial sensors, and power products. Its main capabilities include:

IPC Class 3 / 3A grade high-reliability PCBA

Complex multi-layer industrial control boards

Industrial IoT and edge computing module

Functional testing and various environmental reliability tests

Jabil's global supply chain system and quality management system make it suitable for large-scale industrial projects with extremely high requirements for consistency, regulations and reliability.

Flex operates in the field of industrial control PCB assembly, covering high-mix, small-batch and large-batch manufacturing. Its advantages mainly include:

Industrial automation hardware

Smart factory and robot control boards

Industrial communication modules (CAN, RS485, EtherCAT, etc.)

Full-process traceability and lifecycle management

Flex has made significant investments in digital manufacturing and Industry 4.0, and is a long-term partner for many industrial OEMs.

Sanmina enjoys a high reputation in demanding industries. As a global supplier of industrial control PCBA, its key features include:

Industrial control board resistant to harsh environments

PCBA for high voltage / large current power supply

Durable products suitable for environments with vibration, temperature differences, humidity, etc.

Full range of reliability and regulatory testing capabilities

Sanmina's strength lies in handling mission-critical industrial systems, making it highly suitable for projects with extremely strict quality requirements.

Celestica offers integrated manufacturing services ranging from assembly to system integration, and has a strong foundation in industrial automation, industrial power supplies, and communication equipment. The main features of its industrial control PCB assembly are:

Complex system-level integration

High-reliability soldering of industrial power modules

Complete testing system (ICT, FCT, thermal testing, vibration testing)

Strong component engineering and lifecycle management capabilities

Celestica is mainly used for industrial OEM customers who require long-term support.

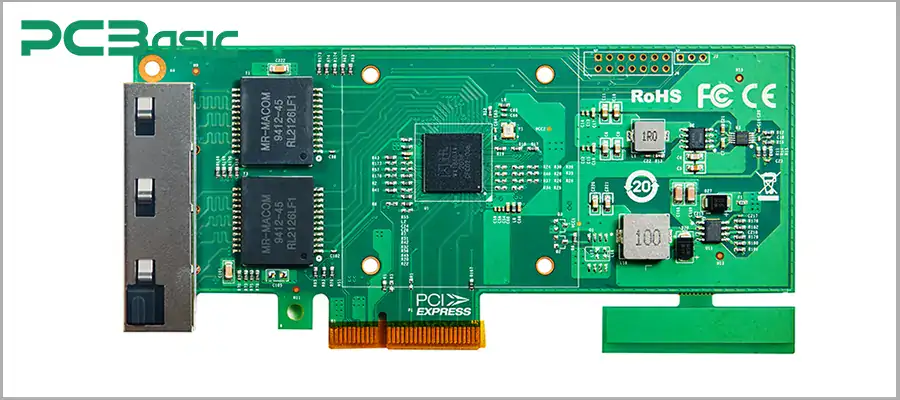

PCBasic is a rapidly growing industrial control PCBA supplier based in Shenzhen. Although it does not enjoy the same level of international recognition as the large-scale EMS giants in the United States, it has a very high level of professionalism in the field of electronic manufacturing. It has risen rapidly by leveraging digital factories and high-mix capabilities.

PCBasic can provide the high precision, stability and full-process traceability required for industrial control boards:

9 fully automatic high-speed SMT lines, supporting 01005, BGA, QFN, LGA

Full-process digital management including MES, ERP, CRM and IoT

100% SPI + 3D AOI + X-Ray + flying probe testing

IPC-A-610 Class 2 / Class 3

Quick quotations, no minimum order quantity,

24–72 hours rush prototyping

Certified by ISO9001, ISO13485, IATF16949, UL, etc.

Compared to large-scale EMS, the advantages of PCBasic lie in:

Faster response, higher flexibility, more reasonable cost, and the ability to provide an engineering-driven overall industrial control PCBA solution.

Whether it is large-scale industrial control manufacturing or high-mix and high-reliability industrial control PCBAs, these five companies are all reliable manufacturers of industrial control PCBAs that you can trust.

Suitable PCBA suppliers are crucial for the manufacturing of industrial control PCBA. Through a comprehensive assessment of aspects such as equipment capabilities, quality systems, component management, engineering support, and industrial-grade processes, it is possible to determine whether a factory truly possesses industrial-grade manufacturing capabilities.

The article introduces five reliable industrial control PCBA service providers: Jabil, Flex, Sanmina, Celestica and PCBasic. Whether it is PLC, drivers, industrial power supplies, or robot control systems, choosing a professional industrial control PCBA partner is essential to ensure the long-term reliable operation of the product.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.