Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Copper Core PCBs

In high-power devices, heat buildup has always been a major challenge. Copper core PCBs, due to their strong heat dissipation and stable structure, are increasingly used in such products. Compared with standard FR-4, its solid copper core enables it to carry higher current and is less likely to fail in high-temperature or high-load environments. Therefore, engineers often choose metal core PCBs, like copper core PCBs, to enhance the stability of the entire machine.

Meanwhile, the thermal conductivity of copper printed circuit boards is significantly stronger than that of aluminum-based metal core boards and FR-4, making it particularly suitable for high-power applications. As a professional metal core PCB manufacturer, PCBasic is capable of producing high-dissipation power boards, hybrid RF/power structures, embedded-copper designs and DTP boards, all of which deliver more stable and reliable performance than that of traditional metal-based PCBs.

This guide will comprehensively analyze various copper core printed circuit boards, including stack-up configuration, hybrid structures, embedded copper solutions, and practical application cases. Whether you are optimizing thermal flow, reducing junction temperature, or enhancing long-term reliability, a deep understanding of the capabilities of copper core PCBs is the key to the success of next-generation electronic design.

A copper core PCB is a type of high-performance circuit board with a solid copper plate as the core material. Compared with the standard FR-4, it adds a thick copper plate beneath the circuit, improving the entire PCB heat dissipation, strengthening the board mechanically, and allowing it to withstand higher operating currents. Therefore, it is particularly suitable for high-power equipment that operates under heavy load for long periods.

Copper core PCBs belong to the broader category of metal PCBs. These circuit boards are all made of metal as the core material and are widely used in high-power LEDs, automotive electronics, RF equipment, industrial control, motor drives, power modules and other application scenarios that require rapid heat dissipation and high stability.

Copper has a thermal conductivity of around 400 W/m·K, which is almost twice that of aluminum (about 205 W/m·K) and thousands of times that of FR-4 (about 0.3 W/m·K). It is precisely because of this extremely high thermal conductivity that the copper core PCB can conduct away the heat generated by the devices more quickly, preventing the components from overheating, and thereby reducing the risks of performance degradation, shortened lifespan, and even device burnout. It is almost always the best choice in electronic products that need to withstand high heat, high current or frequent thermal cycling.

In the entire electronic manufacturing industry, copper printed circuit boards and various metal core circuit boards undertake the important responsibility of maintaining the stable operation of equipment. They can effectively reduce faults such as solder-joint fatigue, board warping and other heat-related issues caused by overheating, thus ensuring the long-term reliable operation of the equipment.

As a leading metal core PCB manufacturer, PCBasic is capable of producing a variety of copper core PCB stack-ups according to different engineering requirements. The following are several of the most commonly used PCB stack-ups in power supply design and RF design at present.

|

Type |

Structure Composition |

Key Features |

Typical Applications |

|

1-Layer Copper Core PCB |

Copper core substrate; thin dielectric insulation; single copper circuit layer; |

Simplest and most cost-effective copper PCB structure; fast heat transfer; commonly referred to as MCPCB, metal PCB, or metal core board in the LED industry; |

High-power LEDs; power drivers; thermal management modules; |

|

2-Layer Copper Core PCB |

Copper core; dielectric layer; top copper layer; prepreg; bottom copper layer; |

More routing flexibility than single-layer boards; ideal for high thermal & functional density designs; a hybrid structure within metal core printed circuit boards; |

Power supplies; industrial controllers; MOSFET driver circuits; |

|

Hybrid Stack-Up (FR-4 + Copper Core) |

FR-4 laminated onto copper core; |

Combines FR-4 electrical performance; high thermal conductivity of a copper core PCB; mechanical strength of metal substrates; |

EV charging modules; robotics controllers; high-reliability power modules; |

|

RF + Power Mixed Stack |

Low-loss RF materials + copper printed circuit board core; |

Excellent signal integrity under high RF load; superior heat spreading; |

RF communication modules; antenna systems; PA boards; radar & microwave systems; |

|

Embedded Copper Block |

Localized copper block beneath heat-source components; |

Direct thermal conduction; ultra-short thermal path; more advanced than standard metal core board designs; |

IGBT modules; motor drivers; automotive LED headlights; |

|

DTP (Direct Thermal Pad / Direct Thermal Path) |

No dielectric under thermal pad; device pad contacts copper core directly; |

Best-in-class thermal performance; heat transfers instantly into metal core; significantly outperforms MCPCB & metal-based PCB; core manufacturing strength of PCBasic; |

1000W+ LED modules; high-pulse laser drivers; CPU/GPU cooling modules; extreme-power semiconductor packaging; |

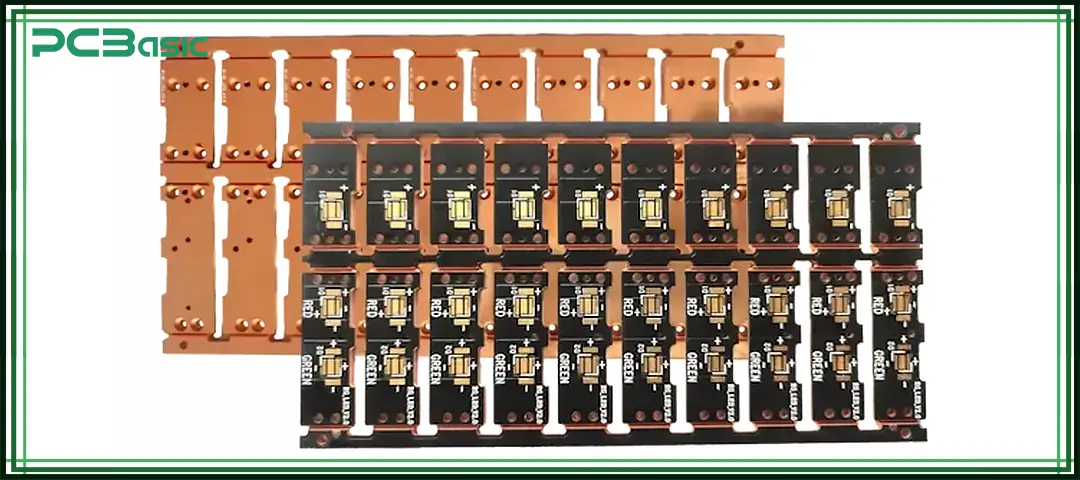

As a professional MCPCB manufacturer, PCBasic mass-produces different structure products for global customers.

The following are the 6 most common types of copper core PCBs in the electronics industry.

This is the most basic type of metal core PCB. Its dielectric thickness is standard and the heat dissipation performance is stable. It is suitable for the mass production of power modules and industrial equipment.

In this type of copper core PCB, LED chips or semiconductor dies are directly mounted onto the copper substrate, which can enable heat to dissipate more quickly, increase light efficiency, make the module smaller, and enhance thermal cycling reliability at the same time. It is often used in plant lights, stage lights, floodlights and laser lighting products, and is a very mainstream structure in the LED industry.

This structure can completely remove the dielectric layer under the thermal pad, allowing the thermal pad of the device to directly contact the copper core and achieve the most efficient thermal transfer. This design can extend the lifespan of power devices and improve energy efficiency. Its performance is significantly superior to that of traditional metal-clad PCBs or ordinary metal PCBs.

This structure combines an aluminum substrate with a localized embedded copper, which can not only reduce cost but also ensure good heat dissipation performance. It is often used in products that are cost-sensitive but still have heat dissipation requirements, such as LED backlights, automotive DRL modules, and power chargers. It combines the cost advantage of aluminum materials with the heat dissipation strength of copper core PCBs.

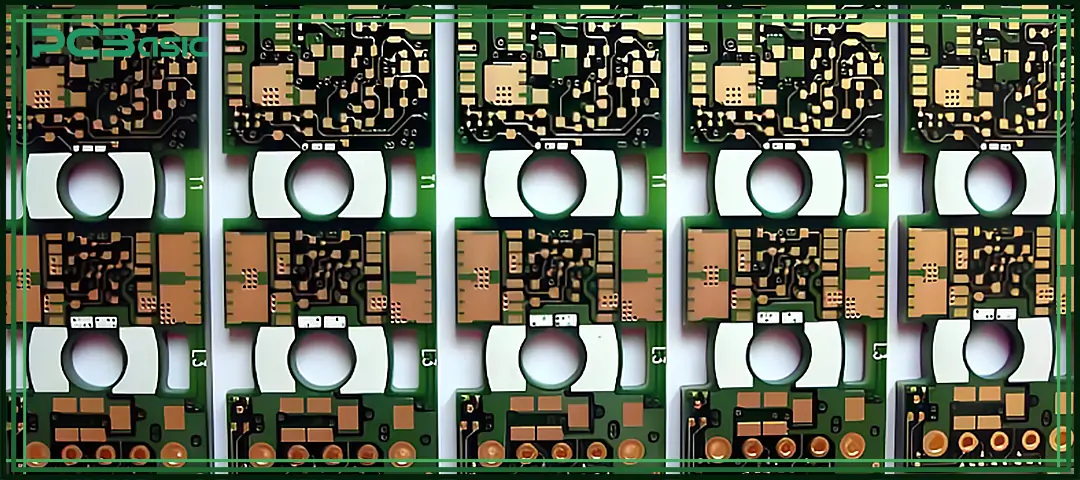

This is a high-end structure for high-frequency and high-power applications. It integrates Rogers 4350B high-frequency laminate with a high-power copper heat dissipation and achieve professional-level thermal management through controlled-depth milling or drilling. This type of structure is mostly used in radar modules, base-station power amplifiers and satellite communication boards, and is one of the most complex types in terms of process among metal core printed circuit boards.

In this design, the copper core is embedded inside a multilayer stack, allowing the design to achieve more complex routing while maintaining strong thermal dissipation capabilities. It is often used in high-power digital systems, automotive ADAS modules, power conversion boards and motor-control MCUs. Although it adopts a multilayer structure, it still belongs to the metal core circuit board family and has higher design flexibility.

The reason why engineers prefer to choose copper core PCBs instead of traditional FR-4 or aluminum substrates is mainly because they perform better in terms of heat dissipation, strength, current carrying capacity and stability.

Copper itself has the highest thermal conductivity among all metal PCB materials. Therefore, metal core PCBs almost always use copper core materials in high-power scenarios. Copper substrates can quickly conduct away the heat generated by components, preventing local overheating and enabling high-power LEDs, power modules and power devices to operate for a long time at a stable temperature.

Due to its thick copper core, this type of structure can resist warpage, bending, vibration and repeated thermal cycling very well, and its overall durability is much higher than that of standard FR-4. This reliability is also why many automotive electronics manufacturers adopt metal core printed circuit boards in critical equipment. They can remain stable in high temperatures, strong vibrations and harsh environments, and are less likely to experience structural fatigue.

Copper printed circuit boards perform particularly well in high-current designs. Copper has strong electrical conductivity and low heat generation, so it can maintain a relatively low temperature rise when high current passes through, and is less likely to experience issues such as trace discoloration, damage or overheating. This is highly suitable for high-current applications such as motor drives, power converters and high-power lighting modules.

The thermal expansion rate of copper is significantly lower than that of FR-4. Therefore, copper PCBs can still maintain accurate dimensions under rapid temperature changes or long-term high-load operation, and will not affect the reliability of solder joints or circuit performance due to thermal expansion and contraction. This is significant for high-frequency devices, precision sensors and high-power applications.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Designing a copper core PCB or any other metal-based PCB requires following several specific engineering rules to ensure good thermal performance, mechanical reliability, and manufacturability.

When choosing the dielectric layer, the main factors to consider are: thermal conductivity, breakdown voltage, thickness tolerance and peel strength. These properties directly affect heat transfer, insulation performance, and long-term board reliability.

For DTP (Direct Thermal Path) or semi-DTP designs, the thermal pad area must match the device’s thermal pad footprint exactly. Proper alignment ensures efficient heat transfer and prevents thermal bottlenecks.

Some metal-clad PCB structures require precise depth-controlled machining, such as:

• Micro-milling

• Step-pockets

• Countersinks

• V-grooves

These features are often used to create thermal cavities or structural details that support high-power components.

Common surface finishes include ENIG, OSP, immersion silver and heavy copper plating. The right finish depends on the soldering method, corrosion resistance, and reliability requirements of the application.

Because the copper core is dense and harder to cut, CNC parameters must be optimized to reduce tool wear and maintain machining accuracy. Proper routing also helps avoid burrs and ensures clean, stable board edges.

A copper core PCB is widely used in industries requiring superior heat management. Key sectors include:

• High-power LED lighting

• Laser and optical drivers

• Automotive electronics

• Base-station RF modules

• Power conversion systems

• Industrial motor drivers

• High-frequency radar modules

• Battery management systems

• Solar inverters

• EV charging modules

In all these applications, metal core PCBs play essential roles in reliability and performance.

PCBasic is a global manufacturer focusing on metal core PCBs, which has long been dedicated to the research, development and production of various high heat dissipation circuit boards, including copper core PCB and various metal core PCB solutions. We serve global customers and provide mature and reliable manufacturing capabilities for the high-power electronics, industrial equipment, automotive electronics and LED industries.

PCBasic has over 9 automated SMT and inspection production lines, capable of providing complete turnkey services, including PCB manufacturing, component procurement, SMT assembly, and functional testing (FCT). This enables customers to avoid coordinating multiple supply chains, shortens project cycles and makes quality more controllable.

In terms of quality management, we adopt ERP, MES and IoT systems to support the full-process material traceability, ensuring that each metal core circuit board can achieve complete tracking of batches, data and production records.

PCBasic provides shipping services to over 170 countries worldwide, covering customers such as LED factories, automotive electronics manufacturers, and industrial power system integrators who require high-reliability metal-based PCBs. Whether it's prototyping or mass production, we can provide stable and reliable technical support and delivery capabilities.

The copper core PCB is one of the most powerful heat dissipation solutions at present. It is far superior to traditional FR-4 in terms of thermal management, high current carrying capacity and long-term reliability. Whether it is the DTP, COB structure, embedded copper solution, RF and power hybrid stack, or Rogers + copper-based composite structure, all kinds of metal core PCBs can demonstrate performance that traditional materials cannot achieve in high-power applications.

As a professional copper core and advanced metal core PCB manufacturer, PCBasic can provide high-quality metal-based PCBs for LEDs, automotive electronics, power electronics, radio frequency systems and industrial equipment worldwide.

For engineers who pursue ultimate heat dissipation performance and long-term stability, copper core PCBs are always the best choice. At every stage, from prototyping and development to low-volume trial production to large-scale mass production, PCBasic can be a reliable partner.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.