Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Conductive Inks in PCBs and Printed Electronics

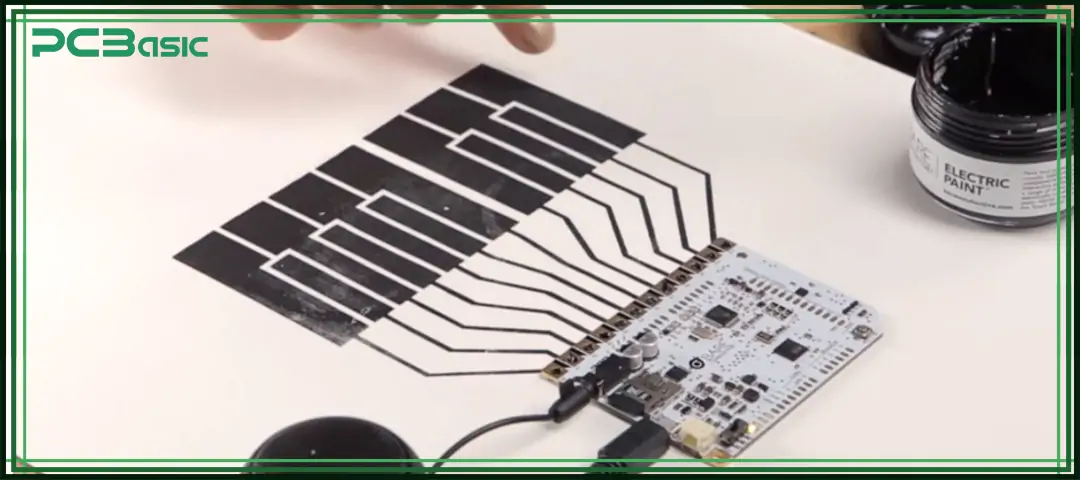

With the increasing popularity of wearable devices, flexible displays, medical sensors and flexible hybrid electronics (FHE), the use of conductive ink in PCBs and printed electronics is also on the rise. Unlike traditional rigid PCBs etched with copper foil, conductive inks can be directly applied to materials such as PET, polyimide, TPU, textiles or glass, just like printed circuits, to achieve conductive pathways.

This article will start from the most basic content and take you to understand what conductive ink is, what it's made of (such as conductive fillers and resin binders), and what common types there are. At the same time, the article will also discuss their advantages and disadvantages, as well as the circuits or PCB processes they are suitable for.

Next, it will compare the traditional PCB manufacturing method (subtractive etching) with the printed electronics process using conductive inks (additive manufacturing), making it easier for you to understand how it helps circuits become thinner, lighter, more flexible, and more suitable for the design of future smart devices.

Conductive ink is an ink that can be printed and conduct electricity. It contains metal powder or carbon particles, and these conductive materials are uniformly dispersed in the liquid medium. When this ink is printed onto substrates such as PET, PI, glass or fabric, and then heated or cured, conductive circuits can be formed.

Unlike ordinary colored inks, conductive inks are not used for visual decoration, but for conducting electricity. It is more like a printed circuit material. Nowadays, it is widely applied in fields such as flexible circuits, RFID antennas, membrane switches, medical electrode patches, printed sensors, and flexible hybrid electronics (FHE).

Among the numerous conductive inks for printed electronics, silver conductive ink is the most commonly used because of its best conductivity, high stability and strong adaptability with different manufacturing processes.

To understand the working principle of conductive ink, we need to first understand how it functions during the printing and curing processes.

During printing, conductive ink is applied to various substrates through methods such as screen printing, inkjet printing, dispensing, flexographic printing or pad printing. As the solvent or resin evaporates or cures, metal or carbon particles will form an interconnected network, which is called the percolation path. This network enables electrons to flow freely within the printing area, thereby making the material conductive.

The performance of different materials can also affect the performance of the ink: silver conductive ink has the lowest resistance, carbon conductive ink has a slightly higher resistance but is more flexible, and copper conductive ink, though inexpensive, is prone to oxidation. Some special formulations, such as flexible conductive ink, are designed to stretch and bend without cracking.

Understanding different types of conductive inks is crucial when choosing PCBs or printed electronic materials. The following are the most commonly used types:

|

Type |

Description |

Advantages |

Limitations |

|

Silver conductive ink |

Contains silver flakes, nanoparticles, or hybrid sintering silver |

Highest conductivity, low curing temperature, stable |

Expensive raw material |

|

Copper conductive ink |

Formulated with copper particles |

Lower cost, SMT solderable |

Oxidizes quickly, requires nitrogen or a reducing atmosphere |

|

Carbon ink/carbon conductive ink |

Uses graphite, carbon black, or graphene |

Cost-effective, flexible, chemically resistant |

Higher resistivity than metals |

|

Flexible conductive ink |

Silver, copper, or carbon-based inks designed to stretch/bend |

Ideal for wearables, textiles, and soft PCB |

Lower current capacity |

|

Resistive ink |

Designed to offer resistance instead of conduction |

Used for heater circuits, resistors |

Not suitable for power traces |

|

Conductive inks for printed electronics |

General term referring to metal or carbon inks used on PET, PI, TPU, etc. |

Enables additive manufacturing, thin-film circuits |

Mechanical durability depends on curing and substrate |

Hybrid inks, such as semi-sintered or flexible conductive ink, combine percolation and sintering technologies. These inks can be used to produce printed circuits that can withstand bending, folding, and even low-temperature reflow soldering.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Filler Materials (Conductive Phase)

The fillers determine the conductivity of conductive ink. Common filler materials include:

|

Filler Type |

Characteristics |

Applications |

|

Silver Conductive Ink |

Best conductivity, oxidation-resistant, printable at low temperatures |

Used in PCBs, RFID antennas, touch panels, etc. |

|

Copper Conductive Ink |

Cheaper than silver, good conductivity, but prone to oxidation |

Used in circuits, antennas, etc., requires a protective atmosphere (nitrogen or forming gas) during curing |

|

Carbon Ink / Carbon Conductive Ink |

Lower conductivity, but offers high flexibility, chemical stability, and abrasion resistance |

Used in membrane switches, sensors, electrodes, etc. |

|

Resistive Ink |

Contains carbon or metal oxides, provides controlled resistance instead of conductivity |

Used in heating circuits, variable resistors |

|

Zinc, Nickel or Polymer-Based Conductive Inks |

Used in specialized electronics, sensors, dielectric layers |

Used in specific electronic products or layers |

Vehicle System (Binder + Solvent)

The carrier system of conductive ink includes binder, solvent, dispersant and additive:

|

Component |

Function |

Description |

|

Binder |

Provides adhesion, mechanical strength, and flexibility |

Typically made of polymer structures |

|

Solvent |

Controls ink viscosity and flow properties |

Ensures ink is suitable for screen printing |

|

Dispersant |

Keeps the particles evenly dispersed in the ink |

Prevents agglomeration, ensuring stability |

|

Additives |

Enhances flexibility, curing speed, stretchability, or thermal resistance |

Especially important for flexible conductive ink |

Traditional PCB manufacturing employs subtractive processes - etching copper laminates to remove unwanted copper, while conductive ink can achieve additive printing:

|

Aspect |

Traditional PCB |

Printed PCB with conductive ink |

|

Process |

Etching, drilling, plating |

Printing, drying, curing |

|

Material waste |

High |

Minimal |

|

Substrate |

FR-4 rigid boards |

PET, PI, glass, TPU, fabrics |

|

Best for |

High-current circuits |

Conductive inks for printed electronics, FPC, sensors |

|

Tools needed |

CNC, chemicals |

Screen printer, inkjet, dispenser |

Conductive inks are particularly popular in fields such as flexible circuits, rapid prototyping, medical patches, and in-mold electronics, especially when traditional PCB methods are too rigid or costly.

Conductive inks are used in many PCB and electronic systems, including:

• Flexible circuits (FPCs)

• Membrane switches and keypads

• Touch screen ITO bus bars using silver conductive ink

• Printed antennas for NFC, RFID, Wi-Fi

• Medical electrodes, ECG/EEG sensors using carbon conductive ink

• In-mold electronics for automotive dashboards

• Printed heating elements using resistive ink

• EMI/RFI shielding using silver conductive ink

• Smart labels, flexible hybrid electronics (FHE)

• Enables flexible conductive ink for bendable PCBs

• Compatible with textiles, PET films, polyimide, TPU

• Low-temperature printing and curing (<250°C)

• Reduces copper waste and hazardous etching chemicals

• Supports rapid prototyping and additive manufacturing

• Ideal for conductive inks for printed electronics, wearables, medical devices

|

Challenge |

Description |

|

Cost |

Silver conductive ink is expensive; alternatives like copper conductive ink or carbon ink have limitations |

|

Oxidation |

Copper conductive ink oxidizes; needs nitrogen or protective coatings |

|

Lower conductivity |

Carbon conductive ink has higher resistance than copper |

|

Durability |

Printed conductive inks can crack under repeated bending unless formulated as flexible conductive ink |

|

Power handling |

Most printed inks cannot carry high current like traditional copper PCBs |

|

Moisture & abrasion |

Requires encapsulation or dielectric protection layers |

Conductive ink technology is changing the design of PCBs and electronic products. Silver conductive ink, carbon ink, copper conductive ink and flexible conductive ink all offer advantages that traditional copper PCBs cannot match.

Conductive inks are the basis of printed electronics and can be used to manufacture lighter, thinner, printable and flexible electronic products. Despite some challenges such as oxidation and cost, innovative inks and new materials will drive future electronic design and meet the demand for smart, thin and light electronic products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.