Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Assembly Fixtures in PCB and PCBA Manufacturing

The precision, efficiency and consistency requirements for electronic products are getting higher and higher in today's fast-paced electronics manufacturing industry. Products such as smartphones, automotive control systems, medical devices and aerospace vehicles all rely on high-quality PCBs and PCBAs. In this high-demand production process, there is a type of tool that is indispensable. This type of tool is the assembly fixture.

They are used throughout the entire circuit board manufacturing and testing process. Assembly fixtures guarantee that every circuit board is processed under the same conditions and lessen the uncertainty that comes with manual operations by offering a reliable reference point. This is especially crucial for large-scale manufacturing since it not only minimizes the possibility of human error but also enables faster production and more reliable products. Therefore, understanding the relevant information about assembly fixtures is essential.

Now, let's learn about the relevant content of assembly fixtures.

Assembly fixtures are a type of specially designed tool or device used to fix, position and stabilize components at different production stages. They can improve accuracy, simplify the production process and reduce human errors. Unlike general tools, fixtures are often customized solutions, specifically designed based on the geometric features of the product and the process requirements. In this article, the assembly fixtures we are referring to are the fixing tools used in the production assembly of circuit boards.

In the field of electronic manufacturing, the role of assembly fixtures is extremely important. Printed Circuit Boards (PCBs) and Printed Circuit Board Assemblies (PCBAs) have extremely high requirements for the precise alignment of components and process consistency. Even minor deviations of chips, capacitors, or connectors can lead to the failure of the entire circuit board. Therefore, a reasonable fixture design not only improves assembly accuracy but also ensures the stability and repeatability of the production process.

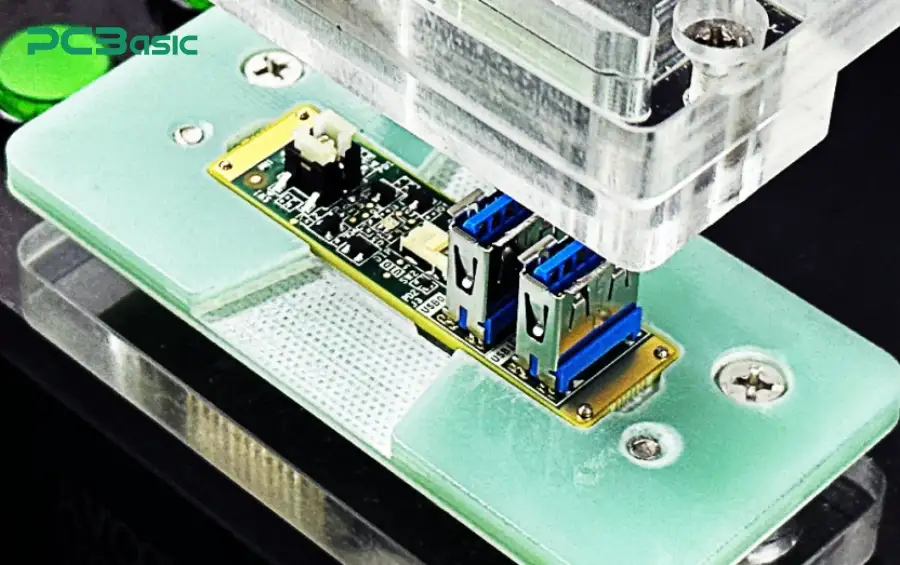

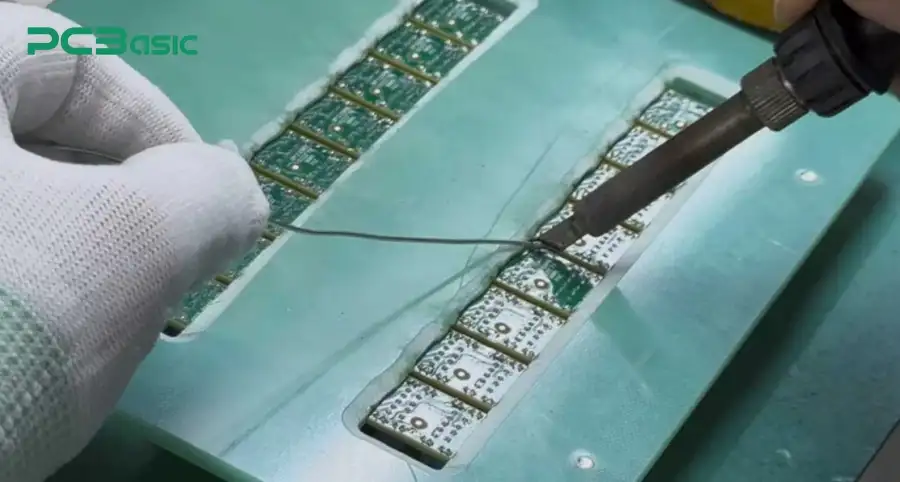

During the soldering process, the assembly fixtures ensure that the PCB remains stable at high temperatures, preventing component displacement. In the testing phase, the PCB test fixture and PCBA test fixture are widely used for online testing (ICT) and functional testing (FCT). The fixtures provide stable positioning and reliable contact, helping engineers quickly identify potential issues and guarantee the electrical performance of the product. In addition, assembly fixtures have many other functions. Let's take a look at the main functions of the assembly fixtures!

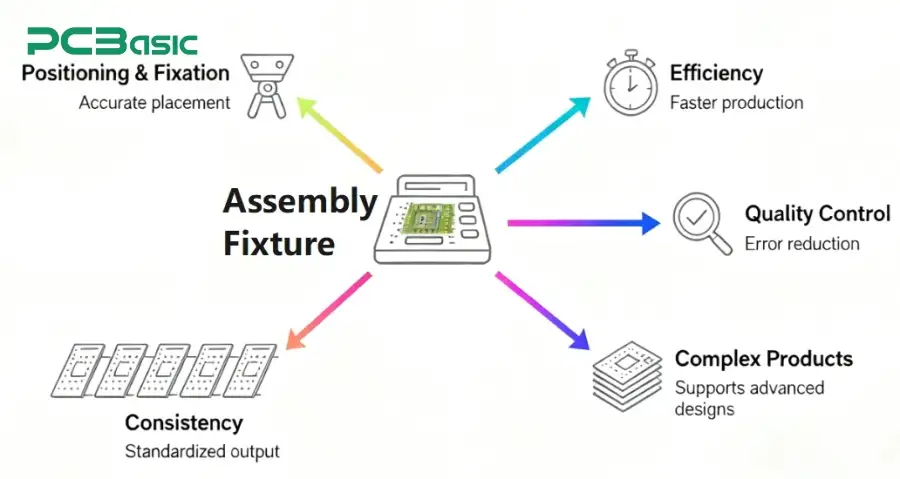

The usefulness of assembly fixtures during the production process is what gives them value. They play a vital and useful role. Assembly fixtures serve the following primary purposes:

The most important function of assembly fixtures is positioning and fixation. Reasonable fixture design can prevent failure due to minor displacements. It provides stable support during soldering, testing, or assembly, preventing component movement and ensuring installation accuracy. This is particularly important in precision electronic manufacturing.

By simplifying or automating repetitive processes, assembly fixtures can accelerate the production rhythm. For example, soldering line assembly fixtures in high-capacity scenarios or wave soldering processes are good methods to significantly shorten production cycles and increase output.

The application of assembly fixtures also helps reduce misalignment, incomplete soldering, or operational errors. For instance, PCB test fixtures ensure consistency in electrical testing, while PCBA test fixtures can verify the overall functionality of the product before delivery, ensuring reliability.

In large-scale production, every product must meet the same quality standards. Manufacturing fixtures provide standardized positioning and support. This helps manufacturers achieve repeatability in the production process and ensures consistent product reliability.

Customized fixture designs can handle irregular shapes, multi-layer PCBs, or special process requirements. In modern electronics with increasingly compact structures and complex designs, assembly fixtures become particularly important and effective. This method can avoid many serious consequences caused by assembly errors.

Assembly fixtures play a critical role in production. Stability, efficiency, control, and repeatability are the best ways to describe their roles. Their features make manual labor easier and less error-prone for workers; they also increase the accuracy and efficiency of machine automation manufacturing. Assembly fixtures fill the gap between large-scale automated production and manual labor.

As per the requirements, the level of production as well as the different needs of the board, the assembly fixtures take different forms. Every fixture plays a different role in making the operations as precise, efficient and reliable as possible. Below are some of the most common types of fixtures in PCB and PCBA production.

Stability is critical when soldering. Soldering line assembly fixtures are designed for wave soldering, manual soldering and selective soldering, maintaining the PCB in a fixed position during the high-temperature soldering. This prevents issues such as solder bridges and cold joints, ensuring that each joint is reliably formed. In automotive electronics, where accuracy and durability are essential, specialized soldering assembly fixtures (automotive assembly fixtures) support the PCB during cycles of extreme heat and heavy component mounting.

After the soldering process, it is important to test each PCB and assess its functionality. During this, test fixtures hold the board and ensure reliable contact points which helps during ICT and FCT processes. They enhance productivity and minimize the chances of needing additional work, as they assist in identifying problems like shorts, open circuits, and defective parts beforehand. In consumer electronics, test assembly fixtures are often highly customized to fit dense smartphone boards, while in industrial automation they are built to handle repetitive cycles without losing precision.

Component assembly fixtures are essential for the mounting or insertion of components. They help secure and align the small components in SMT operations, and they guide the pins to precisely fit into the through holes in DIP insertion. Aerospace product applications are tough and complicated, and every component connection needs to adhere to stringent dependability requirements. Manufacturers may lower product error rates, expedite assembly times, and guarantee product consistency across the board by utilizing component assembly fixtures. This is especially important for the production of aircraft.

Not all circuit boards are of standard size or regular shape. Customized fixtures and tooling are used for PCBs with extremely large dimensions, special structures, or those containing mechanical components. Common types of such fixtures include modular clamps, precision positioning pins, or adjustable support devices, all of which are designed to facilitate manufacturers in quickly adapting to the assembly requirements of special products.

|

Fixture Type |

Main Purpose |

Key Advantages |

|

Soldering Assembly Fixtures |

Fix PCB during high-temperature soldering (wave, selective, manual) |

Prevents defects (bridges, cold joints); Withstands repeated heat cycles; Ensures durability under heavy components |

|

Testing Assembly Fixtures |

Secure PCB and provide reliable contacts for ICT & FCT |

Detects faults early; Reduces rework risk; Can be customized for dense layouts or repetitive cycles |

|

Component Assembly Fixtures |

Assist in precise component insertion/placement (DIP, SMT) |

Improves placement accuracy; Reduces assembly time; Ensures consistency across batches |

|

Customized Assembly Fixtures and Tooling |

Adapt to special PCB sizes, shapes, or structures |

Flexible design (clamps, pins, supports); Supports hybrid mechanical-electronic assembly; Prevents contamination in sensitive environments |

The design of PCB assembly fixtures also requires comprehensive consideration of various factors. We must ensure that the fixtures designed can meet the precision requirements in the production line while also having sufficient practicality and durability. The following are the factors we can consider during the design process:

PCB size, thickness and component layout

The main function of the assembly fixture is to assist in production. In PCB production and assembly, the fixture must be designed according to the specific size, thickness and component distribution of the PCB. If the circuit board is too large or too small, the positioning and support methods of the fixture need to be specially optimized. For circuit boards with dense components, it is necessary to ensure that the fixture does not cause compression or interference to the components, and avoid deviations during soldering or testing.

Material Selection (Durability and Heat Resistance)

In addition to considering the compatibility with the PCB, the lifespan and stability of the fixture material should also be taken into account. Since the assembly fixture is often used in high-temperature reflow soldering or wave soldering processes, the material must have good heat resistance to avoid deformation. Commonly used materials include high-temperature resistant composite materials, aluminum alloys, and wear-resistant plastics.

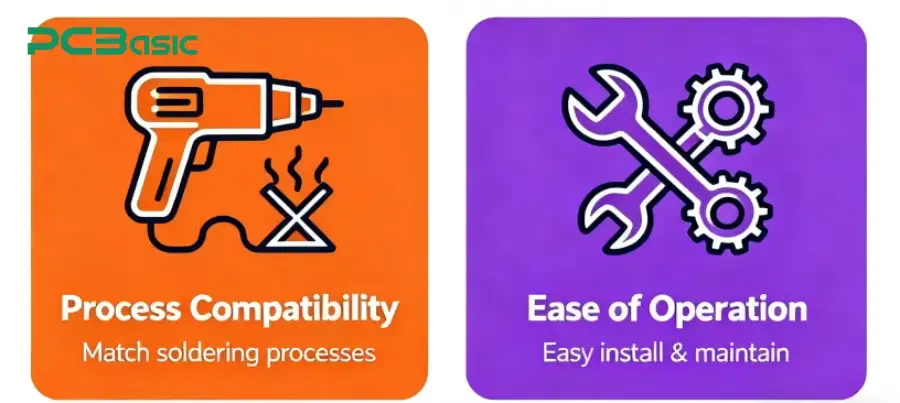

Process Compatibility

During the design process, it is also necessary to ensure that the fixture can be compatible with different production processes and equipment, such as wave soldering, selective soldering, and reflow soldering machines. If the design of the assembly fixture is unreasonable, it is very likely to affect the direction of solder flow and the distribution of hot air flow, thereby reducing the quality of the solder joints.

Ease of Operation and Maintenance

During the manufacturing and use of the fixture, convenient operation and maintenance are also very important. The fixture should be easy to install, clean, and undergo regular maintenance. This can reduce downtime and improve production efficiency. Therefore, we recommend using modular and replaceable component designs, which can extend the overall lifespan of the assembly fixture.

Assembly fixtures play a crucial role in various industries.

In the automotive electronics sector, assembly fixtures are widely used in automotive electronic control systems, in-vehicle infotainment systems, and various safety devices. They ensure a reliable connection between PCBA and mechanical structures.

Assembly fixtures on soldering lines are particularly prevalent in large-scale industrial and automotive production. Soldering, insertion, and inspection procedures can be seamlessly integrated with these fixtures' quick clamping and positioning on automated production lines.

Universal assembly fixtures are used extensively in the consumer electronics, medical equipment, and industrial automation industries. They can satisfy the flexibility needs of small-batch manufacturing while guaranteeing consistency in large-scale production since they often have great cost-effectiveness and good repeatability.

In conclusion, assembly fixtures play an irreplaceable role in the automotive electronics, large-scale industrial production, and consumer electronics and medical equipment sectors.

Assembly fixtures are more than just supplementary tools in PCB and PCBA manufacturing; they are necessary to ensure accuracy, efficiency, and reliability. Whether in soldering, testing, component installation, or highly specialized fixture applications, the fixtures may guarantee that each circuit board is produced under regulated and reproducible conditions.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.