Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Inside Top Consumer Electronics PCB Assembly Factories

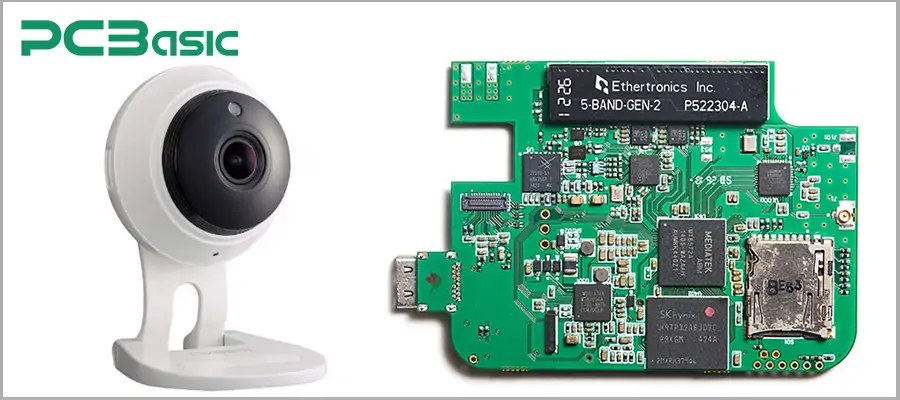

Consumer electronics have permeated every aspect of our lives. Various consumer electronics such as mobile phones, watches, tablets, headphones, game consoles, and smart home products all rely on compact and high-density consumer electronics PCBs. These PCBs determine the size, performance, heat dissipation, and reliability of our products and are the foundation for realising all functions.

As consumers' demands for devices continue to rise, products are becoming lighter, thinner, more functional, and have a faster update cycle. These changes are the result of continuous upgrades in consumer electronics PCBs in all aspects. Consequently, the manufacturing and assembly of consumer electronics PCBs have become more challenging.

In this context, choosing a suitable consumer electronics PCB and PCBA factory is of great importance. This article introduces consumer electronics and several reliable consumer electronics PCB assembly factories to you. It will also provide some references for the key points you should focus on when choosing a PCBA factory. Reading this article can help you find the right direction for a suitable consumer electronics PCB assembly partner.

Consumer electronics PCB assembly (PCBA) refers to the process of assembling various electronic components onto a circuit board specifically designed for consumer products, thereby forming a circuit board component that can be directly used for the assembly of the entire device. Consumer electronics PCBs typically have a compact layout, lightweight materials, and highly miniaturised components. In addition, they must also meet strict reliability requirements. As consumer electronic devices continue to evolve towards thinner, lighter, and more complex designs, the technical challenges faced by PCBs and their assembly process have also increased, mainly manifested in the following aspects:

1. Miniaturisation and high-density assembly

Modern consumer electronic products usually require:

01005, 0201, 0402 and other ultra-small passive components

Fine-pitch QFN, BGA, LGA packages

Miniature BGA and CSP for compact spaces

Multi-layer HDI circuit boards with blind vias and buried vias

The PCB assembly factory possesses these technologies, which enable consumer electronics manufacturers to create thin and lightweight mobile devices, lightweight IoT products, and smaller wearable devices.

2. High Capacity and Scalability

The production cycle of consumer electronics typically involves:

Fast prototyping for early verification

Stable mass production at medium to large scale

Order peaks caused by seasons or promotions

Fixed and strict product launch schedule

3. Reliability Requirements

Consumers expect the equipment to operate stably for many years. Therefore, the PCBA must be able to withstand:

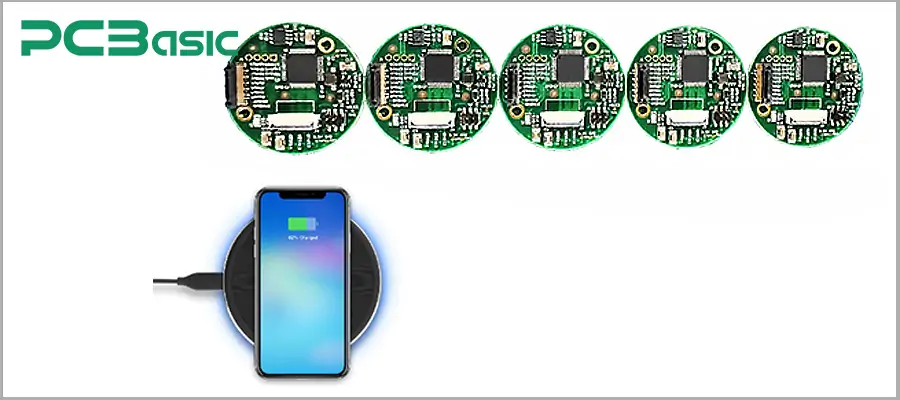

Multiple charging cycles

Impact caused by drops and vibrations

Thermal stress during operation or charging

Complex environments such as humidity

Mechanical fatigue resulting from long-term use

This requires that the assembly factory be capable of conducting multiple reliability verification tests such as X-ray inspection, functional testing, ICT, temperature and humidity cycling, and drop tests.

4. Complying with international norms and standards

Consumer electronics PCBs must adhere to the following standards:

RoHS / REACH

UL

ISO9001 / ISO14001

IPC-A-610 Assembly Process Standard

Producing the products by PCB assembly manufacturers that comply with these standards is a guarantee of product quality.

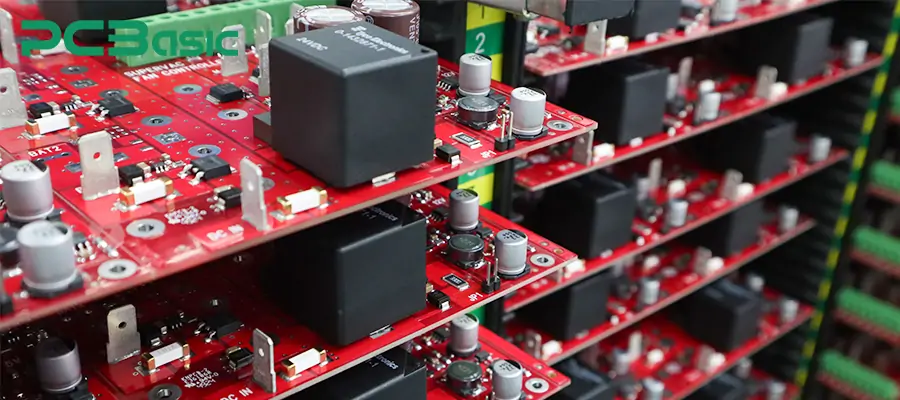

PCBasic is a reliable manufacturer among many consumer electronics PCB manufacturing and assembly service providers. It stands out for its reliability and stability in multi-variety small-to-medium batch production, rapid prototyping, and various consumer electronics assembly fields. PCBasic has a complete one-stop manufacturing model, which can support brands in achieving rapid development, flexible production, and high-quality delivery. The advantages of PCBasic mainly lie in:

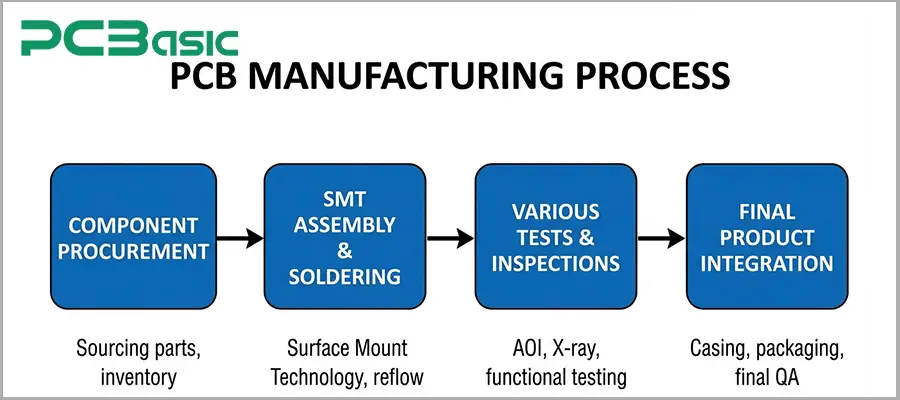

1. Complete PCBA manufacturing system

PCBasic integrates all the key steps of the PCBA manufacturing process onto a single platform, including:

PCB manufacturing

Component procurement

SMT assembly and soldering

Various tests and inspections

Final product integration

This vertical integration model can bring more significant advantages to consumer electronics brands:

Shorter delivery time and more controllable

Smoother communication between engineering and production

Lower supply chain-related risks

More consistent quality among different batches and versions

2. Advanced SMT equipment and miniaturised assembly capabilities

The SMT production line of PCBasic can meet the following requirements:

01005, 0201 and other ultra-small-sized components

Micro BGA, fine-pitch QFN, CSP packaging

4K high-definition SPI and AOI inspection

Nitrogen reflow soldering for cleaner and stronger solder joints

X-Ray inspection

These capabilities ensure that compact and structurally complex consumer electronic products can also maintain stable and high yield rates.

3. Professional Engineering Team

The engineering team of PCBASIC can provide support throughout all stages of development and production. The services include:

DFM and DFA review

Customisation of functional test or ICT test fixtures

Component selection and cost optimisation suggestions

HDI stack-up and impedance planning

Engineering feedback during prototype and trial production stages

4. Comprehensive Testing and Certification Support

PCBasic can also provide comprehensive testing and verification services to ensure the long-term stable operation of products. The testing services include:

Functional Test (FCT)

In-Circuit Test (ICT)

Flying Probe Test

Firmware Programming and Verification

Various Reliability Tests (Temperature and Humidity Cycling, Vibration, Drop, Thermal Shock)

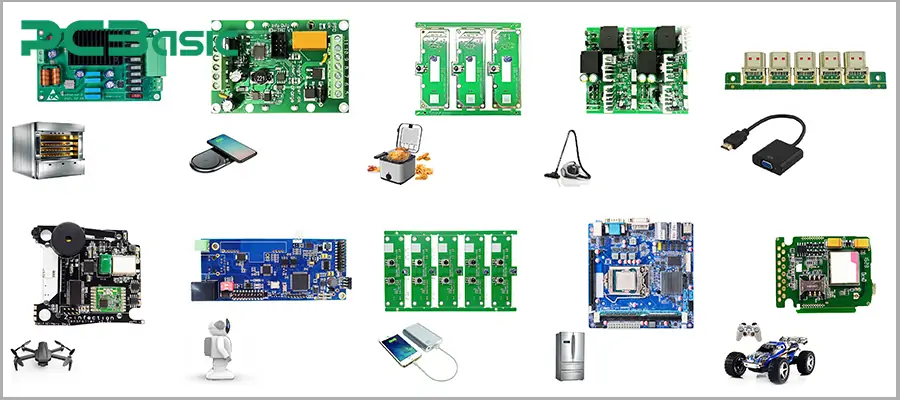

5. Experience in multiple types of consumer electronics products

PCBasic has been involved in the manufacturing of various consumer electronics products. For example:

Smart home devices

Wearable products

Various wireless and RF modules

Chargers, power banks and other power supply devices

Audio and acoustic equipment

Portable game devices and controllers

Various IoT sensors and small modules

6. Certification and Compliance System

For consumer electronics brands targeting the global market, certification and compliance are indispensable requirements. PCBasic has:

ISO 9001

ISO 14001

ISO 13485

IATF 16949

UL Certified

PCBasic is a reliable partner for many brands in the consumer electronics field.

Large multinational EMS companies dominate the high-volume production of consumer electronics. Here are several reliable large-scale consumer electronics PCBA factories:

1. Foxconn

Foxconn is the world's largest electronics manufacturing company and is at the top of the industry in consumer electronics PCBA and system assembly. Its advantages include:

Supporting ultra-large-scale product output

Maintaining in-depth cooperation with major consumer electronics brands

Highly automated SMT, testing and final assembly lines

Having a wide production layout in China, India, Vietnam, Mexico and other places

Foxconn's manufacturing system is mainly oriented towards products with a production volume of over ten million units and is more suitable for mature large-scale consumer electronics PCB production projects.

2. Pegatron

Pegatron has strong capabilities in high-precision PCBA, engineering collaboration, and component supply chain management, mainly involving:

Smartphone products

Computing devices

Consumer Internet of Things (IoT) devices and wearable products

With its engineering capabilities and supply chain integration, Pegatron is well-suited to be a long-term consumer electronics PCB assembly partner for large OEMs.

3. Jabil

Jabil is one of the EMS enterprises with the most extensive global presence, having large-scale factories in Asia, Europe, and the Americas, and offering:

Complete services from product design to industrialisation

Global procurement and supply chain optimisation

Highly automated large-scale assembly lines

Strict reliability verification processes for consumer electronics

Jabil is often chosen by international brands for cross-regional and scalable consumer electronics PCBs manufacturing and assembly.

4. Flex

Flex offers manufacturing services covering the entire lifecycle of consumer electronics, including:

Product design and early-stage engineering collaboration

High-precision assembly of consumer electronics PCBs

Automated production lines for miniaturised products

After-sales repair, refurbishment and global logistics system

Flex has extensive experience in handling multi-category and cross-regional consumer electronics projects.

A suitable consumer electronics PCB manufacturing partner can help enterprises shorten the R&D cycle, improve the overall quality of products, and ensure stability from prototyping to mass production. Below, we list several aspects that can be considered when choosing a consumer electronics PCB assembly factory:

1. Check if the factory has engineering and DFM support

In the manufacturing of consumer electronics PCBs, engineering capabilities are often more crucial than equipment. A qualified PCBA factory should be able to provide:

PCB Layout and Schematic Review

DFM/DFT Risk Optimisation

Stackups and Impedance Recommendations for High-Density Design

Component Substitution and Cost Optimisation Solutions

Thermal Design, Power Integrity, and Signal Integrity Checks

Engineering Support during EVT/DVT/PVT Stages

2. Whether it has advanced SMT equipment and processing capabilities

As modern consumer electronics all use high-density, miniaturised, and close-pitch packaging, therefore, the PCB assembly factory should have:

High-speed SMT production line capable of handling 01005, 0201, micro BGA, and CSP

Nitrogen reflow soldering to enhance solder joint quality

Full-process inspection equipment such as SPI, AOI, and X-ray

Selective wave soldering for mixed-board assembly

Stable, controlled, and continuously calibrated production equipment

3. Reliable supply chain management of components

The consumer electronics PCB assembly project has an extremely high dependence on the stable supply of components. Therefore, a reliable PCB assembly factory should have:

Cooperation channels with authorised distributors

Complete component traceability system

Strict IQC testing for each batch of materials

Alternative solutions for long-delivery-time materials

Transparent BOM and supply chain management

In addition, if the factory can provide tracking of the material's lifecycle, it would be even better to offer equivalent alternative solutions during periods of supply shortage.

4. The ability to conduct rapid prototyping and smoothly scale up for mass production

The development cycle for consumer electronics is fast, requiring rapid iterations. Factories must be able to:

Deliver samples within a short delivery period

Successfully transition from pilot production to mass production

Manage multiple SKUs in the project

Maintain strict version control

Support flexible order batching

5. Complete Quality Control System

Since quality control directly affects the long-term reliability of the product in the market, a professional PCBA factory should have the following capabilities:

IQC incoming material inspection

IPQC process inspection

FCT, ICT and other finished product tests

Full-process traceability based on MES

Complete documents, reports and defect analysis

6. Excellent Communication and Project Management

A top-notch PCBA partner will maintain transparent communication throughout the entire project, which is mainly manifested in:

Timely responses

Clear timeframes and project progress

Professional English communication

Specialist responsible for project coordination

Transparent costs, processes and delivery schedules

In conclusion, choosing a suitable PCBA factory is not as simple as just comparing prices. We need to conduct a comprehensive assessment from multiple aspects. Below is a quick checklist to determine whether a factory is suitable for your consumer electronics projects:

|

Key Dimension |

What You Should Confirm |

Typical Red Flags |

|

Engineering Strength |

Professional engineering support, DFM capability, involvement in EVT/DVT/PVT |

Purely processing-focused factory with no manufacturability review |

|

SMT Capability |

Ability to handle 01005, micro-BGA, fine-pitch packages with SPI/AOI/X-ray |

Outdated equipment or inability to provide inspection records |

|

Component Supply Chain |

Authorised sourcing, strict IQC, alternative part solutions |

Very low pricing, untraceable parts, missing IQC documentation |

|

Prototype → Mass Production Transition |

Fast prototype lead time, stable yields, proper version control |

Prototype OK but mass production unstable or frequently delayed |

|

Quality System |

MES traceability, FCT/ICT, reliability tests |

No traceability, minimal testing, incomplete reports |

|

Communication & Project Management |

Dedicated support, clear English communication, transparent timelines |

Slow responses, unclear schedules, vague quotations |

To ensure the stability of product quality, reliable delivery dates, and the smooth progress of R&D and mass production, it is necessary to select an appropriate consumer electronics PCBA factory. Large EMS factories are suitable for highly standardised and high-volume projects, while specialised factories like PCBasic are more suitable for small and medium batch consumer electronics projects that require rapid response, flexible production, and in-depth engineering support. For more information about PCBasic's consumer electronics PCBA factory, please visit here.

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.