Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > What is Toll Manufacturing? | PCBasic

As manufacturing becomes increasingly specialized and supply chains grow more complex, many enterprises, when making production decisions, start to focus on three core questions: whether costs can be controlled, whether there is control over production, and whether capacity can be scaled flexibly in the future. Against such a backdrop, the model of toll manufacturing has gradually been adopted by more enterprises in industries such as electronics, chemicals, food and industry.

You may have heard of terms like toll processing and tolling agreement, or you may be learning about what toll manufacturing is, and what exactly the difference is between it and the full-process production model where "the manufacturer handles everything"? In actual operation, many enterprises hesitate when making a choice: contract manufacturing vs. toll manufacturing - which one is more suitable for them? Especially when it comes to intellectual property protection, material ownership, and cost transparency, this choice will directly affect long-term operational risks.

This article will introduce what toll manufacturing is in a clear and understandable way, and explain how the toll manufacturing agreement operates, as well as comparing the actual differences between toll manufacturing vs contract manufacturing, helping you determine why more and more enterprises are beginning to choose toll manufacturing services. At the same time, we will also explain how PCBasic supports both toll manufacturing and contract manufacturing models, flexibly matching the production needs of different customers.

Toll manufacturing is essentially a production model where "customers provide the materials and manufacturers do the processing". The customer purchases and owns the raw materials or key components by themselves. The third-party toll manufacturer is only responsible for the processing, assembly or manufacturing stages and charges the processing fees (the toll) as agreed, and does not participate in the trading of materials.

In simple terms,

• Raw materials and components belong to the customer

• Equipment, production lines, and labor belong to the toll manufacturer

• The customer pays only for the processing and manufacturing work

This model is also often referred to as toll processing, and enterprises providing such services are usually called toll processing companies or toll manufacturing companies.

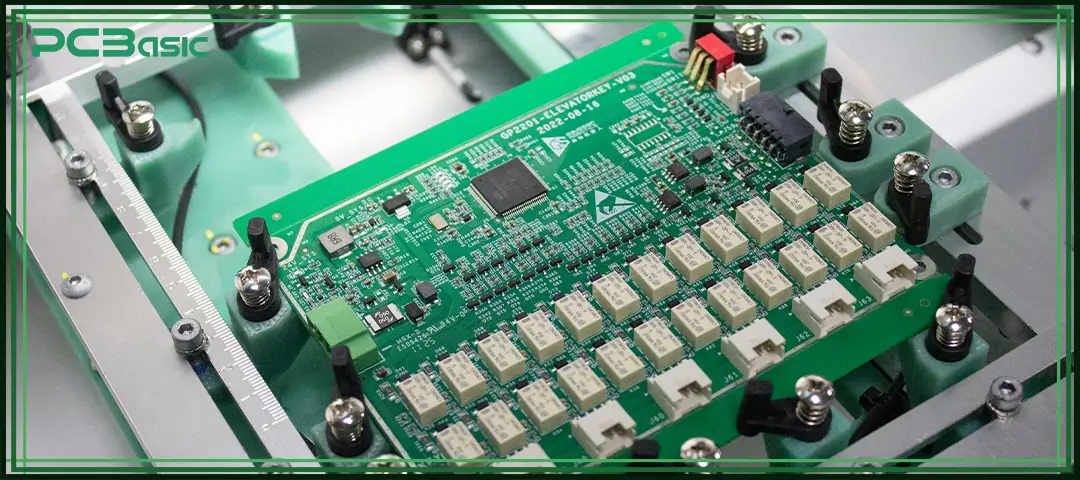

In the electronics manufacturing industry, toll manufacturing refers to the situation where customers provide PCBs, electronic components or ICs by themselves, and the toll manufacturer is responsible for SMT, THT, full board assembly, testing or specified processes. After processing, the finished or semi-finished products are returned to the customers.

If you are asking what a toll manufacturer is, it can actually be understood in this way:

A toll manufacturer is a partner that only engages in manufacturing execution, responsible for processing the customer-owned materials into the required products, but does not own any materials or finished goods.

A toll manufacturing agreement, also often called a tolling agreement, is essentially a contract that defines how toll manufacturing is carried out, who is responsible for what, and how risks are allocated.

A common toll manufacturing agreement usually makes these things clear:

• Ownership of raw materials and finished goods

• Scope of toll manufacturing services

• Processing fees and payment terms

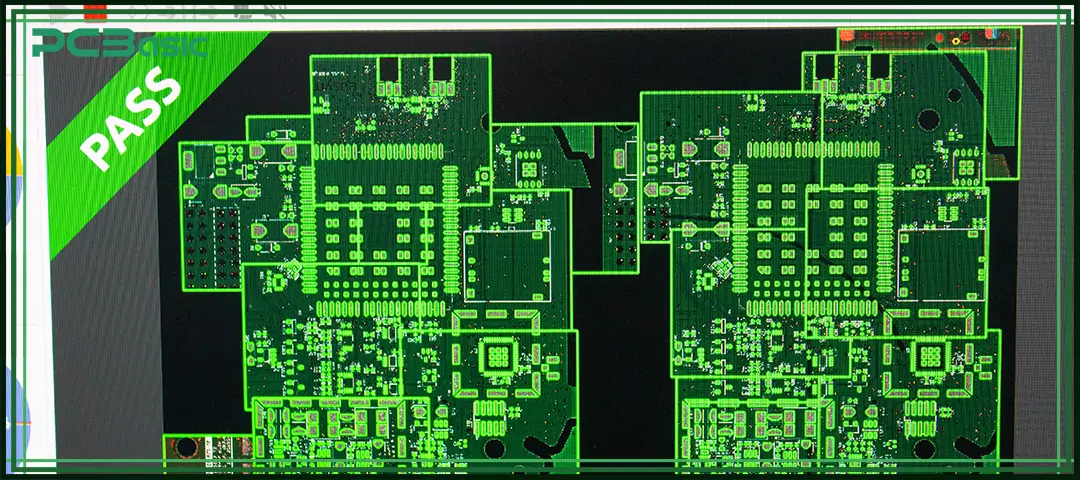

• Quality standards and inspection criteria

• IP protection and confidentiality

• Liability and risk allocation

Compared with the contract manufacturing agreement, the most significant feature of the toll manufacturing agreement is that it explicitly states that the materials always belong to the customer throughout the entire production process. The contract manufacturing factory is only responsible for production execution and does not participate in the ownership of the materials. This is also why in product fields with strict regulatory requirements or those with IP-sensitive products, many enterprises are more willing to choose the cooperation model of toll manufacturing.

Key characteristics of toll manufacturing include:

1. Customer-Owned Materials

The customer supplies and retains ownership of materials, components, or substrates.

2. Process-Focused Services

The toll manufacturer focuses on manufacturing execution, not sourcing.

3. Lower Inventory Risk

Since materials belong to the customer, the manufacturer carries less financial risk.

4. Strong IP Control

Ideal for designs where IP security is critical.

5. Flexible Production Volumes

Suitable for pilot runs, niche products, or fluctuating demand.

These features make toll manufacturing services especially attractive for companies with established supply chains or strict compliance requirements.

Before choosing the production mode, it is very necessary to fully understand toll manufacturing vs contract manufacturing. Essentially, the core difference between the two lies in who owns the raw materials and who is responsible for sourcing.

Contract manufacturing is a production model dominated by manufacturers. In most cases, manufacturers are responsible for the following tasks:

• Procuring raw materials and components

• Production and assembly

• Testing and quality control

• Packaging and delivery

After signing the contract manufacturing agreement, manufacturers usually purchase the required material first, then proceed with production, and deliver the finished products to customers. In the electronics manufacturing industry, this model is also often referred to as turnkey manufacturing.

Contract manufacturing usually has the following characteristics:

• Manufacturer-managed sourcing

• Simplified customer operations

• End-to-end responsibility

• Faster setup for new products

• Higher reliance on supplier trust

It should be noted that although contract manufacturing can reduce the operational complexity for customers, it is usually limited in terms of cost transparency and production controllability compared with toll manufacturing.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

When comparing contract manufacturing vs. toll manufacturing, the following aspects can be used for judgment:

|

Aspect |

Toll Manufacturing |

Contract Manufacturing |

|

Material ownership |

Customer |

Manufacturer |

|

Sourcing |

Customer-managed |

Manufacturer-managed |

|

Cost structure |

Processing fee |

Product price |

|

IP control |

High |

Medium |

|

Flexibility |

High |

Medium |

|

Typical agreement |

Toll manufacturing agreement |

Contract manufacturing agreement |

For companies that are evaluating contract manufacturing vs. toll manufacturing, the final choice usually depends on the maturity of their own supply chain and the acceptance of costs, control rights and risks.

A clear and well-defined toll manufacturing process can help enterprises better control quality, efficiency and traceability during the production process.

Toll manufacturing usually begins with early-stage communication. Both parties will clarify the specific scope of the toll manufacturing service, confirm what materials the customer provides, and what processes and quality standards need to be met. At the same time, the expected output and delivery cycle will also be discussed. The core purpose of this step is to ensure that both parties have a consistent understanding and clear responsibilities before signing the tolling agreement.

In electronics toll manufacturing projects, the prototyping phase usually includes DFM review, process validation and small-batch assembly testing. Since the materials are provided by the customer, thorough communication and cooperation in the early stage are essential, which can effectively reduce the risks in subsequent mass production.

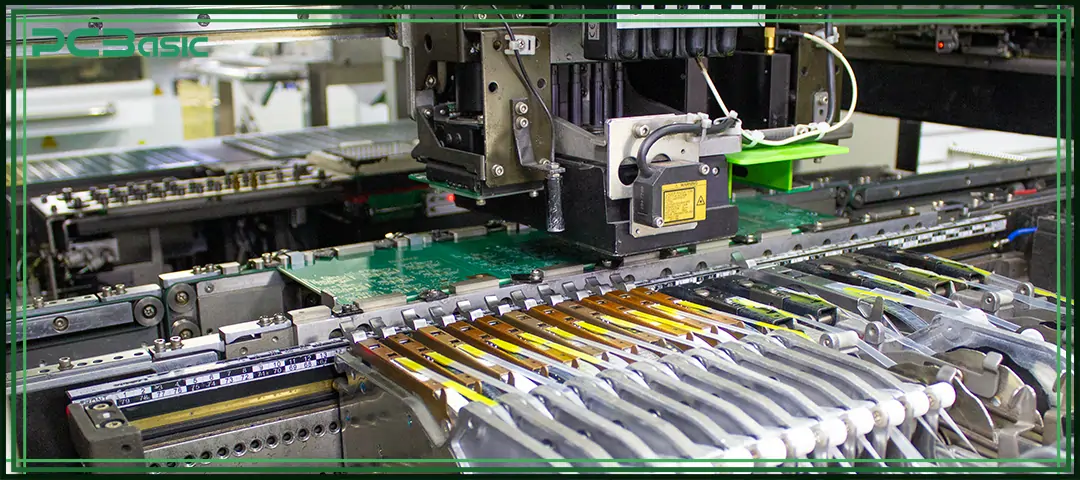

The production planning stage mainly involves arranging equipment, production lines and process flows, while defining key quality control points. Experienced toll manufacturing companies will use careful planning to minimize resource waste, avoid line stoppages, and improve overall manufacturing efficiency.

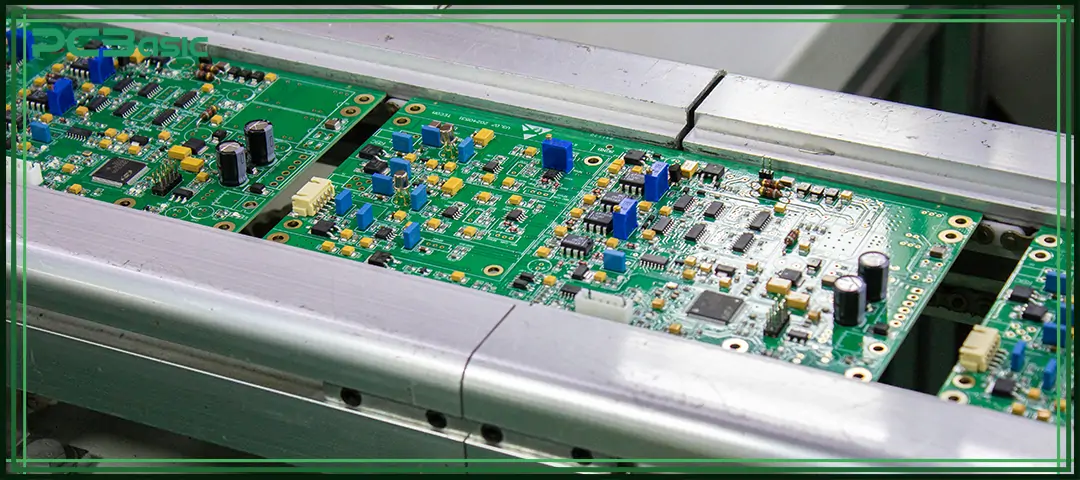

After entering mass production, the toll manufacturer will carry out specific processes as agreed, such as SMT assembly, through-hole soldering, selective soldering or mechanical assembly. At this stage, the execution efficiency of toll processing will directly affect the production cost and delivery performance.

Quality control is the core content in toll manufacturing services and runs through the entire production process. It usually includes incoming material inspection, process inspection, as well as tests such as AOI, X-Ray, ICT or FCT. By clearly defining quality requirements and responsibilities in the toll manufacturing agreement, it helps to reduce subsequent disputes.

According to the tolling agreement, the products can be returned to the customer or directly sent to the designated warehouse and packaged as per the customer's requirements. Throughout the entire contract manufacturing process, the ownership of materials and products always belongs to the customer.

Companies choose toll manufacturing for several strategic reasons:

1. Supply Chain Control

Ideal if you already have qualified suppliers.

2. Cost Transparency

Clear separation between material cost and processing cost.

3. IP and Compliance Protection

Common in medical, automotive, and industrial sectors.

4. Process Specialization

Access to advanced manufacturing without capital investment.

5. Scalability

Scale production without restructuring procurement.

For businesses asking what a toll manufacturer is best suited for, the answer is: companies that want control without owning factories.

PCBasic provides both toll manufacturing services and complete turnkey manufacturing solutions, allowing customers to select the most suitable production mode according to different project requirements.

As an experienced toll manufacturer, PCBasic supports:

• Customer-supplied PCBs and components

• SMT, THT, and mixed assembly

• Dedicated process control

• MES-based traceability

• Flexible volumes from prototype to mass production

Our toll manufacturing agreement structure ensures material ownership clarity, IP protection, and transparent pricing.

For customers preferring contract manufacturing vs toll manufacturing, PCBasic also offers:

• Component sourcing

• Full turnkey manufacturing

• Testing and certification support

• Logistics and global shipping

Whether you need a contract manufacturing agreement or a tolling agreement, PCBasic adapts to your supply chain strategy.

Understanding what toll manufacturing is is crucial for addressing various challenges in today's manufacturing environment. Compared with the turnkey production model, toll manufacturing has more advantages in terms of control, transparency and flexibility, and is particularly suitable for enterprises with mature supply chain systems or high requirements for intellectual property rights.

When evaluating toll manufacturing vs. contract manufacturing, there is no one-size-fits-all answer. The most suitable choice depends on the enterprise's own cost structure, risk management approach and operational focus.

With its complete toll manufacturing services and scalable contract manufacturing capabilities, PCBasic can provide stable and reliable support to customers in both models. We do not compromise in terms of quality, delivery and manufacturing professionalism.

If you are weighing contract manufacturing vs. toll manufacturing, PCBasic is ready to support your next project with the appropriate solution.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.