Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Some PCBA Suppliers for IoT Devices | Recommended for You

IoT is the core driving force behind the rapid development of smart homes, industrial automation, wearable medical devices, and the Internet of Vehicles today. The stable operation of all these intelligent systems is inseparable from PCBA. Different application scenarios have different requirements for the size of the board, wiring density, and other aspects. It is crucial to find a PCBA supplier that can provide high-quality PCB assembly services.

Next, this article will introduce the key requirements for IoT PCBA manufacturing, how to select the right suppliers, and will particularly recommend several reliable Chinese PCBA manufacturers.

From the perspective of a PCBA manufacturer, to meet the requirements of IoT devices in terms of performance, stability and miniaturization, any PCBA supplier should possess the following key manufacturing capabilities.

1. Miniaturized and High-Density PCB Assembly

In the era of the IoT, the smaller the device, the more functions it has. IoT electronic products often adopt HDI design with extremely small component spacing. This poses a highly demanding task for PCB assembly suppliers in terms of precision and equipment. This requires PCBA suppliers to have a full-process collaboration of high-speed placement machines, precise solder paste printing control, and 3D SPI and AOI inspection systems.

2. RF and High-Frequency Performance

Most IoT devices are equipped with wireless communication capabilities, such as Wi-Fi, Bluetooth, NB-IoT, LoRa, Zigbee, etc. This means that the circuit boards must have excellent radio frequency and high-frequency signal performance. Electronic PCB assembly suppliers need to consider the following factors during the design and manufacturing stages:

Using substrates with stable dielectric constants

Strictly controlling impedance to reduce signal loss

Reasonable grounding design and matching of trace lengths

3. Low Power Consumption and Thermal Stability

Most IoT devices rely on battery power. During the IoT PCB assembly process, proper component selection, copper foil thickness, and heat dissipation design are crucial for ensuring the product's lifespan. Professional PCB assembly manufacturers should be able to:

Select low-power MCUs and high-efficiency power management chips;

Optimize the layout of signal and power layers through multi-layer board stacking;

Add thermal vias and heat dissipation copper layers at key heat sources;

Conduct thermal simulation analysis and infrared temperature detection.

4. Environmental and Reliability Testing

Unlike traditional consumer electronics, many IoT products are applied in complex environments, such as outdoor monitoring, industrial factories, or vehicle-mounted systems. This requires PCBA manufacturers to possess comprehensive reliability and environmental testing capabilities. Common tests include:

Temperature cycling test

Vibration and shock test

Humidity and salt spray test

Functional aging test

5. Quality Certifications and Digital Traceability

A qualified PCB assembly services supplier should have support from international certification systems and a complete production traceability mechanism, including:

ISO9001

ISO13485

IATF16949

UL Certification

When choosing a suitable PCBA supplier for your IoT products, the following points can be taken into consideration:

1. Technical Capability and Equipment Level

The first thing to consider is the technical capabilities and production equipment level of the factory. A capable PCB assembly supplier usually has:

High-speed surface mount machines

Precise solder paste printing and 3D SPI, AOI, X-Ray

Advanced processes such as selective wave soldering, nitrogen reflow furnace, etc.

Fully automated loading and unloading, online board splitting, automatic cleaning and other intelligent production lines.

Because these devices can demonstrate the manufacturing process stability and high yield capability of PCB assembly manufacturers.

2. Experience with IoT and RF Projects

IoT devices typically involve wireless communication modules, radio frequency signals, sensor interfaces and low-power systems. Therefore, when selecting electronic PCB assembly suppliers, the following aspects should be taken into consideration:

Do you have experience with wireless products such as Wi-Fi, BLE, LoRa, and NB-IoT?

Do you have the processing capability for high-frequency/hybrid boards (FR4 + Rogers)?

Can you assist with impedance matching and DFM/DFT optimization?

Do you provide support for small batch prototyping and sample verification?

3. One-Stop Turnkey Service

Check whether the PCB assembly manufacturer offers one-stop electronic manufacturing services. The benefits of having such a service model are:

It can reduce the need for multi-vendor coordination, lower communication costs; shorten delivery times, enhance supply chain collaboration efficiency; reduce hidden risks in the procurement and logistics processes; and respond quickly to design changes or urgent deliveries.

4. Scalability and Quick Turnaround

IoT products often start with small-batch verification (prototypes). So, if you are in the same situation and need a supplier that can not only provide quick turn PCB assembly but also support large-scale mass production, then when making your choice, you can focus on the following indicators:

Whether 24-hour express sample making is provided;

Whether multiple SMT production lines are available and the production capacity can be flexibly adjusted;

Whether a complete quality control system including IQC, IPQC, FQC and OQC is in place;

Whether a stable component procurement channel can be provided to avoid production line stoppages due to material shortages.

5. Transparent Communication and Engineering Support

Good communication is the key to successful cooperation. Take PCB assembly suppliers for example:

Whether BOM substitutability assessment is conducted before assembly;

Whether problems are fed back in real time during the production process and improvement suggestions are provided;

Whether after-sales support and batch quality reports are provided after shipment.

6. Quality Certifications and Long-Term Stability

Stable quality and long-term cooperation ability are important indicators to measure whether a PCBA manufacturing supplier is trustworthy. In addition to basic systems such as ISO9001, ISO13485, and IATF16949, attention should also be paid to the supplier's:

Material traceability management;

Process yield and scrap rate data;

Environmental compliance (RoHS, REACH certification);

Whether it is an IPC member unit and complies with industry standards.

China's electronic manufacturing industry chain is highly complete and has a mature supply system. Below, we list three PCB assembly manufacturers, each of which is trustworthy. The ranking is not in any particular order.

Shennan Circuits is a leading high-end PCB assembly supplier and PCBA manufacturing supplier in China. Renowned for its strong engineering capabilities and quality control, it is an important partner for many globally renowned brands.

Core Advantages:

IoT PCB Assembly

Manufacturing in high-reliability fields such as automotive electronics, communication equipment, and industrial control

Manufacturing Strengths:

Equipped with multiple automated SMT production lines and AOI, X-Ray, and ICT inspection equipment

Capable of supporting both prototype PCB assembly and large-scale production simultaneously

Quality System: Certified with multiple international standards including ISO9001, IATF16949, and ISO13485

Customer Base: Provide high-precision electronic PCB assembly and system integration manufacturing services for top global enterprises

Shennan Circuits has strong manufacturing capabilities and international service standards, and is one of the representatives of China's electronic manufacturing industry.

Kinwong Electronics is also one of the well-known PCB assembly service providers in China. It has an integrated production system covering the entire process from PCB manufacturing to PCB assembly.

Technical features: mature solutions in areas such as smart wearables, smart lighting, and industrial IoT

Production Capacity:

Utilizing fully automated surface mount assembly line

AOI inspection and X-Ray solder joint analysis

Supporting high-frequency signal and high-density wiring design

Delivery speed: Offer quick turn PCB assembly and a multi-variety small-batch production model

Service support: The engineering team can provide DFM/DFT design optimization and production feasibility analysis

Kinwong Electronics boasts high stability, excellent cost-effectiveness and technical support. It is one of the reliable PCBA suppliers that customers can trust.

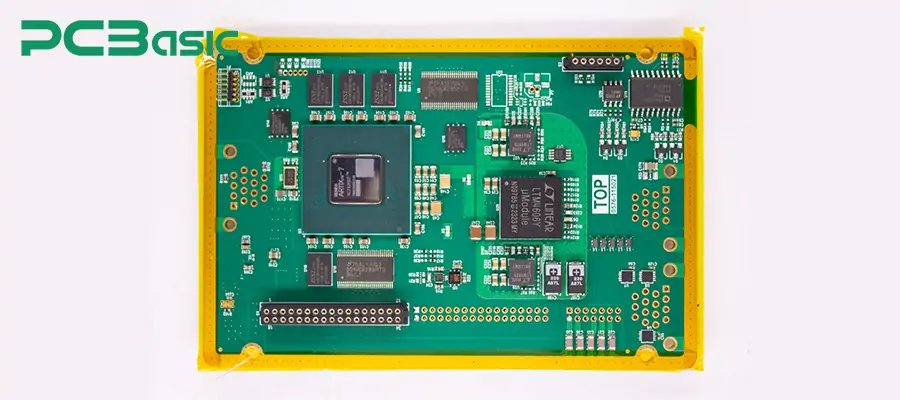

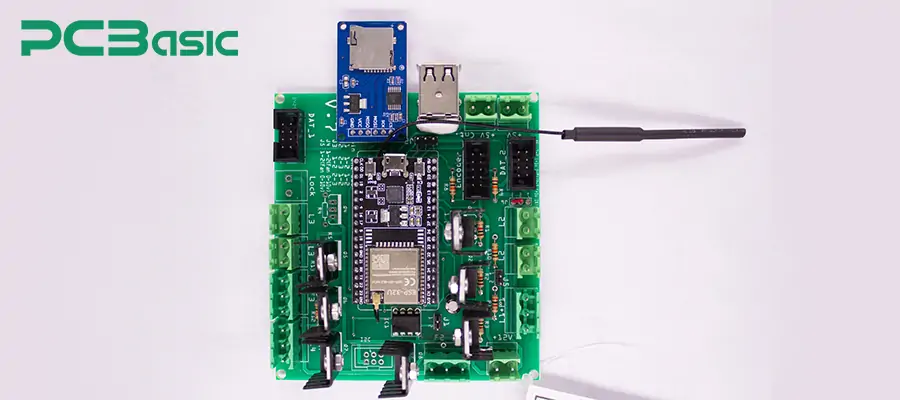

PCBasic is a medium-sized professional PCBA manufacturing supplier, dedicated to providing customers with high-quality and prompt PCB manufacturing and assembly services.

Manufacturing capabilities:

In possession of 9 fully automated SMT production lines and 2 DIP assembly lines

Equipped with nitrogen and argon reflow soldering, 3D SPI, AOI, X-Ray, flying probe and functional testing equipment

Capable of reliably completing high-precision packaging production such as 01005, BGA, and QFN

Intelligent System: Utilizes MES + ERP + CRM + IoT digital management system to achieve full-process traceability, real-time monitoring, and data-driven production management

Quality Assurance: Obtains international certifications such as ISO9001, ISO13485, and IATF16949

Service Scope:

Offer rapid prototype and quick turn PCB assembly

Wholesale PCB assembly services

Full-process electronic manufacturing services

Application Areas: Covering smart home, industrial Internet of Things, medical equipment, wearable products, and automotive electronics.

PCBasic is dedicated to creating an efficient and controllable one-stop electronic manufacturing platform for customers. Please visit us and feel free to leave a message if you have any questions.

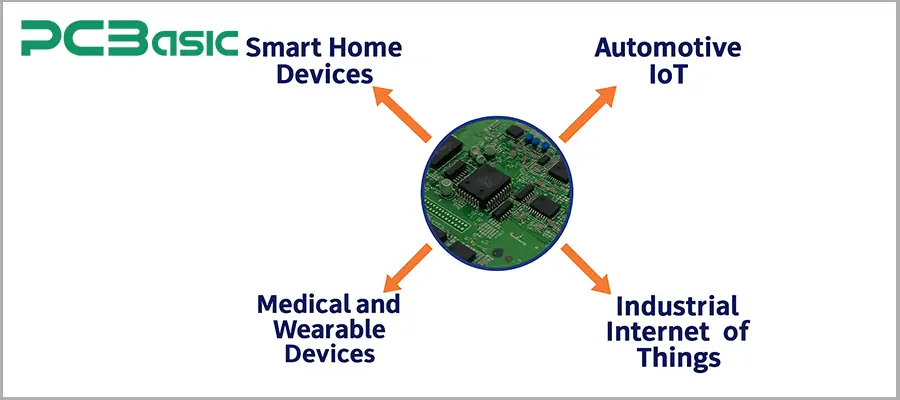

The application of IoT PCBAs is also very extensive. The following are the most typical application directions at present:

1. Smart Home Devices

The circuit boards used in smart sockets, Wi-Fi cameras, temperature controllers, air purifiers, door locks and lighting controls, etc., need to take into account miniaturization, low power consumption and signal stability. The IoT PCBAs not only meet these requirements, but also ensure reliable wireless connections, precise power consumption control, and the realization of multi-functional layouts within a limited space.

2. Industrial Internet of Things

IoT PCBAs are also commonly used in industrial control systems, automation gateways, sensor nodes and data collection terminals. These products are usually capable of operating in complex environments such as high temperatures, vibrations and dust. This requires that the PCBA used in these applications have higher reliability and anti-interference performance. Therefore, manufacturers should possess the capabilities of moisture-proofing, corrosion resistance and EMC control.

3. Medical and Wearable Devices

These products have extremely high requirements for precision, safety and stability. When manufacturing medical IoT devices, PCBA manufacturers must strictly follow the ISO13485 quality system and conduct comprehensive functional and aging tests.

4. Automotive IoT

In vehicle communication, ADAS systems, intelligent driving monitoring, and vehicle networking modules, the PCBA for IoT Electronics needs to meet higher reliability, high-temperature resistance, and long-term supply requirements.

The reliable operation of IoT devices cannot be achieved without high-quality PCBA manufacturing. High-quality PCBA requires a reliable professional IoT PCB assembly manufacturer. As the application of IoT continues to expand, collaborating with an experienced, technologically reliable and trustworthy PCBA supplier will become the key to achieving smarter, safer and more competitive electronic products.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.