Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > SMT PCB Assembly: Definition, Features and PCBA Process

In today's electronic manufacturing industry, the advanced method of surface mount technology has become the core and foundation of the vast majority of circuit board assembly processes. It has changed the traditional production models, enabling electronic components to be directly mounted on the surface of the printed circuit board (PCB) and undergo high-speed and precise soldering through automated equipment.

In this blog, we will introduce SMT PCB assembly step by step: including its basic definition, main advantages and disadvantages; showing its typical applications in various industries, and comprehensively sort out the SMT process. In addition, we will also compare SMT with SMD and THT to help you understand their differences intuitively. Meanwhile, this article will also mention the important role of quality control in the SMT PCB assembly process, and at the end, recommend a reliable SMT PCB assembly supplier in China to you: PCBasic.

SMT (Surface Mount Technology) PCB assembly is the process of directly mounting electronic components onto the surface of a printed circuit board (PCB) to form a complete printed circuit board assembly (PCBA). Unlike the earlier through-hole technology (THT) assembly, which required drilling holes and inserting component leads, SMT assembly places SMD (surface mount device) components such as resistors, integrated circuits (ICs), and transistors directly on the PCB surface and performs soldering.

This method saves circuit board space, enabling components to be mounted on both sides of the PCB and achieving a compact, lightweight and high-density design. Due to its reliance on the automated equipment in the SMT production line, it can support high-speed, precise mounting as well as large-scale PCB assembly manufacturing. Nowadays, SMT PCB assembly is no longer just an option; it has become the global standard for modern circuit board assembly services.

The reason why SMT PCB assembly holds a crucial position in modern electronic manufacturing is that it has irreplaceable advantages over other technologies. However, like any process, SMT PCB assembly also has its drawbacks. Therefore, both designers and manufacturers need to take all aspects into consideration when choosing assembly technologies.

• Compact Design & High Density: Due to the smaller size of SMD components, SMT assembly can achieve a more compact layout, double-sided mounting, and overall miniaturization of electronic products.

• Cost-Effective for High-Volume Production: PCBs used for SMT assembly require fewer holes to be drilled, and combined with automated placement, this can significantly reduce labor and processing costs, making SMT PCB manufacturing and assembly more economical in mass production.

Faster Production: The automated SMT production line can place thousands of components per hour, significantly reducing assembly time compared with the through-hole method.

• High Reliability: Strong solder joints and consistent machine mounting enhance durability, ensuring stability even in harsh environments.

• Flexibility: SMT assembly is suitable for various components and supports all simple and complex PCB assembly manufacturing projects.

• Difficult Manual Repair: Very small SMD components are more challenging when manually reworked or replaced.

• Thermal Stress Sensitivity: Some components may be damaged during reflow soldering if not properly designed.

• Not Suitable for All Components: Larger connectors, high-power or high-voltage devices usually still require through-hole PCB assembly to obtain stronger mechanical support.

• High Initial Investment: Establishing an automated SMT PCB assembly line requires advanced equipment, which may be too costly for small-batch production or prototyping.

Despite these drawbacks, the advantages brought by SMT PCB assembly - speed, cost efficiency, miniaturization and reliability - still far outweigh its limitations. This is also the reason why it has become the preferred process for global electronics assembly services and the core of modern PCB board assembly.

SMT PCB assembly is almost applied in all fields that require high-performance and miniaturized designs. The main applications include:

• Consumer Electronics

• Telecommunications

• Automotive Electronics

• Aerospace and Defense

• Medical Devices

• Industrial Electronics & Automation

Whether it is the pursuit of smaller, lighter, faster and more powerful consumer electronics, or the need for reliable and high-performance modules in the automotive, aerospace, medical and industrial fields, SMT PCB assembly services can all provide compact, stable and scalable solutions.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

SMT PCB assembly directly mounts SMD components onto the surface of the PCB. The entire assembly process mainly includes the following steps:

At the starting point of the SMT production line, the loader conveys the bare boards into the production line one by one. At this step, we will inspect the appearance, cleanliness and batch of the PCB to ensure it is suitable for subsequent processes.

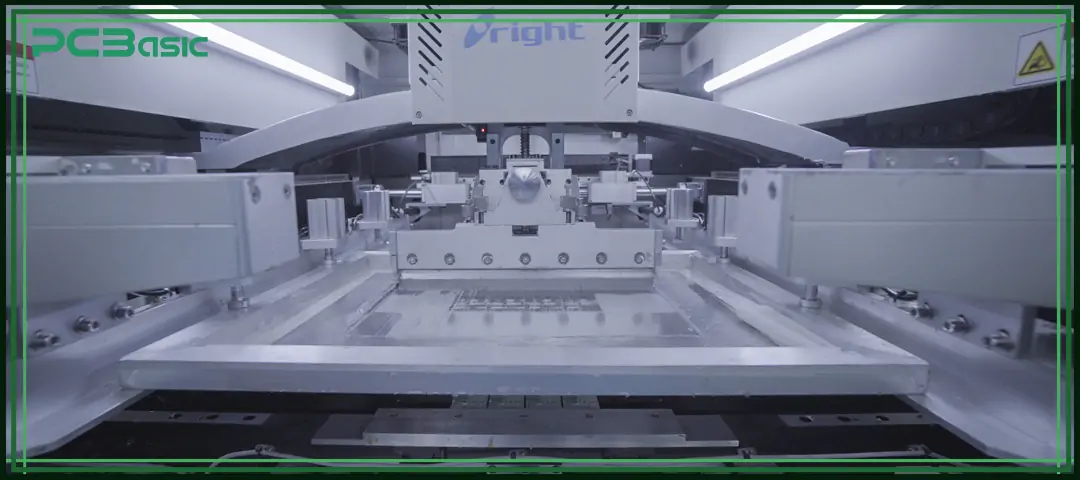

The solder paste is precisely printed onto the PCB pads through the SMT stencil and the scraper. The solder paste will melt to form solder joints in the subsequent reflow soldering.

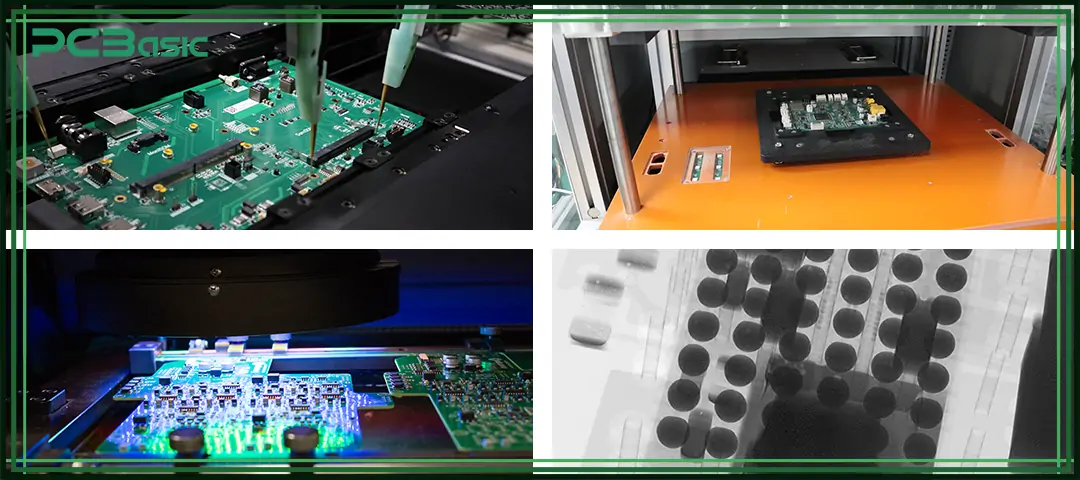

The PCB passes through the solder paste inspection machine, and the infrared camera quickly records and analyzes whether the volume, thickness, position and shape of the solder paste are qualified.

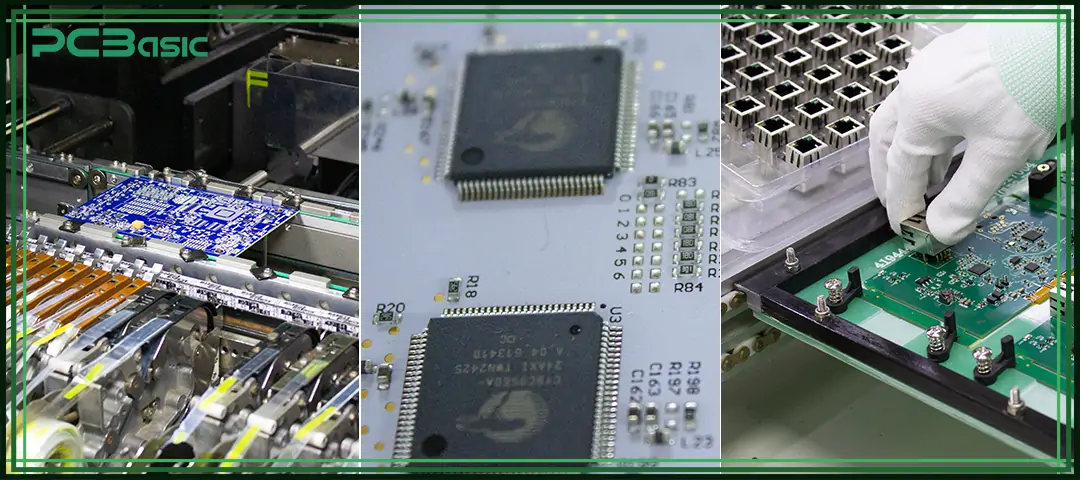

Qualified PCBs enter the pick-and-place machine. Components are provided by feeders in tape, tray or tube form. The robotic arm uses suction nozzles to quickly pick them up and precisely place them on the pads covered with solder paste.

If there are BGA chips on the PCB, X-ray inspection should be used to scan the hidden solder balls to confirm that there are no defects such as cold solder joints, cracks, or voids.

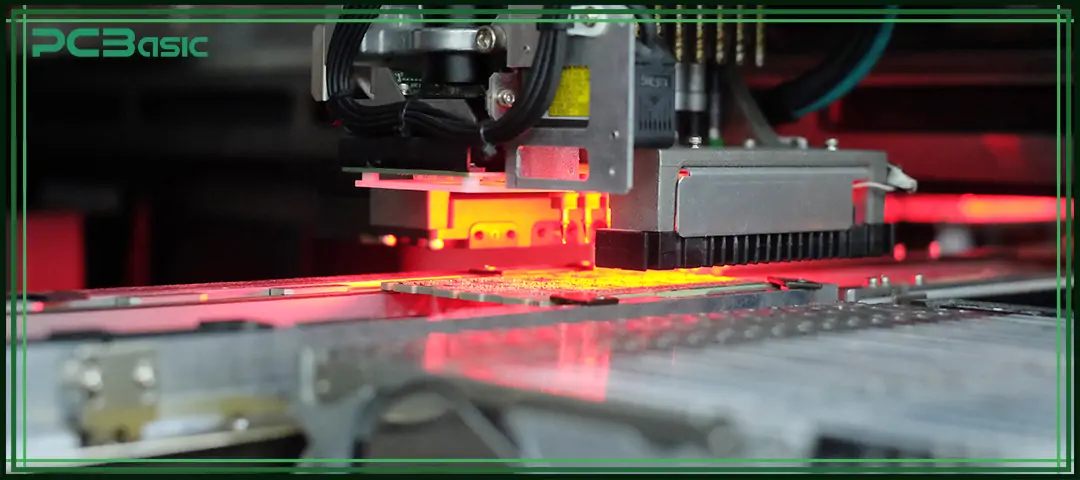

The PCB that has been mounted will enter the reflow oven, which usually has 8 to 12 temperature zones, including preheat, soak, reflow and cooling. Under a controlled temperature curve, the solder paste melts and forms an intermetallic compound with the pads, ultimately fixing the components.

After the soldering is completed, the PCBA goes through AOI. The high-speed camera system will detect whether there are missing components, misalignment, polarity errors, bridging, or cold solder joints. When necessary, manual re-inspection will also be carried out to ensure 100% reliable quality.

When prototyping or conducting small-batch production, the first PCBA will be randomly selected for inspection. Operators contact the solder joints one by one with the probe, measure and compare the component parameters to ensure consistency with the design.

In mass production, PCBA usually undergoes functional testing to verify its electrical performance and working condition, ensuring that the final product meets the usage requirements.

If the PCB is designed as double-sided, after one side is completed, the board needs to be flipped over, and the steps of solder paste printing - mounting - reflow soldering - inspection should be repeated until both sides are completed.

This series of efficient and highly automated SMT PCB assembly processes ensures the high speed, high precision and high reliability of PCB assembly manufacturing.

In mass production, PCB assembly services must carry out strict quality control to ensure that the circuit boards have no defects. Common quality inspections throughout the entire SMT PCB assembly process include:

• AOI (Automated Optical Inspection): Used to check whether components are misaligned, whether there is a solder bridge, or any missing components.

• X-ray Inspection: Mainly used to check devices like BGA, where solder joints are not visible, ensuring that there are no issues inside the solder joints.

• In-Circuit Testing (ICT): By inspecting electrical performance, it is confirmed that each circuit can operate normally.

• Functional Testing: To verify whether the entire electronic assembly meets the design requirements.

Without these strict quality controls, serious malfunctions may occur in PCB assembly manufacturing in some critical applications. For this reason, professional SMT PCB assembly suppliers like PCBasic attach great importance to end-to-end testing to ensure the reliability of products.

SMD (Surface Mount Device) refers to surface mount components, such as resistors, capacitors, diodes and ICs. They are small in size, have no long leads, and can be directly mounted to the surface of the PCB for SMT assembly.

THT (Through-Hole Technology) is a through-hole mounting process. It requires drilling holes on the PCB first, inserting the component leads, and then fixing them through soldering. Its connection is more secure, and it is often used in high-power devices, connectors, automotive electronics, aerospace and other occasions with high reliability requirements.

Modern PCB SMT assembly usually combines SMT and THT to form a hybrid PCB board assembly solution.

Comparison of SMT vs SMD vs THT

|

Term |

Full Name |

Meaning |

Pros |

Cons |

Applications |

|

SMT |

Surface Mount Technology (SMT) |

Process of mounting and soldering parts on the PCB surface. |

Compact, fast, low cost, supports high density. |

Weaker joints, heat sensitive. |

Phones, PCs, consumer electronics. |

|

SMD |

Surface Mount Device (SMD) |

The components used in SMT, like resistors, capacitors, ICs. |

Small size, wide variety. |

Hard to rework, not for high power. |

Resistors, capacitors, ICs, BGAs. |

|

THT |

Through-Hole Technology (THT) |

Components inserted into drilled holes and soldered. |

Strong, reliable, good for high power. |

Bulky, slower, costly. |

Automotive, aerospace, connectors, and power parts. |

PCBasic is a professional electronic manufacturing service company located in Shenzhen, dedicated to providing high-quality PCB manufacturing and assembly solutions for global customers. The company focuses on serving the production needs of medium and small batches. By integrating years of industry experience and advanced production equipment, it can flexibly support customers from product research and prototyping to rapid delivery of medium-volume production, helping customers efficiently achieve design implementation and market application.

1. Advanced Production Capability

• Equipped with 8 efficient SMT production lines

2. Hybrid Assembly Solutions

• Provides hybrid assembly solutions (SMT + THT) tailored to customer needs

3. Strict Quality Control

Multiple inspection methods throughout the entire process:

• AOI (Automated Optical Inspection)

• Flying Probe Testing

• X-ray Inspection

• ICT (In-Circuit Testing)

• Functional Testing (FCT)

These inspection machines guarantee reliable and defect-free PCBAs

4. Comprehensive International Certifications

Certified to multiple global standards:

• ISO 9001 (Quality Management System)

• ISO 14001 (Environmental Management System)

• ISO 13485 (Medical Devices Quality Management System)

• ISO 45001 (Occupational Health and Safety Management)

• IATF 16949 (Automotive Quality Management System)

• RoHS (Restriction of Hazardous Substances)

• UL, CE, FCC (Product Safety and Compliance)

These certifications indicate that PCBasic can comply with worldwide quality, safety, and environmental requirements

By choosing PCBasic, you can obtain stable, reliable, cost-effective and scalable SMT PCB assembly services, providing strong support for your industry applications.

SMT PCB assembly has changed the traditional way of PCB manufacturing and assembly, enabling circuit boards to be smaller, faster and more reliable.

As a reliable SMT PCB assembly supplier, PCBasic has advanced SMT production lines and strictly controls the quality management at every level. PCBasic can provide complete electronic assembly services. Whether it is small-batch prototypes or high-volume PCB board assembly, it can ensure that the products meet the highest performance and reliability standards.

Choose PCBasic to make your products more reliable.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.