Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Design Services: From Ideas to Products

In the development of electronic products, PCB design services can help you turn an idea into a truly usable circuit board. Whether you are a newly established company or a large-scale technology enterprise, as long as you find the right PCB company, you can complete the development faster, reduce errors and improve product quality. From sketching to making a PCB prototype, every step is inseparable from professional electronic design services and PCB manufacturing experience.

In this article, I’ll introduce you to comprehensive PCB design services and steps. And after the PCB designed, how the idea is turned into a product.

PCB design service is the complete process required to turn an idea into a producible printed circuit board (PCB). It includes the design of circuit diagrams, the drawing of schematic diagrams, the simulation of performance, PCB layout services, and design for manufacturability (DFM) that considers whether it is feasible for actual production. Companies that offer custom PCB design services usually also have the capabilities of electronic design services and PCB manufacturing. This ensures that every step from design files to finished circuit boards can be smoothly done without any problems.

Professional PCB design companies offer a range of services, including:

• Custom PCB design and schematic creation

• PCB layout services optimized for signal integrity and EMI control

• 3D visualization and mechanical integration

• PCB printing services and fabrication-ready output files

• PCB prototype development to support rapid product testing

All these services are designed to simplify the PCB manufacturing process and reduce the risk of errors in production.

Here’s how a professional PCB design service typically flows:

Before heading to create your custom printed circuit board, it wouldn't be a bad idea to check whether it can work. Usually, printed circuit board designs are irreversible once produced, making every mistake during the PCB design process. And you'll need to produce a new PCB to correct that mistake.

In order to lower the risks and the time, before going for production and actual printed circuit board design, it is highly suggested that the prototype be built using direct components and a breadboard. PCB design services will often recommend the same before approaching a design. They would like to custom-design circuit boards according to the customer's requirements. The idea is feasible and workable.

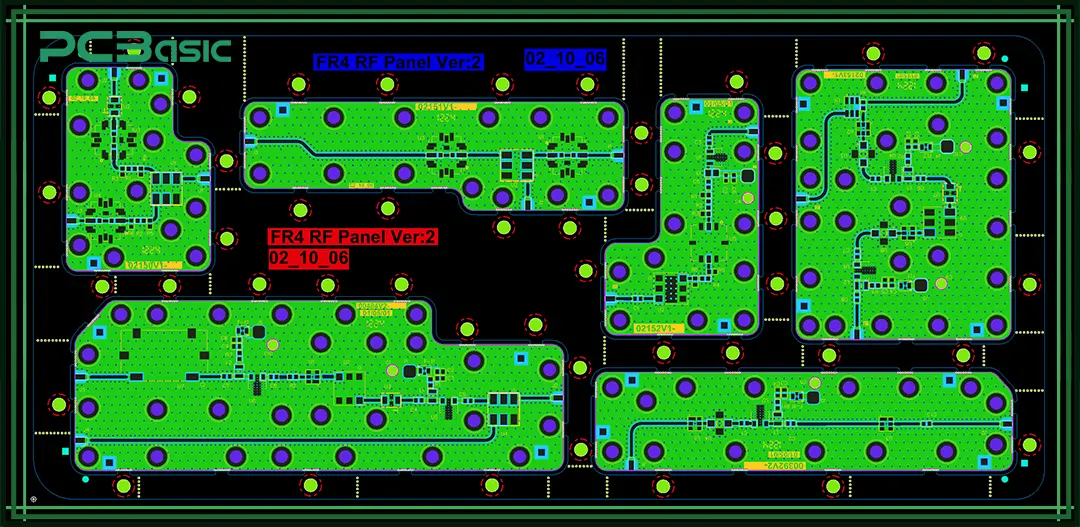

Once you validate your circuit board design idea, the first stage is to design a printed circuit board. The PCB design has two main steps: PCB circuit board design (also called PCB Design Services - from an idea to a product) and PCB schematic design services to fulfill your needs. The second is PCB layout design. We combine these two stages into one final design. The result after manufacturing will be a printed circuit board (PCB).

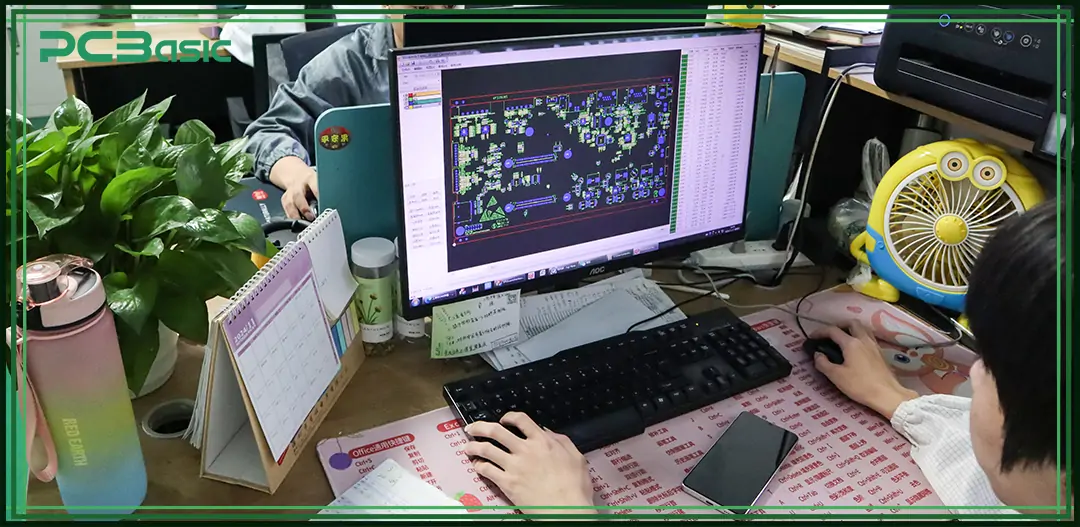

The PCB design service provider will use PCB design software such as Altium Designer or Eagle. The software is just a tool, and each hardware designer will choose the one he is familiar with. The decision of which software to use will usually not affect the quality of the PCB design.

In the circuit board design process, the engineer will first understand the logic of the board and its function. He will choose which components to use and which integrated circuits (ICs) to embed, and he will create the logic that will result in the functionality of the circuit board design. This stage is crucial and is directly connected to the board functionality and the behavior of the final product.

In this stage, it's also important to consider the environment that will expose the PCB circuit board, such as excessive heat or cold radiation. Based on those parameters, the PCB designer could choose suitable components for either industrial or commercial use. To avoid costly mistakes, it's essential to communicate with the design service provider (individual engineer or a company) sufficiently to make sure that the design fits the end-case use of the final product.

The PCB layout design follows the schematic design. Once we finish the PCB circuit board design and the schematic, it's time to lay out the components. This stage complexity depends on the number of layers that the printed circuit board design includes. The more layers, the more complex the task will be. While the layout is usually easier than the initial PCB schematic, there are many things that the engineer or the PCB design service provider should consider, such as components' location and orientation, correct grounding, antenna placement, and high-speed data transfers, which might require specific circuit board design requirements.

The printed circuit board designer will consider other, more technical approaches, such as making sure that the board nodes are accessible and providing clear orientation for the components to avoid mistakes in production. PCB design services that take an idea from a product will fulfill your needs.

In the layout process, the circuit board designer will be able to put a layer of silkscreen. This layer is visible and often used to place texts and logos on the printed circuit board. In this case, it would be a great idea to provide your designer or engineer with extra content such as project or company logo and other information that should be visible on top of the final printed circuit board.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

When the printed circuit board layout and schematic design are finished, it's time to approach the production stage. During the printed circuit board assembly service, we'll handle the production of the finished printed circuit board design. This includes purchasing and placing components, applying solder paste using custom stencil steel mesh, and performing multiple tests to ensure product quality.

We are at PCBasic to provide a turn-key solution for PCB and PCBA services, including but not limited to all the above. Let's read the details of such complicated fabrication services to understand what is going on behind the scenes.

To facilitate the custom circuit board, we need to purchase the required components. At PCBasic, we'll take care of that by offering a turn-key solution from PCB to PCBA production. Purchasing components might sound like an easy task, but that's far from the truth. The market is suffering from component and integrated circuit shortages. Finding suitable suppliers at a reasonable price is not an easy task. Another issue when purchasing components is to avoid counterfeit parts, resulting in the entire design malfunction and loss of profits. Although such implications are severe, we can avoid those problems by using a trusted supplier and service provider.

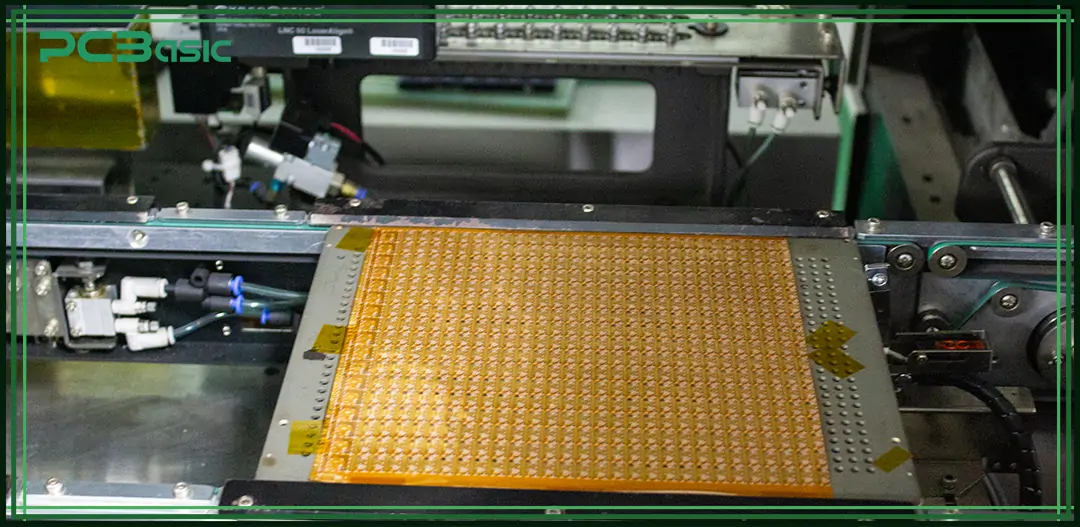

Every printed circuit board contains electronic components. Those can be a few components and sometimes hundreds of different parts. Usually, the industry uses solder paste to apply the components to the printed circuit board. Stencil steel mesh is used to distribute the solder paste eventually across the entire printed circuit board. A single stencil can be used thousands of times, which is also a cost-effective approach for a finalized design. PCB design services – from an idea to a product, PCB/PCBA services to fulfill your needs.

Once we have the printed circuit board, the components, and the stencil steel mesh in place, it's time to head over to our published circuit board assembly procedure or, in short - PCBA. The PCBA is the final stage in the printed circuit board design, and the result is a final working electronic board that behaves based on the designer's expectations.

After the PCBA manufacturing is completed, the final step is final product assembly, which involves installing the circuit board into the enclosure and connecting other components such as the display screen, battery, and connectors to form a complete and functional electronic product.

At this stage, not only should the parts be properly packed, but also functional tests, appearance inspections and packaging should be conducted to ensure that the product can work properly and has a qualified appearance and meets the quality requirements of the customers.

It is very important to choose a reliable PCB manufacturer or PCB design company. PCBasic is a leading PCB company in the industry, with strong advantages in custom PCB design services, powerful production capacity, and stable PCB printing and assembly services.

As an outstanding Chinese PCB and PCBA manufacturer, PCBasic can offer one-stop services from design to production and assembly, applicable to multiple fields such as medical devices and consumer electronics.

Whether you need a PCB prototype or batch PCB manufacturing, PCBasic can provide high-quality and efficient solutions based on your requirements.

PCBasic is a reliable and experienced company that provides complete PCB and assembly solutions. Here’s what makes us stand out:

1. Experienced Teams

We have a team with over 10 years of PCB design experience and another with 10+ years of project management experience, so your projects are handled professionally from start to finish.

2. Multiple Factories

We operate different factories in different locations, such as a small-batch factory in Shenzhen and a large-batch factory in Huizhou, to meet different order needs.

3. In-house Stencil and Fixture Production

We have our own factory to make stencils and fixtures, and we can deliver stencils in as fast as 1 hour.

4. CNC Precision Machining

We provide CNC processing for high-precision mechanical parts to ensure perfect assembly.

5. Smart Central Warehouse for Components

We use an intelligent warehouse system to manage parts and make sure all components are original and in stock.

6. Quick BOM Upload and Instant Quoting

Just upload your BOM to our system, and you’ll get a fast quote and lead time, making the process quick and easy.

7. Trusted Certifications and Patents

PCBasic is a national high-tech enterprise certified with ISO13485, IATF 16949, ISO9001, ISO14001, and UL, and is also an IPC member. We’ve also earned 20+ patents related to quality inspection and production systems.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.