Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > 21700 vs 18650 Batteries: What is the Difference?

When you think about rechargeable gadgets like a flashlight, a laptop battery pack, and even an electric car, they generally depend on special batteries inside. These are often lithium-ion batteries. They come in different shapes and sizes. For a long time, one size was really common: the 18650. Lately, however, another size has become very popular, especially in newer devices and vehicles: the 21700.

You see, the size and type of battery cell used inside a device are really important design choices. It affects:

1. How much power does the device have?

2. How long does it run?

3. And how big or heavy is it?

In simple words, picking the right battery cell matters a lot. This point is important for anyone building and using electronics.

Let's start somewhere and compare the 18650 and 21700 battery cells to see what's different and why both are used.

First off, what do these numbers mean? They are not just random codes. Engineers know it's actually a simple way to tell you the size of the battery cell.

18650

This name breaks down into dimensions.

• 18 means the battery is 18 millimeters (mm) in diameter.

• 65 means the battery is 65 millimeters (mm) long.

• 0 at the end usually means it's a cylindrical battery shape.

So, an 18650 battery is a cylinder, 18mm across and 65mm tall. For many years, this was the standard for high-energy rechargeable cells. You know, it's been used in everything from laptops to many early electric bikes.

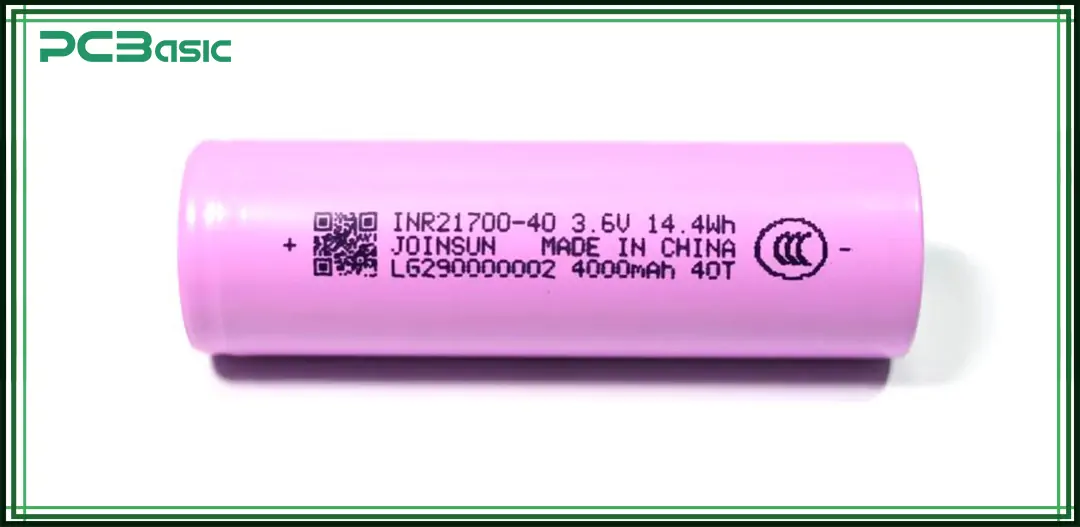

21700

This follows the same pattern.

• 21 means the battery is 21 millimeters (mm) in diameter.

• 70 means the battery is 70 millimeters (mm) long.

• 0 again means it's cylindrical.

So, a 21700 battery is a cylinder, 21mm across and 70mm tall. It's basically a bit fatter and a bit longer than an 18650.

Definitely, the 21700 is physically larger than the 18650. This difference in size, even though it seems small, has a big effect on performance.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Comparing these two sizes reveals why manufacturers choose one over the other. This point is noticeable once you look at the specs.

As we covered, the 21700 is 3mm wider and 5mm longer than the 18650. While these differences are small, they mean a device designed for one cannot fit the other without changing the battery holder and internal layout. They are not interchangeable just because they look similar. You can say it is the most common "mistake" beginners might assume they can just swap them, but do not panic, it's a simple physical size problem.

This is a major difference. Because the 21700 is bigger, it has more internal volume. This extra space allows manufacturers to put more of the active materials inside the cell that store energy. You will see that typical 18650 cells have capacities ranging from around 2000mAh to 3500mAh (mAh stands for milliampere-hour, a unit of charge capacity). In contrast, 21700 cells often range from 3000mAh up to 5000mAh or even higher. This point is important: a single 21700 cell can usually store significantly more energy than a single 18650 cell.

The larger size of the 21700 also helps with power output. The internal parts that carry current are larger, and the cell's design can often handle higher discharge rates. This means a 21700 cell can often provide more power to a device when it needs it, like when a power tool is working hard or an electric car is accelerating quickly. Simultaneously, it can often maintain a higher voltage under load compared to a similar 18650. Benchmark test shows this power advantage in demanding applications.

This relates to how much energy is stored per unit of volume or weight. Because the 21700 is larger, it has a better ratio of active material to packaging material (the metal casing, safety features, etc.). This means that, generally, 21700 cells can achieve higher energy density (energy per volume or per weight) than 18650 cells. You get more energy for roughly the same amount of material and packaging overhead per cell. Everything counts when designing lightweight, long-lasting portable devices or EVs.

Per cell, a 21700 is often slightly more expensive than an 18650. However, because one 21700 can replace maybe 1.5 or 2 smaller 18650 cells in terms of total energy, the cost per watt-hour (Wh) of energy stored might actually be lower for 21700 cells in some cases.

The development and widespread adoption of the 21700 size didn't happen just because someone wanted a new size. It was largely driven by the needs of new technologies, especially electric vehicles (EVs). Companies building EVs needed more energy and power from their battery packs to give cars longer range and better performance.

Using 18650 cells meant building very large battery packs with thousands of cells. By switching to a slightly larger cell like the 21700, which holds more energy per cell and offers higher power, they could build battery packs with fewer cells to get the same or more total energy and power.

Fewer cells means simpler wiring, fewer connections, and potentially easier manufacturing and thermal management for the whole pack. It allowed designers to think outside the box of the standard 18650 and unlock new possibilities for battery pack design and performance. The quest for more range and faster charging in EVs was a significant root cause for the move to larger formats like the 21700.

You will see both 18650 and 21700 batteries powering a wide range of devices.

Still widely used in things like laptop battery packs (though less common in newer, sleeker models), power banks, many LED flashlights, portable fans, vape devices, and older electric vehicle models. It's a mature technology with a wide variety of suppliers. PCB and PCBA companies are designing products that need moderate power and energy, and have long used 18650s.

Increasingly found in newer electric vehicles (Tesla was an early, large-scale adopter), high-power cordless power tools, newer and more powerful LED flashlights, some e-bikes, and home energy storage systems. They are being designed into new prototypes for devices needing that extra boost in energy or power without a huge jump in size.

Customers are so right in their opinion that battery life and performance are key features. The move to 21700 in many products directly addresses customer demand for longer runtime and more power.

It's very important to remember that a 21700 battery will not fit in a device designed for an 18650 battery, and vice versa. Their physical dimensions are different. Battery holders, charging cradles, and the internal layout of devices are made specifically for one size or the other.

When designers are creating a new product, they look at the power and energy requirements. They also consider the available space and the cost target. Based on these factors, they choose which cell size makes the most sense. For example, a small, thin device might stick with smaller, less powerful cells or even flat pouch-type batteries.

A large power tool or an EV will look at 18650 or 21700 (or even larger cells) to pack in the most energy and power. Choosing the right cell size and type is a critical part of Design for Manufacturability (DFM) for battery-powered products. You need to find a balance between performance, size, cost, and ease of assembly.

Neither battery size is universally "better." It entirely depends on what you need it for.

If you need the smallest possible device and moderate power/energy, an 18650 might still be the right choice, or even smaller cells. Just because the 21700 is newer and holds more energy doesn't mean it's always the best fit.

If you need the maximum amount of energy and power in a relatively compact cylindrical format, the 21700 often wins. It offers a step up in performance.

When choosing or comparing, stay focused on the requirements of the application. Look within the specifications of the individual battery cells (capacity, max discharge current, voltage, lifespan) and compare them against what your device needs. Be patient when researching different cell options; specs can vary even within the same size.

So the basic point is that 18650 and 21700 are two common sizes of lithium-ion battery cells. The 21700 is slightly larger than the 18650. This larger size means the 21700 generally offers higher capacity and can deliver more power. You will see 18650s in many older and smaller gadgets, while 21700s are increasingly found in high-demand applications like EVs and power tools. Choosing between them involves balancing needs for energy, power, size, and cost.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.