Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Hybrid PCBs | Mixed-Material PCBs

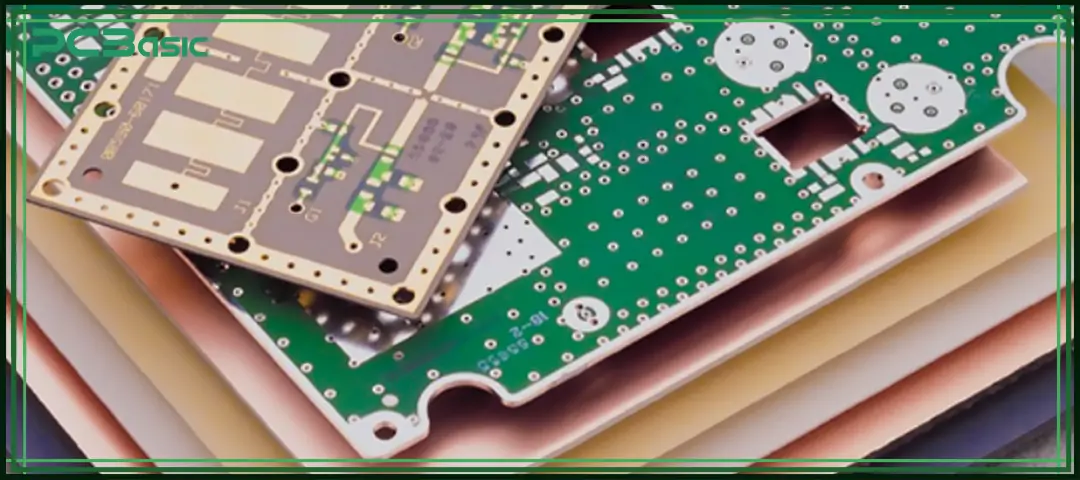

As electronic products have demands for higher frequency, greater power and improved stability, traditional single-material circuit boards are difficult to meet advanced performance requirements. To ensure the reliability of circuits in complex environments such as high speed, high temperature and strong power, engineers began to use hybrid materials to make circuit boards, which are known as hybrid circuit boards.

Nowadays, hybrid circuit boards have been widely used in various high-end products, such as automotive millimeter-wave radars, wireless communication modules, satellite and aerospace electronics, IoT devices, and high-performance consumer electronics.

This guide will systematically explain the core knowledge of hybrid PCBs for you, including how they are constructed, what common materials used, what should be noted in the stack-up design, what advantages they can bring, what difficulties may be encountered in production, and the applicable industry scenarios, as well as how PCBasic provides reliable hybrid PCB design and manufacturing services to help your products achieve higher performance and quality.

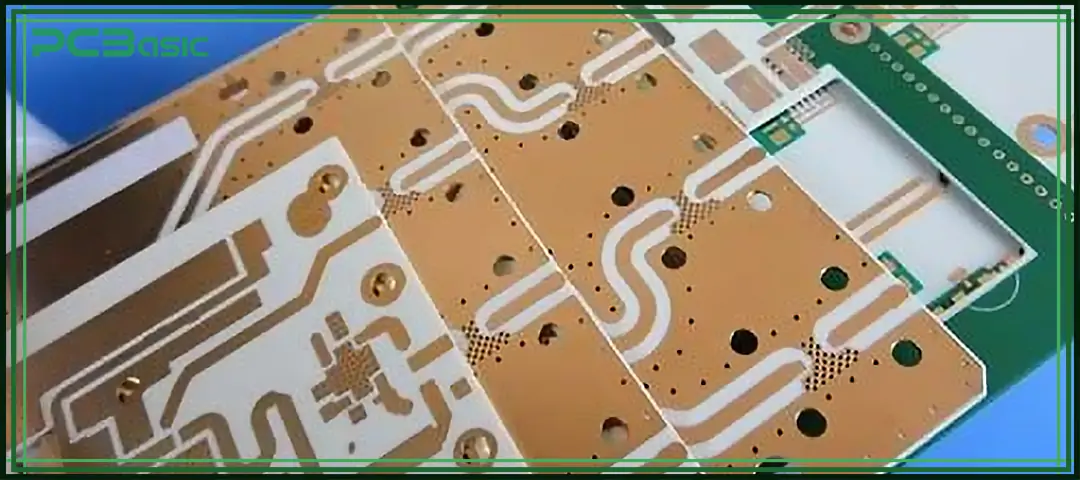

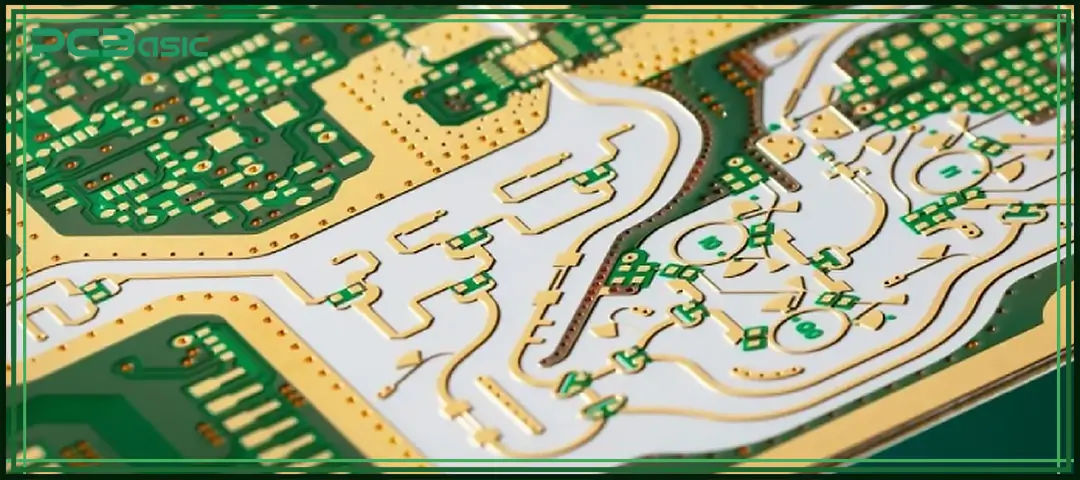

A hybrid PCB refers to a printed circuit board that uses two or more different dielectric materials within the same design, thereby enabling the board to achieve higher performance in complex applications. Compared with making the entire board with only a single material such as FR-4, Rogers, PTFE, ceramic or polyimide, the hybrid circuit board will place various materials in the most suitable positions according to the different requirements of the circuit, so as to achieve a better balance among electrical performance, mechanical strength, heat dissipation capacity and structural stability.

In traditional PCB design, the overall performance of the circuit board is completely limited by the characteristics of the material itself. In the hybrid PCB structure, engineers can combine the advantages of different materials, and each material plays a role in its own best area.

For example:

• The low cost and mechanical stability of FR-4

• The high-frequency performance of PTFE/Rogers laminates

• The thermal conductivity of ceramic materials

• The flexibility of polyimide (in rigid-flex hybrid designs)

It is precisely because of this flexibility that hybrid circuit boards demonstrate far superior performance compared to standard PCBs in scenarios such as high-speed digital circuits, RF and microwave applications, high-power modules, automotive radars, and communication systems. They can simultaneously provide strong signal integrity, thermal stability, cost efficiency, and reliability, ensuring that the product still operates stably in harsh environments.

In simple terms, a hybrid PCB is a combination of different materials, enabling the circuit board to handle high-speed signals, withstand high temperatures, and reduce overall costs. It is the best solution that combines performance and economy.

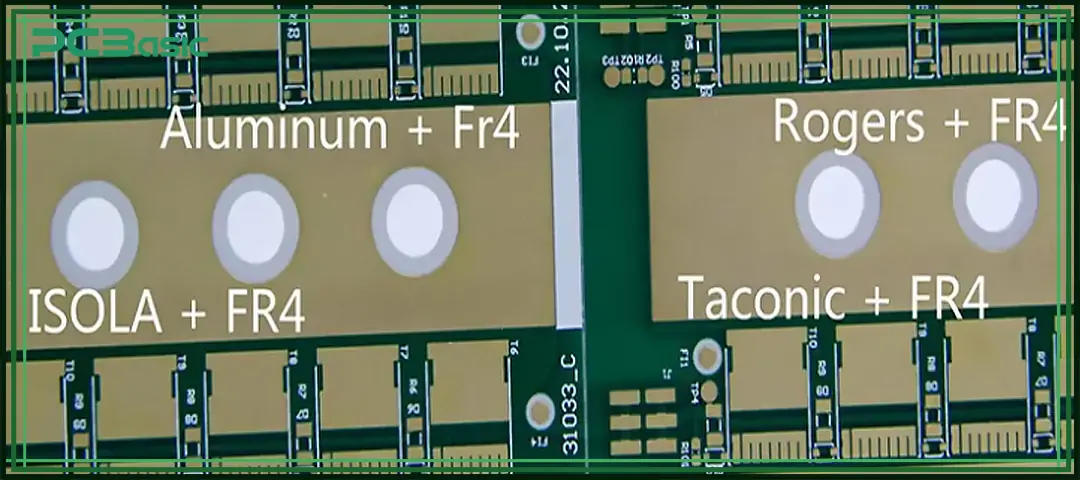

When making hybrid PCBs, engineers usually combine two or more different substrates within a circuit board. Common materials include:

|

Material Type |

Key Features / Advantages |

Typical Use in a Hybrid PCB |

|

FR-4 (Standard Epoxy Glass) |

• Low cost • Good mechanical strength • Suitable for digital logic, power control, and connector circuits |

Commonly used as the base material in a hybrid circuit board, applied to non-RF areas |

|

Rogers / PTFE (High-Frequency Laminates) |

• Low dielectric loss • Stable dielectric constant (Dk) • Excellent high-frequency performance • Low signal attenuation |

Primarily used in RF and microwave zones; the most common material in RF hybrid PCBs |

|

Ceramic Substrates (Al₂O₃ / AlN) |

• Excellent thermal conductivity • High reliability • High dielectric strength |

Used in high-power modules, LED drivers, and power electronics that require strong heat dissipation and stability |

|

Polyimide (Flexible Material) |

• High heat resistance • Flexibility • Strong mechanical durability |

Applied in rigid-flex hybrid PCBs, ideal for boards requiring bending or lightweight construction |

|

Metal Core (Aluminum / Copper) |

• Strong thermal dissipation • High structural stability |

Used in high-power or high-heat-density hybrid structures, such as power modules and LED PCBs |

In hybrid PCBs, each material has its own specialized functions: some offer better electrical performance, some have stronger heat dissipation capacity, and some provide a more stable structure. By combining these materials together, the circuit board can achieve performance that a single material cannot. Through this hybrid design, engineers can not only meet the circuit requirements of higher frequency, higher power or higher reliability, but also avoid using expensive materials for the entire circuit board, thereby significantly reducing the overall manufacturing cost.

When designing a hybrid PCB, the stack-up is one of the most crucial steps. Because multiple materials are used in the same board, and each material has different physical properties, if not planned well in advance, problems such as warpage, delamination, or unstable impedance are very likely to occur in subsequent production.

Common differences between these materials include

• Different coefficients of thermal expansion (CTE)

• Different lamination temperatures

• Different dielectric constants (Dk)

• Different copper adhesion levels

• Different moisture absorption rates

These differences determine whether the material can be smoothly laminated, whether it can maintain dimensional stability, and whether it can meet the requirements of high-speed signals.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

1. Material Compatibility

The most crucial point is that different materials must be able to go through the lamination temperature together without causing any problems.

2. Layer Symmetry

For RF layers using high-frequency materials such as PTFE and Rogers, it is usually necessary to place them symmetrically to reduce the risk of material deformation.

3. Controlled Impedance Requirements

In high-speed or RF designs, impedance must remain stable. Therefore, engineers need to plan the materials and thickness during the stack-up design stage to ensure that the hybrid PCB can achieve precise impedance control.

4. Bondply and Prepreg Compatibility

The hybrid structure means that the adhesion between materials is extremely crucial. If bondply or prepreg is not compatible with the material, problems such as poor lamination, voids, and even delamination will occur. Therefore, it is necessary to select adhesive materials that are suitable for all substrates.

5. Drilling, Plating, and Via Reliability

Because different materials have different hardness levels, drilling can easily result in rough hole walls, misalignment, or even hole damage. Therefore, in the manufacturing of hybrid PCBs, special attention must be paid to the quality of hole walls and the reliability of PTH, and usually higher-level drilling and electroplating processes are required.

A well-planned and structurally reasonable stack-up design can ensure that the hybrid PCB remains stable in terms of high-speed signal, RF performance, mechanical strength and long-term reliability, while also making the manufacturing process smoother and achieving a higher yield.

The greatest value of a hybrid PCB lies in its ability to flexibly select materials based on different circuit requirements, thereby achieving a balance among performance, cost and reliability that standard PCBs cannot reach.

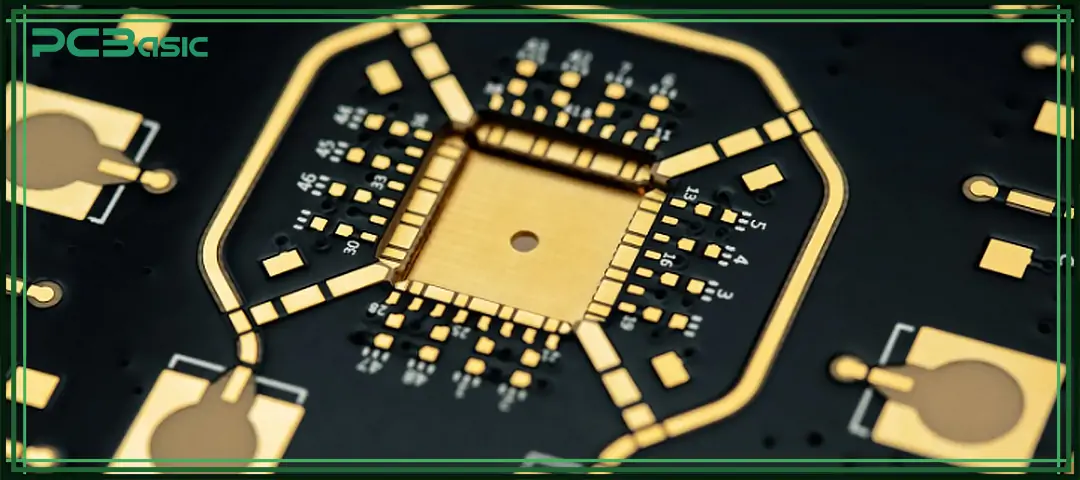

RF signals are highly sensitive to material loss. By placing the RF section on a low-loss substrate, the hybrid circuit board can maintain better signal integrity during transmission, provide a wider bandwidth, stronger noise immunity, and more stable transmission-line performance.

Not every part of the board requires high-frequency or expensive materials. Engineers only need to use high-performance materials in key positions, while FR-4 can continue to be used in ordinary areas. This can not only enhance performance but also significantly reduce overall costs.

For circuits that need to handle high power or high heat, ceramic or metal substrates can be added at key positions to significantly enhance heat dissipation efficiency and help the product operate continuously and stably in high-temperature environments.

FR-4 offers structural rigidity, while polyimide provides excellent flexibility. By combining different materials, hybrid PCBs can maintain the overall rigidity of the board while remaining flexible in areas that need to be bent, making it highly suitable for rigid-flex combination designs.

RF, digital, analog and power circuits have different requirements for materials. However, hybrid PCBs allow these circuits to use appropriate materials on the same board, respectively, thus achieving true multi-system integration.

By choosing high-temperature, low-loss or high-stability materials in key areas, hybrid PCBs still perform stably in harsh environments such as high temperatures, vibrations and humidity changes, and have a longer product lifespan.

Hybrid PCBs are widely used in high-end industries with extremely high requirements for electrical performance, heat dissipation capacity and reliability.

• Antennas

• Radar systems

• LNA/PA modules

• RF transceivers

• 24 GHz / 77 GHz automotive radar

• EV power modules

• Battery management systems (BMS)

• Avionics

• Satellite payloads

• Navigation systems

• RF front-ends

• LED lighting systems

• Power converters

• Inverters

• Motor control boards

• Smart home devices

• Wearables

• High-speed WiFi / BT modules

In all these applications, a hybrid PCB provides a balance between performance, cost, and reliability.

Due to the highly complex processing technology of hybrid material PCBs, choosing the right manufacturer is very important. PCBasic is one of the leading manufacturers in the industry that can stably produce high-precision and reliable hybrid circuit boards.

PCBasic is a professional factory dedicated to the manufacturing of high-quality PCBs, possessing comprehensive manufacturing capabilities ranging from standard FR-4, multilayer boards, high-frequency boards, to hybrid PCBs and rigid-flex boards.

The production system of PCBasic has been certified by ISO9001, IATF16949, ISO13485 and UL, ensuring that the products meet international standards in terms of reliability, consistency and long-term stability. With mature technological capabilities and strict quality management, PCBasic can provide global customers with high-precision PCB production services ranging from prototypes, small batches, to large batches.

1. Extensive Experience in Mixed-Material Lamination

PCBasic has long been engaged in the production of hybrid PCBs and is very familiar with combining different materials such as Rogers, PTFE, FR-4, ceramics, and polyimide. Whether it is high-frequency materials or high-temperature resistant materials, we can stably laminate them together without delamination or warpage.

2. Advanced PCB Manufacturing Equipment

PCBasic is equipped with a large number of high-specification devices, including precision lamination presses, laser drilling machines specifically designed for PTFE, 3D AOI, X-Ray, flying probe testing machines and impedance testing systems.

3. Professional Stack-Up Engineering Capability

Our engineering team can design a reliable hybrid PCB stack-up based on material properties, Dk/Df, thickness and thermal expansion parameters. Whether you are pursuing high-frequency performance, heat dissipation capacity or cost optimization, we can provide stable and mass-producible laminated solutions.

4. High-Quality Materials from Official Sources

All high-frequency materials of PCBasic - including Rogers, Taconic, Isola, Nelco, Panasonic, etc. - are sourced from globally authorized suppliers. This can ensure that the parameters of each batch of materials are consistent, the quality is stable, and the supply chain is reliable and traceable.

5. Flexible Production Capability: From Prototypes to Mass Production

Whether you need one or two prototypes or mass-produce hybrid PCBs, PCBasic can maintain the same quality and consistency. We are good at handling multi-variety and small-batch orders, and can also stably support large-scale production.

6. Fully Digitalized Manufacturing Management System

PCBasic's factory adopts MES, ERP, CRM and IoT systems to manage production. The material, process parameters and inspection records of each PCB can be tracked in real time, making the production process transparent and controllable, and also ensuring more reliable quality.

As electronic systems become increasingly complex and performance-oriented, the demand for hybrid PCBs continues to grow. Hybrid circuit boards offer unparalleled flexibility, enabling designers to integrate high-frequency materials, high thermal conductivity substrates, and cost-effective FR-4 materials in a single structure.

By mastering material selection, stack-up design and related manufacturing process challenges, engineers can fully leverage the advantages of hybrid PCBs in RF applications, power systems, automotive electronics, IoT devices, aerospace systems and advanced communication modules.

Working with an experienced manufacturer like PCBasic can ensure that the hybrid PCB you obtain features precise craftsmanship, outstanding stability and long-term reliability.

If you need RF, high-frequency or hybrid material PCB solutions, PCBasic is always ready to provide you with comprehensive support from prototype development to mass production for your project.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.