Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > Full Turnkey PCB Assembly Services | PCBasic

As the global demand for electronic products continues to increase, businesses need fast, efficient and reliable manufacturing solutions to ensure that their products can stand out in the highly competitive market. Full turnkey PCB assembly emerged precisely to meet this demand. It enables enterprises to focus more on product design and market strategy, while outsourcing the complex manufacturing process to experienced manufacturers.

In the full turnkey PCB assembly service, PCBasic offers flexible production capabilities to meet various demands ranging from small-batch prototyping to large-scale mass production. For instance, in turnkey PCB manufacturing, businesses can obtain rapid prototyping services, and it usually only takes a few days to complete the production of initial samples. This offers customers the possibility of rapid iteration, especially suitable for the product development stage, where frequent design modifications are required.

This article will deeply explore the detailed process, advantages and applicable scenarios of full turnkey PCB assembly. By comparing the differences between full and partial turnkey PCB assembly, you will be able to understand which service is the most suitable for your needs. It will also introduce why PCBasic, as a full turnkey PCB assembly manufacturer, can become the preferred partner of many enterprises.

Full turnkey PCB assembly is a service where the manufacturer is responsible for all steps in the entire printed circuit board (PCB) assembly process. Specifically, manufacturers are not only responsible for sourcing all necessary components but also for producing PCBs, accurately assembling components onto circuit boards, conducting functional tests, and even handling the final shipment to the end user.

The term "turnkey" means that when the project is completed, the client can use it directly without doing any additional work. The customer only needs to provide the design files. All other processes, including component procurement, manufacturing, assembly, testing and transportation, will be handled by the manufacturer. Finally, a fully assembled and tested PCB with normal functions will be delivered to the customer.

For companies that do not want to manage multiple suppliers and coordinate different stages of production, full turnkey PCB assembly provides great convenience and efficiency. By outsourcing the entire process to the manufacturer, businesses can save time, reduce management costs, and avoid coordination issues that may arise from multiple partners, ensuring a smooth and efficient production process.

PCBasic offers a full turnkey PCB assembly service to meet the needs of businesses in various industries, from PCB prototypes to mass production. The following is an overview of the full turnkey PCB assembly services available:

Whether you are testing a new design or verifying the functionality of a circuit board, turnkey PCB electronics services offer rapid prototyping. PCBasic can quickly produce prototypes, allowing you to test and refine the design before entering full-scale production, saving time and costs.

Once the prototype is determined, PCBasic can quickly scale up production to meet your high-volume demands. Whether you are producing hundreds or thousands of units, turnkey PCB assembly services ensure consistent quality and fast delivery times.

In addition to turnkey PCB assembly, PCBasic also provides box build services, including the final assembly of products. This could involve adding enclosures, connectors, wiring, and other components required for the finished product.

Managing inventory is a complex task, especially when dealing with a large number of components. PCBasic offers inventory management services, tracking the components required for the project to ensure that materials are available when needed.

Once your turnkey PCB electronics are assembled and pass the test, PCBasic will directly handle the final shipment to your end users. This eliminates your need to manage logistics and ensures a seamless supply chain from manufacturing to delivery.

Managing multiple suppliers for components, assembly and testing can often be stressful. Turnkey assembly services simplify the entire process by providing a single point of contact. In this way, you can reduce the complexity of the project and focus more energy on other business.

Outsourcing the entire turnkey PCB manufacturing process to the manufacturer can save a significant amount of time and reduce the risk of delays. Turnkey PCB electronics manufacturers can usually complete projects more quickly, providing rapid prototyping and turnaround times. Moreover, concentrating all the processes in one place for processing can often reduce the overall cost.

When manufacturers are responsible for the entire process, they can better control the quality of the products. This ensures that all parts and components meet the standards and reduces the risk of problems occurring during assembly. Turnkey PCB assembly services usually also include comprehensive testing to ensure that each circuit board works as expected.

Whether you need a few prototypes or thousands of mass production units, turnkey PCB manufacturing services can be adjusted according to your requirements. This flexibility is significant for companies that need rapid prototyping and want to quickly shift to mass production, while avoiding the hassle of re-establishing supplier relationships or changing manufacturing processes.

The full turnkey assembly process of PCBasic is renowned for its simplicity, efficiency and transparency, enabling customers to easily complete the entire production cycle from design to delivery. The following are the basic steps of the all-round turnkey assembly services:

In the first step, you only need to provide the necessary design documents to PCBasic, including Gerber files, bill of materials (BOM, silkscreen/assembly drawings, coordinate files, and more. Our engineering team will conduct a comprehensive DFM manufacturability review on the documents to confirm that the design has no potential risks and ensure that the subsequent production process is smoother and more efficient.

During the component sourcing stage, PCBasic will procure all electronic components, including ICs, passive devices, connectors, and other parts from authorized and reputable global suppliers.

In the PCB Fabrication stage, PCBasic will produce high-quality printed circuit boards according to your design requirements. All PCBs will undergo visual inspection and electrical testing to ensure that the boards themselves are free of defects.

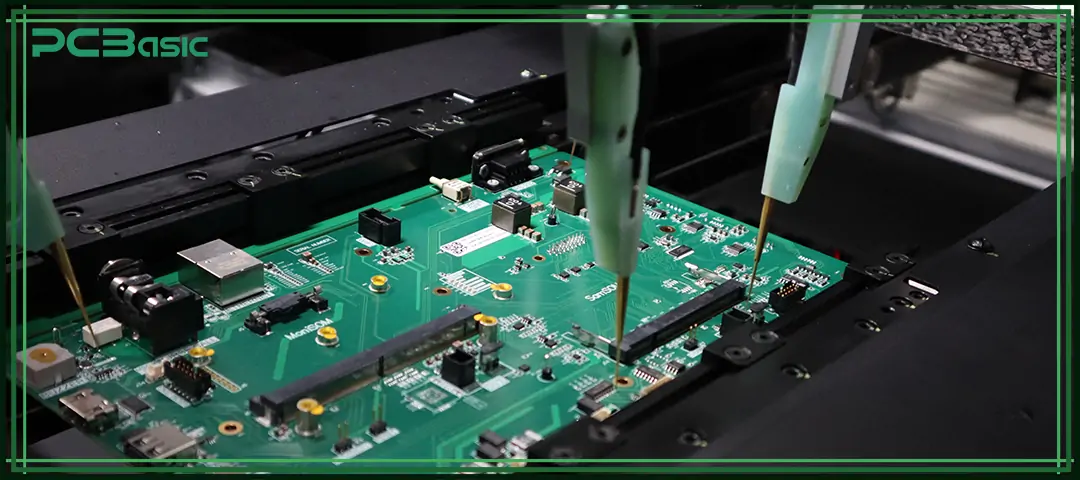

During the assembly stage, we use advanced SMT placement equipment, reflow ovens, selective wave soldering machines and other professional production lines. The engineering team of PCBasic will accurately mount components onto the PCB.

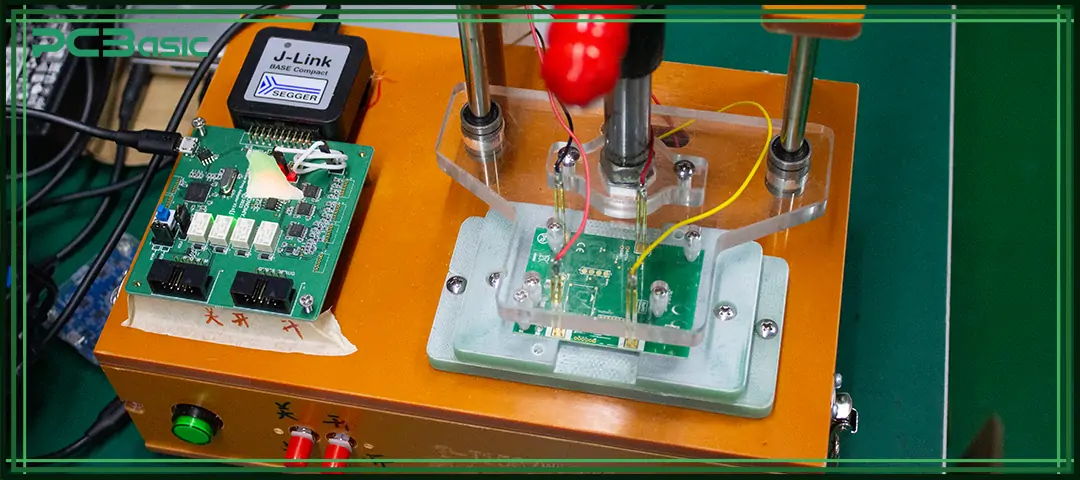

To ensure the reliability of the final product, all circuit boards will undergo multiple strict tests, including:

• Automated Optical Inspection (AOI): Detecting solder defects, misalignment, missing components, polarity errors, and more.

• BGA X-ray Inspection: Verifying that BGA solder balls are fully soldered and free from voids.

• Functional Testing (FCT): Performing firmware programming, electrical performance measurements, and custom test procedures as required by the customer.

These tests ensure each PCB performs as intended and meets all functional requirements.

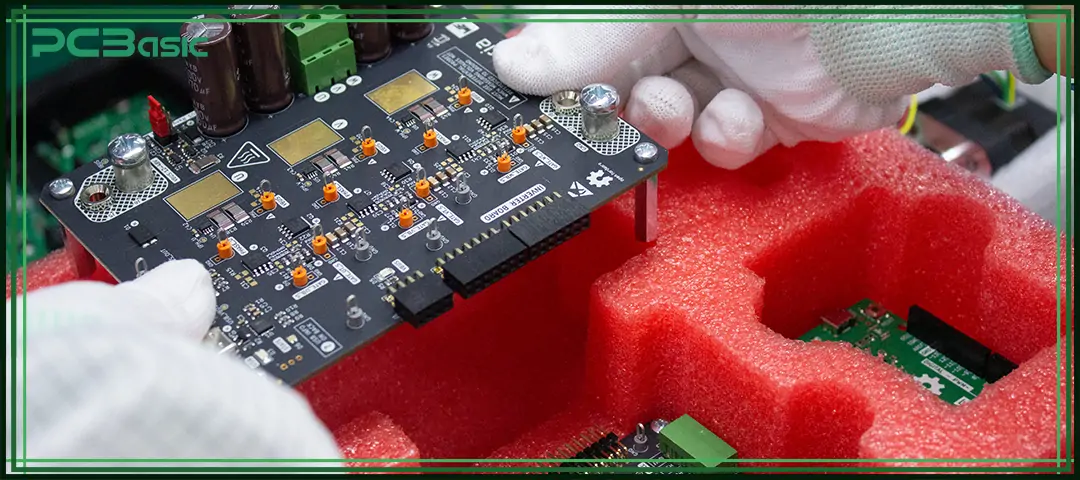

During the shipping step, PCBasic will provide all finished products with anti-static protection, cushioning packaging, proper labelling, and select express delivery, air freight or sea freight according to customer requirements.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Although full turnkey PCB assembly services offer a comprehensive and integrated one-stop service, some companies also choose partial turnkey PCB assembly services.

In some turnkey PCB assemblies, the manufacturers are only responsible for certain processes, while customers provide some components or materials by themselves, such as certain key ICs, connectors of designated brands, scarce materials, and more. Manufacturers are usually responsible for PCB manufacturing, purchasing of remaining components, assembly and testing, while the portion that customers bear is limited to the components they choose to prepare themselves.

This model is suitable for customers who already have some inventory or wish to purchase materials from specific suppliers, while reducing costs and maintaining a certain degree of flexibility.

|

Category |

Full Turnkey PCB Assembly |

Partial Turnkey PCB Assembly |

|

Customer Responsibility |

No components need to be provided; all materials are sourced by the manufacturer |

The customer must supply certain components or materials |

|

Level of Involvement |

Minimal involvement; the manufacturer manages the entire process |

Higher involvement required; the customer handles part of the component sourcing and logistics |

|

Cost & Efficiency |

Higher cost, but offers greater convenience and faster lead times |

More cost-effective, but requires additional coordination, which may affect efficiency |

|

Procurement Flexibility |

Centralized sourcing by the manufacturer with high standardization |

Customers can choose specific brands or suppliers, offering higher flexibility |

|

Ideal Use Cases |

Suitable for companies without procurement resources or those wanting to save time |

Ideal for companies with existing inventory or strict component brand requirements |

|

Supply Chain Risk |

Lower risk since the manufacturer manages the full supply chain |

Higher risk due to potential delays or mismatches from customer-provided components |

PCBasic offers high-quality, fast delivery, and customer-satisfaction-centered all-around turnkey PCB assembly services. Here are the reasons why PCBasic becomes your ideal full turnkey PCB assembly manufacturer:

1. Experience: With years of experience in turnkey PCB manufacturing, PCBasic has the expertise to handle projects of any size or complexity.

2. Quality Assurance: All of our turnkey PCB electronics undergo thorough testing to ensure they meet the highest standards of functionality and reliability.

3. Fast Turnaround: Our advanced manufacturing capabilities allow us to deliver high-quality PCBs quickly, reducing lead times and keeping your projects on schedule.

4. Global Shipping: We offer global shipping services, ensuring that your finished products reach their destination on time and in perfect condition.

Whether you are developing prototypes or preparing for large-scale mass production, full turnkey PCB assembly is an efficient and cost-effective solution that can significantly simplify the entire production process. By choosing a full turnkey PCB assembly manufacturer like PCBasic, you can ensure that every aspect of your project, from design, component procurement, to assembly and testing, is handled professionally and meticulously.

With the turnkey assembly services of PCBasic, you can focus more on the most important things: bringing your innovative products to market faster and more efficiently.

Are you ready to start? Contact PCBasic immediately to learn how our all-round turnkey PCB assembly service can help your business grow.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.