Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Turnkey Manufacturing Solutions: A Complete Guide

In a highly globalized and highly competitive manufacturing environment, enterprises are under pressure of shorter development cycles, rising costs and complex supply chains at the same time. For many startups, OEMs and technology-driven enterprises, building a complete in-house manufacturing system is no longer feasible in reality.

It is precisely for this reason that turnkey manufacturing solutions have gradually become the choice of an increasing number of enterprises.

In this guide, we will focus on explaining what turnkey manufacturing is and systematically introduce how turnkey manufacturing solutions work, and highlight the key differences between turnkey manufacturing and traditional contract manufacturing, as well as why more and more enterprises are adopting turnkey manufacturing services as a long-term and stable manufacturing model. Meanwhile, we will also introduce how PCBasic, as a reliable turnkey electronic manufacturer, provides customers with efficient, practical, and one-stop manufacturing support.

To understand turnkey manufacturing solutions, we can start with the turnkey definition first.

Turnkey, in simple terms, means that customers do not need to do any additional development or configuration. As long as they receive the finished product, they can directly put it into use or release it to the market.

So, what is a turnkey solution in the manufacturing industry?

Turnkey manufacturing solutions refer to a one-stop manufacturing model in which a single turnkey manufacturer is responsible for the entire product realization process. From the early design support to engineering development, manufacturing, and finally to delivery, all key stages are coordinated and managed by the same manufacturer. These services typically include:

• Product design support

• Engineering and turnkey product development

• Material sourcing and supply chain management

• Manufacturing, turnkey fabrication, and turnkey assembly

• Testing, quality control, and compliance management

• Packaging, logistics, and final product delivery

Under the turnkey manufacturing model, customers can focus more on product planning, intellectual property (IP), and market development, while the specific manufacturing execution and process management are handled by turnkey manufacturing companies, significantly reducing management complexity and project risks.

Most turnkey manufacturing solutions follow a clear end-to-end workflow to reduce project risks and improve execution efficiency.

Projects usually start with design reviews. The turnkey manufacturer will evaluate whether the design is suitable for production and optimize costs and reliability through DFM (Design for Manufacturability). This is one of the important advantages of turnkey manufacturing services.

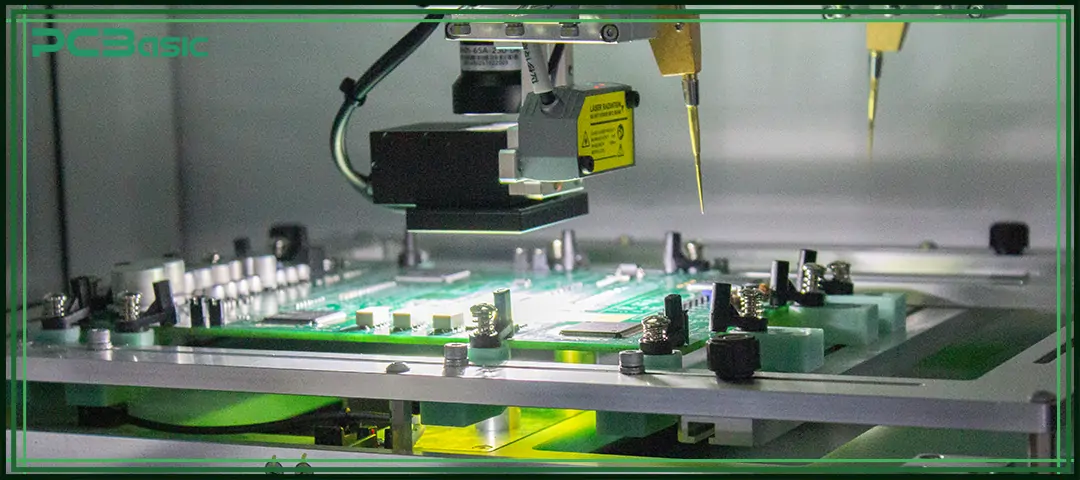

After the design is confirmed, prototypes will be made first for functional and reliability verification to identify issues as early as possible and avoid mass production risks. Most turnkey manufacturing companies accelerate time to market through prototyping.

Materials are purchased and managed under a unified turnkey solution, including supplier management, lead-time control, and supply risk assessment. This step is particularly crucial in the turnkey electronic manufacturing project.

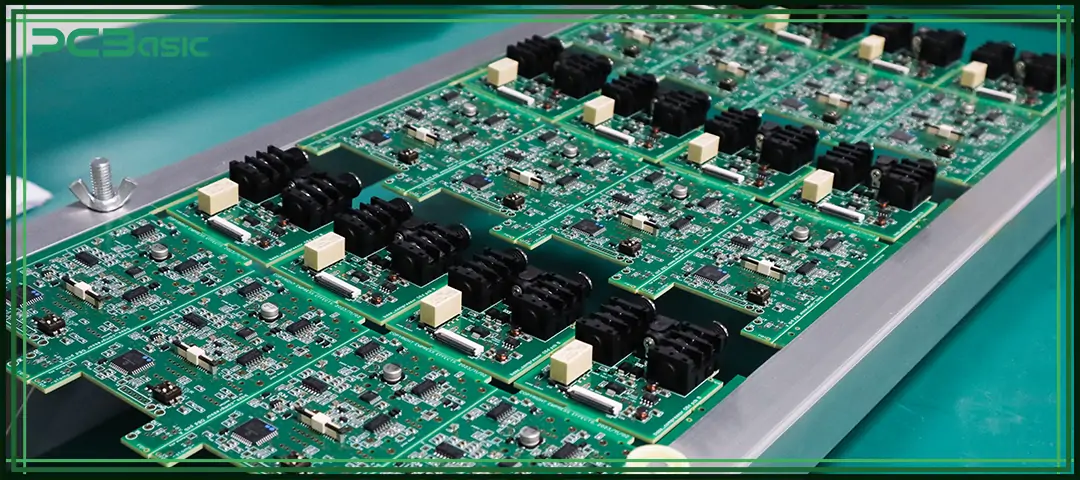

After the materials are ready, production begins, covering turnkey fabrication and turnkey assembly, such as PCB assembly, box build or system integration. Professional turnkey electronic manufacturers can usually complete these processes within a single manufacturing system.

Continuous testing and quality control are carried out during the production process to ensure that the products meet the design requirements, industry standards and regulatory compliance. This is also the key reason why many enterprises choose turnkey contract manufacturing.

Finally, the turnkey manufacturer is responsible for packaging, shipping and required inventory management, and the customer directly receives the finished products that can be used or sold.

When choosing a manufacturing model, many enterprises encounter a common question: What exactly is the difference between turnkey manufacturing and contract manufacturing?

Contract manufacturing is a relatively traditional outsourcing model. Under this model, customers usually complete the product design and are responsible for selecting and procuring key materials on their own. The manufacturer is mainly responsible for the specific production and assembly execution based on the drawings, BOM and process requirements provided by the customer.

In simple terms, contract manufacturing places more emphasis on producing as required. The role of the manufacturer is mainly that of the production executor, while product design, supply chain management, project coordination and overall risk control are still mainly borne by the customer side.

|

Comparison Aspect |

Contract Manufacturing |

Turnkey Manufacturing |

|

Scope |

Focuses mainly on production and assembly |

Covers the full process from design support to final delivery |

|

Responsibility |

Overall project responsibility largely remains with the customer |

The turnkey manufacturer assumes full project responsibility |

|

Supply Chain Management |

Materials sourcing and supplier management are handled by the customer |

Turnkey contract manufacturing includes sourcing, supplier management, and logistics coordination |

|

Project Coordination |

The customer must coordinate multiple suppliers and processes |

All stages are managed by a single manufacturing partner |

|

Risk Allocation |

Design, material, and coordination risks are primarily borne by the customer |

Risks are managed or shared by the turnkey manufacturing company |

|

Management Complexity |

Higher management and communication overhead |

Simplified management with a more controlled workflow |

|

Best Suited For |

Companies with mature design capabilities and strong supply chain management |

Companies looking to reduce complexity, shorten time to market, and improve overall control |

If your company only requires additional production capacity support and already has mature product design capabilities and supply chain management systems, then contract manufacturing is usually sufficient to meet the demands.

However, if your goal is to reduce cross-supplier coordination costs, shorten the product launch cycle, and lower overall project risks, then choosing turnkey manufacturing solutions often leads to higher efficiency and stronger controllability.

For enterprises that are still pondering what a turnkey solution is, the answer lies precisely in this "end-to-end, unified responsibility" manufacturing model.

Companies choose turnkey manufacturing solutions for several strategic reasons.

With a turnkey solution, all activities are managed through one partner. This simplifies communication, budgeting, and project control.

By eliminating multiple vendors, turnkey manufacturing services reduce coordination errors, delays, and hidden costs.

Integrated workflows allow turnkey manufacturing companies to move faster from concept to production.

Companies avoid building factories, hiring manufacturing teams, or managing warehouses by working with a turnkey manufacturer.

A professional turnkey electronic manufacturer brings engineering, supply chain, and quality expertise that would be difficult to replicate internally.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Many industries depend on turnkey manufacturing solutions due to complexity and compliance requirements, including:

• Electronics and turnkey electronic manufacturing

• Medical devices

• Aerospace and defense

• Industrial automation

• Semiconductor equipment

• Energy and power systems

In these sectors, turnkey manufacturing services provide speed, consistency, and risk reduction.

A turnkey solution is ideal if your company:

• Lacks in-house manufacturing infrastructure

• Needs rapid scaling

• Operates in regulated markets

• Wants to focus on sales, marketing, or IP

• Requires global supply chain coordination

If you are asking what turnkey manufacturing is from a strategic perspective, the answer is often tied to focus and efficiency.

PCBasic has over 15 years of experience in electronic manufacturing and PCB assembly. Its headquarters is located in Shenzhen, providing mature and reliable turnkey manufacturing solutions for global customers. From design support to production, testing and delivery, PCBasic provides a complete one-stop manufacturing service through a unified process.

The turnkey manufacturing services of PCBasic cover the core stages of electronic manufacturing and are uniformly responsible for project execution by a turnkey manufacturer.

• Engineering support and design review

• Component sourcing and supply chain management

• PCB fabrication and turnkey assembly

• Testing and quality control

• Packaging and global logistics

As an experienced turnkey contract manufacturing partner, PCBasic helps customers reduce manufacturing complexity and accelerate product launch:

• One-stop turnkey solution from development to mass production

• Certified quality systems (ISO9001 / IATF16949 / ISO13485)

• Cost-effective supply chain capabilities

• Flexible production from prototypes to high volume

• Dedicated project management and clear communication

Whether it's new product development or large-scale production, PCBasic's turnkey electronic manufacturing service can provide you with efficient and controllable manufacturing support.

In today's increasingly complex manufacturing environment, it is crucial for enterprises to understand what turnkey manufacturing is and make the right manufacturing decisions.

Turnkey manufacturing solutions offer a simpler and more efficient option for the traditional multi-vendor outsourcing model. By having a professional turnkey manufacturer uniformly responsible for the entire manufacturing process, from design and procurement to turnkey manufacturing, turnkey assembly and final delivery, enterprises can effectively reduce project risks and accelerate the pace of product promotion at the same time.

With the acceleration of market changes and the continuous increase in the difficulty of supply chain management, cooperating with experienced turnkey manufacturing companies is no longer just for convenience, but has become a way for enterprises to maintain competitive advantages.

If you are learning about what turnkey solutions are and considering whether they are suitable for your next product, then turnkey manufacturing solutions are very likely to help you make the product faster, more stable and more reliable.

1: What is turnkey manufacturing in simple terms?

Turnkey manufacturing means working with one manufacturer who handles everything—from design support and sourcing to production, assembly, and delivery—so you receive a finished, ready-to-use product.

2: How is turnkey manufacturing different from contract manufacturing?

Contract manufacturing focuses mainly on production, while turnkey manufacturing solutions cover the full process, with the turnkey manufacturer taking overall responsibility for execution and coordination.

3: When should I choose turnkey manufacturing solutions?

You should consider turnkey manufacturing solutions if you want to reduce supplier coordination, shorten time to market, or lack in-house manufacturing and supply chain resources.

4: Is turnkey manufacturing more expensive?

Not necessarily. While unit prices may seem higher, turnkey manufacturing often lowers total cost by reducing rework, delays, management overhead, and supply chain risks.

5: What industries benefit most from turnkey manufacturing services?

Industries such as electronics, medical devices, industrial equipment, and aerospace benefit most from turnkey manufacturing services due to their complexity, quality requirements, and need for tight process control.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.