Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Desoldering Wire (Solder Wick): How to Remove Solder from a Circuit Board

When repairing electronics or reworking PCBs, we often encounter this step - removing the solder cleanly and safely. This is actually a very fundamental and crucial skill. When dealing with solder bridges or replacing components, the solder must be removed completely; otherwise, it will affect the pads and circuits.

In this article, we will introduce a widely used solder removal tool - the desoldering wire (also known as the solder wick). Next, we will explain what the desoldering wire is, its working principle, specific usage methods, and when it is suitable to use the desoldering wire. First, let's learn about the desoldering wire.

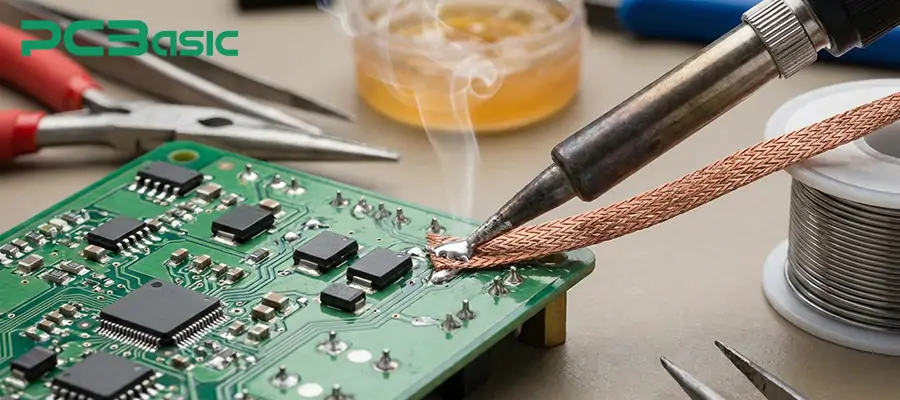

Desoldering wire, a tool for removing solder, is made of fine copper wire woven closely together. Its working principle is to utilize capillary action to absorb molten solder. When solder wick is placed on the solder joint and heated with a soldering iron, the solder melts and is drawn into the interstices between the braided copper strands. As shown in the following figure,

In this way, we can directly remove solder from PCB pads, component pins and copper traces without sudden mechanical shock or suction force. Compared with mechanical desoldering tools such as desoldering pumps, desoldering wire has more advantages in terms of operation accuracy and surface control.

There are many benefits to using desoldering wire to remove solder and repair PCBs:

1. High precision. The desoldering wire is ideal for removing excess solder from small pads, fine traces, and SMD components such as QFN and fine-pitch ICs.

2. Minimal damage to circuit boards. Using desoldering wire to remove excess solder does not involve sudden suction force or mechanical shock, which means the risk of pads being lifted or PCB traces being damaged is significantly reduced.

3. Simple operation. The desoldering wire can be used in conjunction with a regular soldering iron.

4. Excellent cleaning effect. When using desoldering wire to remove old solder, leftover solder after component removal, etc., it is very practical. Now let's introduce the tools needed when using desoldering wire.

Whether it is for basic solder cleaning or for the meticulous PCB repair work, we always need to prepare the necessary tools first.

1. Desoldering Wire/Solder Wick

The first thing to prepare is of course the desoldering wire. The desoldering wire is the most frequently used and fundamental tool among all the solder removal tools. There are various widths available for the desoldering wire, and we can determine the appropriate width based on the size of the pads and the size of the solder joints. Choosing the right width of the desoldering wire is beneficial for improving the solder removal efficiency and reducing the impact of local overheating on the PCB.

2. Controllable temperature soldering iron

A stable heat source is a prerequisite for using a good desoldering wire. Therefore, during repair and maintenance processes, we usually need to use a temperature-controlled soldering iron. It can provide a relatively stable and adjustable heating temperature. Generally, the recommended temperature for soldering operations is between 320°C and 380°C. Of course, the specific temperature needs to be adjusted according to the type of solder. If the temperature is too low or fluctuates greatly, the solder is not easily melted and it is difficult for the desoldering wire to effectively absorb it.

3. Flux (Recommended)

Although flux is not a necessary item in PCB repair, it plays a very significant auxiliary role during the process of removing solder (especially when removing old solder or lead-free solder). It can improve the heat conduction conditions, making the solder easier to melt and allowing it to be absorbed more smoothly by the desoldering tool. Therefore, we strongly recommend using this tool during the repair process.

4. Forceps or small pliers

In actual operation, we usually need to use forceps or small pliers to hold the desoldering wire. Because the desoldering wire will heat up rapidly during the operation, it is not recommended to touch it directly with your hands.

5. Isopropyl alcohol and dust-free wiping materials

After the soldering is removed, we need to clean the PCB. There should be no residual flux or soldering residue. Because if these residues are not dealt with in time, it is very likely to affect the subsequent inspection.

First, prepare the necessary tools. Then, follow the steps below to proceed.

1. Place the desoldering wire directly on the soldering point or pad where the solder needs to be removed. Remember, when placing it, make sure that the copper braided line can cover the area of the solder that needs to be dealt with, so as to ensure a uniform heating effect.

2. Press the tip of the soldering iron above the desoldering wire. Be careful not to make direct contact with the PCB surface; instead, use the desoldering wire to conduct indirect heating (this helps reduce the risk of thermal shock to the pads and circuits).

3. The solder beneath the pad gradually melts and is drawn upwards into the copper mesh structure. Please be careful not to apply excessive pressure at this time, as doing so will increase the risk of the pad peeling or the circuit being damaged.

4. The solder is fully absorbed while the soldering iron and the desoldering wire are lifted, ensuring a smooth and continuous movement. Note:

Do not separate and remove the solder before it has completely solidified. Otherwise, the solder may pull the surface of the soldering pad or smear it, which will affect the quality of the solder joints.

After each solder suction operation is completed, the desoldering wire that has been fully filled with solder should be cut off. Because the saturated copper braided wire cannot continue to effectively remove solder.

If there is difficult-to-remove old solder or lead-free solder, an appropriate amount of flux can be added before the desoldering wire.

The application of desoldering wire is very extensive and is mainly used in scenarios for removing solder. In the following scenarios, desoldering wires are particularly suitable for use:

1. Remove the solder bridges between components with small pitch pins. The controlled solder removal method using a desoldering wire can effectively remove excess solder without affecting adjacent solder joints.

2. Remove the aged or contaminated old solder before rework or reassembly. Using a desoldering wire for solder removal can improve the wetting effect of new solder and enhance the reliability of solder joints.

3. Repair fine-pitch SMD and QFN components. Using a desoldering wire for repair is more conducive to maintaining the integrity of the pads.

The appropriate specification of desoldering wire can enhance the efficiency of solder removal while reducing the thermal risk to the PCB pads and circuits. The following table presents some of our recommendations:

|

Selection Factor |

Description |

Practical Guidance |

|

Wire Width |

The width of the desoldering wire determines how much solder can be absorbed at one time |

Match the wire width to the pad or joint size to improve solder removal efficiency |

|

Flux Type |

Some solder wick is pre-impregnated with flux |

Fluxed desoldering wire is easier to use, especially for beginners or when removing old solder |

|

Copper Quality |

The purity and weave of the copper braid affect absorption |

High-purity copper braid improves capillary action and solder absorption |

|

Application Type |

Different applications require different braid sizes |

Use fine braid for SMD and QFN work, and wider braid for larger solder joints |

Please note that do not use unsuitable desoldering wires. If the selected desoldering wire is inappropriate, or the copper weaving quality is poor, and the solder is not removed thoroughly, the risk of damage to the PCB and the solder pads will be greater.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The desoldering wire is a very practical and indispensable tool for electronic repair and PCB refurbishment. Learning to use it correctly and mastering its usage, we can effectively remove the solder while minimizing the risk of soldering pads peeling or circuit damage.

1. Why isn't my desoldering wire able to suck the solder?

Usually, it might be because the surface of the solder has oxidized, or the desoldering wire itself lacks a coating of flux. In this case, adding an appropriate amount of flux can help improve the situation. Another possible reason is that the temperature of the soldering iron is too low. In this case, the solder cannot melt completely, and thus it becomes difficult to be sucked into the copper mesh structure of the soldering wire.

2. Which is better, the desoldering wire or the desoldering pump?

These two tools are used in different scenarios.

|

Comparison Aspect |

Desoldering Wire (Solder Wick) |

Desoldering Pump |

|

Suitable Solder Volume |

Small amounts of solder |

Large solder volume |

|

Typical Applications |

Solder bridge removal, fine solder joints, small pads |

Through-hole joints, larger pads |

|

Operation Precision |

High, allows localized control |

Lower compared to solder wick |

|

Impact on PCB Pads |

No mechanical shock, lower risk |

Instant suction force, requires care |

|

Common Usage Method |

Used for fine cleanup and finishing |

Used for rapid bulk solder removal |

|

Practical Rework Recommendation |

Often used as the final cleanup step |

Commonly used as the first step |

3. Can the desoldering be accomplished only with an electric soldering iron?

Using only an electric soldering iron, it is possible to melt the solder, but it is difficult to effectively remove the solder because after melting, the solder often reflows back onto the pads or pins.

4. What are the differences between desoldering wire and ordinary copper wire?

Desoldering wire is made by tightly weaving multiple thin copper wires together, and usually contains flux. Ordinary copper wire lacks this weaving structure and flux, and is not suitable for use as a solder removal tool.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.