Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Rapid Prototyping Services: From Concept to Functional Prototype

With the frequent changes in market demand, technology advancing at a faster pace, and the continuous increase in customers' requirements for product customization, enterprises must complete the work from design concepts to engineering validation within a short time. In this case, rapid prototyping services, which can quickly complete design verification and reduce trial-and-error costs, have become an indispensable part of the product development process.

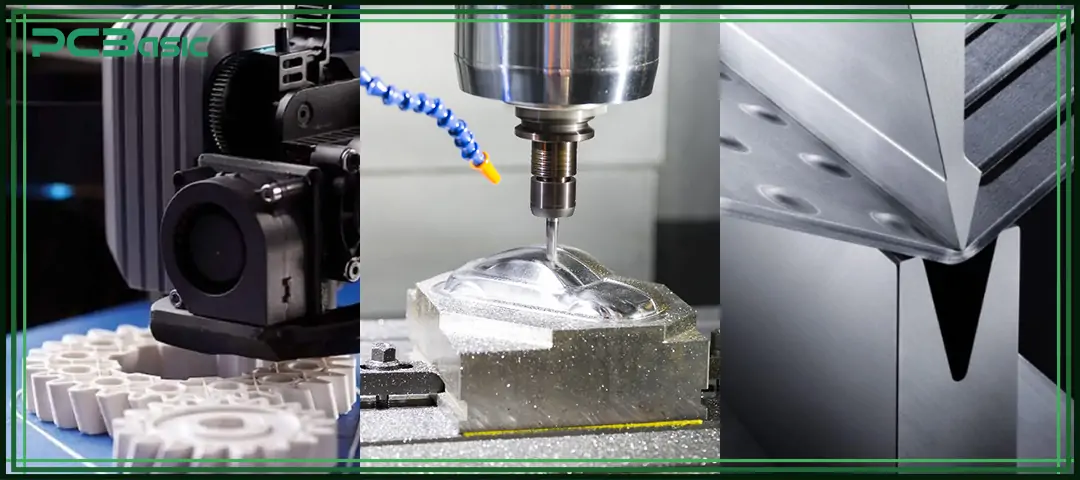

Compared with the traditional method that relies on tooling, which has a long development cycle and high costs, advanced prototyping services - such as rapid prototyping 3D printing, CNC rapid prototyping and sheet metal prototyping -allow the engineering team to produce rapid prototypes close to the final product states in a relatively short period of time. These prototypes are used for visual inspection, structural validation, and basic functional testing.

This article will explain the basic concepts and common applications of rapid prototyping services, introduce the characteristics of different processes and materials, and help you select the appropriate rapid prototyping service to achieve an efficient transition from concept designs to functional prototypes.

Rapid prototyping services refer to a type of prototype manufacturing technology that uses digital CAD files to quickly process physical samples. The core purpose of rapid prototyping is to shorten the product development time as much as possible while reducing the R&D cost and risk, without sacrificing the testing effectiveness.

Rapid prototyping services pay more attention to processing speed and design flexibility rather than production volume. This enables enterprises to repeatedly modify the design at the early stage of product development, verify structure and functions, and promptly obtain testing results and user feedback.

Therefore, rapid prototyping companies are widely used in the stages of product design verification, engineering testing, and prototype production before formal mass production.

Using rapid prototyping services offers multiple advantages:

• Faster product development cycles

• Reduced design and engineering risk

• Lower overall development costs

• Improved communication between teams

By producing rapid prototypes early, companies can identify design flaws before committing to mass production.

3D printing rapid prototyping is the most common type of rapid prototyping service. It applies additive manufacturing methods, stacking materials layer by layer to form parts, which is very suitable for making product prototypes with complex structures that require frequent design changes.

Rapid prototypes have a fast production speed and can complete samples in a relatively short period of time. At the same time, the material utilization is high, and the waste is minimal, keeping the overall cost under control. In addition, this method is highly suitable for product appearance evaluation and design validation, which helps to identify and correct design issues at an early stage.

• FDM (Fused Deposition Modeling): Low cost and suitable for early concept samples

• SLA (Stereolithography): High precision and good surface quality

• SLS (Selective Laser Sintering): High strength, suitable for functional testing, and does not require support structures

In 3D printing and prototyping, plastic materials are often used for appearance models and functional testing.

Common materials include:

• PLA: Easy to process and low cost, suitable for concept models

• ABS: Higher strength and better heat resistance

• Nylon: Durable and suitable for parts with moving structures

• Resin: Excellent detail performance, suitable for rapid prototyping and 3D printing

These materials make 3D printing prototyping highly suitable for fast design validation and ergonomic testing.

CNC rapid prototyping is a typical subtractive prototype machining service that produces high-precision parts by cutting material from solid blocks. CNC machining is a more suitable choice for the prototype that has high requirements for dimensional tolerances or needs to be made from materials close to those used in mass production.

• High-dimensional accuracy

• Good surface quality

• Well-suited for functional testing and mechanical performance testing

CNC rapid prototyping is often used for machining metal and engineering plastic parts. For this reason, it plays an important role in prototype manufacturing in fields such as automotive, aerospace, and industrial equipment.

When conducting functional testing and structural validation, metallic materials are indispensable in prototype manufacturing.

Common metal materials include:

• Aluminum: Lightweight and easy to machine

• Stainless steel: High strength and corrosion resistant

• Copper and brass: Commonly used for electrical and thermal applications

Both CNC rapid prototyping and sheet metal prototyping mainly rely on these materials to manufacture stable and reliable rapid prototypes.

Sheet metal prototyping is a method of processing parts by using thin metal sheets and processes such as cutting, bending and forming. It is an important part of many rapid prototyping services and is particularly suitable for making enclosures and structural components.

• Laser cutting

• CNC punching

• Bending and forming

• Welding and assembly

Sheet metal prototype fabrication is widely used in parts such as chassis, housing, brackets and frames. Compared with machining solid blocks of material, sheet metal rapid prototyping uses less material, costs less and have a shorter delivery time when manufacturing large or hollow parts.

When selecting materials for rapid prototyping services, consider:

• Mechanical strength requirements

• Thermal and electrical performance

• Surface finish and aesthetics

• Budget and lead time

Experienced rapid prototyping companies help customers align materials with real-world use cases.

Rapid prototyping services are widely adopted across industries:

• Consumer electronics

• Automotive and transportation

• Medical devices

• Industrial automation

• Aerospace and defense

From startups to global manufacturers, prototyping companies rely on fast prototyping to stay competitive.

Most rapid prototyping companies operate according to a standard workflow to ensure that rapid prototyping services can be completed efficiently and stably.

The customer provides CAD design files and specifies requirements such as materials, quantities, tolerances and surface finishing.

Engineers check whether the designs are suitable for manufacturing and, based on the structure and application of the parts, select appropriate processing methods, such as 3D printing, CNC machining or sheet metal prototyping.

Parts are produced in accordance with the confirmed process and materials to produce rapid prototypes that meet the design requirements.

Inspect the dimensions and appearance of the prototype and conduct necessary basic functional tests to ensure compliance with the drawing requirements.

Package and ship the finished prototype for the customer for testing, verification or demonstration.

Through this clear and efficient workflow, rapid prototyping services can help enterprises quickly turn design concepts into physical samples and play a significant role in the product development process.

When evaluating rapid prototyping services, consider:

• Available processes (3D printing and rapid prototyping, CNC, sheet metal)

• Material options

• Lead time and scalability

• Engineering support

• Quality control systems

The right rapid prototyping company should act as a technical partner, not just a supplier.

PCBasic offers an integrated rapid prototyping service, including CNC rapid prototyping, 3D printing rapid prototyping and sheet metal rapid prototyping. With strong engineering support, advanced equipment and rapid delivery capabilities, PCBasic helps customers shorten the development cycle and reduce the risks of prototyping.

PCBasic not only manufactures prototypes but also offers engineering reviews and process selection to ensure that each project adopts the most suitable technology for cost, speed and performance.

PCBasic's CNC machining services focus on high-precision milling (three-axis, four-axis and five-axis), turning and post-processing, and are dedicated to manufacturing custom metal and engineering plastic parts.

Key features include:

• High-dimensional accuracy and stable quality

• Support for various metals and plastics

• Professional engineering review and process optimization

• Fast turnaround and strict quality inspection

PCBasic offers online 3D printing services, supporting rapid prototyping and custom parts production. Customers can upload CAD files and immediately receive quotations. The selection of materials and precision grades is flexible. This service utilizes SLA and other additive manufacturing technologies to rapidly produce complex parts, making it highly suitable for proof-of-concept, iterative design, and parts with fine geometries.

Key features include:

• Short lead time for prototype production

• Support for complex geometries

• Multiple plastic and resin material options

• Cost-effective for low-volume orders

PCBasic offers a full range of sheet metal processing services, including laser cutting, bending, punching, welding, and assembly. These services are widely applied to products such as enclosures, chassis, brackets, and frames that have high requirements for structural strength and surface quality.

Key features include:

• Integrated in-house fabrication processes

• Support for aluminum, stainless steel, steel, copper, and brass

• Optional surface finishing such as anodizing and powder coating

• Suitable for large or hollow structural parts with lower material cost

Rapid prototyping services are an effective way to quickly transform design ideas into physical samples. Whether using rapid prototyping, 3D printing or prototype machining services, or sheet metal prototype fabrication, these technologies can all help enterprises shorten development time, reduce costs and decrease design risks.

By working with professional rapid prototyping companies, enterprises can complete product verification more quickly, accelerate the pace of innovation, and bring products to market more efficiently.

Q1: What is the fastest rapid prototyping service?

A: 3D printing rapid prototyping is usually the fastest option for simple plastic parts.

Q2: Are rapid prototypes suitable for functional testing?

A: Yes. CNC rapid prototyping and sheet metal rapid prototyping are ideal for functional and mechanical testing.

Q3: How do prototyping companies control quality?

A: Professional prototyping services use inspection tools, process controls, and engineering reviews to ensure accuracy.

Q4: Can rapid prototyping lead directly to production?

A: Absolutely. Many rapid prototyping services are designed to transition smoothly into full prototype manufacturing and mass production.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.