Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > SMT Process: Everything OEMs Need to Know

In today's electronic manufacturing industry, SMT is the core technology for efficient and high-quality PCB assembly. SMT technology has transformed the way electronic products are produced, enabling manufacturers to produce smaller, more compact and more complex items. Whether it is smartphones, automotive electronics or medical devices, SMT technology plays a key role in the production of almost all modern electronic products.

For OEMs (Original Equipment Manufacturers), understanding the SMT process is significant for enhancing production efficiency, reducing costs and ensuring product quality. In this blog, we will introduce what SMT is, why OEMs should pay attention to it, the main components of the SMT assembly line, and the detailed steps of SMT PCB assembly.

SMT (Surface Mount Technology) is a method of directly mounting electronic components on the surface of a PCB (Printed Circuit Board). Unlike the traditional THT (Through Hole) technology, which requires inserting components into holes in the circuit board, SMT places components on the surface of the circuit board. In this way, SMT makes circuit boards more compact and improves efficiency, especially suitable for applications that require high-density components. In this way, SMT can mount components on both sides of the circuit board, further improving the utilization rate of space and enabling more components to be placed in a smaller space.

Since the 1980s, SMT technology has been widely applied in electronic manufacturing and has gradually become the standard for modern electronics manufacturing. It has promoted the miniaturization of electronic products. This approach enables more complex designs to be implemented in smaller devices, all thanks to the high density, flexibility and efficiency of SMT technology.

An SMT assembly line is a highly automated production system specifically designed for assembling SMT components onto circuit boards. By implementing the SMT process, these key components work together to ensure the high quality of SMT board assembly.

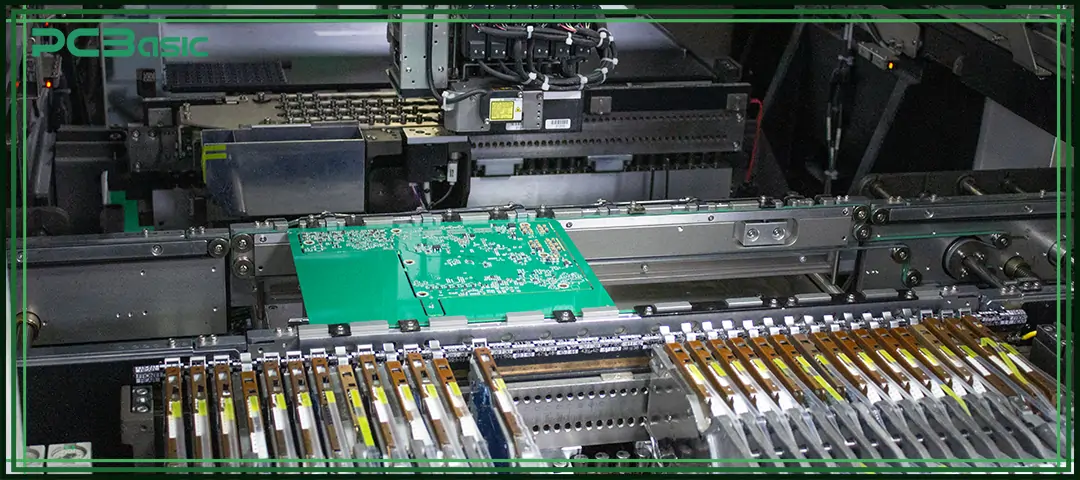

This machine accurately places SMT components on the PCB through high-precision and high-speed operation. Each component is precisely placed according to the preset X-Y coordinates to ensure that all components are in the correct position, thereby improving the assembly accuracy and efficiency.

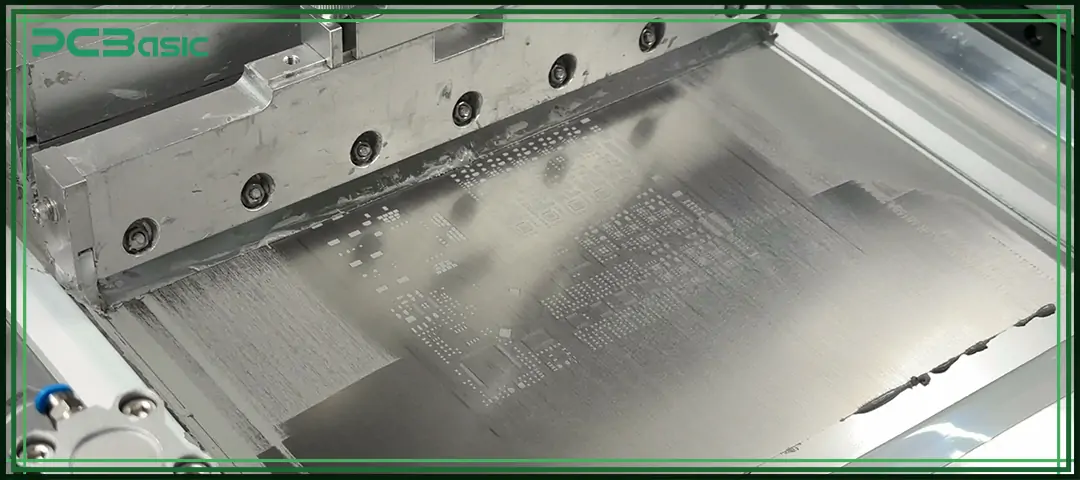

This machine uses screen printing technology to apply an appropriate amount of solder paste to the pads on the PCB. The function of solder paste is to provide a stable electrical connection between SMT components and circuit boards, ensuring the quality of soldering.

After the components are placed, the SMT PCB assembly will pass through the reflow oven. The solder paste is heated in the oven to melt, forming a firm solder point. The temperature and heating time of the reflow oven need to be precisely controlled to avoid overheating and ensure a firm connection.

After the soldering is completed, the AOI system will inspect the SMT circuit boards to confirm whether the components are placed correctly and if the solder joints meet the quality standards. AOI uses high-resolution cameras to scan circuit boards and check for soldering defects such as missing components, misalignment or solder bridges.

For products that require additional protection, conformal coatings will be applied to SMT components. The coating can protect components from moisture, dust and other external environmental factors, extending the product's service life and enhancing reliability.

These components work closely together in the SMT assembly line. Every step from component placement to final inspection is guaranteed to be precise, ensuring the quality and performance of the final product.

The SMT process includes several key steps, each of which contributes to the successful assembly of the SMT circuit board. The following is a detailed introduction to these steps:

Before starting SMT assembly, all incoming materials - SMT components and PCBs - need to undergo strict inspection. This is to ensure that all components comply with the specifications in the BOM, and that the PCB is not affected by oxidation, physical damage or other defects. High-quality components are crucial for the smooth operation of the SMT assembly line, and any problem can affect the subsequent assembly process.

After the material inspection is passed, the next step is to prepare for the SMT process. This includes making an SMT stencil, baking BGA chips, and ensuring that pick-and-place files and feeders are all ready. These preparations ensure that the SMT PCB assembly line can proceed smoothly and efficiently, avoiding any interruption or delay.

The solder paste printer applies solder paste to PCB pads through an SMT stencil. The function of solder paste is to establish a reliable electrical connection between surface-mount components and the PCB. This step is extremely crucial because inaccurate application of solder paste can lead to poor soldering, which in turn affects the overall assembly quality. After printing, the solder paste inspection (SPI) system is used for inspection to ensure the accuracy and consistency of solder paste application.

After the solder paste is applied and inspected, the SMT components will be placed on the PCB. This process is carried out using a Pick-and-Place Machine, which accurately picks up components through suction nozzles and places them at the predetermined positions on the SMT circuit board. Mounting accuracy is significant because even the slightest misalignment can lead to poor connection of components and even cause the product to fail to function properly.

After component mounting is completed, the SMT circuit board enters the reflow soldering oven. In a reflow soldering oven, the solder paste is heated and melted to form a permanent solder joint. The temperature and heating time during reflow soldering need to be precisely controlled to prevent overheating that damages components or low temperatures that result in poor soldering. The correct temperature curve is crucial for ensuring the quality of welding.

After the soldering is completed, the AOI system checks the SMT circuit board to ensure that the components have been correctly placed and the solder joints meet the quality requirements. AOI uses high-resolution cameras to scan circuit boards and inspect defects such as missing components, misalignment, and solder bridges. AOI can detect problems in real time during the production process and provide feedback to help make timely corrections and prevent defects from advancing to the next production stage.

Although AOI systems are already very precise, visual inspection is still necessary, especially to detect appearance defects such as scratches, surface blemishes or component appearance issues. Visual inspection ensures that not only are there no functional issues, but the product's appearance also meets the requirements.

Finally, the QA (Quality Assurance) team will conduct a comprehensive inspection of the completed SMT PCB assembly to ensure that the products meet all customer requirements. This includes comparing with the design specifications to confirm whether the components are placed correctly, whether the solder joints are firm, and whether all functions meet the standards. QA inspection is an important link to ensure the quality and performance of the final product and help avoid potential problems in production.

The precise execution of each step ensures the high quality and high efficiency of the SMT process, ultimately guaranteeing the reliability and functionality of the product.

SMT has brought obvious production and quality advantages to OEMs and electronic manufacturers, mainly reflected in the following aspects:

Through SMT technology, electronic components can be directly mounted on the surface of the PCB, and even arranged on both sides of the circuit board. This significantly enhances the utilization rate of PCBs, enabling more functions to be accommodated on smaller SMT circuit boards and achieving miniaturization + high performance of equipment.

The SMT process is highly automated and almost does not rely on manual soldering, significantly reducing labor costs and human errors. Meanwhile, automated equipment in SMT production lines can operate continuously for 24 hours, featuring high production speed and low scrap rate, helping enterprises reduce overall manufacturing costs and improve delivery efficiency.

The use of surface mount technology can shorten the electrical connection paths between components, thereby reducing resistance, inductance and signal delay. This not only enhances signal integrity but also improves the stability and anti-interference ability of the circuit.

The SMT assembly line is not only suitable for large-scale production, but also can quickly switch production for small-batch and multi-model orders (high-mix, low-volume). Whether it is small-scale trial production in the R&D stage or commercial mass production, it can flexibly respond and meet the needs of OEM enterprises at different stages.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

While the SMT process offers many benefits, it also comes with challenges, including:

|

Challenge |

Common Issues |

Solutions |

|

Soldering Defects |

Cold solder joints, insufficient solder, solder bridges, open joints |

Control reflow soldering temperature profile accurately; use SPI and AOI for inspection; optimize stencil design and solder paste quality. |

|

Component Misplacement |

Misaligned components, tombstoning, and incorrect placement |

Regularly calibrate pick-and-place machines; perform First Article Inspection (FAI); optimize coordinate files and nozzle conditions. |

|

Material Handling Issues |

Moisture-sensitive components (MSL), "popcorning," oxidation, and ESD damage |

Follow MSL (Moisture Sensitivity Level) standards; use dry cabinets; bake components when necessary; implement strict ESD protection. |

|

Equipment Maintenance |

Clogged nozzles, worn stencils, unstable reflow temperature |

Establish maintenance schedules; regularly clean, calibrate, and inspect machines; trace anomalies through production data. |

|

Poor PCB/DFM Design |

Pads too small or too large, insufficient spacing, no test points |

Apply DFM (Design for Manufacturability) guidelines; conduct file reviews with the SMT supplier before production. |

SMT technology is at the core of modern electronic manufacturing, making electronic products smaller, lighter and of higher performance. From solder paste printing to the final quality inspection, every step of SMT PCB assembly is related to the reliability of the product and production efficiency.

For OEMs, understanding and correctly applying SMT technology is the key to enhancing efficiency, reducing costs and maintaining competitiveness. The adoption of surface mount technology can not only increase component density and performance, but also reduce errors and rework through automation, precise temperature control and regular inspection.

In the future, with the development of automation and environmental protection technologies, SMT products will become smarter, more efficient and more sustainable. For OEM enterprises that want to optimize the PCB production line and ensure high-quality SMT board assembly, cooperating with professional and experienced SMT manufacturers is an important step towards steady success.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.