Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Rapid PCB Prototyping Services from PCBasic

In the development of electronic products, PCB prototyping is a key step in the initial design of the product. Its main purpose is to test whether the circuit board design meets the functional specifications before entering mass production. Although this is not the final version, the prototype board should have all the functions required for the final design. Whether developing IoT devices, medical instruments, or industrial control systems, completing prototype boards as early as possible can significantly enhance project efficiency and success rates.

This is precisely where rapid PCB prototyping comes into play. It significantly shortens the product development cycle by rapidly providing PCB design prototypes and accelerating design verification and iteration. As a globally leading provider of PCB prototyping and small-batch production services, PCBasic offers rapid delivery capabilities in PCB manufacturing and PCB fabrication. After receiving the Gerber files and having them reviewed by engineers, it can complete the delivery within 24 hours at the fastest, supporting small-batch prototypes of 5 to 100 pieces.

This article will deeply analyze the definition, advantages, and application scenarios of rapid PCB prototyping, helping you understand how to improve project efficiency through rapid prototyping. Meanwhile, we will introduce PCBasic as a one-stop solution provided by professional PCB makers in PCB manufacturing, PCB fabrication, and PCB design and assembly. Get your product one step ahead from concept to prototype.

Rapid PCB prototyping is a method for quickly making custom PCB prototypes, which is used to test and verify the functions of circuit boards. Compared with the traditional process which may take several weeks, the quick turn PCB service provided by professional PCB makers can complete the PCB prototypes within 24-72 hours at the fastest.

This rapid process covers:

• PCB design and assembly

• PCB fabrication

• PCB prototype fabrication service

• Optional PCB manufacturing and assembly

By integrating these parts, rapid PCB prototyping helps engineers quickly identify and correct problems, accelerate the overall process from design to mass production, and improve the efficiency of product development.

Every electronic manufacturing industry goes through PCB prototyping to ensure that the design meets all the set specifications and meets all the design requirements. Rapid PCB prototyping services are valuable for electronic manufacturing companies to streamline the design process. Rapid PCB prototyping has many advantages, as follows:

1. Quick Turnaround Time

One of the most valuable advantages of rapid PCB prototyping is quick turnaround time. Quick turn time speeds up the design process and reduces the fabrication time from weeks to days. This helps reduce the design and testing phase.

2. Design Validation and Functional Testing

PCB Prototyping is a tool for PCB designers to test and evaluate the circuit design to ensure that the designed circuit performs as per the set specifications. This also ensures that the designed circuit fulfills all the required functionality of the design before it goes into the production phase.

3. Flexibility and Fast Iteration

Rapid PCB prototyping allows the designers to modify the design if the design does not perform as per the set specifications. This will help the designers to quickly modify the design before it goes into production, resulting in a cost-effective solution and offering designers more flexibility and creative freedom.

4. Cost-Effective Small Volume Production

One of the advantages of rapid prototyping services is that they are manufactured in small volumes, resulting in savings for the company.

5. Streamlined Process with Thorough Testing

The ultimate goal of a PCB designer is to achieve first-class PCB products to make sure its customers are satisfied. PCBasic provides rapid prototype services to its clients to allow them thorough testing and design modification. This results in minimum turnaround time and a streamlined process.

6. Reduced Overall Production Cost

Another advantage of rapid PCB prototyping is a reduction in the company’s production cost. PCB prototyping allows the designers to test and identify the problems in design before it goes into the production phase, resulting in a reduction in production cost.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Rapid PCB prototyping is crucial in multiple industries, including:

• Consumer electronics: Testing early versions of smart gadgets, wearables, and mobile accessories

• Medical devices: Creating functional boards for diagnostics and monitoring systems

• Automotive systems: Prototyping for in-vehicle electronics and sensor interfaces

• Industrial control: Developing controllers and automation systems

• Telecommunication: Rapid testing of signal transmission boards

No matter which industry you are in, custom PCB prototyping can accelerate the innovation process and effectively enhance the reliability of products before entering large-scale PCB production.

PCBasic is a leading Chinese PCBA manufacturing company with 15 years of experience in PCBA fabrication, rapid PCB prototyping, and the SMT industry. The company specializes in rapid production of small to large volume PCBA, rapid PCB prototyping services, PCB design services, and finished product assembly. Over the years PCBasic has developed an efficient and intelligent production management system to improve the efficiency and quality of PCB fabrication services.

Selecting the right PCB manufacturing and assembly partner is critical for your product design and development. Selecting PCBasic for your PCB manufacturing and assembly partner offers you numerous benefits, which include:

1. Advanced SMT Equipment for High-Precision Manufacturing

PCBasic has advanced Surface Mount Technology (SMT) equipment, including high-speed automatic pick and place machines, solder paste printers, and SMT cleaning machines. This equipment enables PCBasic to manufacture high-density circuit boards with precision and accuracy, resulting in a state-of-the-art product design.

2. Compliance with International Quality Standards

PCBasic has a well-established quality control management system, and its designs comply with international quality standards, i.e., ISO9001, IATF16949, and ISO13485 standards. Complying with international quality standards improves your product reliability and durability and reduces costs.

3. Comprehensive Quality Control Measures

PCBasic is committed to advancing its quality control and assurance process by implementing advanced quality control methods such as flying probe testing, X-ray inspection, and Automatic Optical Inspection (AOI) machines to identify potential defects in PCB assembly by using high-resolution cameras and advanced image processing software. By implementing these techniques, PCBasic ensures that your final product is defect-free, performs as per set specifications, and is fully functional according to the designed requirements.

4. Efficient CRM and MES Systems for Faster Turnaround

PCBasic has developed a state-of-the-art Customer Relationship Management and Manufacturing Execution System (MES). This will allow PCBasic to have a rapid turnaround time for the prototype PCB assembly. This will allow the designers to quickly identify the problems in the prototype and go for mass production as soon as possible.

5. Streamlined Process and Mass Production Capability

It is not only the management system that allows for a quick turnaround time. PCBasic has advanced SMT technology and a streamlined assembly process that allows for the quick manufacturing of PCBs. This is especially useful in mass production.

6. Flexible Order Quantities from Prototypes to Production

PCBasic has a flexible production process that allows companies to order single to 100s quantities of products. This allows the customer more freedom in design and development, whether prototype designing or PCB mass production.

7. Cost-Effective Rapid PCB Prototyping with Free Assembly for New Clients

It is the idea that is translated into an electronic design. But what if, after a production, your design has flaws? You can avoid such mistakes by using PCB prototyping. PCBasic offers rapid PCB prototyping services to reduce your financial burden, enhance product design through an iterative process, and ensure functional testing. PCBasic offers PCB prototyping at a very reasonable price compared to the market and offers free assembly-to-prototype service for new customers.

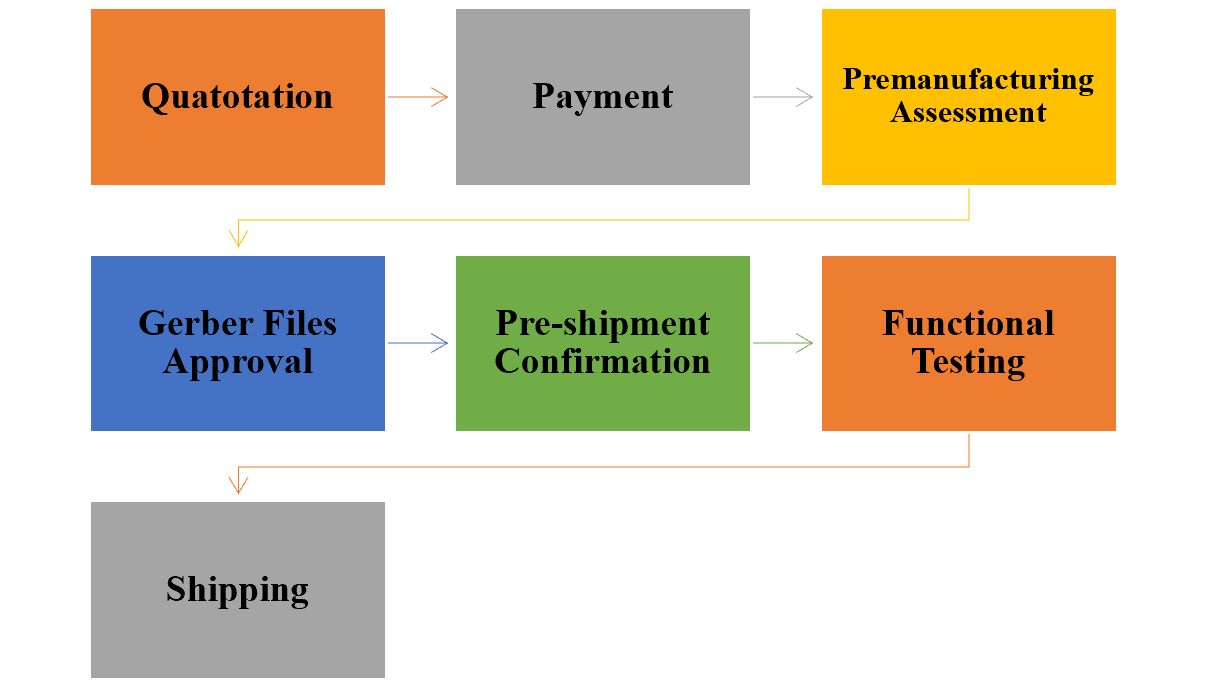

PCBasic has a very user-friendly and streamlined ordering process, whether for a prototype or mass production. The ordering process allows customers to use it easily, as shown in Figure 1.

Figure 1: PCBasic PCB Manufacturing ordering process

In conclusion, rapid PCB prototyping is a critical step in the development cycle. It translates the conceptual design into reality and enables the designer to modify the PCB design to make the design error-free before it goes into mass production. PCBasic is a leading PCBA manufacturing company that has rich experience in PCB prototyping to enable design engineers to convert their ideas into reality and verify their concepts to minimize the cost and time of the company.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.