Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > Maximizing Efficiency in Industrial PCBA Prototyping: Techniques and Cost-Effective Solutions

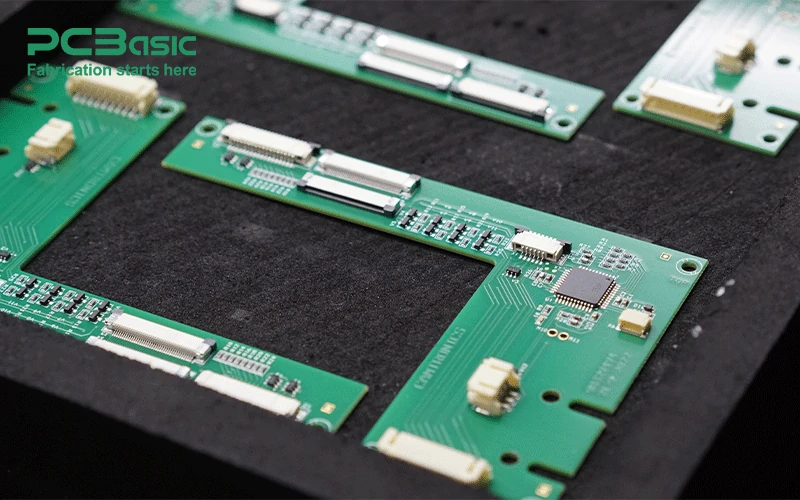

Industrial PCBA prototyping refers to creating circuit board assemblies tailored for testing and validation in industrial applications. It bridges the gap between PCB design and mass production, ensuring that each PCB assembly meets functional requirements before scaling up. This process is integral to PCB manufacturing, as it allows for troubleshooting and fine-tuning designs early.

At the heart of industrial electronics, PCB prototyping ensures that custom PCBs are reliable, efficient, and meet the unique demands of various industries. It’s also a key differentiator for wholesale PCBA prototyping manufacturers, enabling them to provide cost-effective solutions tailored to clients’ needs.

PCBA prototyping is the backbone of the PCB fabrication process. It reduces risk by identifying design flaws early, ensuring the final product meets both functional and industry standards. For manufacturers specializing in custom PCBs, prototyping enables design verification without incurring the high costs of large-scale production.

Enhancing PCB Assembly Accuracy: Prototyping ensures that the circuit board assembly process is streamlined, reducing errors in final production.

Faster Time-to-Market: In competitive industries, PCB manufacturing benefits greatly from efficient prototyping that shortens development cycles.

Quality Control: Rigorous testing during PCB prototyping ensures that every board meets specifications before proceeding to full production.

The industrial PCBA prototyping process is divided into several critical stages:

Design Phase

Using CAD software, engineers develop a detailed schematic and layout for the circuit board assembly. This step ensures that all components are correctly configured for seamless PCB manufacturing.

Gerber File Generation

Gerber files act as the blueprint for PCB fabrication, containing precise details about the board’s layout, traces, and component placement. These files are crucial for custom PCB projects.

PCB Fabrication

During this step, the physical board is manufactured. The material selection, layer configuration, and surface finish play a pivotal role in ensuring the durability and functionality of the PCB assembly.

Component Assembly

Components are mounted onto the board using either surface-mount technology (SMT) or through-hole techniques. This phase is critical for ensuring an accurate circuit board assembly.

Testing

Prototypes undergo electrical and functional testing to ensure the custom PCB meets design expectations. This step identifies and resolves potential issues before mass production.

Emphasis on Rapid PCB Prototyping

Rapid prototyping is essential for wholesale PCBA prototyping manufacturers looking to reduce lead times. By leveraging technologies like CNC machining and automated pick-and-place systems, PCB assembly can be completed more efficiently, ensuring quick iterations for industrial PCBA prototyping.

Advanced Technologies in PCB Fabrication

Incorporating tools like 3D printing for enclosures and automated optical inspection (AOI) during circuit board assembly helps enhance both speed and accuracy. These advancements reduce human error, ensuring superior PCB manufacturing outcomes.

Supply Chain Optimization

By building strong supplier relationships, wholesale PCBA prototyping manufacturers can minimize delays in sourcing components for custom PCBs, ensuring smooth transitions between PCB fabrication and assembly stages.

Design Optimization for Custom PCBs

Simplifying board layouts and selecting cost-effective components during the design phase can significantly reduce PCB manufacturing costs. Optimized custom PCB designs also improve assembly efficiency.

Leveraging Economies of Scale

Producing prototypes in bulk allows wholesale PCBA prototyping manufacturers to lower per-unit costs. This strategy benefits clients seeking affordable PCB prototyping for mass-market applications.

Minimizing Rework Costs

Investing in quality control during circuit board assembly ensures fewer errors, reducing the need for costly rework later in the PCB manufacturing process.

Priority Manufacturing Options

For urgent projects, industrial PCBA prototyping can be expedited through priority scheduling. This approach is ideal for businesses needing quick custom PCB prototypes.

Automation in Circuit Board Assembly

Automation streamlines repetitive tasks in PCB fabrication, ensuring prototypes are completed faster without sacrificing quality. Automated SMT and wave soldering processes enhance speed in PCB assembly.

Technology-Driven Solutions

By employing cutting-edge tools, such as impedance testing and thermal imaging, wholesale PCBA prototyping manufacturers can identify issues early and deliver rapid, high-quality prototypes.

Comprehensive Testing Protocols

Thorough testing, including impedance analysis and AOI, ensures that every custom PCB meets stringent performance standards. This is especially crucial in industrial PCBA prototyping, where reliability is non-negotiable.

Employee Training and Standards Compliance

Ongoing employee training ensures that teams stay updated with industry best practices, particularly for high-precision circuit board assembly tasks.

Customer Feedback Integration

Feedback from clients helps improve the prototyping process. PCB prototyping services that incorporate customer insights produce better-aligned solutions, enhancing satisfaction.

When selecting a partner for industrial PCBA prototyping, consider the following:

Expertise in Custom PCBs: Ensure the manufacturer has experience handling complex PCB fabrication requirements.

Quality Assurance: Verify that the provider employs rigorous testing during the PCB prototyping process.

Turnaround Time: Choose partners known for delivering rapid, high-quality circuit board assembly services.

Cost-Effectiveness: Look for wholesale PCBA prototyping manufacturers offering competitive pricing without compromising quality.

At PCBasic, we specialize in industrial PCBA prototyping, delivering superior PCB assembly and custom PCB solutions tailored to your needs. As one of the leading wholesale PCBA prototyping manufacturers, we ensure:

Rapid Turnaround: Streamlined processes and advanced automation reduce lead times.

Cost Efficiency: Optimized PCB fabrication and design strategies lower production costs.

Quality Assurance: Comprehensive testing ensures that every circuit board assembly meets industry standards.

Whether you need a prototype for an innovative product or are looking for scalable solutions in PCB manufacturing, PCBasic is here to help. Contact us today to start your next PCB prototyping project!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.