Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Advanced PCB Manufacturing Equipment: A Complete Guide

Every high-quality PCB starts with precise engineering and advanced manufacturing equipment. As a professional PCB manufacturer, one should be well aware that the quality of a circuit board begins with the equipment used in the manufacturing process. From cutting, drilling, exposure, etching, to inspection and final testing, every step requires a high degree of precision. Therefore, our PCB factory has invested a large amount of resources to equip a full range of advanced PCB equipment to ensure that the circuit boards we manufacture are of high quality and reliable performance.

Then, we will take you through the core PCB equipment equipped in our factory to help you understand how we provide you with high-precision, high-consistency and scalable PCB manufacturing services.

PCB equipment is the key to accuracy and consistency in the modern circuit board manufacturing process. Our factory is equipped with a complete set of advanced PCB manufacturing equipment, which not only supports small-batch prototyping but is also suitable for large-scale production. These machines ensure each PCB meets strict performance and quality standards.

Each link is equipped with corresponding advanced equipment. For example, LDI automatic exposure machines for exposing circuit patterns, PCB etching equipment machines, multi-layer laminating machines and fully automatic electroplating production lines. These devices can achieve extremely small tolerances, smooth trace edges and highly consistent laminated structures.

Our factory, equipped with advanced facilities, is capable of providing circuit boards with high reliability and electrical consistency. It can fully meet the strict demands of industries such as automobiles, medical care, industrial control and communication. Whether you are concerned about "what are circuit boards made of" or scalable PCB production solutions, we can all provide you with professional, efficient and reliable PCB manufacturing services.

The main PCB manufacturing equipment includes:

The PCB drilling machine is a kind of high-precision numerical control equipment, which is used to drill through holes, component holes and mounting holes on printed circuit boards. PCB drilling machines can achieve extremely small hole diameter tolerances and high repeatability accuracy, which will directly affect the electrical performance and reliability of circuit boards. PCB cutting machines are used to cut large-sized copper-clad laminates (such as FR-4, CEM-1, aluminum substrates, etc.) into small-sized boards that meet production requirements. This is one of the initial steps in PCB manufacturing process, directly affecting the alignment accuracy and material utilization rate of subsequent steps such as drilling, exposure, and etching.

High-speed PCB drilling machines and advanced cutting machines are important components of the PCB manufacturing equipment system. As a key process in circuit board manufacturing, drilling and cutting directly affect the performance and reliability of printed circuit boards. The high precision of these PCB machines can ensure accurate hole positions and consistent board sizes.

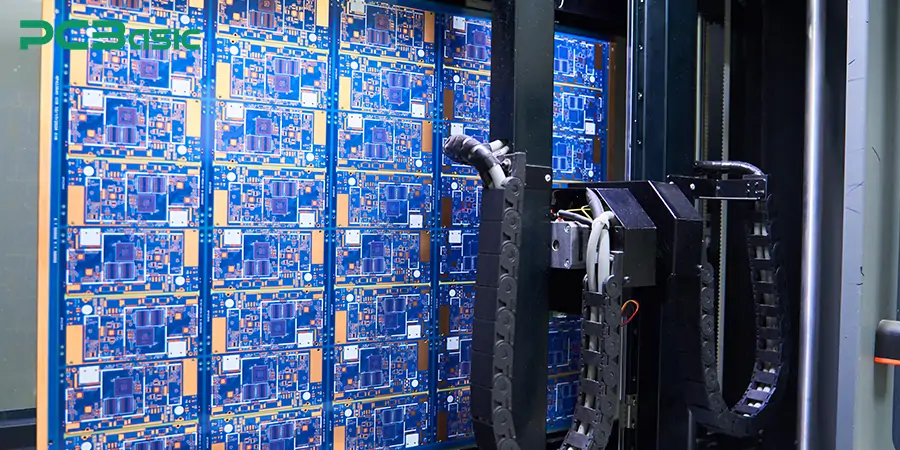

The LDI exposure machine is a kind of high-precision PCB manufacturing equipment. It adopts laser direct writing technology to expose the circuit graphics directly onto the surface of the printed circuit board coated with photosensitive glue. It does not require the use of traditional film. This can avoid the alignment errors and defects caused by the thermal expansion and contraction of traditional film. It also supports ultra-fine line width/line spacing and is the most advanced core equipment for line pattern exposure in modern PCB manufacturing equipment. It has the high-precision alignment capability between the inner and outer layers, and is particularly suitable for the PCB fabrication process of HDI and multi-layer boards.

As an important piece of equipment in our PCB manufacturing production line, the LDI exposure machine significantly improves the quality of graphic transfer and production efficiency. It widely supports applications in high-end fields such as medical PCBA, automotive electronics, communication equipment, and industrial control.

PCB etching equipment is a key manufacturing equipment in circuit board manufacturing used to remove excess copper foil and form precise circuit patterns. It etches a conductive copper layer through chemical or plasma methods. It determines the circuit width, circuit spacing and graphic integrity of the printed circuit board, and is one of the core processes that affect the quality of the finished product.

In standard PCB production, etching is a crucial step after the pattern is exposed. After the circuit pattern is formed into an image through an LDI exposure machine or film transfer, the unprotected copper layer is dissolved in the etching machine, ultimately leaving the required conductive path. This step is the basis for providing high-quality graphics for the subsequent PCB testing equipment.

In circuit board manufacturing, electroplating is used to deposit metal layers on the hole walls and copper surfaces. Common electroplating methods include: PTH, copper plating, and nickel/gold electroplating. This type of process is usually accomplished by fully automatic electroplating lines and is a core component of modern PCB manufacturing equipment, ensuring the high reliability and conduction consistency of circuit boards.

Surface treatment determines the soldering performance and storage life of PCBs. Common methods include: HASL, ENIG, OSP, Immersion Silver/Tin.

PCB plating and surface finish is one of the key stages in the manufacturing of printed circuit boards. The main purpose of these two steps is to improve the welding performance, the reliability of electrical connections, and enhance the anti-oxidation capacity. PCB electroplating and surface treatment not only affect the appearance quality of the circuit board, but also directly relate to the stability of subsequent assembly and long-term use.

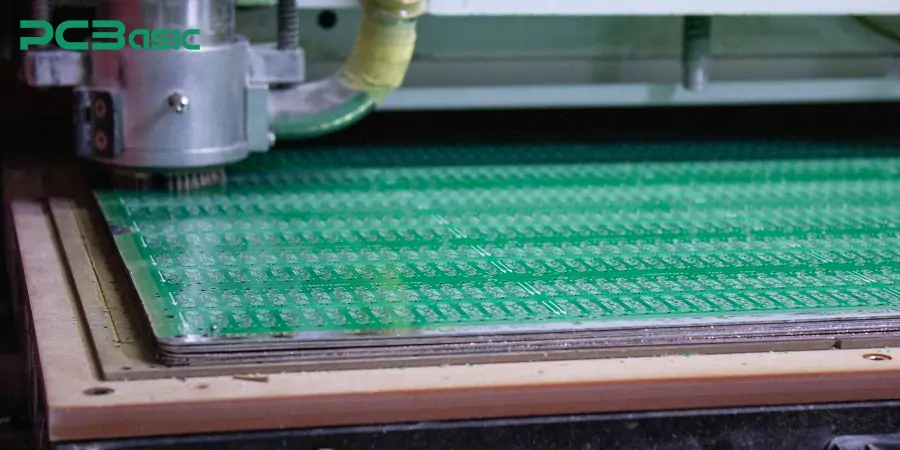

The PCB routing machine is used to mill and separate multiple printed circuit boards from a single panel along a predetermined path. Unlike the traditional v-cutting method, edge milling can achieve more flexible contours, smoother edge treatment, and significantly reduce mechanical stress. It is particularly suitable for applications with irregular plate shapes, complex components or high reliability requirements. Edge milling determines the external dimensions of the circuit board and ensures its mechanical strength. This technology is widely applied in industries such as medical electronics, automotive control systems, smart home devices, and industrial control. In the manufacturing of circuit boards, reaching the PCB production stage indicates that the PCB production process is coming to an end.

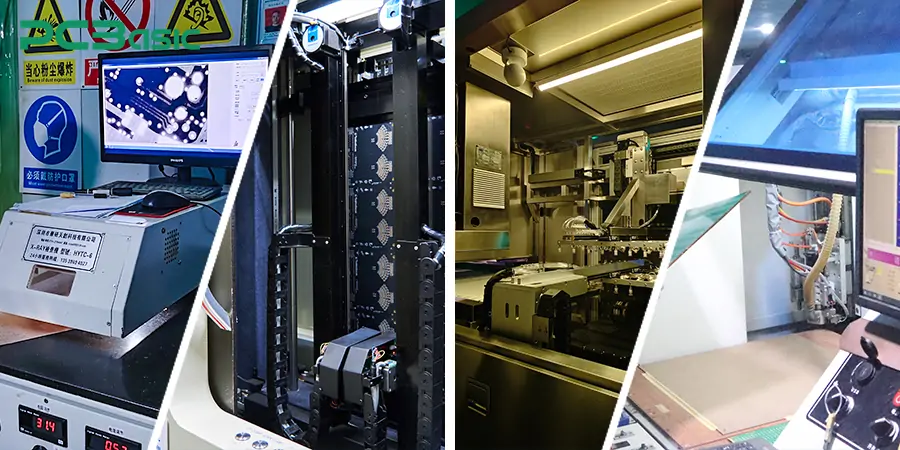

To ensure that every link in the circuit board manufacturing process meets the quality standards, the factory surely needs to be equipped with advanced PCB inspection equipment. The main PCB inspection equipment includes: AOI, X-ray inspection equipment, as well as microscopes and manual visual inspection. They are also an important part of our high-reliability PCB manufacturing equipment system.

According to the requirements of customers, we can implement the IPC Class II or higher IPC Class III testing standards to meet the application scenarios with extremely high-quality requirements for circuit boards such as industrial control, communication, and medical care.

In the process of high-reliability circuit board manufacturing, PCB testing equipment is the key guarantee to ensure the stable performance and good electrical on-off of each printed circuit board. Only by equipping a complete set of automated and manual testing systems can the consistency and reliability of PCB manufacturing quality be fully guaranteed.

The main testing equipment includes: flying probe testing machine, ICT online testing system, FCT functional testing equipment, and four-wire low-resistance testing.

These test devices, in coordination with our PCB inspection equipment, constitute a complete quality control system. Meanwhile, combined with the automatic test equipment for PCB, rapid testing and automatic determination in mass production are achieved, significantly improving production efficiency and product reliability.

When evaluating whether a PCB manufacturer is worth cooperating with, apart from looking at the price, delivery time and service, one of the most core judgment criteria is the PCB manufacturing equipment it is equipped with. You need to check whether the manufacturer's PCB equipment is advanced, complete and matches the technical requirements of your products. Because the capabilities of the equipment can directly determine the accuracy, consistency, yield and delivery capacity of the circuit board. Here are a few points for your reference, hoping to help you determine whether a manufacturer is professional and reliable based on the level of PCB equipment:

1. Check whether the PCB manufacturer's process equipment is advanced. A high-quality PCB manufacturer should be equipped with high-end PCB manufacturing equipment, including: LDI exposure machine, multi-layer laminating machine, automatic electroplating line, PCB drilling machine and panel cutting machine. The more advanced the equipment is, the stronger its manufacturing capacity in the fields of high-frequency, high-speed and high-density boards will be.

2. Check whether the manufacturer's inspection and testing equipment is complete. A reliable PCB manufacturer will be equipped with complete PCB inspection equipment and PCB testing equipment, such as: AOI, X-ray inspection equipment, flying probe testing /FCT/ICT, 4-wire Kelvin test equipment, etc. These devices can significantly enhance the quality assurance capability of products before shipment.

3. Check whether the manufacturer has the capabilities of automation and intelligence. Advanced manufacturers usually also invest in automatic testing equipment, intelligent logistics systems and MES tracking systems to achieve full-process traceability and efficiency optimization from production to testing. This is crucial for large-scale delivery and highly consistent products.

When choosing a suitable PCB manufacturer, it is necessary to see whether it has a complete, advanced and professional PCB equipment system. The level of equipment not only reflects the technical capabilities of the manufacturer, but also directly affects the delivery time, quality and stability.

Evaluating the equipment level of a PCB is a crucial but often overlooked core criterion in the process of choosing a PCB manufacturer. Advanced PCB manufacturing equipment not only enhances production efficiency but is also directly related to product quality, technical capabilities, and the reliability of subsequent delivery. Whether you are focused on HDI boards, multi-layer boards, or high-demand PCBs, only manufacturers with a complete PCB equipment system can truly support you in achieving the performance goals and delivery commitments of your products. Welcome to learn about PCBasic - your trusted PCB manufacturer.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.