Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Get Reliable PCB Assembly Services from PCBasic in China

The Printed Circuit Boards are the base of a modernistic electronic device, and there is no modernistic electronic device that can function without one. Circuit boards are an essential component for all electronic devices from small smartphones to large industrial equipment as they are a connecting base that provides a platform to mount many electronic components into one unit. Circuit boards are necessary to support the manufacturing of many electronic products. We all know PCB manufacturing is the way to make bare boards, and PCB assembly (PCBA) is used to make these bare boards into integral parts of electronics.

If you happen to have PCB fabrication or board assembly needs, then come to PCBasic. PCBasic is committed to providing reliable PCB assembly services, whether it is custom PCB design or printed circuit board assembly, PCBasic can meet your every need.

If you paid some attention to electronics before, then you already know how great influence circuit board quality and its assembly has on the device. Bare boards are fabricated by printed circuit boards manufacturers based upon the design, and assemblers mount components such as resistors, capacitors and diodes onto circuit boards to form complete, functional electronic modules. The entire assembly process ensures seamless connection and optimal performance between components, it is the basis for the efficient operation of modern electronic devices.

However, with the evolution of technology, and the update of equipment, the PCBs that only process relatively simple signals cannot meet the new needs, and is replaced by some advanced PCBs. Whether it is a prototype PCB for initial testing or a finished product for mass production, reliable PCB manufacturing and printed circuit assembly are essential to ensure the quality and performance of the final product.

PCBasic is a leading PCB manufacturing and PCBA supplier focused on providing one-stop services, including fast multi-variety production of small and high volume PCBAs. As an innovative PCBA company, PCBasic is committed to providing online PCB design, PCB manufacturing and comprehensive PCB assembly services. With speed, quality and technology and service as the core values, PCBasic provides tailor-made solutions for your PCB needs.

PCBasic's services are not limited to PCB manufacturing, but also cover R&D support, material selection and OEM production. With self-developed CRM, MES, ERP and IoT management systems, PCBasic has built an intelligent digital factory designed to optimize the PCB assembly process at each step. PCBasic's core service areas include industrial control, smart home, instrumentation, vehicle networking, communication power, medical equipment, automotive electronics and aerospace.

As a trusted PCB manufacturing and assembly company, PCBasic has obtained a number of authoritative certifications, including ISO9001, IATF16949 and ISO13485, and has been recognized as a national high-tech enterprise. In addition, PCBasic has more than 200 professional employees, including more than 30 PCB design engineers, 20 quality management experts, 10 IT experts and 2 research and development personnel.

At the same time, PCBasic can provide 7x24 hours of support, and is committed to providing customers with fast and professional prototype PCB assembly services.

With over 15 years of expertise in the SMT industry, PCBasic has consistently addressed complex challenges in PCB manufacturing and PCB assembly. Our continuous investment in advanced PCBA technology has resulted in the development of intelligent production management systems that improve efficiency and ensure exceptional quality.

PCBasic's innovations include:

Self-developed LCR incoming inspection system for component quality assurance

SMT fault detection system to minimize errors in PCB assembly

Sample patch systems for precise prototyping

Advanced MES systems for seamless production management

Intelligent material rack to optimize inventory workflows

Cutting-edge ESD electrostatic protection systems for sensitive components.

PCBasic is committed to providing customers with efficient, transparent and high-quality PCB and PCB assembly services, seamless from design to delivery.

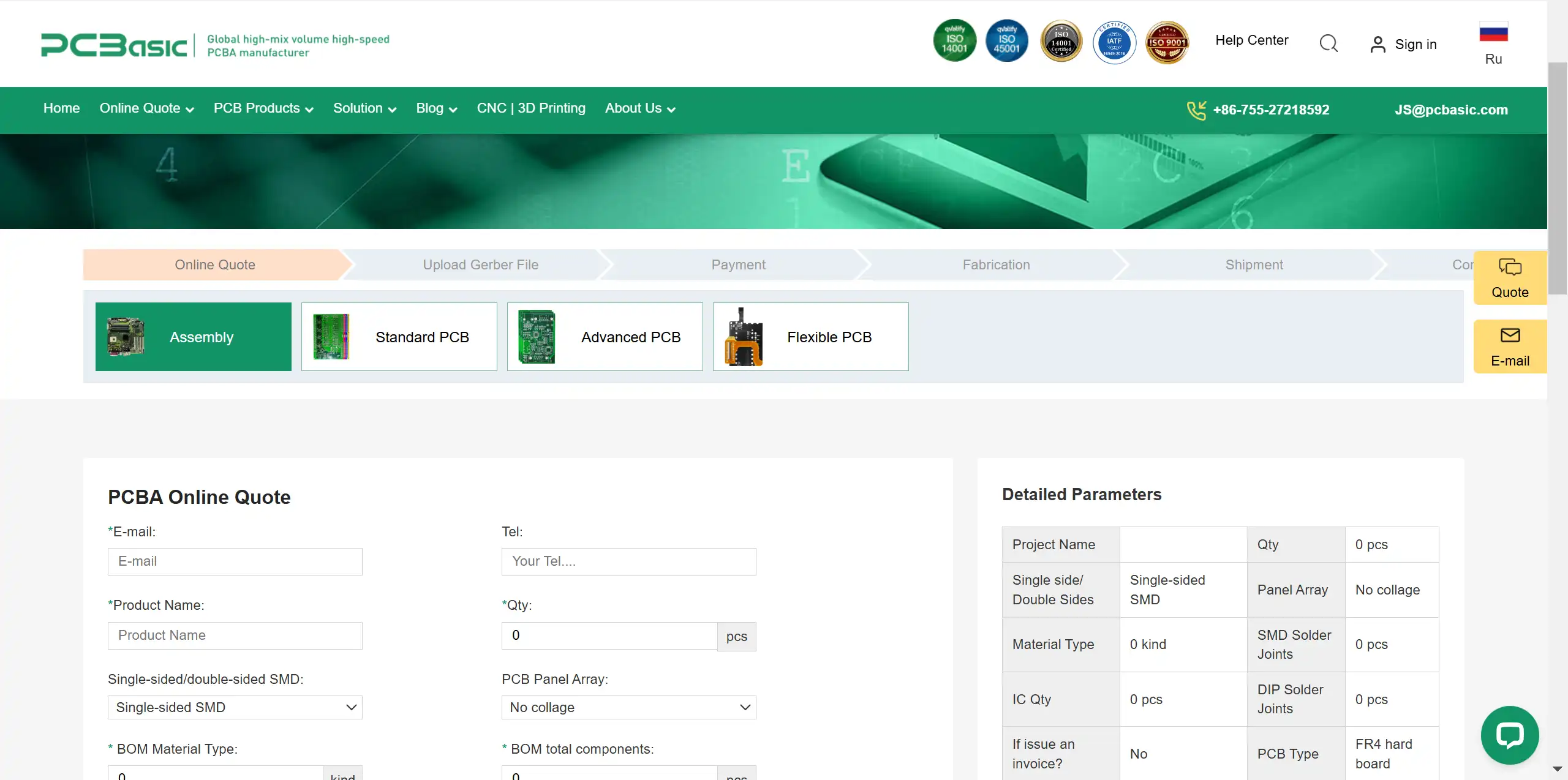

Submission of Requirements: Customers can submit design files, such as Gerber files, BOM lists, assembly drawings, and other technical documentation, via PCBasic.com or other channels. Upon receiving the request, PCBasic representatives confirm project specifications, including board material type, layer count, surface finish, assembly requirements, production volume, lead time, and any special requirements.

Engineering Evaluation and Quotation: After confirming the requirements, PCBasic's engineering team conducts a DFM review to ensure the design is production-ready. The team also evaluates the assembly process and any special requirements. Upon completing the evaluation, a detailed quotation is provided based on materials, components procurement, process complexity, and lead time. Production begins upon customer approval of the quotation.

PCB Fabrication and Assembly: Based on the provided design documents, PCBs are manufactured and assembled with rigorous quality control. Every PCB undergoes AOI (Automated Optical Inspection) and electrical testing to ensure there are no shorts or open circuits.

Throughout the production process, MES systems enable real-time monitoring and data collection to ensure high precision and efficiency. After assembly, functional testing is conducted to verify the performance and reliability of every PCBA board.

Pre-Shipment Inspection: PCBasic adheres to ISO9001 and IATF16949 quality management systems, ensuring strict quality checks at every production stage. ESD (Electrostatic Discharge) protection systems are utilized to prevent static damage, guaranteeing safe shipment of products.

Customers may request sample confirmation to ensure that large-scale production fully meets expectations before proceeding.

Packaging and Logistics: PCBasic uses professional packaging methods, including anti-static packaging and shockproof protection, to ensure safe product transportation. Multiple shipping options are available, including express delivery, air freight, and sea freight. With global shipping services, customers can track their order status at any time.

A good PCBA manufacturer becomes especially important in the fast- and quality-driven electronics industry, as efficient and trustworthy PCB manufacturing and assembly services contribute to high-quality innovative products.

Whether you need a PCB prototype to test a new design or need to mass-produce a mature product, PCBasic is your trusted partner. Choose PCBasic for all your PCB manufacturing and PCB assembly needs and experience the difference high-quality service makes.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.