Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: Your Trusted PCBA Supplier in China

China has emerged as a global hub for PCB manufacturing and PCB assembly services, providing high-quality solutions at competitive prices. Among the many players in this industry, PCBasic stands out as a reliable PCB assembly manufacturer with a proven track record of delivering excellence.

Whether you need PCB prototypes, custom PCB fabrication, or complete circuit board assembly services, PCBasic offers comprehensive solutions tailored to your specific requirements. In this blog, we’ll explore why PCBasic is a leading PCBA supplier in China, how we cater to diverse industries, and the advantages of partnering with us for your PCB manufacturing and assembly needs.

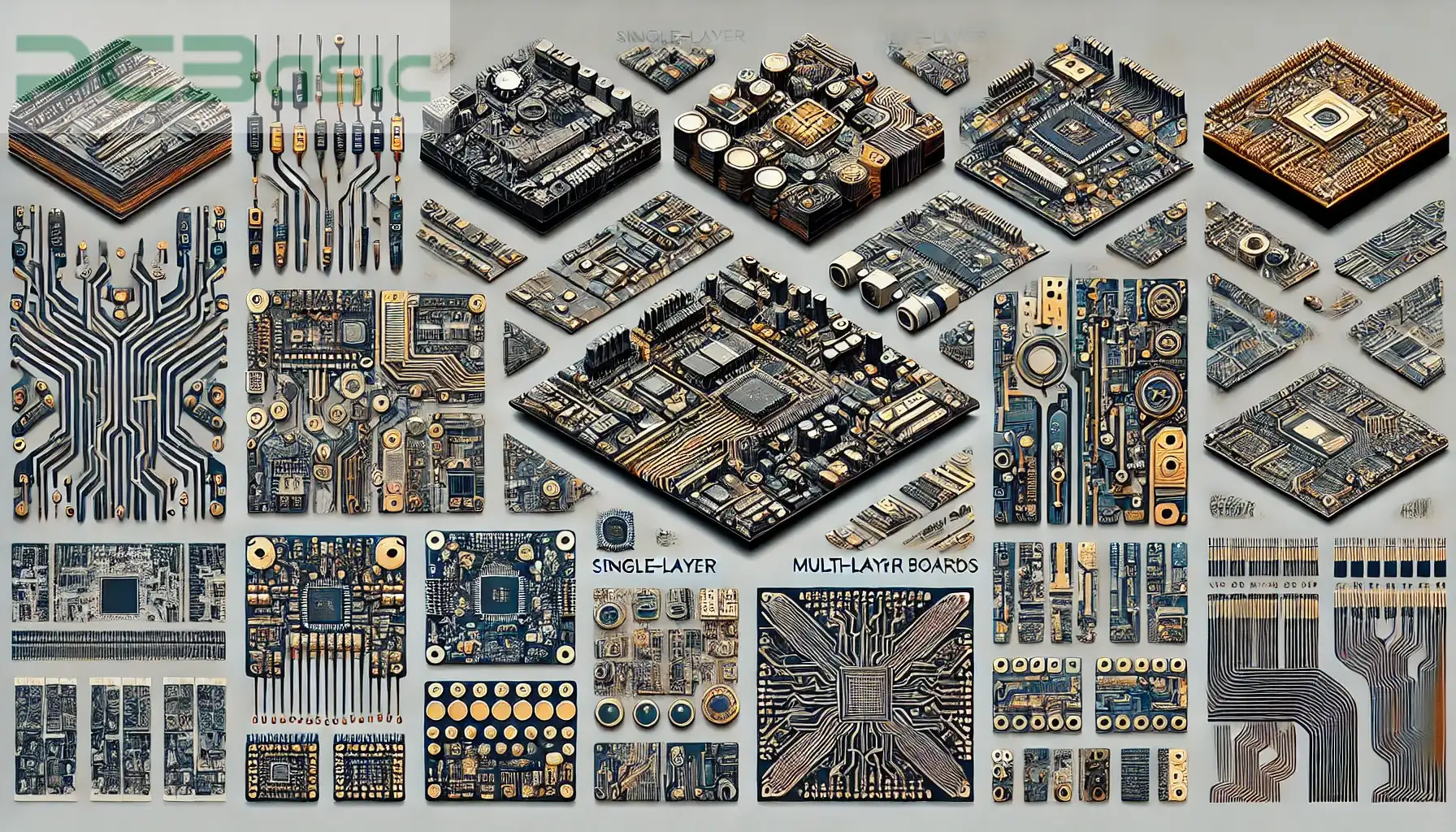

PCBasic provides end-to-end PCB assembly services, covering everything from prototype PCB assembly to full-scale production. Whether you need a single-layer PCB prototype or a multi-layer board with complex requirements, we have the expertise and technology to deliver on time and within budget.

As a leading PCB manufacturer, PCBasic specializes in PCB fabrication using state-of-the-art equipment and advanced techniques. Our precision manufacturing ensures high-quality PCB boards that meet the most stringent industry standards, making us a trusted partner for printed circuit board manufacturers worldwide.

At PCBasic, we understand that every project has unique requirements. That’s why we offer custom PCB design and manufacturing services. Whether you need a compact design for consumer electronics or a robust solution for industrial applications, our team works closely with you to create a PCB tailored to your specifications.

Our prototype PCB assembly services are designed for rapid development, enabling you to test and refine your designs before moving into full-scale production. With quick turnaround times and precise assembly, we help you accelerate your product development process.

Being located in China gives PCBasic access to a vast supply chain of components and materials, allowing us to offer competitive pricing without compromising on quality. Additionally, our streamlined manufacturing processes ensure efficiency at every stage of production.

PCBasic’s PCB manufacturing and assembly process is designed to deliver quality and efficiency. Here’s how we do it:

Step 1: PCB Prototype Fabrication

The process begins with PCB prototype fabrication, where we transform your design files into a physical PCB for initial testing. Our engineers use advanced tools and software to ensure accuracy and precision in every prototype.

Step 2: Component Sourcing

We source high-quality components from reliable suppliers, ensuring that each part meets the specifications of your design. With access to a robust supply chain in China, we can procure components quickly and cost-effectively.

Step 3: PCB Assembly

Our PCB assembly services include surface mount technology (SMT) and through-hole technology (THT). Using automated pick-and-place machines, reflow ovens, and wave soldering equipment, we ensure precise and reliable assembly for every board.

Step 4: Inspection and Testing

Quality assurance is a top priority at PCBasic. We use advanced inspection methods such as automated optical inspection (AOI) and X-ray testing to verify the integrity of every board. Functional testing is also performed to ensure the PCB meets your performance requirements.

Step 5: Delivery and Support

Once assembly is complete, we carefully package and deliver your boards. Our team provides ongoing support to address any questions or concerns, ensuring a seamless experience from start to finish.

As a trusted PCB assembly manufacturer, PCBasic caters to a wide range of industries, including:

Our versatile capabilities make us a preferred partner for clients across diverse sectors.

1. High-Quality Standards

PCBasic adheres to stringent quality control measures at every stage of PCB manufacturing and assembly, ensuring that every board meets industry certifications such as IPC and ISO standards.

2. Cost-Effective Solutions

Leveraging China’s extensive supply chain and efficient manufacturing infrastructure, PCBasic offers competitive pricing for all PCB assembly services without compromising on quality.

3. Rapid Turnaround Times

Our efficient processes and advanced equipment enable us to deliver projects on time, whether it’s a quick-turn PCB prototype or a large-scale production order.

4. Custom PCB Expertise

From design to delivery, we provide tailored solutions to meet your specific needs, ensuring that your project is executed to perfection.

Partnering with PCBasic is simple and efficient. Here’s how you can get started:

1. Contact Us: Reach out with your project requirements, whether it’s a custom PCB design or a request for PCB assembly services.

2. Submit Your Design Files: Share your Gerber files or other design documents so our engineers can review and prepare an accurate quote.

3. Receive a Quote: Get a transparent and detailed quote for your project, including costs for PCB fabrication, components, and assembly.

4. Approve and Begin Production: Once you approve the quote, we’ll move your project into production and keep you updated every step of the way.

PCBasic has established itself as a leading PCBA supplier in China, offering comprehensive PCB manufacturing and assembly services to clients worldwide. Whether you need prototype PCB assembly, custom PCB fabrication, or full-scale production, PCBasic delivers high-quality solutions tailored to your needs.

By combining advanced technology, competitive pricing, and a commitment to quality, PCBasic ensures that your electronic products are built to perform. Contact us today to learn more about our PCB assembly services and how we can help you achieve your project goals with precision and efficiency.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.