Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How to Solder Wires: The Complete Guide for Beginners

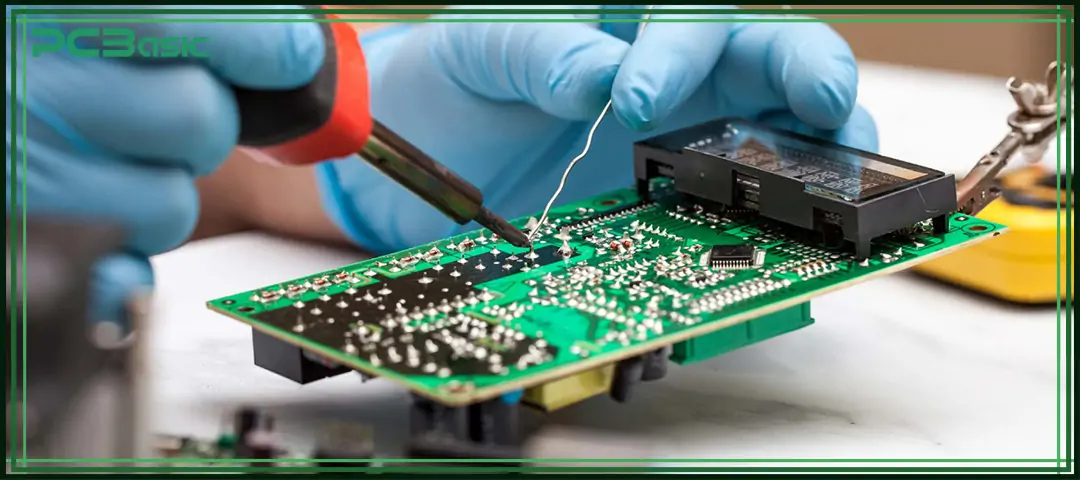

Learning how to solder wires is the most fundamental and commonly used skill in the electronics industry and home repairs. From the early radios and television repairs to today's smart home appliances, automotive electronics, robots and PCB prototyping, soldering wires has always been the core process for connecting various electrical systems. Even though the automated equipment is widespread today, hand soldering remains irreplaceable - many repairs, custom modifications, and prototype builds need to be done manually, which is why mastering how to solder wires is still so important.

Whether you are fixing a broken power cable, connecting sensors in a robot project, repairing the circuit of a refrigerator, or learning how to solder wires to a circuit board, the correct soldering method can ensure stable, safe and long-term reliable electrical performance.

This guide provides a truly complete and understandable teaching framework for beginners, covering soldering wire usage, wire soldering techniques, common tools, preparatory work, standard operating procedures, solder joint inspection, and solutions to common problems. You will also learn about the composition and selection methods of electrical wire soldering, and master the key skills of how to solder copper wire, making your soldering stronger and more reliable.

This is a practical guide suitable for beginners, engineers, repair technicians and DIY equipment enthusiasts, enabling you to master truly effective soldering methods in the shortest time.

Soldering is the process of joining two metal surfaces together using a metal material with a melting point lower than 450°C-known as wire solder or electrical solder wire. When heated, the solder melts and flows onto a clean metal surface. Once it cools down, it forms a solder joint that is both conductive and mechanically strong.

In wire soldering, these solders are usually Sn60/Pb40 leaded solders, or SAC305 lead-free solders. When they melt, they will firmly connect the wires, allowing the current to pass through smoothly. To ensure reliable solder joints, it is generally necessary to have the right temperature, a clean metal surface, active flux, the correct solder copper wire alloy, and enough mechanical stability at the connection point, so that the solder joints are less likely to break.

Before learning wire soldering, it is very important to first clarify the differences between soldering, brazing and welding. Many beginners tend to confuse them, but in fact, their temperatures, uses, and applications are completely different. Understanding these differences can help us master more accurately how to solder wires.

• Welding: melts base metals together at extremely high heat. Not used for electronics.

• Brazing: uses high-temperature filler metal (>450°C).

• Soldering: low-temperature wire soldering below 450°C—safe for electronics and insulation.

This is the most common practice for beginners when learning how to solder wire. Wire-to-wire soldering is simple:

• Twisting strands

• Creating a mechanical bond

• Heating and applying solder to copper wire

• Protecting with heat-shrink tubing

When learning how to solder wires to a circuit board, through-hole soldering is the most commonly used method.

• Insert the stripped wire into the plated hole

• Bend and secure

• Heat pad + wire

• Feed electrical soldering wire

• Form a clean fillet

If there are no through-holes on the circuit board, the wires need to be directly soldered onto the surface of the pads.

• Thorough cleaning

• Pre-tinning

• Careful heat application

• Excellent strain relief

To effectively learn how to solder wires, beginners need to prepare some basic but reliable tools.

|

Category |

Item |

Description |

|

Core Tools |

Adjustable Temperature Soldering Iron (300–400°C) |

A soldering iron with a controllable temperature for different solder alloys. |

|

Soldering Station with Stand & Sponge |

Holds the soldering iron safely and allows tip cleaning. |

|

|

Assorted Soldering Iron Tips (Conical, Chisel, etc.) |

Different tip shapes for various solder joints. |

|

|

Wire Stripper |

Used to remove insulation cleanly without damaging the conductor. |

|

|

Helping Hands / Clamps |

Holds wires or PCBs steady during soldering. |

|

|

Heat Gun |

Used to shrink heat-shrink tubing. |

|

|

Tweezers, Cutters |

For gripping, positioning, and trimming wires. |

|

|

Materials |

Electrical Solder Wire (Rosin Core) |

Solder wire with built-in rosin flux for easier soldering. |

|

Lead-Free or Leaded Solder (SAC305 or Sn60/Pb40) |

Common solder alloys used in electronics. |

|

|

Rosin Flux Paste or Flux Pen |

Enhances solder flow and removes oxidation. |

|

|

Heat-Shrink Tubing |

Provides insulation and strain relief for soldered joints. |

|

|

IPA (Isopropyl Alcohol) |

Used to clean pads, wires, and flux residues. |

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

When learning how to solder wires, the more thoroughly you prepare in advance, the cleaner, more stable and more repeatable the solder joints will be.

When stripping the wire, use a wire stripper to remove about 1/4 to 1/2 inch of the insulation layer. Do not use scissors or knives, nor break or cut the copper wire; otherwise, it will affect the subsequent solder quality.

Stranded wires tend to flare outward after stripping, which is called birdcaging. To avoid this situation, you can gently twist the copper wire and apply a little flux. In this way, when soldering wires, the solder is more likely to penetrate evenly into the copper wire.

Before soldering, it is best to clean the wires and PCB pads with IPA (isopropyl alcohol) to remove oils, fingerprints, dust and oxidation. The cleaner the metal, the less effort and the smoother the wire soldering.

Pre-tinning is a crucial step in learning how to solder copper wire. It can reduce the heating time for formal soldering, prevent the insulation layer from being damaged by heat, and also make the solder joints more secure.

The following 9 steps are the most complete and practical workflow for beginners to learn how to solder wires.

First of all, the insulation layer of the wire needs to be stripped clean. Generally, a length of 1/4 to 1/2 inch is sufficient. When stripping the wire, keep the copper wire neat and uniform, and do not damage the conductor. Only in this way can the subsequent solder joints be firm.

Before soldering, put the heat-shrink tubing onto the wire in advance and move it away from the solder joint. Heat-shrink tubing can only be used after soldering.

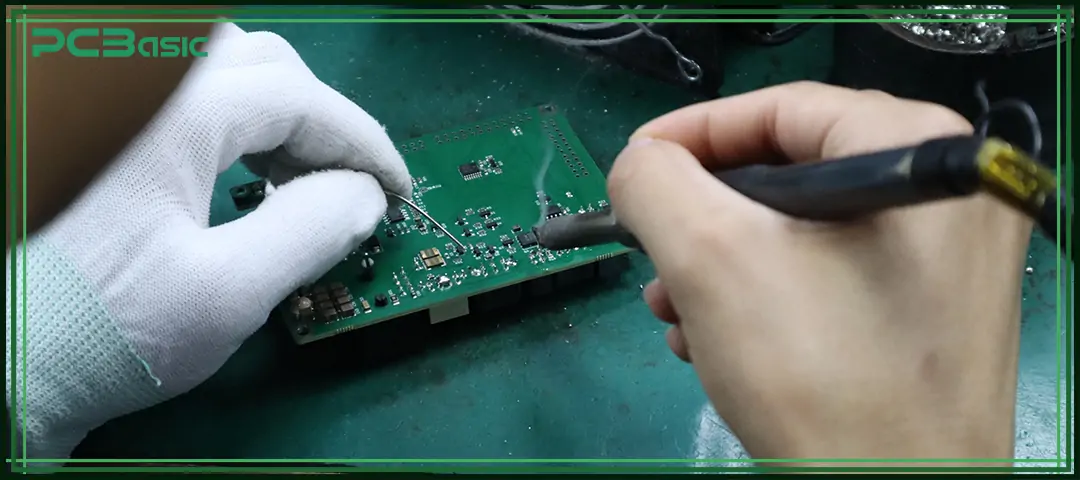

Apply a thin layer of flux, which can remove the oxide layer and make the melted electrical solder wire flow smoothly and wet the copper surface.

Heat the copper from underneath, then feed the solder copper wire from the top to coat the copper wire with a thin layer of tin.

Before adding solder, make sure the wires are mechanically stable. For wire-to-wire connections, hook and twist the strands together. For PCB soldering, insert the wire through the plated hole and bend it slightly to hold it in place.

When soldering, let the soldering iron touch both the wire and the pad at the same time to heat them up together. Once everything reaches the right temperature, the solder will flow more easily.

Bring the electrical soldering wire close to the solder joint, not on the tip of the soldering iron. Let the heat from the joint melt the solder naturally and flow into the connection.

After soldering, do not touch the solder joint immediately. Let it cool down naturally. When inspecting, check if the solder joints are smooth and shiny, without cracks, voids, or excess solder. A qualified solder joint should be both clean and mechanically reliable.

After the solder joint is completely cooled, slide the previously prepared heat-shrink tubing back to the solder joint position, and heat it evenly with a heat gun to shrink it evenly so it tightly covers the solder joint, providing insulation and strain relief.

To make sure the solder joint is reliable, you can check it in a few simple ways:

Look at the solder joint and check whether it has a smooth, concave shape. The solder should fully wet the wire and the pad, and the surface should not appear dull, grainy, or gray—signs of a cold joint.

Use a multimeter to check for continuity. This ensures that the signal can pass through the joint without interruption.

Gently pull the wire. A good solder joint should stay firm and should not loosen or detach.

Even if the tools are fully prepared, beginners still tend to encounter various common problems when soldering. Understanding the causes of these errors and knowing how to fix them correctly can greatly enhance the quality and reliability of solder joints.

|

Issue |

Appearance / Symptoms |

Main Cause |

Solution |

|

Cold Joint |

Dull, gray, grainy surface; weak mechanical strength |

Insufficient heat, movement during cooling, oxidized metal surfaces |

Reheat the joint, add flux, and apply the right amount of wire solder |

|

Excess Solder / Solder Bridge |

Large solder blob; two pads unintentionally connected |

Too much solder, uneven heating |

Remove excess solder with desoldering braid |

|

Overheating |

Lifted pads, melted insulation, and discoloration on PCB |

Iron temperature too high or heating too long |

Lower the temperature or switch to a larger iron tip to reduce heating time |

|

Dirty Iron Tip |

Solder won’t stick to the tip; solder flow becomes inconsistent |

Oxidized or contaminated soldering tip |

Clean the tip on a damp sponge and keep it tinned frequently |

|

Poor Wetting |

Solder beads up, does not spread; uneven coverage on wire or pad |

Dirty or oxidized copper, insufficient flux |

Clean the copper surface and apply fresh flux to allow proper solder flow |

Learning how to solder wires is one of the most fundamental and important skills in the electronics industry, DIY repairs and product prototyping. Whether you are connecting cables, repairing household appliances, or learning how to solder wires to a circuit board, the quality of soldering depends on several core elements: the metal surfaces must be clean, the tools must be selected correctly, the flux must play its role, the solder joint itself must have mechanical strength, temperature control must be precise, and high-quality electrical solder wire must be used.

With repeated practice, patience and attention to detail, anyone can master wire soldering and soldering skills, truly learn how to solder copper wire, and make professional-level solder joints.

1. What temperature should I use for soldering wires?

• Leaded solder: 315–350°C

• Lead-free solder: 360–400°C

• Larger wires require more heat

2. Should I use leaded or lead-free solder?

Leaded solder is easier for beginners; lead-free solder is environmentally safer.

3. Why is flux so important?

Flux removes oxides, improves wetting, and ensures smooth wire soldering.

4. How long will soldered wires last?

A properly soldered joint can last decades.

5. Can electricians solder home wiring?

No. Electricians use wire nuts; soldering is not permitted for household AC wiring.

6. How much solder is enough?

Just enough to create a concave fillet—no large blobs.

7. Can stranded wires be soldered on PCBs?

Yes. Pre-tin strands and insert them as a single conductor.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.