Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > High-Volume Quick-turn PCB Assembly with PCBasic

In the rapidly developing electronic manufacturing industry today, high-volume quick-turn PCB assembly has become an important way for enterprises to expand production capacity and improve efficiency. Whether it is developing new products or enhancing existing production capacity, the combination of high-volume PCB assembly and quick-turn PCB assembly can achieve faster delivery, higher precision and lower cost. PCBasic focuses on providing high-volume quick-turn PCB assembly services that meet the demands of modern electronic manufacturing.

High-capacity rapid delivery of PCB assembly means completing a large number of PCB assembly productions in a short period of time. Traditional PCB assembly usually takes 2 to 3 weeks, but by quick-turn PCB assembly, the delivery time can be shortened to just a few days. Although there is no unified standard, PCBasic regards orders of more than 5,000 pieces as high-capacity PCB assembly.

This kind of service is very important for enterprises that need to quickly transfer the PCB assembly prototype to mass production. Quick-turn PCB assembly can help enterprises quickly modify prototype designs, shorten development time and accelerate the time to market. High-volume and quick-turn PCB assembly is currently widely used in industries such as defense, medical care, aerospace, and consumer electronics, where both delivery time and output are highly demanded.

The development of modern electronics is evolving rapidly, and high-volume quick-turn PCB has emerged as a transformative solution for accelerating mass production, reducing time to market for product success, and offering design engineers the ability to rectify their prototype designs rapidly to ensure accuracy and efficiency.

PCBasic quick-turn PCB service uses advanced techniques to reduce mass production time, ensuring companies adopt market needs timely and stay one step ahead of their competitors. PCBasic reduces lead time from weeks to days in high-volume quick-turn PCB service and ensures customers' critical needs for rapid prototyping and quick mass production.

High-volume PCB assembly means manufacturing of mass production of PCBA in bulk quantities. Manufacturing high-volume PCB assembly needs advanced technical equipment such as a self-operated stencil and fixture factory and CNC precision parts processing to ensure high precision and fulfill the exact specifications of printed circuit board set by the designer. By utilizing advanced technologies, PCBasic produces a high volume of PCBs in a short period with precision and accuracy.

Therefore, high-volume PCB assembly is the most effective solution used by industries for producing high-quality and low-cost PCBs. High-volume PCB assembly service is a great choice for applications such as consumer electronics, automobiles, medical, and gadgets.

Quick-turn PCB assembly means manufacturing PCBA, whether small batch or mass production, in a stipulated time. The major difference between manufacturing quick-turn PCBs and conventional PCBs lies in their manufacturing speed and volume. The quick-turn PCB service major focuses on manufacturing speed irrespective of PCB assembly volume. Conventional PCB lead time is 2-3 weeks, whereas quick-turn PCB assembly minimum lead time is 24-48 hours.

Customers can benefit from quick-turn PCB assembly services such as reducing time to market for product success, offering industries to swiftly adopt technological advancements and staying one step ahead of market competitors. Utilizing quick-turn PCB assembly service allows industries to save money by quickly reefing the prototype designs before mass production.

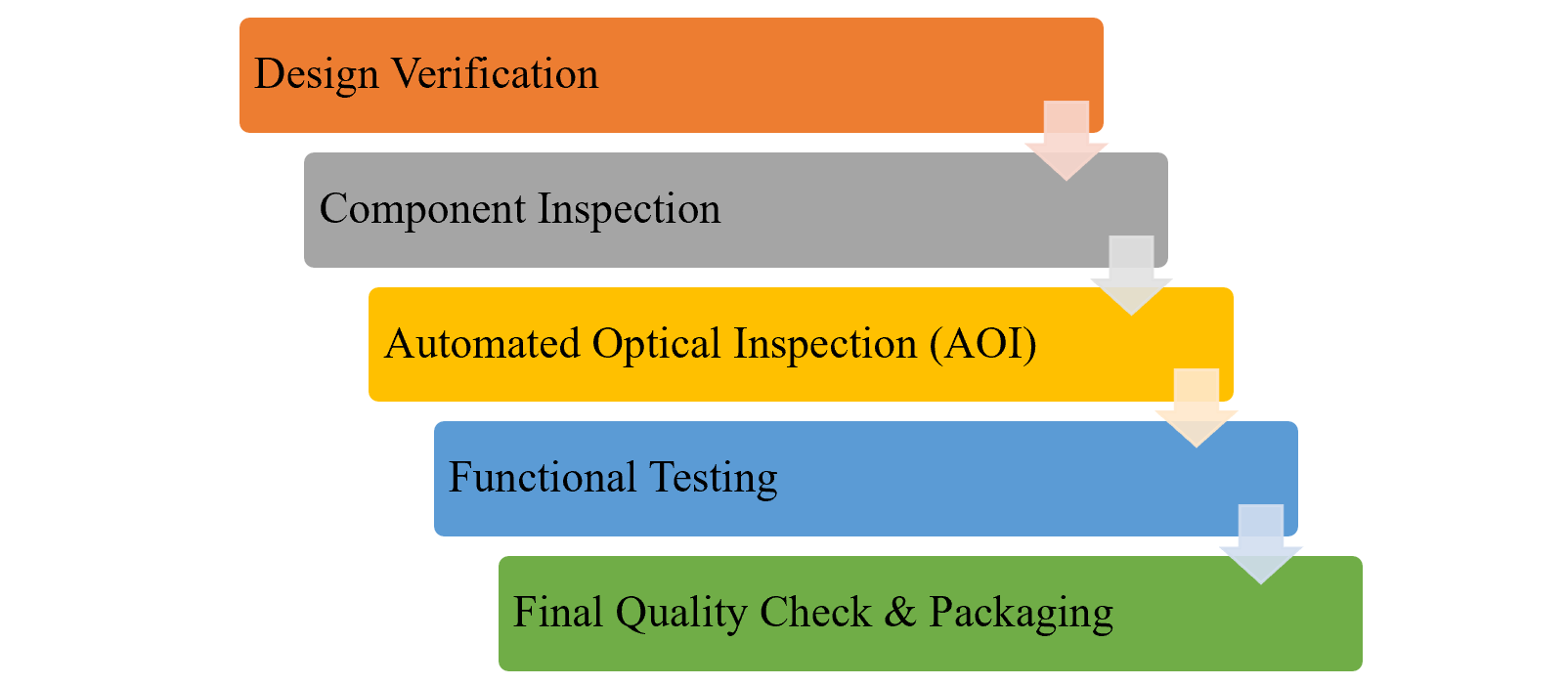

A highly effective quality control process reflects quick-turn PCB assembly precision and accuracy. A typical quality control process for a quick-turn PCB assembly involves the following steps.

Combining high-volume PCB with Quick-turn PCB offers distinct advantages, including reduced time to market, rapid prototype PCB assembly, small batch and mass production PCB assembly, cost savings, fast production time, and many more.

1. Improved Efficiency: High-volume quick-turn PCB assembly enhances efficiency by reducing lead time and labor costs.

2. Faster Time-to-Market: High-volume and quick-turn PCB assembly service allows industries to refine their prototype designs quickly, resulting in a faster production cycle and allowing industries to launch their products into the market quickly to stay ahead of market competition.

3. Cost Savings: With high-volume manufacturing per unit, the cost of PCB is reduced, which eventually reduces the product cost and makes the product more affordable for the end customer.

4. Minimum Design Flaws: Quick-turn allows designers to identify potential PCB flaws on time and rectify them faster. Final design goes into mass production faster to capture the market demands on time and allow industries to generate revenue.

5. Enhanced Quality Control: Producing a high volume of PCBs in quick turn required PCBA manufacturing companies to streamline quality control processes. PCBasic complies with international standards such as ISO 13485, IATF 16949, ISO9001, and ISO140001, making it a leading high-volume quick-turn PCBA manufacturer.

PCBasic is a leading high-volume quick-turn PCBA manufacturer across the globe, offering its clients rapid production of PCBs with high-quality standards. PCBasic has over 10 years of experience in PCBA manufacturing, both small-batch and high-volume. PCBasic has a reputation for producing quick-turn PCBs in a record time of less than 48 hours.

Simply put, PCBasic provides a one-stop solution for all your needs, from manufacturing to procurement and PCB testing. PCBasic ensures that your PCB assembly meets all design specifications and complies with international quality standards.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Are you looking for a high-volume quick-turn PCB manufacturing service? Congratulations, you have landed in the right place. PCBasic is a leading high-volume quick-turn PCB manufacturer offering its customers distinct features.

1. Advanced Manufacturing Technologies: PCBasic has SMT, THT, and mixed-signal technology, offering a one-stop solution for all your design needs. With its self-operated stencil and CNC precision equipment, it ensures precision in your design.

2. Advanced Quality Control: PCBasic is a member of IPC and has international quality standard certifications that reflect PCBasic commitment to ensuring quality control in the entire manufacturing process.

3. Reduce Lead Time: With high-volume quick-turn PCB, PCBasic offers a minimum lead time to its customers with a minimum of less than 48 hours.

4. Higher Efficiency: PCBasic has an automated fixture factory and automated pick-and-place machines to prevent human involvement, resulting in higher efficiency.

5. Cost Savings: PCBasic provides its customers with High-volume quick-turn PCB service at competitive market rates that result in reduced per unit cost and save customers money.

In conclusion, high-volume quick-turn PCB assembly is a transformative tool for industries, small businesses, and start-ups to accelerate their product's mass production, reducing time to market for product success and allowing engineers to validate their design prototypes rapidly to stay ahead of their market competitors.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.