Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How to Find Trustworthy PCBA Suppliers for International Buyers

Choosing the right PCBA supplier is important to hardware companies, OEMs and start-up teams worldwide. Whether you need prototype PCB assembly or small-batch PCB assembly, or it is the latter mass production PCB assembly, a reliable PCB assembly manufacturer can directly affect your product quality, production speed and future market competitiveness.

This guide compiles the key points of several industry articles, with the aim of helping international buyers determine which PCBA manufacturers are reliable and which are not, and teaches you how to evaluate from aspects such as technical strength and supply chain capabilities, thereby reducing various common risks when cooperating with overseas electronic manufacturing services. Finally, this article will also explain why PCBasic has become the preferred Chinese PCBA manufacturer for many global customers, and why it is a truly reliable turnkey PCB assembly partner.

Nowadays, the competition in the electronics industry is extremely fierce. Products are updated rapidly, technical requirements are high, and the component supply chain is becoming increasingly complex. Therefore, finding a reliable PCB assembly supplier is more important than ever.

International buyers often encounter various troubles when cooperating with overseas PCBA manufacturing, such as inconsistent printed circuit board assembly quality, counterfeit components, poor SMT workmanship, miscommunication during engineering reviews, delayed timelines due to weak supply chain planning, unstable production when scaling from prototype to mass manufacturing and so on.

A powerful PCB assembly manufacturer can help you avoid these risks through professional engineering support, strict quality control, reliable sourcing and clear and transparent communication.

This article will introduce to you step by step how to select the most reliable China EMS provider, enabling you to reduce the cost of trial and error in cooperation and avoid falling into common traps.

Before choosing a PCBA supplier, you must prepare clear and complete technical materials. The more comprehensive the information is, the more accurate the supplier's quotation will be, and the more controllable the quality expectation will be.

You need to first determine the basic parameters of your PCBs, such as the number of layers, thickness, stack-up, material type (FR4, Rogers, ceramic), impedance requirements, via structures (through-hole, blind, buried, via-in-pad), and surface finish (ENIG, HASL, OSP).

The BOM must clearly state the brand of the components, the approved manufacturer, the rules for acceptable alternative materials, whether there is a risk of production suspension or shortage of components, and which special materials are to be provided by the buyer.

You need to inform the supplier of your planned production volume, whether it is for a PCBA prototype, small-batch PCB assembly, or if you will enter mass production PCB assembly in the future.

You need to clearly define the mandatory test contents, such as AOI, SPI, X-ray (especially for BGA), ICT, FCT, burn-in testing, thermal cycling, and whether firmware programming is needed.

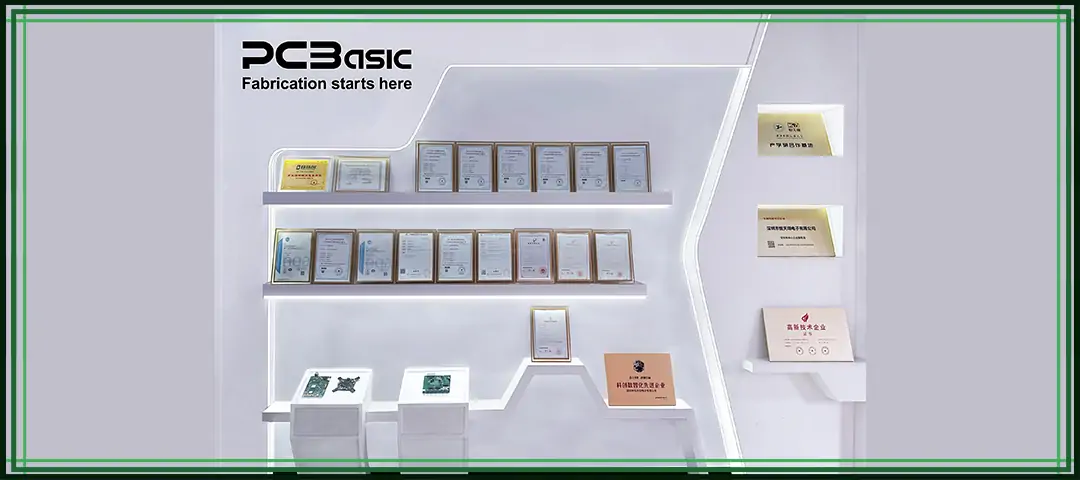

Relevant certifications are one of the fastest ways to determine whether a PCB assembly supplier is mature and reliable.

Common and important certifications include:

• ISO 9001 — universal quality management

• ISO 13485 — medical electronics

• IATF 16949 — automotive electronics

• IPC-A-610 & J-STD-001 — soldering workmanship

• RoHS / REACH compliance

A truly reliable Chinese PCBA manufacturer must provide genuine and valid certification documents instead of merely displaying promotional images on its website. These certifications can ensure that its printed circuit board assembly process complies with internationally recognized quality standards.

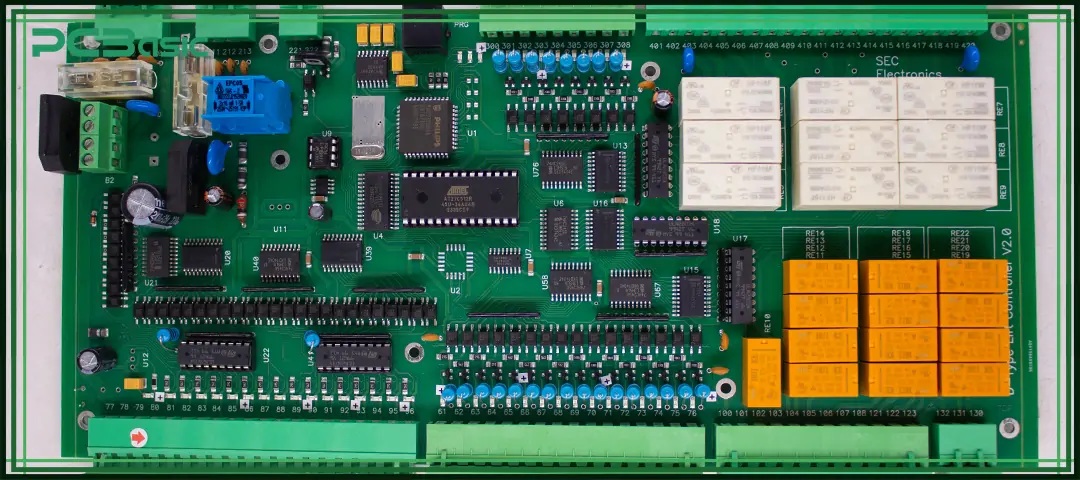

A truly reliable PCB assembly manufacturer must possess advanced production equipment and strong engineering capabilities, rather than merely relying on low-cost labor and highly competitive prices.

You need to confirm whether the supplier has SMT assembly capabilities to handle various SMT production issues. Advanced SMT production lines can directly enhance the overall quality of high-reliability PCB assembly.

A reliable PCBA supplier should possess a variety of inspection capabilities, including SPI, AOI, 3D X-ray, and ICT/FCT.

You also need to confirm whether this company has engineering support capabilities, such as Gerber file optimization or early detection of potential problems in PCB design.

In PCBA production, most problems stem from substandard components or those of unknown origin. Therefore, a powerful turnkey PCBA manufacturer must rely on authorized channels for procurement and provide complete traceability. For international buyers, component transparency is one of the most effective ways to reduce risks and avoid potential quality issues.

To judge whether a PCBA supplier is reliable or not, the most crucial thing is to look at its quality control. You need to confirm whether it really strictly controls each production stage, such as:

• IQC material inspection

• Paste inspection (SPI)

• Reflow profiling

• AOI 100% inspection

• 3D X-ray for BGA and QFN

• ICT/FCT test coverage

• Environmental and reliability testing

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

For international buyers, whether communication is timely and professional is important, as even the slightest misunderstanding during the production process can lead to serious quality or progress issues.

A reliable PCB assembly supplier will reply within 2 to 4 hours, proactively update the project progress during production, have professional engineers who can provide technical advice, and be willing to share photos, videos and test reports during the production process, allowing you to clearly understand each step.

A truly stable China EMS provider will also have a mature project management process and provide clear and executable after-sales service, making the cooperation process more reassuring.

Cheap does not always mean cost-effective. Many buyers only realize this after the product has problems.

If PCBA manufacturing is unreliable, the hidden costs that follow are often higher. For instance, if a product needs rework, poor communication leads to project delays, a high on-site failure rate after shipment, counterfeit components result in customer returns, or the quality of each batch is unstable, all of these questions are often much more expensive than the initial quotations.

A truly reliable turnkey PCBA manufacturer does not focus on offering you the lowest price, but rather ensures stable quality, controllable delivery time, and long-term product reliability.

Trial production can help buyers verify the multi-faceted capabilities of suppliers, including whether engineering support is in place, whether SMT soldering quality is qualified, whether packaging and labeling are accurate, whether communication is smooth, and whether the supplier is stable enough under real production conditions.

Whether you place an order for a PCBA prototype or a small-batch PCB assembly, the trial production step can effectively reduce risks, laying a reliable foundation for the subsequent expansion to mass production PCB assembly.

From the previous requirements, it can be clearly seen that PCBasic fully complies with all the key standards of a world-class PCB assembly manufacturer.

PCBasic holds:

• ISO 9001

• ISO 13485

• IATF 16949

• ISO 14001

• ISO 45001

This ensures industry-standard quality for medical, industrial, automotive, and consumer devices.

PCBasic provides:

• 16 SMT assembly lines, supporting 01005, BGA, QFN

• Full inspection: SPI → AOI → 3D X-ray → ICT/FCT

• MES production traceability

• Nitrogen reflow for high-reliability PCB assembly

PCBasic is a complete turnkey PCBA manufacturer, offering:

• PCB fabrication

• Component sourcing

• PCB assembly

• Testing

• Box-build & final assembly

This makes PCBasic ideal for global OEMs needing a stable China PCB assembly service.

All components are sourced from authorized channels with complete traceability.

• Fast technical communication

• Transparent project updates

• Complete documentation

• Professional after-sales support and root-cause analysis

To find a truly reliable PCBA manufacturer, you must evaluate from multiple aspects, including certification qualifications, engineering capabilities, quality control, supply chain reliability, communication efficiency, and whether the supplier can cooperate stably in the long term.

By following the 8 steps of this guide, international buyers can choose reliable PCB assembly suppliers with more confidence, reducing cooperation risks while ensuring the stability of product quality all the time.

PCBasic performs well in all these standards and is a leading PCB assembly manufacturer and PCBA supplier in China and a reliable turnkey PCB assembly partner. PCBasic not only offers high reliability and strong engineering capabilities, but also features a transparent quality control system and scalable EMS manufacturing, providing stable, safe and sustainable production support for global customers.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.