Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How to Evaluate a PCBA Manufacturer’s Capability?

Whether electronic products can operate stably in real application scenarios is closely related to the choice of PCBA manufacturers. The performance, stability and long-term reliability of the final product are highly dependent on your circuit board assembly partner. Therefore, we need to choose a suitable and reliable PCBA manufacturer. But how do we know if the manufacturer is suitable? First, assess its capabilities.

This article aims to provide you with a clear evaluation framework to help you judge the real capabilities of PCBA manufacturers from multiple perspectives. Without further ado, let's get straight to the point. First, evaluate the manufacturer's qualifications and compliance.

The first step in evaluating a PCBA manufacturer is to confirm whether it has industry-recognized qualifications and a complete compliance system. This is the most fundamental condition. These not only prove that its production capacity meets the standards, but also ensure that it can enter the target market, meet industry regulatory requirements, and provide stable and reliable PCB assembly services in subsequent projects.

It is recommended to carefully verify the following qualifications:

|

Certification |

Key Value & Purpose |

Applicable Field / Meaning |

|

ISO 9001 |

Ensures controlled processes, standardized documentation, and continuous improvement; a fundamental requirement for all PCBA manufacturers. |

General quality management system |

|

IATF 16949 |

Strengthens risk control, traceability, and production consistency; essential for automotive-grade PCBA manufacturing. |

Automotive electronics industry |

|

ISO 13485 |

Requires strict documentation, process validation, and safety control to ensure medical PCBA compliance. |

Medical device electronics |

|

AS9100 |

Aerospace-grade quality system |

Aerospace and defense industry |

|

RoHS / RoHS 2.0 |

Restricts hazardous substances such as lead, mercury, and cadmium to ensure smooth market entry into the EU. |

Environmental compliance (EU) |

|

REACH |

Limits SVHC chemicals, reducing material risks across the supply chain. |

Chemical safety compliance |

|

UL (e.g., UL94, UL796) |

Validates flammability and safety of PCB materials and assemblies; crucial for North American markets. |

Safety certification for PCB materials and electronic assemblies |

Compliance is not limited to certificates; it also includes whether the factory has the legal operating qualifications and actual production capacity. The key assessment points are:

Are all the legal documents such as business license, production license, and customs registration complete?

Does the factory area size meet the standards?

The number of SMT production lines

The independent THT/DIP hand insertion area

The configuration of processes such as reflow soldering and wave soldering

Does it have a dust-free environment?

The material storage capacity

Does it have a long-term stable operation record?

These infrastructures can reflect the operational maturity of the PCBA factory and also determine whether it can undertake long-term cooperation.

A reliable PCB assembly manufacturer should have sufficient production capacity and flexibility. It should be capable of handling both small-scale trial production in the research and development stage and continuous orders during the mass production stage. We can observe this supplier as follows:

Can it support the trial production from 1 to 100 prototypes to large-scale mass production of over 10,000 pieces?

Can it quickly switch production lines to meet the requirements of multiple batches, small batches, and customization?

Does it offer 24-hour rush prototyping or rapid machine startup services?

Does it have the long-term capacity for expansion?

A mature PCBA manufacturer must possess sufficient technical depth and reliable manufacturing capabilities.

High-precision SMT assembly process is the core of modern PCBA. Key aspects to evaluate include:

Minimum mountable size: 01005 / 0201 / 0402

Fine pitch packaging capabilities: BGA, CSP, QFN, LGA, etc. with pitches ranging from 0.3 to 0.4 mm

Multi-zone reflow soldering temperature curve control, capable of adapting to lead-free, mixed processes, and high heat capacity devices

Equipped with SPI solder paste detection and has closed-loop regulation capability

High-speed mounting accuracy reaches ±0.03 mm level

The THT/DIP plug-in capabilities and hybrid manufacturing processes are also an aspect for evaluating PCBA manufacturers. There are still many products that rely on THT manufacturing, such as power supplies, connectors, and large-volume components, etc. When assessing the THT/DIP capabilities of this factory, we can focus on the following aspects:

Selective wave soldering

Automated or semi-automatic assembly stations

Standardized hand assembly procedures, including MSD control, ESD protection, etc.

The ability to fix and reinforce large-volume components such as transformers and electrolytic capacitors

The key capabilities in this area include assessing whether the manufacturer:

Support multi-layer boards (4–20 layers or more)

Have experience in mass production of impedance-controlled PCBs

Capable of handling HDI, blind vias, and micro-hole structures

Support thick copper boards (2–6 oz), high TG materials

Compatible with special materials such as aluminum-based, ceramic, flexible boards, and rigid-flex combinations

Many high-end electronic products rely on advanced packaging components. In such cases, the factory should have the capability to handle the following packaging processes:

BGA, uBGA, FBGA, WLCSP, POP stacked packaging

Reliability-enhancing processes such as underfill substrate filling and corner adhesive reinforcement

X-ray inspection of BGA voids and hidden solder joints

Capable of handling complex devices with high pin counts, such as FPGAs, CPUs, PMICs, and AI chips

Only factories with these capabilities can undertake fields requiring high performance and high reliability, such as automotive-grade electronics, communication equipment, industrial control, and medical devices.

If your product requires special processing techniques, for example:

Circuit board cleaning, ion contamination control and cleanliness testing

Three-proof paint spraying or selective coating

Encapsulation, dispensing, and glue curing

Soldering point/structure reinforcement under high vibration or harsh environments

Programming interface capability for connection with ICT/FCT (not involving the testing content itself)

Then, you should also conduct a corresponding examination of the special processes used by the selected PCBA manufacturer.

Whether a company has a quality system that can maintain consistent quality over the long term is also one of the key aspects in evaluating a PCBA manufacturer.

The focus of this aspect of the assessment lies in whether the factory has established a process-based, standardized, and data-driven reliability system.

The quality of a first-class factory stems from the process. The key points to focus on for this PCBA partner are:

Is strict process window management implemented for key processes such as SMT and reflow soldering?

Does the reflow soldering have a unified curve file (profile) + parameter locking mechanism?

Is the production line stability continuously monitored through key process parameters (temperature, pressure, speed)?

Do all process changes have an ECN/PCN documented process?

When evaluating a supplier, consider whether they can provide:

Can the process data be tracked in real time, including the assembly rate, yield rate, and distribution of defect types?

Are statistical methods such as SPC and CPK used to analyze the process capability?

Can the quality reports be automatically exported, including defect trend analysis, batch reports, and customer visualization data panels?

Is the continuous improvement (Kaizen) mechanism implemented?

Highly reliable PCBA must control risks from the design stage. Excellent manufacturers should provide:

DFM, DFA, DFT, DFR recommendations

Preventive guidance such as pad design, shape optimization, thermal relief, etc.

Factory engineers can proactively identify potential risks (such as via hole coating, impedance requirements, micro-solder joint stress)

In addition to manufacturing capabilities, a reliable PCB assembly manufacturer must also possess strong service and collaboration capabilities. This is the key factor that distinguishes a "contract manufacturer" from a "partner".

Including:

Engineering Review conducted within 24 hours

DFM reports, material substitution suggestions, soldering risk warnings

Quick feedback on issues during the Prototype Build stage

Engineers can communicate directly with the customer's R&D team

The stronger the engineering capabilities are, the smoother the process of product development to mass production will be.

Communication efficiency will directly determine the delivery quality of PCBA. We can make the judgment based on the following points:

Is there a dedicated project manager (PM) responsible for progress, issue coordination and tracking?

Is there a periodic update, production line photos, and test reports?

Does it have a fast track for emergency materials, design changes, and abnormal handling?

Is there a fully transparent communication mechanism?

Risk-resistance capability is the foundation for determining the reliability of a supply chain. This aspect is often overlooked but is a very crucial factor that reveals whether a supplier can maintain stability in long-term cooperation.

Evaluate whether the factory can maintain stable production in a volatile supply environment.

Key points include:

Multi-channel material procurement (to avoid risks from a single supplier)

Real inventory capabilities (safety stock, mechanism for stocking key components)

Material substitution strategies (cross-reference management)

Does it have a professional procurement team to manage long-term supply risks (EOL, long lead times, price fluctuations)

A reliable PCBA factory must possess the ability for long-term stable operation:

Operating years, financial stability

Proportion of factory-owned equipment (non-leased equipment is more stable)

Redundant design of production lines (equipment maintenance, backup production lines)

Standardized operation system (SOP, Flow Chart, Management System)

Evaluate whether the manufacturer has a systematic risk management mechanism:

FMEA (Process Failure Mode Analysis)

Emergency response plans for unexpected events such as power outages, equipment shutdowns, and fires

Regular maintenance schedule for key equipment

Abnormal handling mechanism (8D, CAPA)

Stability is also reflected in the attitude of cooperation:

Are you willing to expand production and add lines based on customer growth?

Do you have the capability to support the introduction of new products and new technologies (NPI)?

Can you provide long-term cost optimization solutions (cost transparency, material integration)?

|

Evaluation Category |

What to Evaluate |

Key Indicators / Questions to Ask |

|

Basic Qualifications & Compliance |

Certifications & Legal Compliance |

• ISO 9001 / IATF 16949 / ISO 13485 / AS9100 • RoHS / REACH / UL compliance • Complete business license, production permit, customs registration |

|

|

Factory Infrastructure |

• Number of SMT lines • Independent THT/DIP area • Reflow, wave, selective soldering configuration • Dust-free environment availability • Controlled storage for materials |

|

|

Production Flexibility |

• Supports 1–100 pcs prototypes • Scalable mass production (10,000+ pcs) • Ability for rapid prototyping (24–48h) • Expandability of future production capacity |

|

Technical & Manufacturing Capabilities |

SMT Capabilities |

• Minimum size (01005 / 0201) • Fine-pitch BGA 0.3–0.4 mm • SPI closed-loop control • Placement accuracy ±0.03 mm |

|

|

THT / Mixed Assembly |

• Selective wave soldering • Automated/semiauto insertion • MSD & ESD management • Large component reinforcement |

|

|

PCB & DFM Capabilities |

• HDI, blind/buried vias • 4–20+ layer compatibility • Controlled-impedance support • Ceramic, aluminum, flex, rigid-flex materials |

|

|

Advanced Packaging |

• BGA / uBGA / WLCSP / POP • Underfill, corner bonding • X-ray inspection capability • Support for high-pin-count devices (FPGA, CPU, PMIC) |

|

|

Specialized Processes |

• Cleaning & ionic contamination testing • Conformal coating • Potting, dispensing • ICT/FCT programming interface compatibility |

|

Quality Control & Reliability |

Process Control |

• Defined process windows • Reflow profile locking • Continuous monitoring of key parameters • ECN/PCN documentation |

|

|

Data-Driven Quality |

• Real-time yield tracking • SPC/CPK analysis • Automated quality reports • Formal Kaizen improvement system |

|

|

Reliability Engineering |

• DFM/DFA/DFT/DFR guidance • Pad/thermal design optimization • Early risk identification from engineering team |

|

Service & Collaboration Capabilities |

Engineering Support |

• 24-hour engineering review • Professional DFM report & material alternatives • Rapid prototype feedback • Direct communication with R&D |

|

|

Communication Performance |

• Dedicated project manager • Build updates, photos, reports • Rapid response to ECN, shortages, abnormalities • Transparent communication channels |

|

Risk Resistance & Stability |

Supply Chain Resilience |

• Multi-source component procurement • Real safety stock • Cross-reference substitution ability • EOL / long-lead-time risk control |

|

|

Operational Stability |

• Years of operation, financial health • Ownership of equipment (vs. leased) • Redundant production line capacity • Mature SOP & management system |

|

|

Risk Management |

• FMEA usage • Emergency response plans • Scheduled equipment maintenance • Formal 8D & CAPA mechanisms |

|

|

Long-Term Partnership |

• Scalable capacity for customer growth • NPI support capability • Ability to provide long-term cost optimization |

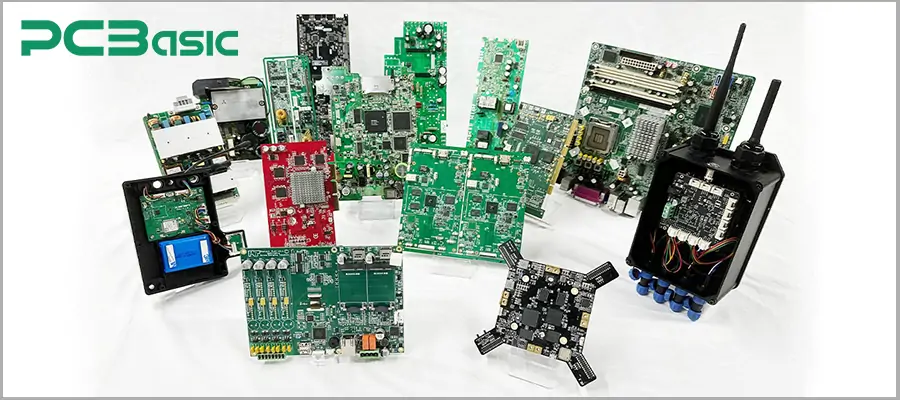

After understanding how to evaluate a manufacturer, here is an example of a PCBA supplier that meets these high standards. PCBasic has always stood out for its comprehensive quality system, advanced production capacity, strict process standards and outstanding collaborative services. As a professional PCB/PCBA manufacturer with a long history in the industry, PCBasic can provide customers with high-reliability electronic manufacturing services ranging from prototypes, small batches to large-scale mass production, and continuously meet the strict requirements of various fields such as consumer electronics, industrial control, medical equipment, and automotive electronics.

If you wish to learn more about PCBasic's manufacturing capabilities, process flow or success stories, you can visit the PCBasic website for more information.

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.