Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Electronic Assembly Services: A Complete Guide to PCB Assembly

In the era of development centered on technology, almost all electronic products require stable and reliable electronic assembly services. As products continue to develop towards intelligence, miniaturization and high speed, enterprises have increasingly higher requirements for production quality and delivery efficiency. Therefore, an increasing number of companies choose to cooperate with professional PCB assembly service suppliers and rely on experienced electronic manufacturing companies to complete the manufacturing process from design to finished products. Whether it is for prototype verification or for later mass production, choosing a suitable PCB assembly manufacturer often directly affects whether the project can proceed smoothly.

This guide will focus on electronic assembly services and mainly introduce the following contents:

• Common types of circuit board assembly

• Essential key quality control processes in production

• Applications across industries

• How to choose a reliable PCBA supplier such as PCBasic

Through this article, you can systematically understand the basic processes of electronic assembly and clearly recognize why professional assembly services occupy such an important position in the modern electronics industry.

Printed circuit board assembly (PCBA), simply put, is the process of mounting various electronic components onto a bare PCB to turn it into a functioning electronic circuit board. Through soldering, inspection and testing, this process truly transforms a design drawing into a usable electronic product.

Unlike PCB manufacturing that only produces empty boards, circuit board assembly services pay more attention to how components are accurately and securely installed on the circuit board. The process mainly includes the following steps:

• Component placement

• Soldering processes

• Inspection and testing

• Final product assembly

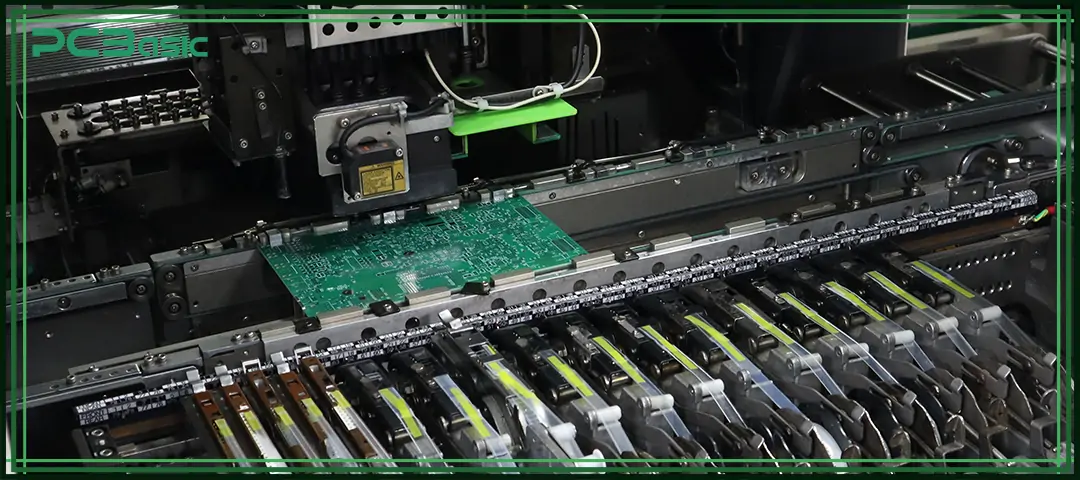

Today, electronic PCB assembly has extensively relied on automated equipment and is combined with precise processes to ensure the stable and consistent quality of each board. Many electronic manufacturers will use advanced equipment, such as SMT pick-and-place machines, reflow ovens, AOI systems and X-Ray inspection equipment to achieve high-quality PCB board assembly manufacturing.

In the professional process of electronic assembly manufacturing, PCBA is the most crucial step. Even if there is a defective solder joint, it may cause the entire circuit board to fail to work properly and even affect the operation of the entire system. Therefore, in the process of electronic product research and development and production, it is very important to choose a reliable printed circuit board assembly manufacturer.

Professional electronic assembly services will select the appropriate assembly method according to different product design requirements and applications to ensure the performance and reliability of the products.

SMT PCB assembly is currently the most widely used PCB assembly method. Electronic components are directly mounted on the surface of the circuit board without being inserted into the holes of the circuit board for installation.

The main advantages of SMT PCB assembly include:

• Higher component density

• Smaller and lighter circuit boards

• Higher automation and production efficiency

• Lower cost in high-volume production

Most electronic manufacturing services take SMT technology as the core because it is suitable for high-speed production and can also meet the design requirements of complex circuit structures. Therefore, SMT is widely used in consumer electronics, communication equipment and industrial automation equipment.

Through-hole technology (THT) involves inserting the component leads into pre-drilled holes and then soldering and fixing them on the back of the circuit board. Although it is not as widely used as SMT at present, it is still very important for components with high requirements for mechanical strength.

Common applications in through-hole PCB board assembly include:

• Power connectors

• Transformers

• Large capacitors

• Industrial and automotive electronics products

Many electronic manufacturing companies adopt both SMT and THT processes simultaneously. Through a hybrid assembly method, they can ensure both compact product design and improved structural reliability.

Box-build assembly is not merely a simple printed circuit board assembly service, but also includes full system integration. This process involves installing the PCBA into the enclosure and completing the assembly of the entire machine together with cables, displays and various mechanical components.

Box-build type electronic assembly services usually include the following contents:

• Enclosure and mechanical structure installation

• Cable harness assembly

• Functional testing

• Packaging and labeling

For enterprises hoping to obtain one-stop solutions, box-build electronic assembly manufacturing can reduce the need to work with multiple suppliers, make the production process simpler, and also help improve delivery efficiency.

Electronic manufacturing services (EMS) refer to the entire production process from product design support to the final product delivery, completing the manufacturing of electronic products in one stop.

EMS service providers usually offer the following services:

• PCB fabrication

• PCB assembly services (PCB assembly services)

• Component sourcing

• Testing and inspection

• Logistics and after-sales support

By cooperating with the PCB assembly service provider that offers full-process services, enterprises can focus more on product research and development and market expansion, while entrusting the complex production and manufacturing work to professional teams for handling.

To ensure product quality and production efficiency, leading electronic manufacturers usually rely on MES and ERP systems to manage the entire PCBA manufacturing process, achieving quality traceability, process control and continuous improvement of manufacturing efficiency.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

In today's highly competitive market, whether a product can be launched on the market as soon as possible is important. Therefore, many customers choose the quick-turn PCB assembly service when building prototypes or handling urgent projects.

Quick-turn PCB assembly usually offers the following advantages:

• Production completed within 24–72 hours

• Fast component sourcing

• Short testing and delivery cycles

Meanwhile, the flexible PCB prototype assembly services can help engineers verify the design before mass production, identify and optimize problems in advance. This type of service is particularly suitable for startups, R&D teams and developers of customized products who need circuit board assembly services that are both efficient and stable.

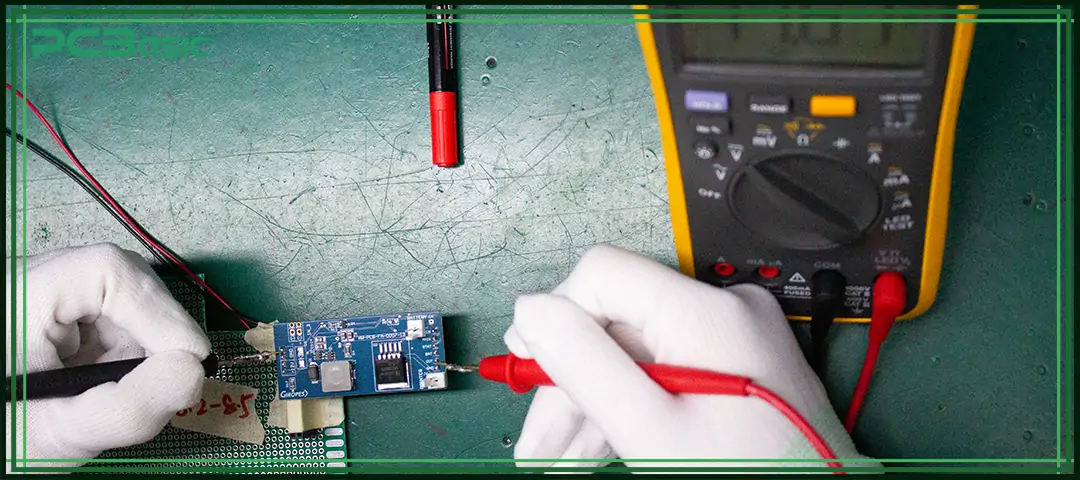

Quality is the foundation of professional electronic assembly services. Without strict quality control, even if the circuit design is highly advanced, the product may still fail to function properly due to solder joint issues, misplaced components, or electrical shorts.

During the production process, the PCB assembly manufacturer usually focuses on the following quality control stages:

Before all components enter the production line, they will first be checked for correct part numbers, proper packaging, and authenticity to prevent defective materials from being used in production.

The AOI system will conduct a comprehensive scan of each electronic PCB assembly, focusing on checking solder defects, missing components, and polarity errors.

X-ray is mainly used to inspect packaged devices such as BGA and QFN. It can examine the solder joints inside multilayer boards that are invisible to the naked eye, ensuring that there are no problems of false soldering or short circuits in hidden solder joints.

Through functional testing, it is confirmed that each PCB board assembly meets the design requirements in electrical performance and can work normally.

Leading electronic manufacturing companies will assign serial numbers to each circuit board and, in combination with the MES system, record and track the entire process of the product from raw materials to finished products, facilitating subsequent quality management and problem analysis.

It is precisely through these complete quality control processes that professional printed circuit board assembly manufacturers can meet the requirements of international standards such as ISO9001, IPC-A-610 and RoHS. Continuously provide stable and reliable product quality.

Electronic assembly services are applied in almost all industry fields.

|

Industry |

Typical Products |

Assembly Requirements |

|

Consumer Electronics |

Smartphones, wearables, routers, and home appliances |

High precision and cost efficiency |

|

Industrial Automation |

Control boards, sensors, robotics systems |

High reliability for harsh environments |

|

Medical Devices |

Medical instruments, monitoring systems, diagnostic equipment |

Strict quality control and traceability |

|

Automotive Electronics |

ECUs, infotainment systems, control modules |

Heat and vibration resistance |

|

Telecommunications |

5G equipment, networking devices, data center hardware |

High-speed and stable performance |

PCBasic is a professional printed circuit board assembly manufacturer, dedicated to providing reliable and flexible electronic assembly services to customers worldwide. PCBasic focuses on small-batch, multi-variety, and fast-turnover production, helping enterprises efficiently bring their products from concept to market.

• PCB fabrication

• PCB assembly services

• Component sourcing

• Testing and inspection

• Box-build assembly

Supports both:

• SMT PCB assembly

• Through-hole assembly

• Capable of handling:

• Complex designs

• Mixed-technology products

PCBasic uses advanced equipment:

• High-speed pick-and-place machines

• AOI inspection systems

• X-ray inspection

• Functional testing systems

Ensures full traceability with:

• MES systems

• ERP systems

• Tracking from incoming materials to finished products

PCBasic supports:

• Prototype builds

• Pilot production

• Mass manufacturing

Delivers:

• Consistent quality

• Short lead times

Ideal PCBA supplier for:

• Startups

• R&D teams

• Growing technology companies

In the modern electronics industry, electronic assembly services are the key stage to truly turn designs into usable products. From PCB assembly, SMT processing, to complete electronic manufacturing services, professional assembly service providers can ensure stable product quality, standardized production processes, and support the production demands of different scales.

When enterprises fully understand different types of circuit board assembly methods, quality control processes and specific industry applications, they can choose the appropriate PCB assembly service partner more rationally.

Cooperating with experienced printed circuit board assembly manufacturers like PCBasic can bring the following advantages:

• Advanced production technology

• Strict quality management

• Fast turnaround times

• Reliable electronic manufacturing support

As the structure of electronic products becomes increasingly complex, choosing a professional and reliable PCBA supplier has become an important prerequisite for ensuring the success of products.

1. What are electronic assembly services?

Electronic assembly services include component placement, soldering, testing, and system integration to produce functional electronic products.

2. What is the difference between PCB fabrication and PCB assembly?

PCB fabrication creates the bare board, while printed circuit board assembly mounts components and makes the board operational.

3. What industries use PCB assembly services?

Industries such as medical, automotive, industrial automation, telecom, and consumer electronics rely on PCB assembly services.

4. What is quick-turn PCB assembly?

Quick-turn PCB assembly provides rapid production for prototypes and urgent orders, usually within 24–72 hours.

5. How do I choose a PCB assembly manufacturer?

Select a PCB assembly manufacturer based on quality certifications, equipment, delivery speed, and experience in electronic manufacturing services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.