Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Quick Turn PCB Fabrication & Fast Turn PCB Manufacturing and Assembly Services | PCBasic

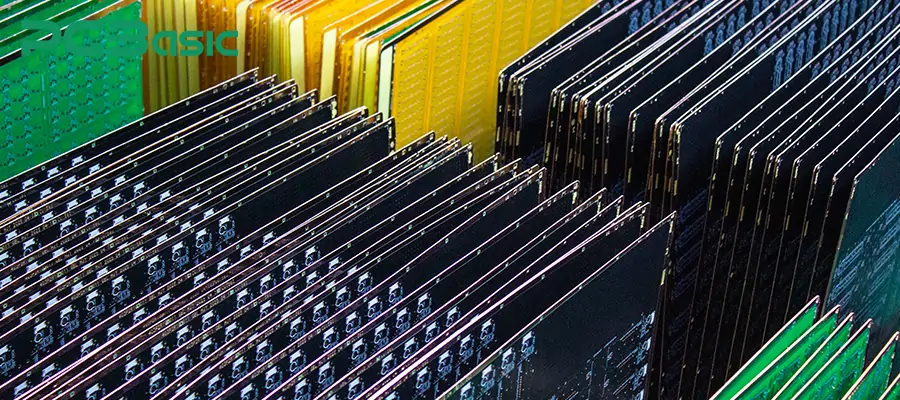

Turnaround time affects the project progress and time-to-market in electronics development and manufacturing. As the update speed of electronic products keeps accelerating, the speed of transition from design to manufacturing becomes increasingly critical. When you need to complete PCB manufacturing within a few days, a stable and reliable quick turn PCB fabrication capability is particularly important.

Therefore, as product development cycles continue to shorten, enterprises increasingly need reliable partners for quick turn PCB fabrication and fast turn printed circuit board assembly to complete design verification as soon as possible and bring products to market. PCBasic has been deeply involved in the PCB and PCBA industry for many years and is capable of providing customers with efficient quick turn PCB fabrication services and PCB assembly solutions. In the following article, we will introduce them to you.

Quick turn PCB fabrication refers to a manufacturing service that completes the production of printed circuit boards within a very short lead time. Compared with the traditional PCB manufacturing that usually takes one to two weeks, the quick turn PCB services can generally complete the production within 24 hours to several days.

In practical applications, "quick turn PCB fabrication" means:

Highly optimized manufacturing process

Accelerated engineering review, material preparation, production manufacturing and inspection stages

Guarantee quality and reliability

Significantly shortened PCB production cycles

All of these are aimed at meeting the extremely strict time requirements for the project.

Typically, rapid PCB prototyping manufacturing is combined with quick turn PCB assembly services. In this way, customers can receive the finished circuit boards that have been assembled and tested in the shortest possible time.

Usually, in some critical scenarios where there is a high demand for time, as well as the need for flexibility and reliability, a quick turn PCB fabrication service is required, such as:

1. Rapid PCB Prototyping

During the product development stage, it is common for multiple design iterations to be required. In such cases, the quick turn PCB fabrication service is highly applicable. This is because designers need to quickly verify the circuit performance and the layout accuracy, so as to identify and optimize problems in a timely manner before entering mass production.

2. Urgent Requirements for Product Delivery

When the product launch time is very tight, the traditional manufacturing cycle often cannot meet the requirements. At this point, enterprises will choose fast turn PCB manufacturing service. This service model can significantly shorten the development cycle and accelerate the speed of products entering the market.

3. Design Verification and Debugging

Before entering mass production, functional testing and debugging must be carried out to confirm the stability of the circuit design. Functional testing and debugging will also involve the use of fast turn PCB fabrication. This allows engineers to quickly obtain test circuit boards for signal verification, thermal performance assessment, and program debugging.

4. Small Batch Customized Projects

Many projects with relatively small quantity requirements but high customization levels usually also rely more on quick-turn PCB manufacturers that can support flexible small-batch production.

5. Unexpected Supply Chain Delays

When regular suppliers are unable to deliver on time due to production capacity or logistics issues, the project progress is likely to be affected. At this point, a quick-turn PCB fabrication factory with rapid response capabilities becomes particularly important.

As a professional quick turn PCB manufacturer, PCBasic has a complete production process and stable capacity allocation, which enables it to respond quickly to customer demands while maintaining quality standards. The quick turn PCB fabrication service and assembly delivery schedules of PCBasic are as shown in the table below:

|

Service Type |

Turnaround Time |

Typical Application |

|

Quick turn PCB fabrication (1–2 layers) |

As fast as 24 hours |

Rapid PCB prototyping, circuit verification |

|

Multilayer quick turn PCB fabrication |

2–5 days (depending on complexity) |

Advanced designs, controlled impedance boards |

|

Fast turn PCB assembly (small batch) |

24–72 hours |

Functional testing and pilot runs |

|

Fast turn PCB assembly with testing |

Available within short lead cycles |

Complete quick turn PCBA solutions |

These delivery capabilities mainly support the following application requirements:

Quick turn PCB assembly services

Quick turn PCBA

Rapid PCB prototyping

Quick turn PCB prototypes

PCBasic operates in an integrated mode. Besides PCB manufacturing, it can also complete PCB assembly within the same production system. This mode can avoid delays caused by third-party collaboration between bare board factories and assembly factories, making the connection from circuit board production to PCBA finished product delivery more seamless.

The turnaround time for quick turn PCB manufacturing and assembly is not fixed and is influenced by multiple technical and production factors. The following are several key factors that affect the PCB turnaround time (understanding these factors will help in more accurately assessing the project cycle).

1. PCB Design Complexity

The complexity of the circuit board itself is the primary factor affecting the delivery time. Mainly includes:

Number of layers

Wire width and spacing requirements

Via structure

HDI and impedance control requirements

Board thickness and complexity of stack-up structure

Surface treatment process

Special processing requirements, such as buried resistance, back drilling, castellated holes, etc.

The more complex the board structure is, the more manufacturing processes are required, and the longer the completion time will be. This is why quick prototyping for simple designs is faster, while high-complexity designs require more time.

2. Material Available

The material preparation situation has a more direct impact on the delivery speed of rapid PCB manufacturing. For instance, if special materials such as Rogers, high-TG, and aluminum-based boards are required, additional time will be needed for material preparation; whereas if conventional FR-4 materials are used directly, they can usually be put into production immediately.

3. Assembly and Testing Requirements

If the project includes quick turn PCB assembly services, then the assembly and testing processes will definitely affect the delivery time of fast turn PCBs.

Mainly includes:

Component supply situation (Only when all components are complete can production start)

Package type (BGA, QFN, etc. has high requirements for surface mount accuracy and process)

Test items (such as AOI and X-ray inspection, which improve reliability but extend processing time)

4. Order Quantity

The quantity of the order also affects the scheduling of the delivery date:

Small-batch quick prototypes can usually be given priority for production and have shorter delivery times. Large-volume orders require more capacity planning and scheduling time. Rapid PCB services are more suitable for sample production, design verification, and pilot production stages.

5. Completeness of Files

The quality of engineering documents directly determines the processing speed of the preparatory work in the early stage, and is also an important factor affecting the quotation and delivery time. Complete and accurate documents should include:

Gerber files

BOM list

Surface mount coordinate file

Assembly drawing

Test requirements explanation

The materials are clear and error-free, which enables the factory to quickly complete the project review and provide an accurate quotation. If there are any omissions or errors in the documents, they need to be repeatedly confirmed, which will delay the overall progress.

Because PCBasic is professional and reliable, it can provide efficient, stable and high-quality production services for customers with strict delivery requirements. PCBasic has

1. One-stop fast PCB solution

PCBasic can offer a complete fast PCB service package, including:

Rapid PCB manufacturing

Rapid PCB assembly service

Fast turn PCB assembly

Component procurement and functional testing

This one-stop service model can prevent the delays in communication and coordination that arise from the collaboration of multiple suppliers. Moreover, customers can achieve a shorter overall project cycle with fewer communication costs.

2. Advanced manufacturing capabilities

PCBasic is equipped with complete production equipment and inspection systems, which can meet the production requirements for high-precision and urgent projects, including:

SMT and THT assembly lines

Automated AOI and X-ray inspection equipment

Flying probe testing and functional testing

BGA, QFN and fine-pitch component assembly

These manufacturing capabilities are not only applicable for rapid prototyping, but also can stably support complex-structured rapid PCB sample projects.

3. Rapid and reliable delivery capability

By optimizing the production scheduling process and establishing a rapid response mechanism, PCBasic is able to efficiently handle urgent order demands. Regarding delivery times, PCBasic:

Delivery date is predictable

Capacity allocation is stable

Capable of supporting the rapid delivery of emergency projects

4. Professional engineering support

PCBasic can provide comprehensive engineering support services throughout the entire project process, including:

DFM (Design for Manufacturability) analysis

Pre-production engineering review

Layout and assembly process optimization suggestions

These engineering services can effectively reduce manufacturing risks and minimize potential errors.

5. Rigorous quality assurance system

All the rapid PCB manufacturing services provided by PCBasic are carried out in accordance with unified quality standards, including:

Electrical testing

Visual inspection

Process monitoring

Soldering quality verification

In addition, PCBasic also supports stable mass production. If the customer has a need, PCBasic can seamlessly transition to large-scale production within the system. This integrated model can effectively reduce the time costs and risks associated with secondary engineering reviews and process adjustments.

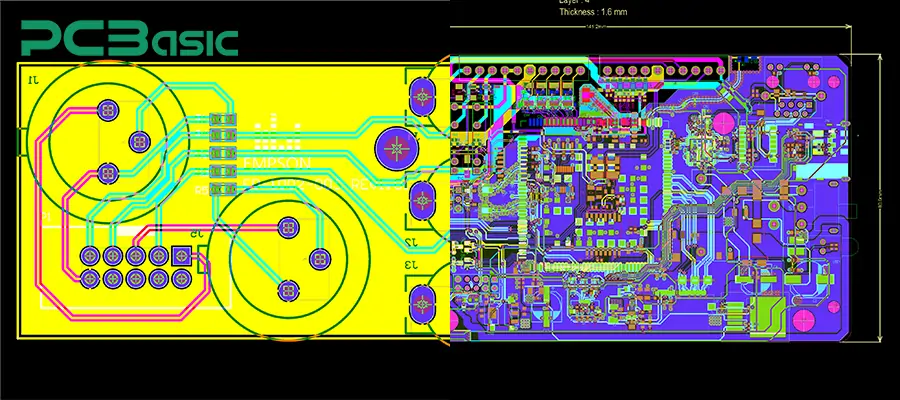

The PCBasic rapid PCB manufacturing project process is simple and efficient. PCBasic has a standardized rapid response process, enabling customers to quickly move from design files to the production stage while ensuring quality and traceability.

1. Submit project files

Firstly, you need to submit the complete engineering documents, including Gerber files for PCB manufacturing. Just log in and upload directly.

If assembly is required, the following items are also needed:

BOM (Bill of Materials)

Assembly drawings

Soldering coordinate files (if including assembly)

Test requirements (if any)

You can also directly send your requirements and document materials to PCBasic at JS@pcbasic.com. Then, a dedicated sales representative will contact you and handle the operation for you. After the document materials are submitted successfully, the engineering team of PCBasic will immediately review the documents to confirm their manufacturability. Complete and accurate materials will help speed up the prototyping process.

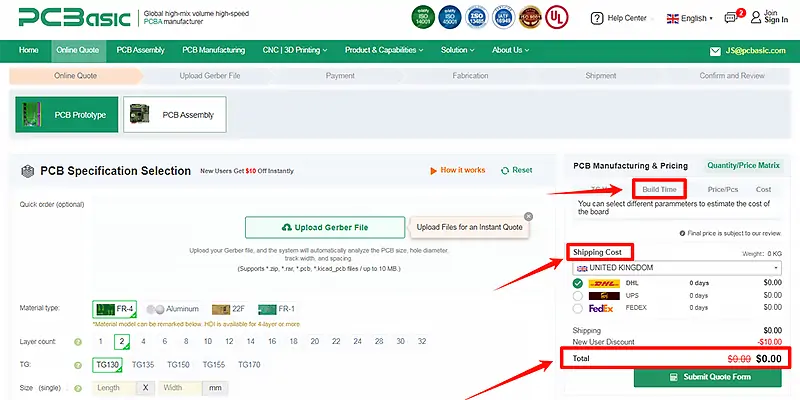

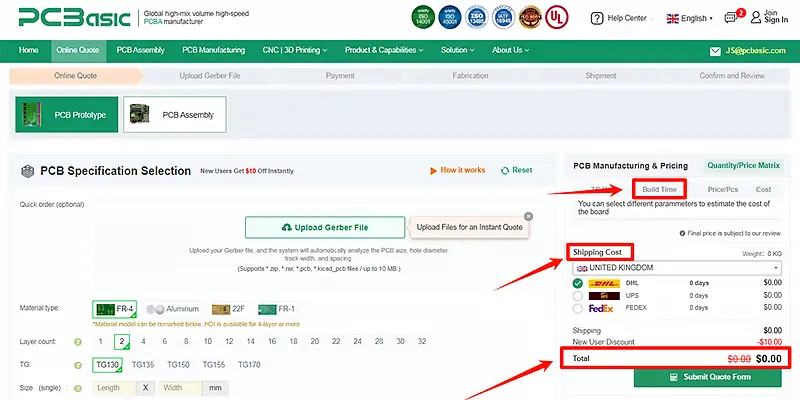

2. Request for Quotation

After the file is submitted, PCBasic will provide clear and efficient rapid PCB quotation solutions, including:

Estimated production delivery date

Price breakdown

Soldering and testing options

Whether special process requirements are involved

You can also see here an estimated PCB delivery time, shipping cost and price:

If assembly services are required, the quotation process will take longer.

3. Confirm production parameters

After confirming the quotation, it is usually necessary for you to further confirm the key production parameters, including:

Number of layers

PCB material and board thickness

Surface treatment process

Soldering method and inspection standard

This step is to ensure that the selected rapid PCB manufacturing and assembly plan fully complies with the technical requirements of the project.

4. Immediately enter the production process

After the parameters are confirmed, the order will be sent to the rapid production channel and production will be arranged according to priority.

5. Testing and Delivery

Before shipment, all circuit boards will undergo the required testing and quality verification, including:

Electrical testing

Visual inspection

Component mounting quality verification

The products that have passed the inspection will be properly packaged and dispatched as soon as possible.

Quick turn PCB fabrication is an important step in the product design verification and pilot production stages. PCBasic has a mature production system and a complete engineering and quality management process, which can provide customers with stable and efficient fast turn PCB manufacturing and assembly services. If you are looking for a dependable partner for quick turn PCB fabrication or fast PCB assembly, PCBasic supports your project from prototype builds to full production. Contact us for a quick quote and let us help you move your design forward.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

1. What are the differences between quick turn PCB fabrication and conventional PCB production?

Quick turn PCB fabrication focuses on "short lead times and accelerated production schedules", and it can usually be completed within 24-72 hours. While conventional PCB production follows the standard production scheduling process, the cycle time is generally 7-14 days or longer.

2. Does PCBasic offer both PCB manufacturing and assembly services?

Yes. PCBasic can offer a complete one-stop rapid PCB assembly service, completing both PCB manufacturing and assembly within the same production system.

3. Is the cost of quick turn PCB prototyping higher?

Compared to regular production, quick turn PCB prototyping may have a slightly higher cost due to the use of priority scheduling and rush processes. However, by identifying design issues at the R&D stage, it is possible to effectively avoid rework and modifications during subsequent mass production, thereby reducing the overall development cost.

4. What types of circuit boards can be produced?

PCBasic supports the production of various types of rapid PCB prototypes, including:

Single-layer board, double-layer board and Multilayer board

HDI circuit board

High-density and fine-pitch design

Circuit boards with BGA and QFN components, etc.

5. How long will it take to receive the quotation?

After the customer submits all the project documents, a quick turn PCB quotation can usually be provided within a few hours. To ensure the efficiency of the quotation process, it is recommended that the customer provide complete and clear documents.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.