Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is Electronic Contract Manufacturing (ECM)?

Electronic contract manufacturing has developed into a key part of the global electronic manufacturing services industry. It is widely applied in fields with high requirements for reliability and consistency, such as consumer electronics, industrial control equipment, medical electronics and automotive electronics. By cooperating with contract manufacturing companies that have complete capabilities, enterprises can directly leverage established mature production lines, engineering experience and quality systems, achieving more efficient large-scale production while reducing overall manufacturing risks.

By introducing a mature external manufacturing system, enterprises can reduce long-term investment in fixed assets and production resources, while achieving more stable manufacturing capabilities and a more controllable delivery schedule. This model has become a highly mature and widely verified manufacturing approach in the electronics industry.

This article will focus on the explanation of electronic contract manufacturing, systematically introducing its fundamental definition and operation process, and the differences between ECM, EMS and OEM manufacturing models. Meanwhile, it will also analyze why electronic contract manufacturing has become the mainstream choice for most electronic product enterprises in the current electronic manufacturing services system.

Electronic contract manufacturing (ECM) refers to the manufacturing model in which an enterprise outsources part or all of the electronics production activities to a third-party electronic contract manufacturer. For most electronic product enterprises, this model can effectively lower the manufacturing threshold and reduce dependence on in-house production resources.

Typically, manufacturers providing contract manufacturing services cover multiple stages of electronic products from the early preparation to delivery, including:

• Product design support

• PCB fabrication and electronic assembly

• Component sourcing

• Testing and quality control

• Final packaging and logistics

In simple terms, enterprises do not need to build factories by themselves or directly manage complex production processes. Instead, they can work with experienced electronic manufacturing companies and rely on their established electronic contract manufacturing services directly to complete the product manufacturing.

This manufacturing model is widely adopted in the EMS industry and is particularly suitable for electronic product projects that have clear requirements for production flexibility, cost control and delivery efficiency.

A professional contract electronic manufacturing process usually features clearly defined workflows, full production traceability, and a stable and well-controlled production management system.

In the early stage of a project, many electronic contract manufacturers will participate in the product design phase, with the main purpose of evaluating in advance whether the design is suitable for mass production. Common support includes:

• Design for Manufacturability (DFM)

• Design for Assembly (DFA)

• BOM optimization

• Prototype validation

In the process of electronic manufacturing, the component sourcing is often one of the stages with the highest risks and uncertainties. Electronics contract manufacturing companies with stable capabilities usually rely on mature supply chain systems to accomplish the following tasks:

• Source original, traceable components

• Mitigate shortages and lead-time risks

• Control component cost volatility

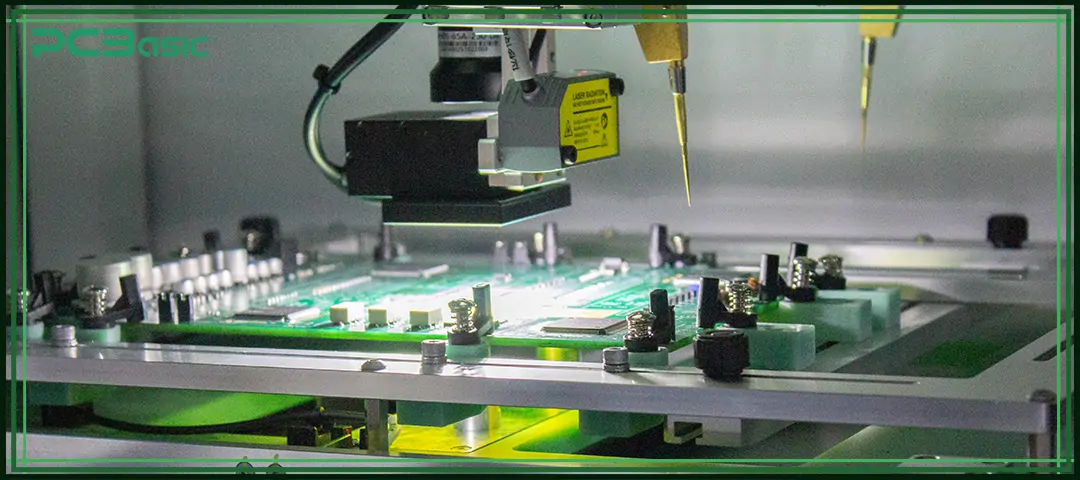

Assembly and production are the core stages of electronic assembly services. According to the product type and process requirements, the actual manufacturing activities usually include:

• SMT (Surface Mount Technology)

• Through-hole assembly

• Mixed-technology electronic assembly

• Box-build and system integration

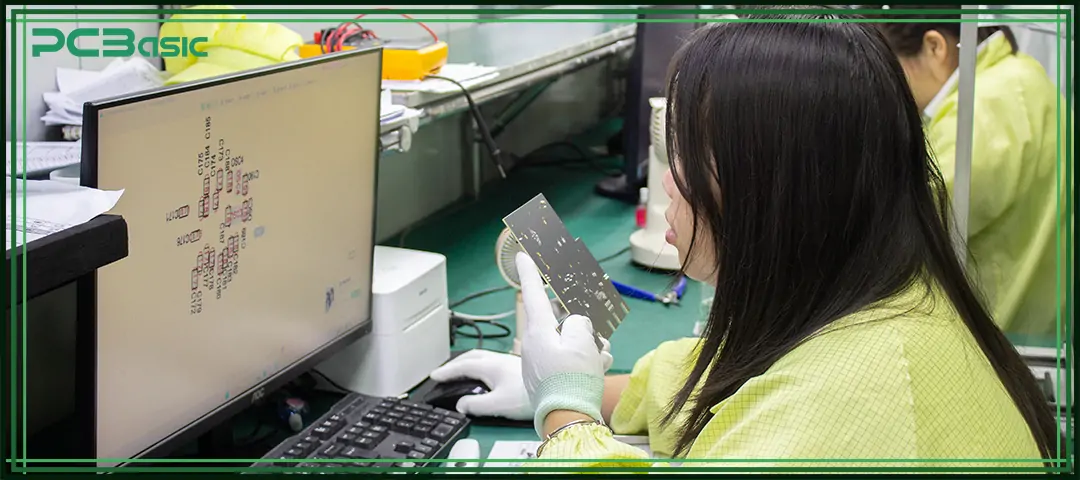

In electronic contract manufacturing, quality control runs through the entire manufacturing process, not just the last step before shipment. Common inspection and testing methods include:

• AOI (Automated Optical Inspection)

• SPI (Solder Paste Inspection)

• X-ray inspection

• ICT and functional testing

After production is completed, many electronic contract manufacturing services will continue to be responsible for the subsequent delivery stages, including:

• Final product packaging

• Labeling and serialization

• Global shipping and logistics coordination

This end-to-end service model from production to delivery enables brand owners to avoid direct involvement in factory operation and management, allowing them to invest more resources in product sales, marketing and business expansion.

More and more enterprises choose electronic contract manufacturing, mainly because this model has more advantages in cost control, production efficiency and management complexity.

Building in-house electronic manufacturing production lines usually requires continuous investment in production equipment, facilities, and workforce management. By cooperating with contract manufacturing companies, enterprises can avoid the pressure of equipment purchases and factory operations.

Experienced electronic contract manufacturers will continue to invest in SMT equipment, testing systems and automated production lines. Through EMS contract manufacturing, enterprises can also obtain stable and mature electronic manufacturing services capabilities.

Electronic contract manufacturing can flexibly adjust production capacity according to order volume and market changes, reducing the management pressure caused by frequent adjustments of internal resources within enterprises.

In the electronic manufacturing services industry, experienced electronic contract manufacturers usually have mature processes and stable supply chains, which can shorten the manufacturing cycle and help products enter the market faster.

By outsourcing contract electronic assembly, enterprises can focus more energy on product design, marketing and customer service, while the specific manufacturing execution is the responsibility of professional electronic contract manufacturers.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

EMS (Electronics Manufacturing Services) refers to a type of manufacturing model that provides outsourced electronic manufacturing services to customers. Enterprises in the EMS industry are mainly responsible for the specific implementation work related to the manufacturing of electronic products.

Common EMS service contents include:

• Electronic assembly services

• Testing and quality control

• Supply chain management

In practical applications, electronic contract manufacturing and EMS often occur simultaneously, but their focuses are not exactly the same. ECM places more emphasis on long-term and continuous manufacturing partnerships, while EMS is often used for short-term projects or phased production support.

OEM (Original Equipment Manufacturer) refers to an enterprise responsible for product definition, design, brand building and market sales. OEMs usually determine the functional specifications, technical solutions and market positioning of the products, and own the intellectual property rights and brand ownership of the products.

In the electronics industry, OEMs often do not directly participate in specific production and manufacturing. Instead, they entrust the manufacturing and assembly processes to professional manufacturing service providers and focus more on product research and development, market promotion, and customer management themselves.

Understanding the division of roles between OEM and electronic contract manufacturing helps to have a clearer understanding of the modern electronic manufacturing model:

• OEM (Original Equipment Manufacturer): Responsible for product design, brand management, and market sales

• Electronic Contract Manufacturer: Manufactures the product according to the OEM’s requirements and specifications

Under this model, OEMs rely on contract electronic manufacturers to complete actual production while still holding the intellectual property rights and market control of the products.

In the current electronic manufacturing services industry, OEMs and electronic contract manufacturers usually cooperate closely in a long-term manner. The two parties are no longer merely in a simple purchasing and supplying relationship, but have established a collaborative cooperative relationship centered on product quality, delivery stability and cost control.

PCBasic is a PCB and PCBA manufacturing enterprise headquartered in Shenzhen. It was established in 2011 and has long been providing electronic contract manufacturing related services to global customers, covering the entire process from design support to production and delivery.

The manufacturing capabilities of PCBasic include PCB manufacturing, component procurement, electronic assembly and functional testing, which can simultaneously support small-batch sample production and large-scale mass production requirements.

As a professional contract electronic manufacturer, PCBasic has established a complete quality management system and has passed a number of internationally recognized certifications, including

• ISO 9001 (Quality Management System)

• IATF 16949 (Automotive Quality Management System)

• ISO 13485 (Medical Device Quality Management System)

• ISO 14001 (Environmental Management System)

• ISO 45001 (Occupational Health and Safety Management System)

In addition, PCBasic's products also comply with multiple international market access standards such as CE, FCC, RoHS, and CCC, demonstrating its capabilities in the manufacturing of high-reliability and compliant electronic products.

PCBasic realizes traceable management and quality control of the production process by introducing CRM, MES and ERP systems, and enhances the stability of electronic contract manufacturing services.

Combining automated production lines and engineering support capabilities, PCBasic can continuously provide reliable delivery performance, embodying the typical characteristics of modern contract electronic manufacturing enterprises.

Electronic contract manufacturing has become a mature and widely adopted manufacturing model in the current electronics industry. Whether it is startups or large brands, an increasing number of companies choose to cooperate with electronic contract manufacturing companies to complete product manufacturing and delivery in a stable and efficient manner.

By adopting professional contract manufacturing services, enterprises do not need to build their own factories. It is also possible to obtain reliable electronic manufacturing capabilities, standardized electronic assembly processes, and corresponding supply chain support.

With the continuous upgrading of product technology, electronic contract manufacturing services will continue to play a significant role in enhancing manufacturing efficiency, shortening delivery cycles, and supporting the global development of enterprises.

What’s the difference between ECM and traditional manufacturing?

Traditional manufacturing requires in-house factories and production teams. Electronic contract manufacturing outsources these functions to specialized electronic contract manufacturers, reducing cost and risk.

How does ECM impact product quality and costs?

High-quality electronic manufacturing services improve consistency and yield while lowering overall production costs through scale, automation, and supply-chain optimization.

What industries rely most on electronic contract manufacturing?

Industries such as consumer electronics, automotive, medical devices, industrial automation, and telecommunications rely heavily on electronics contract manufacturing companies and EMS contract manufacturing models.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.