Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Comprehensive Guide to CNC Rapid Prototyping? | PCBasic

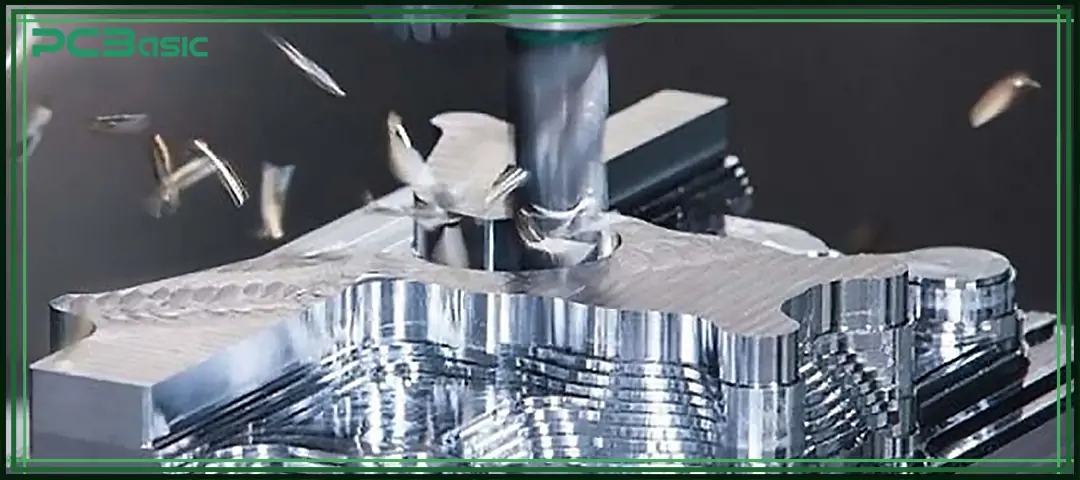

In the current product development process, the development cycle time, machining accuracy and manufacturing flexibility are the key factors influencing the success of a project. In order to complete the design verification as soon as possible on the premise of ensuring product quality and cost control, more and more enterprises have begun to adopt CNC rapid prototyping as the core prototype manufacturing method.

CNC rapid prototyping combines the dimensional accuracy of CNC machining with the high efficiency of rapid prototyping, enabling engineering teams to directly process the CAD design into a physical prototype that can be assembled and tested in a relatively short time. These prototypes can be used for structural validation, assembly verification and functional testing, truly reflecting the actual performance of subsequent mass-produced parts.

This article will focus on explaining what CNC rapid prototyping is, systematically introducing the working model and application of CNC prototyping services, comparing the differences between traditional prototype manufacturing and modern rapid prototyping technology, and, at the same time, explaining how PCBasic, through its mature CNC machining services and prototyping manufacturing system, provides stable and efficient technical support for product development.

CNC rapid prototyping refers to a manufacturing method that uses CNC equipment to process physical prototype parts based on CAD design data within a relatively short timeframe. Its core purpose is to verify the part structure, assembly fit and functional performance before mass production.

During the CNC rapid prototyping process, computer-controlled machine tools precisely cut raw materials such as metals or plastics according to programmed instructions, and form the final part's geometric shape by removing excess materials.

As CNC prototyping is a typical subtractive manufacturing process, it has more obvious advantages over additive manufacturing methods in terms of dimensional accuracy, surface quality and material realism. Therefore, it is more suitable for functional testing, assembly validation and applications with high precision requirements.

Plastic CNC prototyping is mainly used for consumer electronic products, enclosures, and parts for preliminary structural verification.

Plastic rapid prototyping has a relatively low cost, a short machining lead time, and stable surface quality of parts, making it suitable for design confirmation and visual evaluation in the early stage of product development.

Metal CNC rapid prototyping is suitable for parts that have specific requirements for strength, thermal resistance or electrical conductivity.

Metal CNC machining prototyping is commonly used in fields such as automobiles, aerospace, industrial equipment, and medical devices, mainly for functional verification, assembly testing, and load-bearing performance evaluation.

Hybrid prototyping manufacturing combines CNC machining services with processes such as 3D printing and sheet metal processing. This approach allows engineers to select the appropriate manufacturing method according to the part structure and testing requirements, while ensuring development efficiency, better balance cost and performance.

|

Prototyping Type |

Plastic CNC prototyping |

Metal CNC rapid prototyping |

Hybrid prototyping manufacturing |

|

Common Materials |

ABS PC (Polycarbonate) Nylon POM (Polyoxymethylene) Acrylic |

Aluminum alloys Stainless steel Brass Copper Titanium |

CNC-machined materials combined with 3D printing materials and sheet metal |

|

Primary Uses |

Consumer electronics Product enclosures Preliminary structural validation |

Functional parts High-strength or heat-resistant components |

Structurally complex or multi-process parts |

|

Typical Industries |

Consumer electronics |

Automotive Aerospace Industrial equipment Medical devices |

Multi-industry product development |

|

Key Advantages |

Lower cost Short machining lead time Stable surface quality |

High strength Production-grade materials Suitable for functional testing |

Flexible process selection Balanced cost and performance |

|

Suitable Development Stage |

Early-stage product development |

Mid to late-stage functional validation |

Cross-stage rapid iteration |

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Compared with other prototyping services, CNC machining prototyping has more advantages in terms of delivery time, accuracy and production scalability.

Fast is one of the main advantages of CNC rapid prototyping. After the design is finalized, the CNC equipment can process continuously, enabling quick turn prototyping to be completed within a few days.

CNC machining can provide stable tolerance control and ensure the consistency of parts batches, ensuring good repeatability across prototype batches.

Unlike some rapid prototyping services that only use plastic or resin, CNC prototyping can use engineering-grade materials such as aluminum, stainless steel, copper, ABS, POM, and nylon, getting closer to the final mass-produced parts.

CNC rapid prototyping can directly use the same CNC manufacturing process as mass production, and is suitable for small-batch trial production and subsequent large-scale production, reducing the risks brought by process changes.

Before the emergence of modern CNC rapid prototyping, the traditional prototyping manufacturing methods were usually time-consuming and costly.

|

Aspect |

Traditional Prototyping |

CNC Rapid Prototyping |

|

Lead Time |

Weeks or months |

Days |

|

Cost |

High tooling costs |

Lower upfront cost |

|

Design Changes |

Difficult |

Easy and fast |

|

Accuracy |

Moderate |

Very high |

|

Materials |

Limited |

Wide material range |

With the help of CNC rapid prototyping, engineers can carry out design iterations more quickly, test multiple design schemes simultaneously, and effectively reduce the high-cost risk caused by design problems before entering mass production.

A common CNC rapid prototyping project is generally carried out in the following steps:

The part model is established using CAD software to clarify the dimensions, structure and assembly relationship. The model serves as the input file for CNC machining.

Conduct DFM analysis on CNC machining to check if the structure is easy to process and make adjustments to unreasonable designs.

According to the functional requirements of the parts, select appropriate metal or plastic materials to make the performance of the prototype closely match that of the mass-produced parts.

Based on the design and materials, generate the CNC machining program and determine the machining sequence and tool path.

Parts are processed through CNC equipment and followed by necessary post-processing deburring, polishing, or surface finishing.

Inspect the key dimensions and assembly interfaces to confirm that the prototype meets the design requirements.

Professional CNC prototyping services will control the machining speed and accuracy throughout the entire process, ensuring stable prototype quality, thereby providing customers with reliable prototyping services, supporting rapid design verification and iteration.

CNC rapid prototyping is widely used in multiple industries, including:

• Consumer electronics housings and brackets

• Automotive functional components

• Industrial control parts

• Medical device prototypes

• Robotics and automation systems

Because CNC machining services can produce parts with stable structures and high precision, CNC prototyping is often used in functional testing, small-batch trial production, and pre-mass production verification stages.

Choosing the right rapid prototyping company is crucial to the success of the project. When evaluating CNC prototyping services, it is recommended to focus on the following aspects:

• Machining accuracy and tolerance control

• Material availability

• Lead time and quick turn prototyping capability

• Engineering support

• Quality inspection standards

A reliable rapid prototyping company should possess the ability to provide one-stop prototyping services from design support to finished product delivery, ensuring a smooth project process and controllable results.

When you are ready to turn your design into reality, PCBasic offers a comprehensive CNC rapid prototyping solution based on years of precision manufacturing experience. As a reliable rapid prototyping company, PCBasic has over 15 years of CNC machining experience and can provide prototyping and custom processing services for projects of all levels of complexity.

From design review and DFM analysis to machining, finishing, and delivery.

Support for 3-axis, 4-axis, and 5-axis CNC machining, suitable for complex geometries and tight tolerances.

Machining support for aluminum, stainless steel, copper, brass, titanium, ABS, POM, nylon, and more.

Ideal for quick turn prototyping, one-off samples, and low-volume pilot runs.

Professional feedback to improve manufacturability, accuracy, and part performance.

Dimensional inspection and quality checks ensure prototypes meet design requirements.

With reliable CNC rapid prototyping services, PCBasic helps you shorten development cycles and move smoothly from prototype to production.

CNC rapid prototyping has become a common method in product development. By combining the efficiency of rapid prototyping with the machining accuracy of CNC, enterprises can identify problems earlier in the development stage, shorten the development cycle, and enhance the consistency and reliability of the final product.

With the help of mature CNC prototyping services, enterprises can achieve fast prototyping, use real engineering materials, and obtain processing accuracy close to the mass production level. PCBasic, as a reliable rapid prototyping company, can provide complete CNC prototyping and CNC manufacturing solutions for global customers, supporting a smooth transition of products from the prototype stage to mass production.

Q1: What is rapid prototyping CNC machining?

It is a process that uses CNC machining to quickly produce accurate prototypes from CAD models using real production materials.

Q2: Is CNC rapid prototyping better than 3D printing?

For functional testing and tight tolerances, CNC rapid prototyping often outperforms additive rapid prototyping services.

Q3: How fast is CNC rapid prototyping?

With professional CNC machining services, prototypes can often be completed within a few days.

Q4: What industries use CNC prototyping services?

Electronics, automotive, industrial equipment, medical devices, and robotics all rely heavily on CNC prototyping services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.