Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Key Certifications of Reliable PCBA Manufacturers

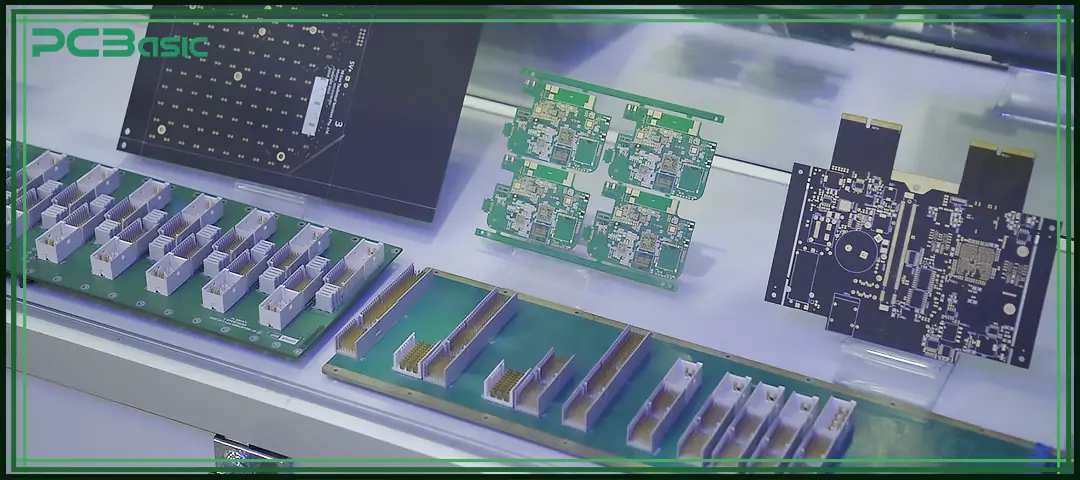

Choosing a reliable PCBA manufacturer is one of the most important decisions in the research and development of electronic products. With the continuous growth of smart hardware, medical devices, automotive electronics and industrial control, the global electronics contract manufacturing market has exceeded $500 billion. Products are getting smaller and more integrated and complex, making it essential to choose a PCBA manufacturer or PCBA supplier with a complete certification system. Cooperating with PCBA manufacturers that have a complete certification system can not only enhance product reliability but also reduce rework, improve yield rates, and accelerate the compliance audits of products in the global market.

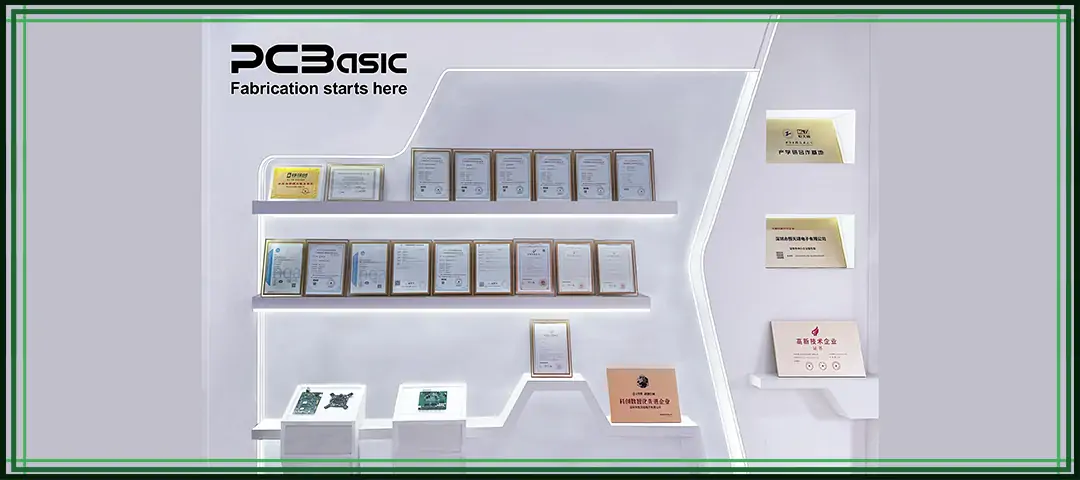

As a leading PCBA supplier in the industry, PCBasic has long served multiple fields, including consumer electronics, medical devices, industrial control, automotive electronics, and energy equipment. PCBasic not only possesses core certifications such as ISO 9001, ISO 13485, RoHS, REACH, and IPC, but also is equipped with advanced SMT production lines, automated testing equipment, a complete traceability system, and strict supply chain management processes, ensuring that each PCBA process and every production stage fully complies with international standards.

This article will systematically introduce to you the key certifications that a reliable PCBA manufacturer must possess, and demonstrate how PCBasic maintains strict compliance throughout the PCBA manufacturing process, providing customers with stable, high-performance, and highly reliable PCB assembly services.

Why can certifications reflect whether a PCBA manufacturer is reliable? Because each certification proves that this enterprise has real, verifiable capabilities, such as:

• A structured quality management system

• A controlled and traceable production environment

• Proven compliance with environmental and safety regulations

• Demonstrated technical competence and reliability

For any PCBA manufacturer, these certifications are the basis of its operational capabilities. Without them, many hidden problems are likely to occur during production, such as unstable solder joints, material contamination, gaps in traceability, or failures in regulatory audits, all of which will directly affect the reliability of the entire PCBA manufacturing process.

PCBasic holds multiple core certifications, proving that it has strict process control capabilities and near-zero-defect production levels in the field of PCB assembly. For customers, cooperating with PCBasic means that the products are safer, more stable, have a higher production yield rate, and can enter the market more quickly.

For any PCBA manufacturer, ISO 9001 is the most fundamental and important quality assurance standard. Having this certification indicates that the factory possesses:

• Documented and controlled workflows

• Standardized procurement and PCB assembly processes

• Continuous improvement

• Consistent output across all batches

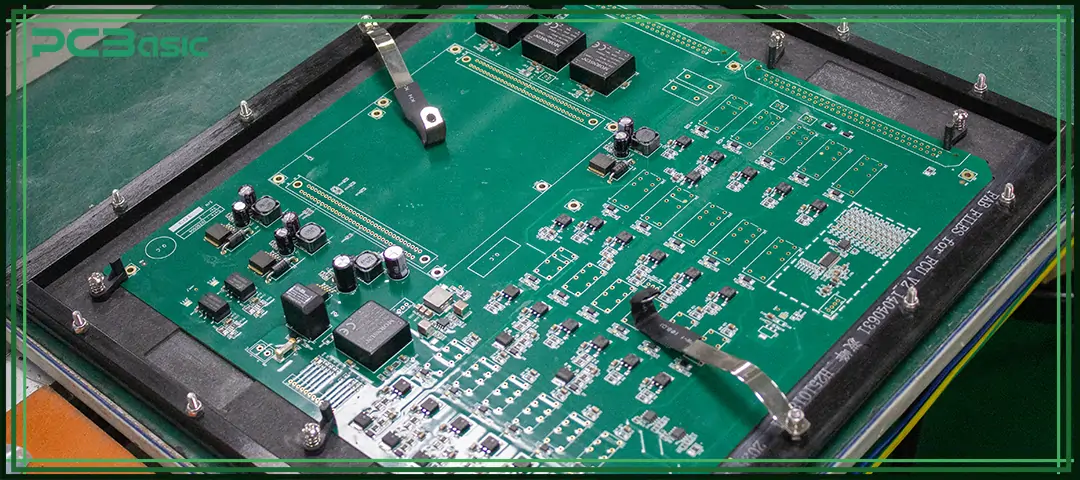

PCBasic integrates the ISO 9001 standard throughout the entire production process, including material procurement, SMT printing, reflow profiling, AOI inspection, X-ray analysis and final testing, ensuring that each PCBA reaches a stable and consistent quality level.

For the purchaser, choosing a PCBA supplier that holds the ISO 9001 certification can greatly reduce uncertainties and make the production performance more controllable and reliable.

In the field of medical electronics, ISO 13485 is almost a necessary requirement for entering the market. PCBA manufacturers that have obtained this certification must demonstrate:

• Enhanced traceability

• Risk management and hazard control

• Process validation

• Documentation rigor tailored to healthcare products

PCBasic strictly adheres to the ISO 13485 standard in medical PCB assembly projects, comprehensively controls materials, processes, tests and document management to ensure that every PCBA produced is safe and reliable and can smoothly meet market regulatory requirements.

The core requirement of RoHS is to enable PCBA manufacturers to avoid using substances harmful to human health and the environment during the production process, such as lead, mercury, cadmium and certain flame retardants.

If a PCBA supplier complies with RoHS, it indicates that it can truly achieve:

• Lead-free PCB assembly

• Verified RoHS-compliant components

• Full material declaration reports (MD/CoC)

PCBasic uses lead-free solder pastes, boards and electronic components that have been certified throughout the process, ensuring that each PCBA fully complies with the global RoHS standard, allowing customers to have no worries when exporting or obtaining certification.

The main purpose of REACH is to restrict the hazardous chemicals that may exist in materials. PCBA manufacturers that comply with REACH requirements can ensure:

• No SVHC (Substances of Very High Concern)

• Safe material handling

• Verified component sources

PCBasic strictly manages REACH documents and material records to ensure that customers' PCBA products do not encounter chemical compliance risks when entering the EU market.

The objective of ISO 14001 is to enable factories to minimize their environmental impact in daily production as much as possible. For responsible PCBA suppliers, this means doing well:

• Recycling waste boards

• Reducing chemical emissions

• Enhancing energy efficiency

• Managing scrap responsibly

PCBasic manages the entire PCB assembly factory in accordance with the requirements of ISO 14001, ensuring high-quality production while reducing the environmental burden, making the manufacturing process greener, safer and more sustainable.

The significance of UL certification is very simple: it ensures that the materials used in PCB assembly meet the standards that meet fire-safety and general safety standards, such as the common UL94-V0 flame-retardant rating.

If a PCBA manufacturer has obtained UL certification, it indicates that this PCBA manufacturer can guarantee:

• Flame-retardant materials

• Safe dielectric properties

• Documented compliance for North America

In all high-reliability PCBA projects, PCBasic uses UL-recognized laminates and materials to ensure that the products remain safe and stable during long-term use.

IPC standards are the universal workmanship and process benchmarks followed by the global electronics manufacturing industry. As long as it is a professional PCBA supplier, it must strictly follow the IPC standards to ensure the soldering quality, reliability and consistency of the PCBA.

IPC-A-610 classifies products into three categories according to reliability grades:

• Class 1: General electronics

• Class 2: Industrial and consumer electronics

• Class 3: Aerospace, medical, and mission-critical systems

The technicians of PCBasic have all received IPC training and are capable of providing PCB assembly that meets the requirements of Class 3, ensuring the stable operation of the products even in harsh environments.

The function of IPC-7711/7721 is to provide clear process standards for the repair of various precision PCBA, including:

• BGAs

• Fine-pitch ICs

• Through-hole components

• Micro-jumpers

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

For automotive electronics, IATF 16949 is mandatory.

It requires:

• Rigorous process control

• Full traceability

• PPAP and APQP documentation

• Ultra-low defect rates

PCBasic provides automotive-grade PCBA and PCB assembly with full documentation support.

ISO 45001 ensures factory workers operate in a safe environment, essential for high-precision PCBA manufacture.

It covers:

• Machine safety

• Chemical handling

• ESD protection

• Operator training

PCBasic maintains ISO 45001 compliance to ensure consistent, safe, and high-quality production.

Although CE applies to final products—not PCBA alone—a reliable PCBA supplier must ensure every assembly supports CE compliance.

PCBasic helps customers by supporting:

• EMC-ready PCB assembly

• Safe creepage/clearance design

• Verified materials and components

FCC regulations govern radio-frequency emissions in the US market.

A competent PCBA manufacturer must:

• Follow EMC design rules

• Minimize EMI/EMC issues

• Use compliant PCB stackups

PCBasic supports FCC compliance through controlled PCB assembly and testing.

This certification applies to test labs—not manufacturers.

However, a top PCBA supplier must use ISO/IEC 17025–accredited partner labs.

PCBasic works with accredited labs for:

• RF testing

• Thermal cycling

• Environmental stress screening

• Reliability verification

Combined with internal AOI, X-ray, SPI, ICT, and FCT, PCBasic ensures every PCBA performs reliably.

|

Category |

Certification |

Primary Purpose |

Requirements for a PCBA Manufacturer |

|

Quality Management |

ISO 9001 |

Fundamental quality management system |

Documented workflows, standardized production, continuous improvement, consistent output |

|

ISO 13485 |

Medical device quality system |

Full traceability, risk control, process validation, and strict documentation |

|

|

Environmental Compliance |

RoHS |

Restriction of hazardous substances |

Lead-free PCB assembly, RoHS components, material declarations |

|

REACH |

Chemical substance regulation |

No SVHC, safe material handling, verified component sources |

|

|

ISO 14001 |

Environmental management |

Waste board recycling, reduced emissions, energy efficiency, controlled waste handling |

|

|

Industry & Product Certifications |

UL |

Fire and safety compliance |

Flame-retardant materials, dielectric safety, North America compliance |

|

IPC-A-610 |

Global workmanship standard |

Class 1/2/3 workmanship requirements |

|

|

IPC-7711/7721 |

Precision rework standard |

BGA, fine-pitch IC, through-hole and micro-jumper rework |

|

|

Manufacturing Process Certifications |

IATF 16949 |

Automotive electronics quality system |

Strict process control, full traceability, PPAP/APQP, extremely low defect rates |

|

ISO 45001 |

Occupational health & safety |

Machine safety, chemical handling, ESD protection, operator training |

|

|

Testing & Reliability |

CE Support |

EU regulatory readiness |

EMC safety, creepage/clearance design, compliant materials |

|

FCC Support |

RF emission compliance |

EMC design rules, reduced EMI, compliant stackups |

|

|

ISO/IEC 17025 (Partner Labs) |

Accredited testing competence |

RF testing, thermal cycling, environmental stress, reliability verification |

PCBasic integrates all core certifications into a complete and traceable PCBA production system, including:

• Self-developed MES system ensuring 100% traceability

• Automated SPI, AOI, and X-ray quality checkpoints

• Strict supplier approval system (AVL)

• Full documentation for CE, FCC, UL, and RoHS support

• Class 3–capable soldering processes

• Lead-free, RoHS-compliant, and REACH-compliant materials

• ISO and IPC-certified engineers overseeing production

These capabilities make PCBasic not only a reliable PCBA manufacturer, but also a long-term cooperative PCBA supplier, which can fully support the needs of different fields such as consumer electronics, industrial control, automotive electronics and medical equipment.

For customers, this means:

• lower defect rates

• faster compliance approvals

• fewer production risks

• stable, high-yield PCB assembly from prototype to mass production

All kinds of certifications are not optional. They are the key basis for judging whether a PCBA manufacturer is reliable. From ISO 9001, IPC-A-610, to RoHS, UL, IATF 16949, and CE/FCC compliance support, each certification protects your products and avoids risks in terms of safety, quality or regulations.

As a PCBA supplier that holds multiple certifications, PCBasic provides industry-leading PCB assembly services to customers with strict process control, advanced testing capabilities and a complete compliance document system. Whether you need to produce 5 prototype samples or 50,000 mass production units, PCBasic can provide every project with safe, stable and globally standard-compliant PCBA.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.