Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Aluminum PCB Ultimate Guide

As electronic devices become smaller and more powerful, the heat generated by components during operation also increases accordingly. If this heat cannot be dissipated in time, it may directly affect the performance of the circuit. Although the traditional FR4 PCB is the most commonly used, it has almost no thermal conduction capacity. To dissipate heat, it is often necessary to add additional heat sinks, drill many thermal vias, and even add fans. This not only makes the circuit board larger in size and higher in cost, but also limits the design flexibility.

To solve these problems, the aluminum PCB emerged. As a metal core PCB (MCPCB), especially the aluminum substrate with aluminum as the core, it has greatly changed the heat dissipation method of high-power electronic products. Nowadays, aluminum PCB has become the first choice for thermal management in many industries.

In this article, we will provide a comprehensive introduction to what an aluminum PCB is, its structure, main advantages, common types, as well as the differences and application scenarios between it and traditional FR4 PCBs. Finally, you will know why almost all metal core PCB manufacturers consider it an important breakthrough in the field of electronic manufacturing.

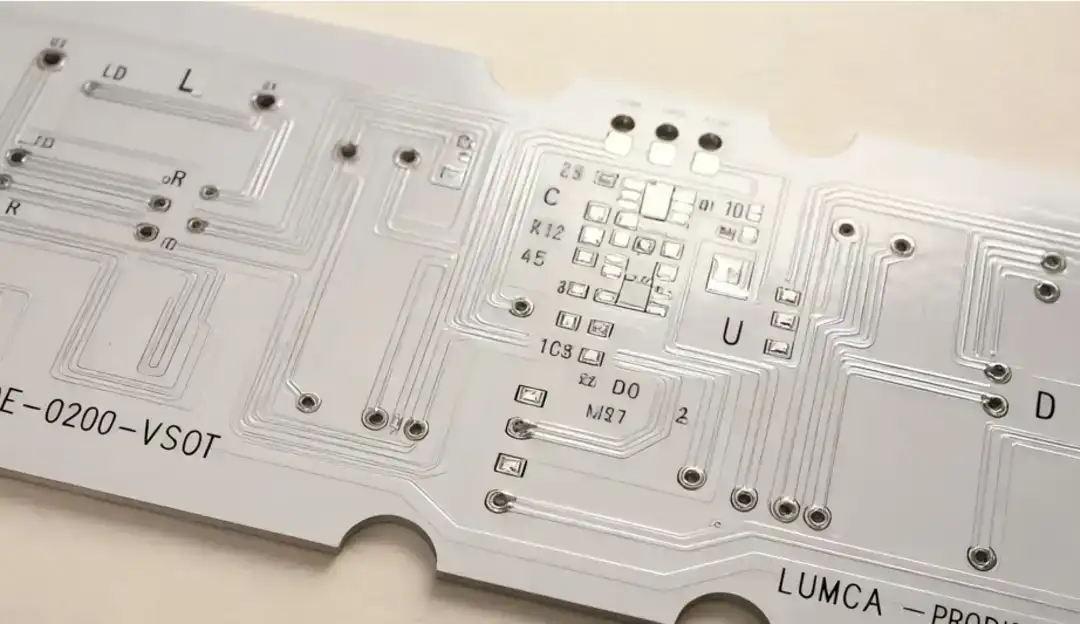

An aluminum PCB is a special type of metal core board. Its base material is an aluminum substrate, rather than the traditional FR4 fiberglass. The aluminum PCB belongs to a type of metal core PCB. It is also often called an aluminum core PCB, thermal clad PCB, aluminum clad PCB or insulated metal substrate PCB.

The concept of this type of circuit board first emerged in the 1970s, when aluminum PCBs were used in power amplifier hybrid integrated circuits. With the development of the LED lighting industry, this type of metal circuit board has been used more and more widely because, in high-power devices, the quality of heat dissipation directly determines the performance and lifespan of the circuit.

Nowadays, the aluminum PCB has become the preferred choice for many applications that require high heat dissipation, strong durability and dimensional stability. Almost all leading metal core PCB manufacturers and aluminum PCB manufacturers treat aluminum PCB prototyping and mass production as important services.

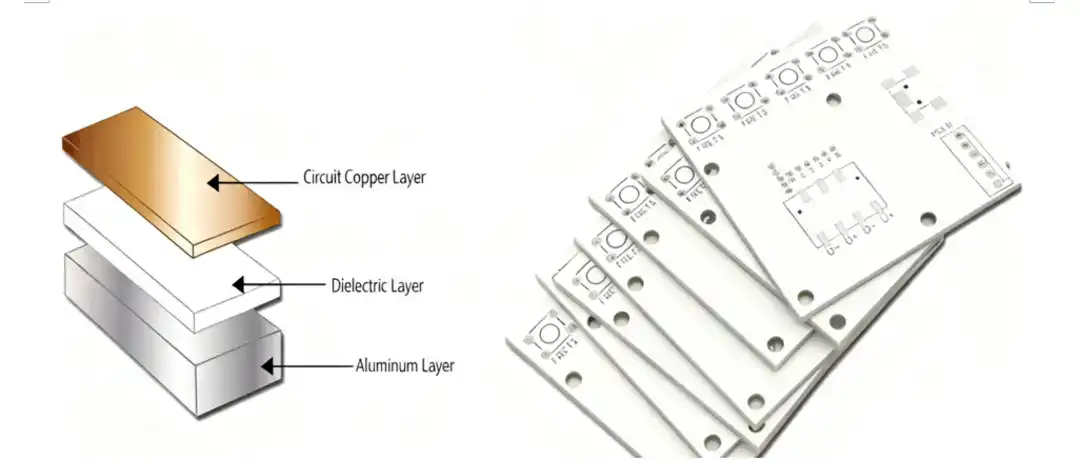

A typical aluminum PCB mainly consists of four parts: the copper foil layer, the dielectric insulation layer (PP layer), the aluminum base layer, and the aluminum base membrane. This structure enables metal core PCBs to not only meet electrical performance requirements but also provide excellent heat conduction effects, making it the core design of aluminum core PCBs.

This is the top layer of the aluminum PCB, which is used to etch circuit patterns and form traces and pads. Similar to an ordinary FR4 PCB, but in an aluminum core PCB, the copper layer is usually thicker and can carry greater currents.

The dielectric layer is a key component of an aluminum PCB. It has three functions:

• Electrical insulation ensures that the copper layer and aluminum base layer do not short-circuit.

• Heat conduction, rapidly transferring the heat in the circuit to the metal core board;

• Mechanical bonding, ensuring a firm bond between the copper layer and the aluminum layer.

This is the bottom layer of the circuit board and also the aluminum substrate itself. It provides mechanical strength, functions as a heat sink, and can also be machined with slots, fins, or other features to improve cooling.

Some aluminum-clad PCBs have an oxide film added to the surface of the aluminum base layer, which serves to prevent scratches, avoid chemical corrosion, and also enhance the adhesion between the dielectric layer and the aluminum layer.

Overall, the structure of an aluminum PCB not only ensures electrical performance but also takes into account heat dissipation performance, which is the greatest advantage of a metal circuit board. It is precisely for this reason that when aluminum PCB manufacturers are conducting aluminum PCB prototyping or mass production, they will focus on optimizing these layers of structure.

Compared with traditional FR4 boards and ceramic substrates, aluminum PCBs have many unique advantages. These features make aluminum core PCBs the preferred solution for high power and high heat dissipation requirements in modern electronic products.

The thermal resistance of a 1.5mm thick FR4 PCB is approximately 20-22 °C/W, while that of an aluminum PCB of the same thickness is only 1-2 °C/W, indicating a significant improvement in heat dissipation efficiency.

The coefficient of thermal expansion (CTE) of aluminum (~22 ppm/°C) is close to that of copper (18 ppm/°C). This matching can reduce the stress on solder joints during temperature changes and enhance the reliability of SMT soldering.

When the temperature rises from 30°C to 140°C, the dimensional change of aluminum PCB is only 2.5% to 3%, which is more stable than FR4 and particularly suitable for equipment with high precision requirements.

Compared with ceramic-based metal circuit boards, aluminum substrates are tougher, less fragile, and more resistant to impact, and are more reliable in production, shipping and use.

Aluminum is a non-toxic, recyclable and abundant material. The use of aluminum-clad PCB is not only environmentally friendly but also in line with the development direction of green manufacturing in the electronics industry.

The aluminum PCB is slightly more expensive than FR4, but much cheaper than a copper-based metal core PCB. Moreover, it can provide heat dissipation, eliminating the need for additional heat sinks and making the overall cost more cost-effective.

The structure of an insulated metal substrate PCB not only ensures electrical insulation but also naturally reduces EMI interference, making the circuit operation more stable and safer.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Aluminum PCBs are not designed in just one form. According to the number of circuit layers and specific application requirements, they can be classified into different types. Each type strikes a balance among heat dissipation performance, cost and circuit complexity, thus being able to meet the application requirements of different industries.

|

Type |

Key Features |

Typical Applications |

|

Single-Layer Aluminum PCB |

Simplest design; components on one side; heat flow: components → copper → dielectric → aluminum |

LED modules, basic lighting circuits |

|

Double-Layer Aluminum PCB (Single-Sided Components) |

Two copper layers separated by a dielectric; only one side for component mounting |

Power supply boards, driver circuits |

|

Double-Layer Aluminum PCB (Dual-Sided Components) |

Components mounted on both sides; resin-filled vias isolate PTHs from the aluminum base |

High-power electronics, automotive modules |

|

Four-Layer Aluminum PCB |

Up to 4 circuit layers; supports HDI (blind/buried vias); slightly lower thermal performance than single/double layer |

Complex control modules, high-frequency circuits |

|

Flexible Aluminum PCB |

Uses flexible aluminum alloys with polyimide dielectric; bendable but not for continuous flexing |

Smartphones, compact devices |

|

Hybrid Aluminum PCB |

Combines FR4 layers with an aluminum substrate; balances routing flexibility with thermal management. |

LED drivers, automotive control units |

|

Through-Hole Aluminum PCB |

Pre-drilled aluminum filled with dielectric supports plated through holes; complex and costly. |

Industrial control, advanced power modules |

|

High Thermal Conductivity PCB |

Customized dielectric with thermal conductivity up to 5–9 W/m·K |

High-power LEDs, power converters |

|

High-Frequency Aluminum PCB |

Uses polyimide or polyolefin dielectrics for RF/microwave circuits |

RF devices, microwave communication equipment |

The standard FR4 circuit board is currently the most widely used type of printed circuit board, and its base material is FR4 (a fiberglass-reinforced epoxy laminate). This material is widely adopted due to several notable advantages:

• Low cost and abundant supply;

• Good insulation performance and high mechanical strength;

• Suitable for single-layer, double-layer and even multi-layer PCB designs.

However, the thermal conductivity of FR4 boards is very poor. It can hardly dissipate heat actively. In high-power circuits, it is usually necessary to install additional heat sinks, drill thermal vias or add air cooling to ensure temperature control.

Aluminum PCBs vs. Standard FR4 PCBs

|

Item |

Aluminum PCB |

Standard FR4 PCB |

|

Substrate Material |

Aluminum substrate, metal core board with excellent thermal conductivity |

FR4 (glass fiber reinforced epoxy resin) a common insulating material |

|

Thermal Conductivity |

Very high (1–9 W/m·K), quickly transfers heat to the metal core |

Very low (~0.3 W/m·K), almost no heat dissipation ability |

|

Heat Dissipation Needs |

Built-in heat dissipation, usually no need for extra heat sinks |

Requires additional heat sinks, thermal vias, or forced air cooling |

|

Mechanical Strength |

Strong, tough, impact-resistant, and not easy to crack |

Decent strength, but weaker than an aluminum substrate, prone to thermal deformation |

|

Dimensional Stability |

When heated from 30°C to 140°C, dimensional change is only about 2.5%–3% |

Higher coefficient of thermal expansion, more deformation under temperature changes |

|

Cost |

Slightly higher than FR4, but cheaper than copper-based MCPCBs; overall cost-effective |

Low cost, the first choice for consumer electronics |

|

Applications |

LED lighting, power modules, automotive electronics, communication equipment, and medical devices |

General consumer electronics, computer motherboards, home appliances, and low-power devices |

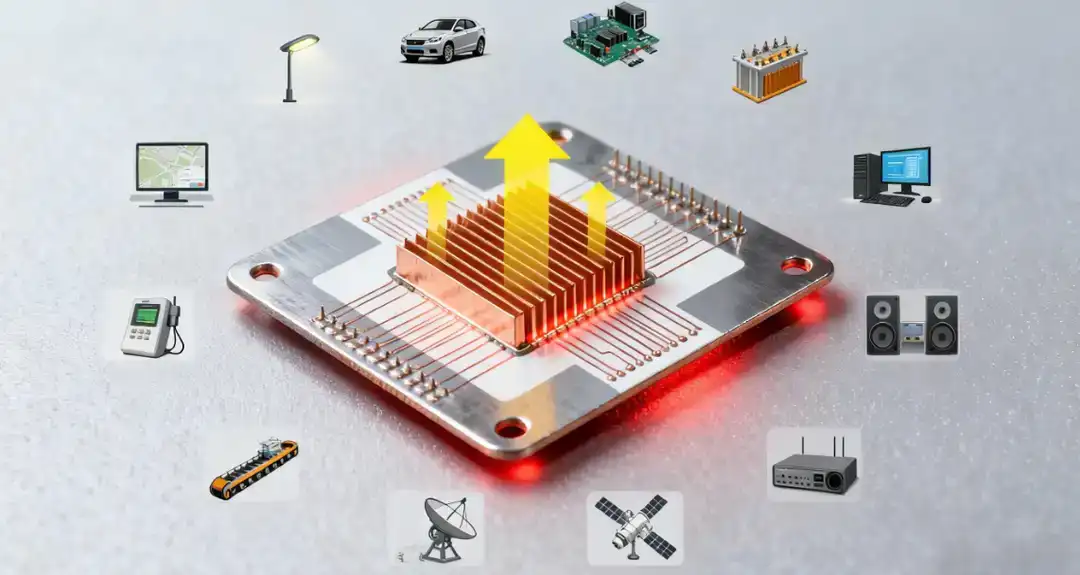

Aluminum PCBs are widely used in industries where heat management is critical:

• LED Lighting: Street lights, automotive headlights, stop lights, residential bulbs, display panels.

• Automotive: ECU, ignition systems, motor controllers, EV battery modules.

• Power Electronics: Inverters, converters, power supplies, regulators.

• Computers: CPU boards, power supplies, cooling modules.

• Consumer Electronics: Smartphones (camera modules), gaming consoles, TVs.

• Medical Devices: Imaging systems, diagnostic equipment, monitoring systems.

• Telecommunications: Base station amplifiers, RF devices, 5G equipment.

• Industrial Automation: Motor drives, factory control, high-power systems.

• Aerospace & Defense: Avionics, radar, satellites.

• Audio Equipment: Power amplifiers, pre-amplifiers, audio drivers.

Aluminum PCBs are no longer merely a circuit board material but have become the core foundation for heat dissipation management in today's electronic products. With the continuous miniaturization of equipment and the continuous improvement of power density, the market demand for metal core PCBs will continue to grow.

With its wide application in fields such as LED lighting, automotive electronics, power electronics, communication equipment, aerospace, and medical devices, aluminum PCB has become an indispensable core component for many high-power products.

It can be said that with the continuous development of the electronics industry, metal circuit boards like aluminum PCBs will continue to drive design innovation and find a more ideal balance point among performance, durability and cost.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.