Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > SMD Capacitor Sizes Explained: Complete Guide with 0201 & 0402 Packages

SMD capacitors are widely used in various fields. They are one of the most widely used electronic components. These miniature capacitors play a crucial role in electronic devices. In different application scenarios, the stability and reliability of capacitors directly depend on their package size. Therefore, it is crucial to understand their package size.

Next, in this article, we will introduce the basic concepts of surface mount capacitors and the importance of their package sizes. And we will also provide a SMD capacitor size chart and focus on analyzing the importance of 0201 and 0402 package sizes. First of all, let's familiarize the definition, functions, types of SMD capacitors.

SMD capacitors are small capacitors directly soldered onto the surface of a PCB. They have no leads and do not require holes. This feature makes them highly suitable for high-density circuit designs. The main functions of SMD capacitors are decoupling, filtering, signal coupling, and energy storage. These functions ensure the stability of circuit voltage, reduction of noise, and reliability of the circuit. SMD capacitors can mainly be classified into SMD ceramic capacitors, SMD tantalum capacitors, and SMD electrolytic capacitors. Then, we will introduce each of them one by one below table.

|

Type of SMD Capacitor |

Structure & Dielectric |

Capacitance Range |

Advantages |

Disadvantages |

Typical Applications |

|

SMD Ceramic Capacitor (MLCC) |

Ceramic dielectric with stacked metal electrodes (multilayer) |

Few pF – tens of µF |

Small size, low cost, excellent frequency characteristics, suitable for high-speed/high-frequency circuits |

May crack under high voltage or thermal shock; sensitive to soldering stress |

IC power decoupling, filtering, RF circuits |

|

SMD Tantalum Capacitor |

Tantalum anode with oxidized tantalum dielectric |

Up to hundreds of µF (higher than ceramics at same size) |

High capacitance in small volume, low leakage, stable, long lifespan, high reliability |

Sensitive to surge current, may fail at power-on without protection |

Power management, medical equipment, portable devices, aerospace & military |

|

SMD Electrolytic Capacitor |

Aluminum electrolyte, cylindrical shape, contains liquid electrolyte |

Much larger range (µF to thousands of µF) |

High capacitance values, widely available, suitable for power circuits |

Poor high-frequency performance, limited lifespan, polarized (must respect polarity) |

Audio amplifiers, motor drives, switching power supplies |

Other special capacitors (film, capacitor, supercapacitor)

|

Type of Capacitor |

Key Features |

Typical Applications |

|

SMD Film Capacitor |

Excellent insulation performance, strong stability |

Industrial electronics, automotive systems |

|

SMD Polymer Capacitor |

Low ESR, good frequency response |

Power supplies, computer motherboards, communication equipment |

|

Supercapacitor |

Extremely large capacitance, suitable for short-term power backup |

IoT devices, renewable energy, backup systems |

The different types of capacitors correspond to various application scenarios. To control costs and circuit board space while ensuring reliability, we need to make a selection based on the package size and capacitor type.

The SMD capacitor package sizes are standardized by international standards organizations such as JEDEC and EIA. This standardization ensures consistency in packaging, mounting, and performance across different manufacturers. This consistency facilitates model selection and replacement during design and production.

Common SMD capacitor package sizes include 0201, 0402, 0603, 0805, and 1206, but smaller (such as 01005) or larger (such as 2220 and 3640) packages are also used in specific applications. Below is a comprehensive SMD capacitor size chart for your reference.

|

Capacitor Size Chart |

|||

|

Imperial Code |

Metric Code (EIA) |

Size (mm) |

Typical Usage |

|

01005 |

0402 |

0.4 × 0.2 |

Ultra-miniature devices, RF modules, implantable medical electronics |

|

0201 |

0603 |

0.6 × 0.3 |

Smartphones, wearables, RF circuits |

|

0402 |

1005 |

1.0 × 0.5 |

Consumer electronics, automotive, Bluetooth/WiFi modules |

|

0603 |

1608 |

1.6 × 0.8 |

General-purpose electronics, computer motherboards, industrial equipment |

|

0805 |

2012 |

2.0 × 1.25 |

Power modules, DC-DC converters, audio circuits |

|

1206 |

3216 |

3.2 × 1.6 |

Automotive control units, industrial control, power circuits |

|

1210 |

3225 |

3.2 × 2.5 |

Power filtering, high current circuits |

|

1812 |

4532 |

4.5 × 3.2 |

Automotive electronics, communication devices |

|

2220 |

5650 |

5.6 × 5.0 |

High-frequency power supplies, LED drivers, large capacitance applications |

|

3640 |

9110 |

9.1 × 10.0 |

Industrial equipment, power electronics, high-power supplies |

Ultra-small packages like 01005 and 0201 are often used in cutting-edge, high-density designs that require extremely high assembly precision. The 0402 and 0603 packages are the most widely used in consumer and industrial electronics because they offer an excellent balance between size, performance, and ease of production.

Next, we will focus on the 0201 and 0402 package sizes.

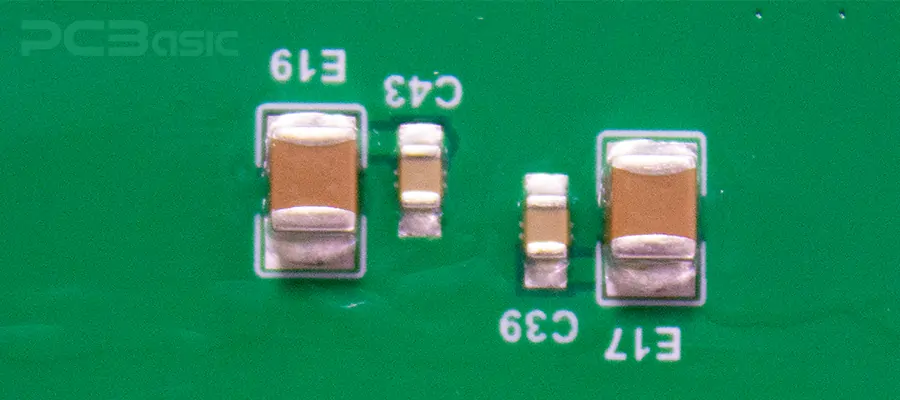

0201 capacitor package size refers to a component with a size of only 0.6 × 0.3 mm. It is one of the smallest standardized SMD capacitor packages available at present. The size of 0201 components is so small that it is almost impossible to be seen with the naked eye, as shown in the following figure:

Capacitors with this package size are very common in extremely miniaturized circuits, such as in smartphones, wearable devices, IoT devices, and RF modules.

The main advantage of the 0201 package size lies in its ability to save space and support high-density layout. Of course, this strong advantage comes with high costs.

In production, 0201 components are extremely difficult to handle, requiring advanced SMT equipment, extremely precise positioning, and strict control of reflow soldering processes to complete assembly and soldering. This is also the reason why 0201 capacitors are usually only used in designs that have the highest priority for ultra-miniaturization.

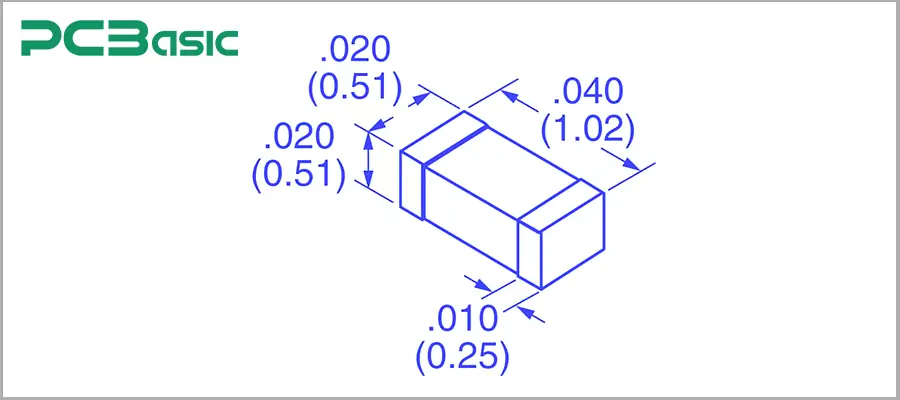

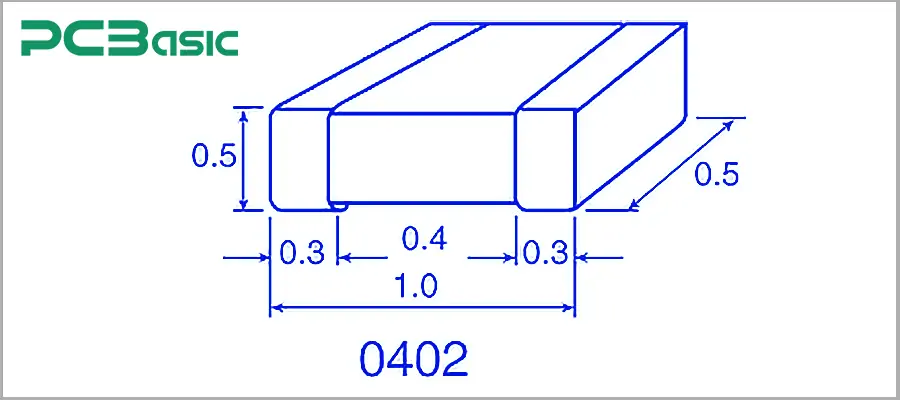

The size of the 0402 capacitor package is 1.0 × 0.5 mm, which is slightly larger than the 0201 package. However, compared to traditional passive components, it is still extremely compact.

The 0402 package size achieves a good balance between miniaturization and manufacturability. This is one of the reasons why it is widely used in the electronics industry. It is widely applied in consumer electronics, automotive electronics, and medical equipment, etc., where reliability and performance are highly demanded.

The advantages of the 0402 capacitor are:

High compatibility with existing SMT production lines;

More reliable solder joints compared to the 0201 package;

Higher cost-effectiveness in large-scale production.

At the same time, this package size capacitor can also provide a wider range of capacitance values and voltage ratings. Its drawback is that it occupies a larger area on the circuit board compared to the 0201 components. As shown in the picture:

This means that it may not be applicable in the most extreme space-constrained devices. However, despite this, the 0402 capacitor is still the best choice in most designs.

|

Feature |

0201 Package Size |

0402 Package Size |

|

Dimensions |

0.6 × 0.3 mm |

1.0 × 0.5 mm |

|

Typical Use |

Smartphones, RF, IoT |

Automotive, medical, consumer |

|

Advantages |

Ultra-compact, space saving |

Easier to assemble, reliable |

|

Challenges |

Placement difficulty, higher cost |

Larger size compared to 0201 |

|

Rated Voltage |

Usually ≤25V |

Up to ~50V |

|

Current/Power Handling |

Very limited, signal-level |

Higher, can handle small power circuits |

|

Reliability / Mechanical Strength |

Fragile, less resistant to bending & thermal stress |

More robust, suitable for harsh environments |

|

Supply & Cost Trend |

Higher cost, limited supply, mainly for high-volume consumer electronics |

Widely available, lower cost |

|

Manufacturing Requirements |

Needs high-precision SMT equipment |

More tolerant, easier for general assembly lines |

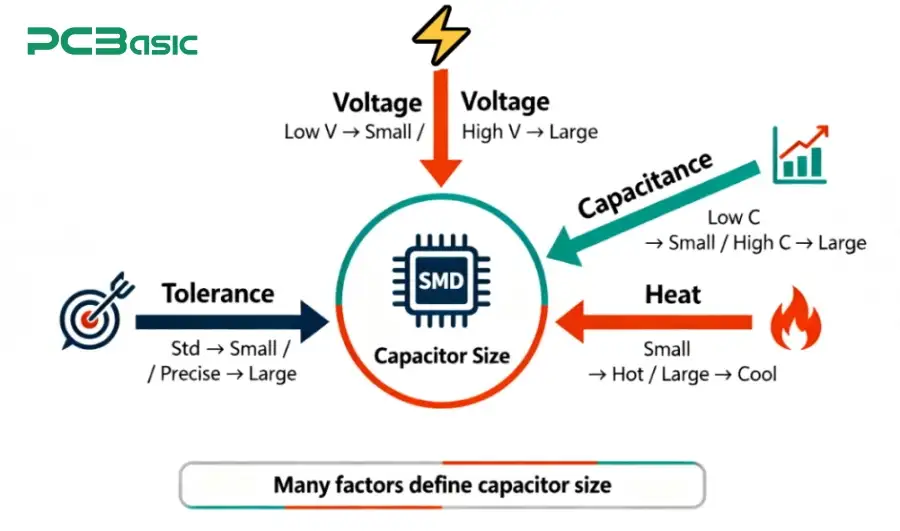

The SMD capacitor size is not solely determined by the package code (such as 0201, 0402, 0603). In actual production, electrical performance requirements, rated voltage, capacitance value, heat dissipation, and mechanical reliability all directly affect the capacitor package size. Let's take a look at what these key factors are!

1. Rated Voltage

To withstand higher working voltages, capacitors require thicker dielectric layers. A thicker dielectric layer directly leads to an increase in device size. Therefore, low-voltage capacitors (such as 6.3V - 16V) can be packaged very small, such as 0201 or 0402. High-voltage capacitors (such as 50V - 100V and above) usually have larger packages, such as 0603, 0805, or even 1206.

2. Capacitance Value

Capacitance is directly proportional to the electrode surface area and dielectric properties. This means that higher capacitance results in a larger volume. Small capacitance (pF to nF range) can easily be achieved in 0201/0402. High capacitance (µF range) usually requires a larger size (0603 - 1210).

3. Heat Dissipation and Thermal Stress

Capacitors generate heat during operation, especially in high-frequency or high-current circuits. Generally, larger packages (0603 and above) can dissipate heat more effectively and extend the lifespan of the capacitor. Very small packages (0201, 01005) are more prone to overheating in power circuits. Therefore, heat dissipation will also be a factor affecting the package size.

4. Tolerance and Precision

High-precision capacitors (±1% or ±2%) require more stable dielectric materials and stricter process control, which often leads to a larger size. Therefore, standard tolerance capacitors (±10% to ±20%) can achieve very small packages. Precision capacitors require larger packages to ensure consistent electrical performance. In summary, the size of SMD capacitors is not determined solely by the package code; it is also influenced by the following factors:

Rated Voltage— Higher voltage → Thicker dielectric → Larger package.

Capacitance Value —— Higher capacitance → More volume → Larger package.

Heat Dissipation Performance —A larger size can better withstand thermal stress.

Tolerance— High-precision capacitors tend to be larger in size.

Many different electronic products use SMD capacitors. Small packages like 0201 and 0402 are frequently used by engineers in consumer electronics, including smartphones, laptops, and wearable technology, to satisfy the demands of high density and miniaturization.

0603, 0805, and even larger packages are more frequently used in automotive electronics because of the harsh environment and the need for high reliability and heat resistance in components like ECU, battery management, and safety systems.

Capacitors in medical devices including monitors, imaging systems, and ECG must strike a compromise between stability and longevity; 0402 to 0805 packages are most frequently selected.

High voltage and high frequency performance are highly valued in industrial and communication systems, such as PLC, Internet of Things, and base station equipment; medium and large-sized capacitors are more prevalent; and 0201 and 0402 are still utilized in RF circuits to lessen parasitic effects. The applications of capacitors are so wide.

When choosing the appropriate SMD capacitor package size, various factors such as electrical, process and reliability should be taken into consideration comprehensively.

The first step is to become acquainted with the industry standard package codes by reading the SMD capacitor size chart. The capacitance value and the rated voltage should then be combined to get the package size. It's also important to take into account the limits of the production and assembly processes.

Ultra-small packages like 0201 or 01005 can reduce space, but not all PCB manufacturers are able to assemble and test them with enough precision. And choosing excessively tiny packaging will actually increase costs and dangers if the production line cannot sustain it.

Finally, rather than pursuing a specific package size mindlessly, we should trade off size, performance, cost, and reliability according to the real application scenario. We can make a good choice with these instructions.

Surface mount capacitors are essential components of many electronic products and are widely used in contemporary electrical design. The 0201 package achieves the ultimate miniaturization. The 0402 package features an excellent balance in terms of size and manufacturability. Find the ideal balance point that works for your application when selecting the right capacitor package size rather than heedlessly going for the smallest package.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.