Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > FQC (Final Quality Control) | PCB Process

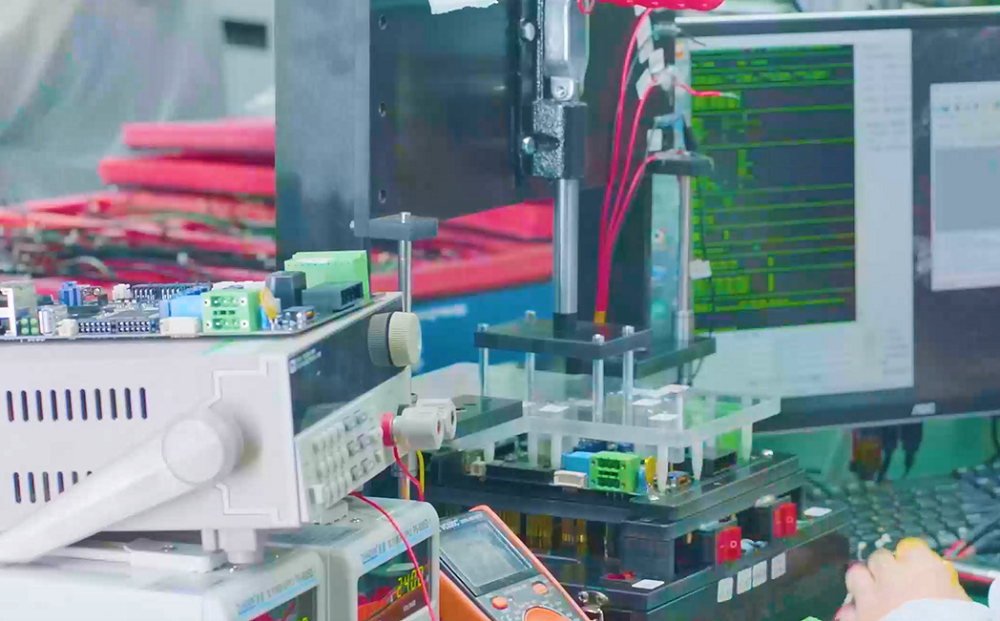

FQC inspection mainly includes the following contents:

Appearance:

Check the appearance of the product for scratches, stains or other visible defects.

Functions:

Test all functions of the product to ensure that it operates normally within the designed working range.

Performance:

Check the performance of the product meets the design specifications, such as electrical characteristics, signal integrity, etc.

Compliance:

Ensure products comply with industry standards and regulations (such as RoHS, CE, FCC…).

Packaging:

Ensure the packaging of the product is in good condition, meets the transportation requirements, and the packaging labels are clear and correct.

The following is PCBasic FQC inspection process table:

FQC Inspection Process

Procedure

Content/Main Points

Inspection Tool

1. Check the test line

Check if the test mark line is drawn and whether it meets the requirements

Visual

2. Check the process card

Check the jack/ink color, V-CUT/X plate requirements, and inspection standards

Visual

3. Check V-CUT

Check the V-cut line direction for missing V, empty, or skipped cuts

Visual

4. Check for gold fingers

Check the gold finger pull edge, position, and hypotenuse

Visual

5. Check optical

Inspect for imperfections, irregularities, tin height, or optical spots with sticking ink

Visual

6. Check the solder mask plane

Check wipe / IC / BGA / through plug oil / poor screen printing / color difference, etc.

Visual

7. Check the line

Check the line for nicks/jags/scratches, etc.

Magnifying glass

8. Check characters

Check whether there is any character; deviation/incomplete/missing/reverse/unclear characters, etc.

Visual

9. Check holes

Inspection hole breakage/hole deviation/ink entering hole/hole size/NPTH hole with copper, etc.

Visual light hole

10. Inspection cycle/marking

Check for cycle errors/clear labeling (mainly UL), etc.

Visual

11. Inspection slot hole

Check for missing slots/large slots/small slots/not in place/burrs/dust

Visual

12. Check the substrate

Check for any bursting, dents, white spots on the substrate, yellowing of the substrate, etc.

Visual

13. Check surface treatment

Check for oxidation/tinning, poor gold deposition/poor SP color, etc.

Visual

14. Check blue glue

Check if there is thin/thick blue glue, PAD on blue glue, or if blue glue falls off

Visual

15. Tree inspection plug/hole filling

Check if the plug hole is full and check for any depressions in the filling hole

Plug gauge

16. Check for board warping/deformation

Check if the board is warped or deformed

Marble table

17. Secondary inspection V-CUT

Confirm V-CUT after the initial inspection is completed

Visual

18. Draw identification lines

Draw personal identification lines on the corners of the board after all inspections are completed

Oily pen

19. Points/Writing Reports

Count the points and verify the quantity of the process card after inspection

Visual

20. Process under board production

Hand over to FQA for sampling and quality verification before proceeding to the next process

FQC inspection daily report

1. What is the difference between FQC and OQC (Outgoing Quality Control)?

FQC: FQC occurs after the product is manufactured, including appearance inspection, functional testing, etc., to ensure that the product meets the internal quality standards.

OQC: It is carried out before the product is shipped, mainly checking the product packaging, logo, instruction manual, etc., to ensure that the product meets customer requirements.

2. What is IQC inspection?

IQC refers to the quality inspection and verification of raw materials, components or semi-finished products provided by suppliers in the manufacturing and production process to ensure that they comply with established standards and specifications. This is the first quality control step in the production process.

3. IQC and FQC

IQC and FQC together constitute the closed loop of quality management. IQC ensures the quality of incoming materials and prevents non-conforming materials from affecting production, while FQC ultimately verifies that the results of the entire production process meet standards. The two complement each other to guarantee the quality of the entire production process, from raw materials to finished products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.