Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What are Printed Circuit Boards and PCB Types?

The Printed Circuit Board (PCB) is the most core supporting component in modern electronic products. Every electronic device relies on one or more types of PCBs to function properly.

According to the design requirements and usage environment, engineers and manufacturers will choose from different PCB types. Common classification methods include classification by the number of layers, by materials, by characteristics and by applications, etc.

In this blog, we will introduce these different types of PCBs in detail, and analyze their structures, advantages and application scenarios in combination with various types of PCB materials. After reading this, you will be able to judge more clearly how to choose the appropriate types of printed circuit boards for your project.

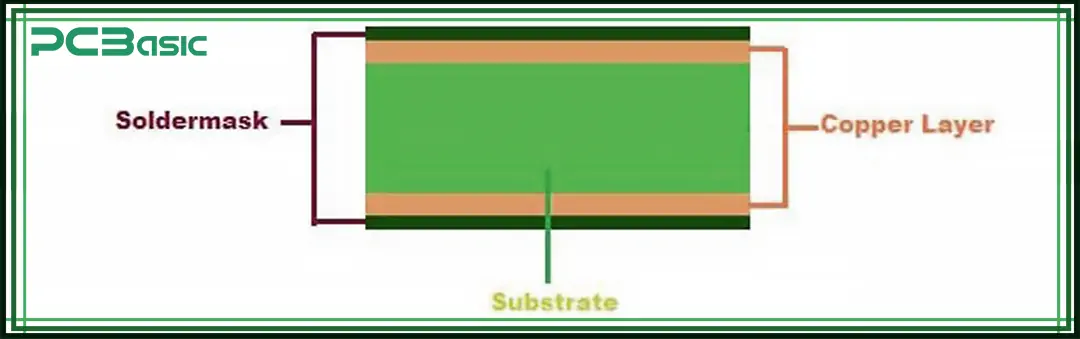

The printed circuit board is an indispensable core component in electronic products. It is made from an insulating substrate (such as fiberglass, epoxy resin, etc.), with copper traces covered on the surface, used to achieve electrical connection and fixed support between electronic components. In simple terms, a PCB is like the "skeleton" and "neural network" of electronic products. It can not only firmly install components in the right positions but also connect them in an orderly manner through copper traces.

Compared with the early point-to-point wiring or manual soldering, the emergence of PCBs has greatly simplified the way circuits are built. It avoids messy and disorganized wiring, making the circuit more compact, neat and enhancing reliability. More importantly, PCBs are suitable for large-scale production and can ensure the consistency and stability of each circuit board. This is also one of the key reasons for the rapid development of the modern electronics industry.

Different PCB types can be classified by the number of layers. The common types include Single-Sided PCB, Double-Sided PCB and Multilayer PCB. They each have their own characteristics in structure and performance, and are suitable for different circuit designs and application scenarios.

Single-sided boards are the most fundamental and simplest type of circuit boards. Their main feature is that all electronic components and copper traces are only arranged on one side of the circuit board, and there is no circuit at all on the other side. This design makes the manufacturing process of single-sided boards relatively simple and the production cost low.

Advantages of Single-Sided PCBs:

• Low cost and easy to design

• Suitable for simple consumer electronics

• Ideal for high-volume production

Double-sided boards go a step further than single-sided ones. Copper traces can be laid on both the top and bottom sides and connected through vias. This enables the double-sided board to accommodate more circuits and components, making it the most common PCB type in medium-complexity products.

Advantages of Double-Sided PCBs

• More circuit density compared to single-sided boards

• Flexibility in routing complex circuits

• Widely used in power supplies, automotive, and LED systems

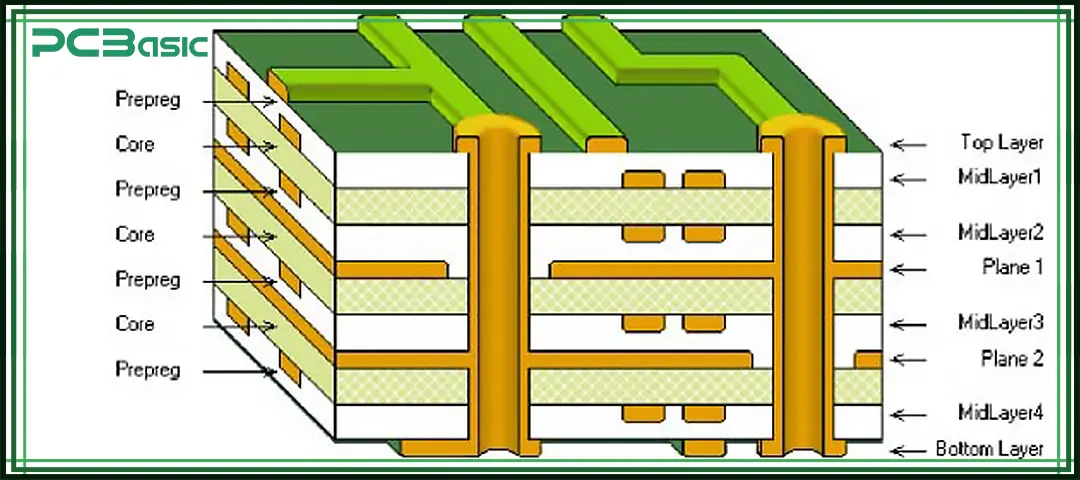

Multilayer boards have evolved from double-sided boards. They are composed of three or more layers of copper circuits stacked together, separated by insulating substrates in the middle. This type of PCB board is typically used in high-performance and high-density electronic products, such as smartphones, computer motherboards, communication equipment, servers, and aerospace systems.

Advantages of Multilayer PCBs

• High circuit density and compact size

• Improved performance for high-speed signals

• Better electromagnetic compatibility

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

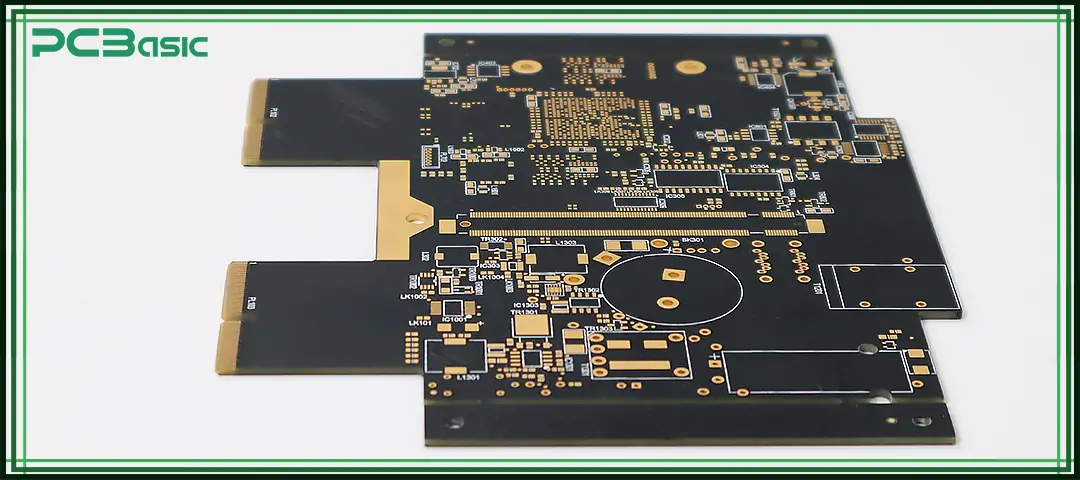

Different types of PCBs can also be classified according to their physical properties and materials. Common types include rigid PCBs, flexible PCBs, and rigid-flex PCBs. They each have different advantages. These types of circuit boards are suitable for various electronic products, ranging from daily consumer electronics to aerospace and medical equipment.

Rigid PCBs, which are manufactured using solid substrates like FR-4, are currently the most widely used type of printed circuit board. It has a solid structure and cannot be bent, so it is used in most consumer electronics and industrial products. Whether it is computer motherboards, household appliances, or some industrial control boards, rigid PCBs can be seen almost everywhere.

Advantages of Rigid PCBs

• Durable and long-lasting structure

• Cost-effective for mass production

• Available in all PCB material types

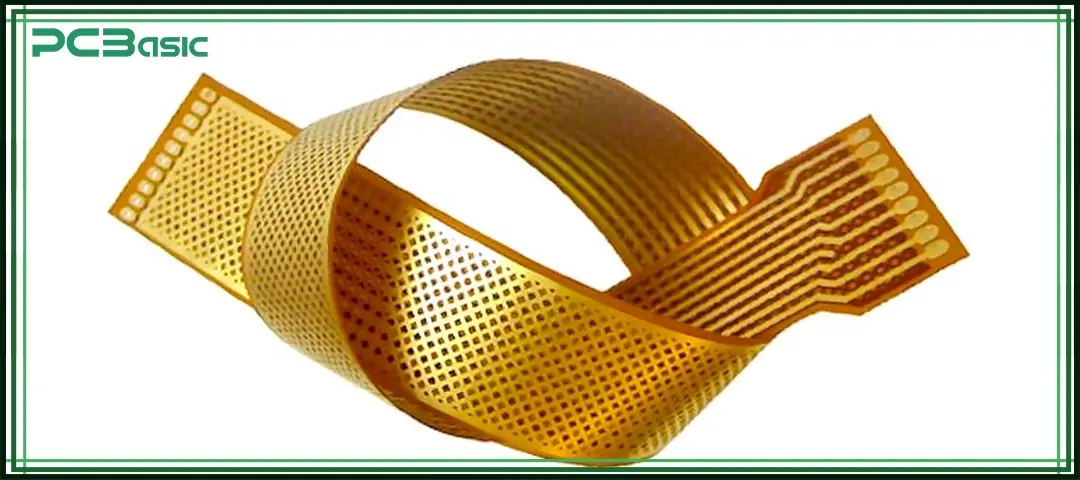

Flex PCBs are types of circuit boards that can be bent and folded. They are usually made from flexible substrates such as polyimide. Due to its flexible characteristics, this type of circuit board can be installed in narrow or irregular spaces, making it highly suitable for modern thin and light electronic products.

Advantages of Flex PCBs

• Lightweight and space-saving

• Can withstand vibration and dynamic bending

• Essential for wearables, cameras, and compact devices

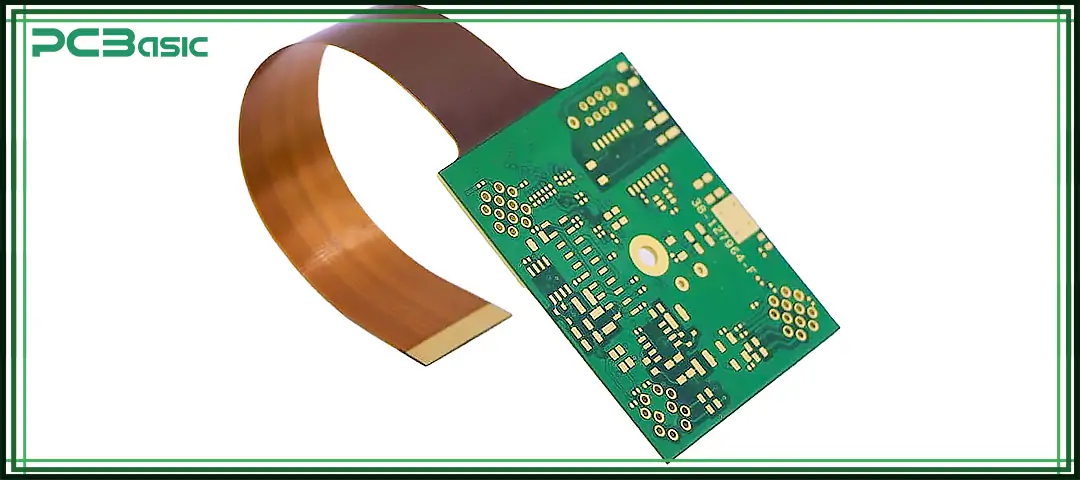

The rigid-flex PCB combines rigid and flex boards in the same design, using rigid materials where support strength is required and flexible materials where flexibility is needed. This hybrid structure makes it one of the most adaptable and multi-functional circuit board types.

Advantages of Rigid-Flex PCBs

• Saves space and reduces connectors

• Highly reliable in compact devices

• Common in aerospace, medical, and military electronics

Different PCB types can also be divided according to application requirements. The common ones include High-Frequency PCBs and Aluminum-Backed PCBs. The former is specifically designed for high-speed signals and radio frequency communication, while the latter is renowned for its excellent heat dissipation performance. They are widely applied in fields such as radar, 5G communication, satellite systems, LED lighting and power electronics.

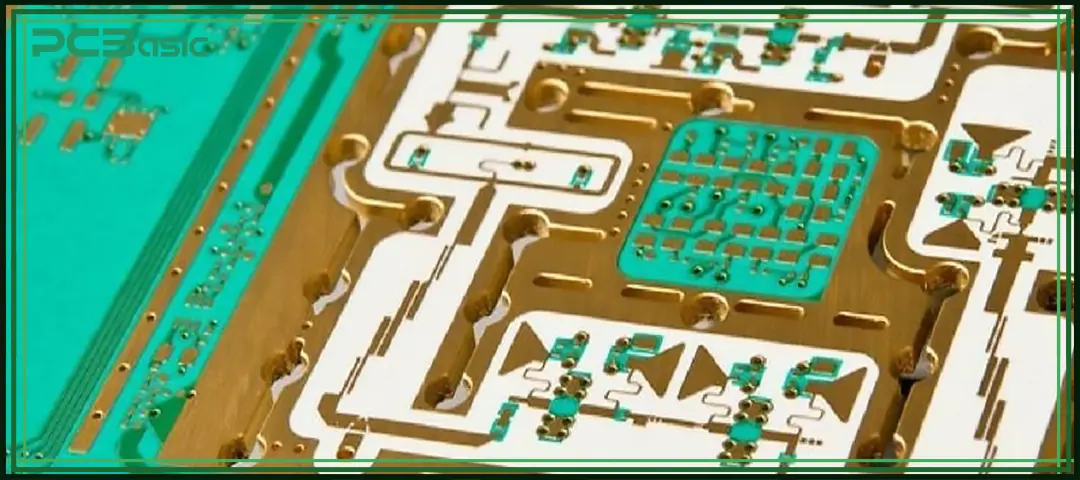

High-frequency PCBs are special types of PCBs specifically designed for high-speed signal transmission. They are usually made of low-loss materials, such as PTFE (polytetrafluoroethylene) or Rogers high-frequency laminates. This type of material features extremely low dielectric loss and stable electrical performance, enabling circuits to operate normally within the high-frequency range of gigahertz (GHz). High-frequency PCBs are widely used in fields such as wireless communication, radar systems, and high-speed data transmission.

Advantages of High-Frequency PCBs

• Low signal loss and high precision

• Stable dielectric properties

• Perfect for radar, 5G, and satellite communications

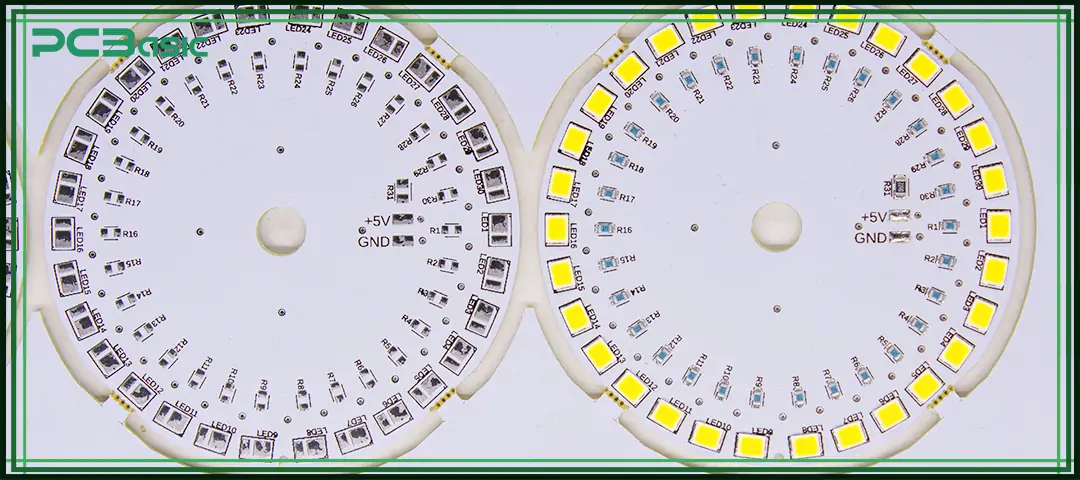

Aluminum-Backed PCBs, also known as Metal-Core PCBs, are a special type of PCB board. Its core layer uses aluminum as the base material. Compared with traditional epoxy resin or fiberglass substrates, the greatest advantage of aluminum substrates is their better heat dissipation performance. This design is particularly suitable for high-power and high-heat-generating electronic products, such as LED lighting, power equipment and automotive electronics.

Advantages of Aluminum-Backed PCBs

• Superior thermal management

• Ideal for high-power LEDs and power electronics

• Long-lasting and durable

From single-sided PCBs to rigid-flex designs, and then to high-frequency PCBs and aluminum-backed boards, there is a wide variety of PCB types, and each has its corresponding application scenarios. Choosing the appropriate types of PCB materials and PCB board types will directly affect the performance, cost and service life of the circuit.

Whether designing consumer electronics, automotive electronics, or aerospace equipment, only by understanding these different types of circuit boards can we ensure that the products meet the actual needs of the industry.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.