Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top Turnkey PCBA Manufacturer for Commercial Drones

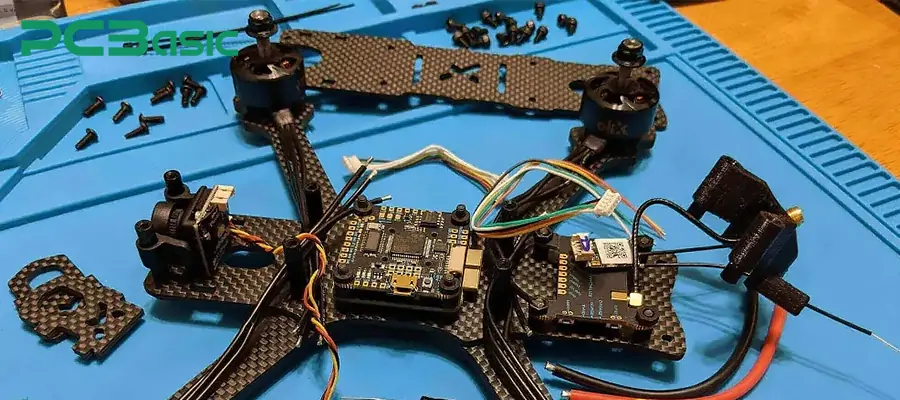

The commercial drone industry is developing at a rapid pace. Whether it's agricultural drones, mapping drones, logistics drones, or inspection and aerial photography UAVs, their flight performance all rely on reliable electronic control systems. As drones become more powerful and their structures more compact, many manufacturers no longer separately source PCBs, purchase components, and assemble them. Instead, they prefer to entrust the entire process to professional PCBA turnkey manufacturers. This approach not only reduces communication and lowers costs, but also accelerates research and development efficiency, enabling products to reach the market faster.

This article is a practical guide for drone companies. We will help you understand:

What is a turnkey PCBA?

Which links should the drone industry pay close attention to?

How to determine whether a supplier is suitable for drone PCBA?

Which factories in China are more trustworthy in the drone field?

Without further ado, let's get straight to the point!

When drone manufacturers are looking for turnkey PCBA manufacturing partners, what they truly desire is not a "pure contract factory". What they actually seek is a long-term partner who can be responsible for the entire electronic manufacturing process. For drone manufacturers, ordinary PCBA processing is simply not enough. Because the failure of a single board can lead to abnormal flight, loss of video transmission, and even the crash of the entire aircraft. Therefore, their requirements for suppliers are naturally much higher than those for ordinary electronic products. Below is an analysis of the contents that a drone manufacturer considers when choosing turnkey PCBA manufacturing suppliers.

1. A truly one-stop partner, rather than multiple suppliers. The drone company would like to reduce the complexity of the supply chain. It would be best if they could directly connect with PCB factories, component distributors, SMT factories and testing institutions at one time. This complete PCBA turnkey manufacturing can enable them:

Hand over the PCB, material procurement, SMT and testing to a single partner

Avoid delays and errors caused by multiple communication channels

Reduce logistics and coordination costs

Achieve more stable delivery schedules

Lower the overall manufacturing costs

2. A genuine understanding of the engineering capabilities related to drone PCBA. The circuits of drones are far more complex than those of ordinary consumer electronics. Components such as flight control, electronic speed controller (ESC), GPS/Beidou modules, high-current distribution boards, and video transmission modules all have specific design requirements. At this point, it is often necessary for turnkey PCBA manufacturers to be able to provide:

Multilayer stacking and impedance optimization

EMI/EMC noise reduction strategy

Suggestions for high current circuits and heat dissipation design

Key points for placement of sensors such as IMU, barometer, and magnetometer

Wire routing optimization for HDI high-density small boards

DFM optimization to reduce defect rates

Suggestions for cost reduction in BOM and alternative solutions

Typically, a mature turnkey PCBA service provider possesses such capabilities. This is because they have accumulated rich engineering experience through long-term cooperation with industries such as drones, robots, and motor control.

3. A stable, transparent and traceable supply chain for components. What drone manufacturers fear most is not the high price, but counterfeit products. IMU, MCU, RF chips, MOS transistors, power chips - once counterfeit products are mixed in, the consequences will be extremely serious. Therefore, they require suppliers to be able to:

Procurement from authorized distributors

The source of materials can be traced

Provide alternative material solutions (in case of shortage, EOL)

Strict IQC inspection and storage management

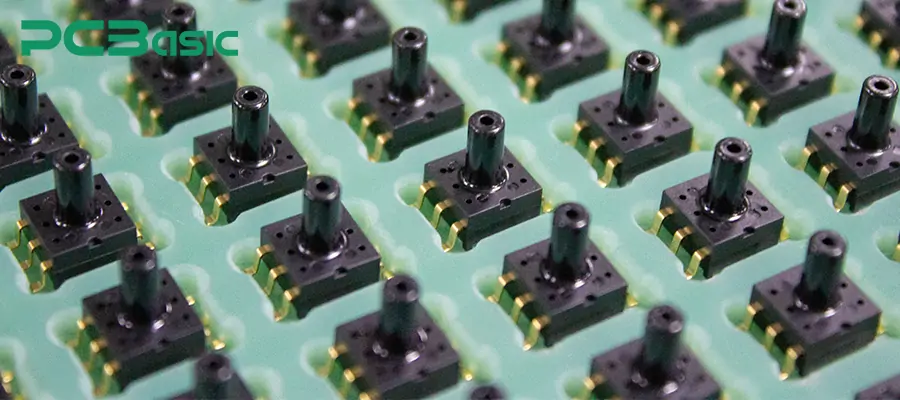

4. High-reliability manufacturing process suitable for outdoor drones. Drones are usually operated in scenarios such as vibration, temperature changes, humidity, dust, corrosive environments, and high-frequency communication interference. Therefore, the quality requirements for the PCBA of drones are very high. Generally, a turnkey PCBA manufacturer needs to be able to provide high-reliability processes, including:

Nitrogen reflow soldering (stronger solder joints)

AOI + X-ray (ensuring BGA/QFN soldering quality)

0201/01005 micro-component soldering capability

Stable batch consistency

Soldering curve optimization adapted to complex component combinations

5. Be capable of rapid prototyping and smoothly transition to mass production. The development pace of drones is very fast. PCBA suppliers should be able to achieve the following:

PCB 24 - 48 hours for sample production

PCBA 3 - 7 days for sample production

Support small-batch verification of tens or hundreds of pieces

Later, quickly expand into mass production

6. Professional project management and smooth communication. In actual cooperation, production issues are often not related to technology, but rather to communication. They require turnkey PCBA manufacturers to be able to:

Quick response

Engineering issues can be responded to within a short period of time

Clear documentation, changes and records

Abnormal project situations can be handled promptly

There is a fixed project manager for coordination

Delivery dates are transparent and the process is standardized

The complete Turnkey PCBA service is much more than just surface mounting and welding. The true PCBA Turnkey Manufacturing is a kind of manufacturing that can handle the entire production process for you - from material procurement to assembly, testing, and logistics - including:

1. Complete material procurement and supply chain management. The PCBA manufacturer is responsible for the procurement of all electronic components and materials, including active and passive devices, various ICs, BGA, QFN, connectors, wiring harnesses, metal parts, structural parts, etc. They should have authorized channels such as DigiKey / Mouser / Arrow, local supply chain inventory, batch traceability and life cycle management systems.

2. PCB manufacturing. Covers a variety of PCB processes and materials, including FR-4, Rogers, high-frequency boards, copper substrates, aluminum substrates, HDI, blind vias, laser micro-holes, ENIG/ENEPIG/lead-free tin-plated surfaces treatment, impedance control, and meets IPC-6012 Class 2/Class 3 process standards.

3. SMT Soldering and Reflow. This stage involves:

Template design and solder paste printing

SPI inspection

High-speed surface mount (including 01005, BGA, LGA, etc.)

Nitrogen reflow soldering

AOI inspection for all accessible SMT areas

THT / Wave soldering / Selective soldering

4. Programming, functional testing and final quality inspection. Professional Turnkey PCBA services will include:

Chip programming, firmware writing

ICT / pin probing test

FCT functional test

Aging test

BGA/QFN X-Ray inspection

Full-process QA and data recording

Ensure that the overall performance of the machine meets the customer's requirements.

5. Finished product assembly, packaging and logistics. Manufacturers can also provide customers with radiator and housing installation, anti-corrosion paint coating, spot welding, encapsulation, customized packaging, as well as global logistics and batch tracking services according to product requirements.

6. Mass production maintenance and subsequent support. It can provide engineering change support (ECO), long-term material reserves and delivery schedule planning, batch repeat orders, as well as material life cycle monitoring, facilitating customers to quickly expand from prototypes to mass production.

Nowadays, there are many companies providing PCBA turnkey manufacturing services. Therefore, evaluation becomes very important. Below, we list several dimensions, based on which we can determine whether the turnkey PCBA manufacturing suppliers are of high quality.

1. Engineering Capabilities. A mature PCBA turnkey manufacturing plant is not merely "producing the documents you provide", but is capable of:

Actively identify design risks

Proactively alert about material supply disruptions and suggestions for substitute materials

Propose modifications for pad designs, defect rates, and layout issues

Identify potential problems that affect mass production (such as insufficient test points, insufficient heat dissipation)

True engineering strength can prevent rework, delays and increased costs. This is more practical than any equipment promotion.

2. Supply chain stability. Let's take this PCB assembly manufacturer as an example.

Whether to continue using authorized channels (such as DigiKey/Mouser/Arrow, etc.)

Whether to have local inventory and secondary distribution capabilities

Whether to have strict IQC and anti-defect mechanisms

Whether to be able to provide batch traceability and material lifecycle monitoring

Whether to have contingency plans for EOL/NRND handling

The stability of the supply chain directly determines whether the delivery time can be controlled.

3. Delivery capability. Evaluate this manufacturer based on its ability to meet delivery deadlines.

Can a clear production schedule be provided?

Can each stage's duration be explained?

Will there be early warnings in case of material risks?

Can engineering issues be responded to within 12-24 hours?

Are production line utilization rates or actual production progress willing to be shown?

A reliable China turnkey PCB assembly manufacturing factory will not frequently "delay the delivery date".

4. Communication efficiency and project management. Take this turnkey PCBA manufacturer as an example,

Is there a dedicated PM or engineer for coordination?

Can engineering issues be answered promptly?

Can test logs, exception reports, and 8D documents be provided?

Is there a digital system (MES, ERP) for tracking progress?

Are you willing to proactively update the project status?

The manufacturers with higher communication efficiency have a higher success rate in their collaborative projects.

5. Price transparency. Check whether the manufacturer's cost structure is clear and if there are any hidden charges. A reliable turnkey PCBA manufacturing factory should have the following features:

Clear PCB price

Transparent BOM material prices

Assembly costs are clearly listed by point or process

No hidden NRE, tooling, or rush charges

Offer price options for different material grades (original factory/first-tier distributor/stock)

The higher the transparency, the easier it is to determine whether this supplier is professional.

6. Quality Control System. An excellent drone PCB assembly supplier should possess the capability for stable mass production. They are able to

Provide a complete quality inspection report

Have strict sampling standards (AQL)

Have version control (ECO process)

Be able to provide quality trend data during the production process

Have a mechanism for reviewing and analyzing abnormal issues

Important reminder: Only factories that can achieve stable mass production are worthy of long-term cooperation.

7. Scalability. A turnkey PCBA manufacturer should be capable of meeting the requirements at the following different stages:

Rapid prototype

Small-scale trial production

Engineering verification stage

Large-scale stable supply

Continuous cost optimization

Below, we have a reliable and trustworthy commercial drone turnkey PCBA manufacturer for your reference.

PCBasic is a one-stop China turnkey PCBA service provider. From PCB manufacturing, component procurement to SMT/DIP assembly, testing and delivery, PCBasic can handle all of these tasks. It has a complete PCBA turnkey manufacturing model.

The advantages of PCBasic mainly lie in the following aspects:

● The SMT assembly capability covers most of the core electronic products of the drone.

Supporting 01005, BGA, QFN, and CSP.

9 automatic SMT lines

Nitrogen reflow soldering

3D SPI, 3D AOI, and X-Ray inspection

Optional flying probe and ICT

● Turnkey: Component Procurement + PCB Manufacturing + SMT Integration

Authorized channels of DigiKey / Mouser / Arrow

Local supply chain in Shenzhen for ensuring delivery and cost

Full-process MES traceability (PCB, part number, batch, solder joints, test records)

● Extremely suitable for drone research and small to medium-scale production

No MOQ

24-72 hours for rapid prototyping

Engineering support (DFM/DFT)

Flexible version adjustment

There are a wide variety of case types on the drone PCBA, including:

Flight control motherboard

ESC electronic speed controller board

GNSS/GPS module

Video transmission module

BMS battery management board

Pan-tilt and IMU driver board

Various sensor interface boards

The commercial drone industry is experiencing rapid development, and the requirements for electronic manufacturing are constantly increasing. Choosing a reliable turnkey PCBA manufacturer is a crucial step. A turnkey PCBA manufacturer is not merely a processing factory capable of surface mount soldering, but rather a complete manufacturing partner that can undertake the entire process from PCB, component sourcing, assembly, testing to delivery.

PCBasic has complete delivery capabilities in one-stop turnkey PCBA services, and is suitable for the entire process requirements of drone enterprises during actual research and development, prototype verification, small batch production, and even stable mass production. If you are looking for a PCBA partner, please feel free to contact us.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.