Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How to Choose a Reliable Turnkey PCBA Manufacturer

Turnkey PCBA manufacturers can help enterprises shorten the R&D cycle, reduce project risks and accelerate product launch. Turnkey PCBA providers handle far more than PCB fabrication and component sourcing. They also take care of SMT assembly, through-hole soldering, testing, quality assurance, packaging, logistics, and ongoing technical support, forming a complete one-stop manufacturing workflow. This complete one-stop turnkey PCBA model has become a preferred supply-chain approach for many fast-moving electronics companies.

However, it is not easy to select a suitable partner from among the numerous turnkey PCBA manufacturing factories. This article will introduce how to choose a reliable turnkey PCBA manufacturer and what key factors to consider during the selection process.

How to choose a suitable and reliable turnkey PCBA manufacturer? This is the most crucial step in the entire hardware development process. A reliable partner can ensure stable product quality, controllable delivery time, transparent costs, and facilitate the smooth transition of the project from prototypes to mass production. Below are the several important aspects we have analyzed and summarized that need to be considered when evaluating a turnkey PCBA manufacturing supplier:

When selecting a supplier, the first step is to confirm whether the supplier truly has the manufacturing capabilities to complete the project. Many PCBA manufacturers can provide turnkey PCBA quotes, but not all factories have the necessary equipment, processes and experience to support high-quality and high-reliability production. Therefore, when evaluating the manufacturing capabilities of this PCBA supplier, the following capabilities should be given special attention:

✔ SMT Soldering Capability

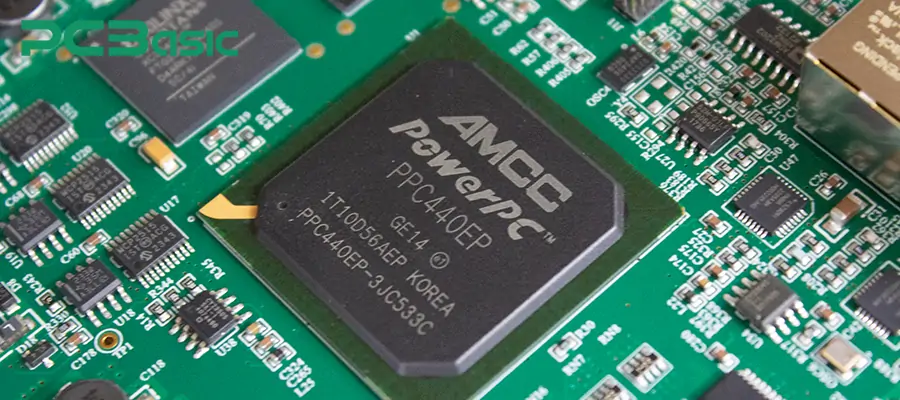

A professional turnkey PCBA assembly factory must have advanced SMT production lines and the necessary process conditions to handle high-density designs, including:

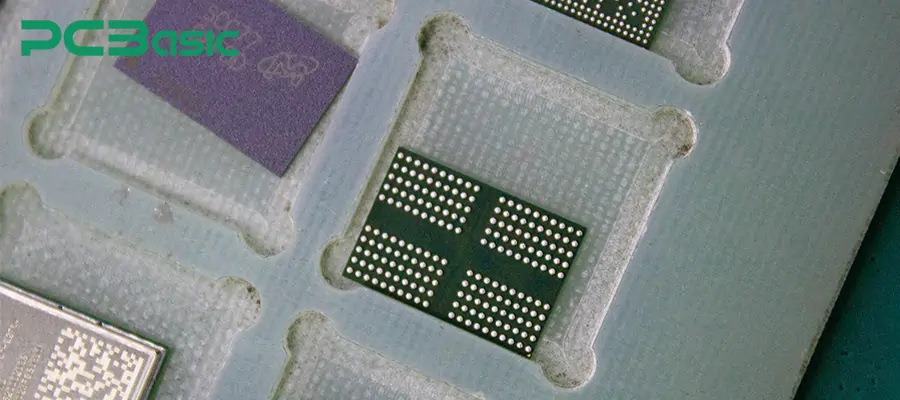

Capable of mounting ultra-small components such as 01005 / 0201

Handling fine-pitch packages like BGA, QFN, CSP, LGA, and micro BGA

±25µm mounting accuracy

Nitrogen and argon reflow soldering (improving solder joint reliability)

Online SPI solder paste inspection

AOI / 3D AOI optical inspection

X-ray inspection of BGA, QFN, and LGA bottom solder joints

✔ PCB Manufacturing Capacity

A genuine turnkey PCBA manufacturing provider typically integrates PCB production capabilities to ensure consistency and shorter delivery times. You can pay attention to:

2–32 layers of circuit board

HDI, laser-drilled microvias, blind and buried vias

Control impedance design

Special materials such as high TG, Rogers, ceramic substrates

Surface treatments like ENIG, OSP, silver plating, hard gold, etc.

✔ THT Assembly Capability

Confirm that the factory has:

Wave soldering

Selective soldering

Manual or semi-automatic assembly station

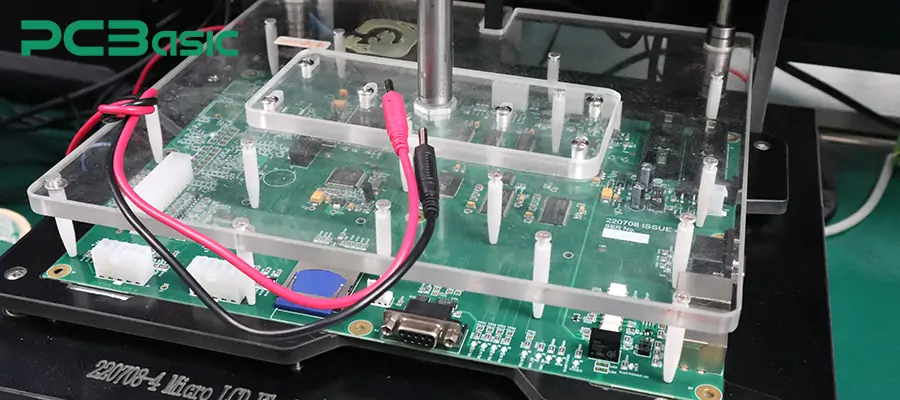

✔ Testing Capability

A reliable turnkey PCBA service provider must have a comprehensive testing system, which includes:

SPI solder paste inspection

AOI / 3D AOI inspection for packaging quality

X-Ray used for BGA/QFN/LGA solder joint detection

Flying Probe test

ICT online testing

Function Testing (FCT)

Aging test (as required)

Strong testing capabilities significantly reduce project risks.

The engineering team can be regarded as a crucial factor in evaluating the level difference of a turnkey PCBA manufacturer. Without engineering review, you might encounter:

Incompatibility of pad sizes leads to bridging or mounting

Unreasonable openings of solder paste and steel mesh affect soldering

Insufficient test points on the PCB prevent ICT

Impedance and signal integrity issues

Incorrect stacking causing board warping or delamination

A large number of defects during the pilot production stage

And a reliable turnkey PCBA manufacturing supplier will provide:

Schematic/Layout Review

Manufacturability Analysis

Test Points and DFT Recommendations

BOM Risk Assessment and Alternatives

Optimization of Reflow Curves

Cost Reduction Analysis

Therefore, before requesting the turnkey PCBA quotation, we need to ensure that the supplier will:

Conduct technical reviews of Gerber and BOM

Identify potential manufacturing risks in advance

Provide engineering suggestions

If the factory does not conduct any review of the engineering data, the reliability of the subsequent mass production will be difficult to guarantee.

The quality system is the cornerstone of any turnkey PCBA factory. Even with advanced equipment, without strict quality procedures, reliability cannot be guaranteed. When selecting a turnkey PCBA supplier, check if the supplier has the following key certifications:

ISO 9001 - Quality Management

ISO 13485 - Medical Class PCBA

IATF 16949 - Automotive Electronics

UL Certification PCB Capability

RoHS / REACH Environmental Compliance

IPC Class 2 / Class 3 Manufacturing Capacity

These certifications can reflect the factory's maturity in document control, processes, traceability and risk management. Then, we will examine the supplier's production process control (QC).

The factory should have:

IQC incoming material inspection

IPQC process monitoring

Outgoing inspection

Whole workshop ESD protection standards

MES full-process traceability

Key quality documents you should request include:

SPI report

Reflow temperature curve

AOI, X-Ray inspection screenshots

Material and batch traceability records

FCT test data

The presence of these documents is usually an indication that the production process in this factory is stable and controllable.

Component sourcing is the most problematic link in turnkey PCBA services and a key factor in determining whether a supplier is reliable. The formal channels for component sourcing include:

DigiKey

Mouser

Arrow

Avnet

Future Electronics

TTI

Domestic authorized agent

If the following situations occur, you should pay attention:

The quotation is obviously too low.

Local market components are used.

Material traceability documents cannot be provided.

There is no ESD control in the storage environment.

New and old components are mixed.

The above-mentioned situations must not occur. A reliable turnkey PCBA manufacturing supplier must ensure that all components come from legitimate channels and provide complete traceability.

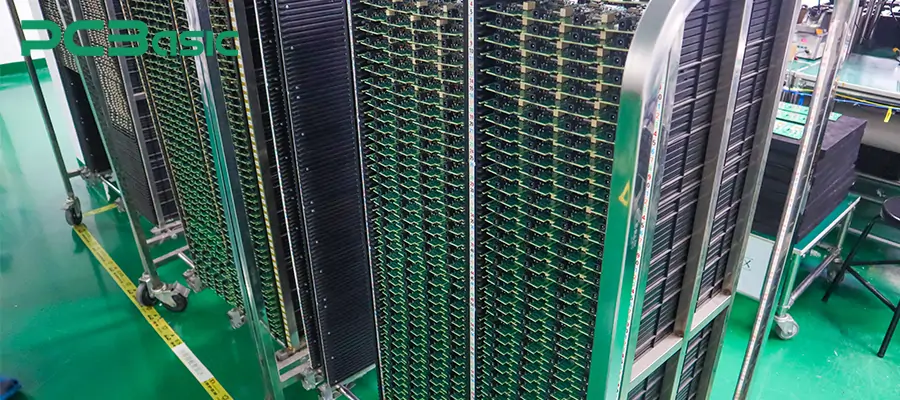

The primary reason why many hardware teams opt for turnkey solutions is to accelerate the iteration process. Typical delivery schedules of excellent factories:

PCB: 24 - 72 hours

SMT: 1 - 2 days

Full Turnkey: 7 - 12 days

To meet the above delivery deadlines, typically, the factory needs to have the following conditions:

Multiple SMT lines

A good production planning system

Sufficient component inventory

Stable PCB manufacturing capacity

A good turnkey PCBA quotation should be clear, standardized and free of hidden charges. The supplier's quotation should include:

PCB cost

Component cost (including procurement channels)

SMT and DIP expenses

Steel mesh cost

Testing cost

Packaging cost

Logistics cost

If the supplier refuses to provide a detailed quotation, you are likely to encounter the following situations:

Hidden charges

Material surcharge

Additional charges in the later stage

Total cost > Unit price

A seemingly cheap factory might lead to:

Re-work costs

Low yield and high scrap rate

Additional losses caused by delays

Component risks

Lack of after-sales service

Therefore, it is essential to carefully and meticulously select a reliable and suitable turnkey PCBA manufacturer, as this will be the most cost-effective option.

Whether communication is smooth usually determines whether our project progresses successfully in the end. Reliable factories typically exhibit the following characteristics:

Quick response (within several hours)

Accurate answers to engineering questions

Active updates of production processes

Complete documents, clear expression

English communication can be provided (if needed)

Support is available even after delivery

Your manufacturing partner should be capable of supporting all stages of the product lifecycle, including prototyping, small-scale production, and mass production. An excellent turnkey PCBA service provider can support:

✔ Prototype (1–20 pieces)

Fast and flexible, with high engineering compatibility

✔ Small batch (50–500 pieces)

Stable production, good consistency

✔ Mass production (1,000–100,000+ pieces)

Cost optimization, stable supply chain, sufficient production capacity

For products exported to Europe and the United States, environmental protection and compliance regulations cannot be ignored. A reliable turnkey PCBA factory should have the following capabilities:

Lead-free production process

Wastewater treatment system

VOC control

Dust and smoke management

Recoverable packaging materials

RoHS/REACH compliance

In summary, a reliable turnkey PCBA factory should have the following features:

Actual production capacity, professional engineering, strict quality system, reliable supply chain, transparent costs, stable delivery time, strong communication skills, scalable production capacity, and compliant environmental protection system.

1. Fully Integrated Turnkey PCBA Service

Unlike suppliers that only offer partial services, PCBasic has independently established a complete system covering PCB, SMT, testing, and packaging logistics. PCBasic has a production process that is uniformly managed by a digital MES/ERP/CRM platform, which can provide customers with stable, fast, and transparent turnkey PCBA services and accurate turnkey PCBA quotations. PCBasic's end-to-end model can help customers directly reduce communication costs, delivery risk, and supply chain uncertainty.

2. Advanced Manufacturing for High-Mix & High-Reliability Products

Currently, PCBasic has multiple high-speed and multi-functional SMT production lines, covering high-density packaging such as 01005, 0201, fine-pitch BGA, CSP, QFN, etc. It is equipped with processes such as nitrogen and argon reflow, 3D SPI, 3D AOI, X-Ray, selective wave soldering, and automatic three-proof coating. These capabilities not only meet the requirements of standard consumer electronics, but also can handle products with extremely high reliability requirements in industrial control, automotive electronics, medical equipment, etc.

3. Engineering-Driven Manufacturing Support

The engineering team of PCBasic was deeply involved in every stage from prototype to mass production, including:

DFM/DFT Optimizations for Manufacturability and Testability

Suggestions for PCB Stack-up and Impedance Structure

Cost Optimization of BOM & Evaluation of Alternative Materials

Debugging of Reflow Curves & Optimization of Process Window

Support during EVT/DVT/PVT Stages

This engineering-led model can help customers reduce trial production issues and improve yield.

4. International-Level Quality System

The quality system of PCBasic meets international production standards and holds:

ISO 9001

ISO 13485

IATF 16949

IPC Class 3

RoHS / REACH Compliance

Batch numbers of materials, temperature zone curves, assembly records, inspection data, serial number tracking, etc. can all be achieved through MES for board-level traceability, ensuring transparent and controllable processes.

5. Authorized and Stable Component Supply Chain

PCBasic has regular component suppliers, including Mouser, DigiKey, and domestic authorized agents. Combined with ESD storage, humidity-sensitive level management, and batch traceability systems, it can provide a stable and secure supply chain for customers' long-term project mass production.

6. Fast Turnaround with Competitive & Transparent Pricing

Relying on its own production lines, digital production scheduling system and vertical integration process, PCBasic can offer:

PCB: 24 - 48 hours

SMT assembly: 1 - 3 days

Full Turnkey: 7 - 12 days

Meanwhile, the turnkey PCBA quote provided by PCBasic is clear and transparent, covering costs such as materials, surface mount, testing, packaging, and logistics. There are no hidden costs, and it offers customers a highly competitive overall budget.

7. Global Communication & Long-Term Support

PCBasic offers an English communication channel, which can support project communication, confirmation of technical materials, and the exchange of production-related information. During the prototype, small batch, and mass production stages, PCBasic will provide customers with data related to work order status, production nodes, or quality, so that customers can promptly grasp the project progress.

Selecting a reliable turnkey PCBA manufacturer is the most crucial decision in the entire hardware development process. In this article, we have listed nine factors that can be considered when choosing a supplier. These criteria provide a clear framework for evaluating any turnkey PCBA factory. Moreover, in this article, we also introduce the actual situation of PCBasic in manufacturing, engineering, quality system, material procurement, delivery management, and communication processes, providing you with a reliable choice.

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.