Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Shenzhen PCBA Suppliers for Quick-Turn Prototyping

In the hardware industry, speed is competitiveness. Whether you are making IoT devices, robot control boards, medical wearables, or other electronic products, as long as the prototype can be made and assembled faster, your product can be launched on the market sooner. Therefore, more and more engineers and startups choose Shenzhen - the world's most complete electronics industry cluster - to carry out quick-turn PCB assembly and turnkey PCB assembly, and various rapid prototyping and iterations.

This article will make a comprehensive comparison of 5 reliable PCBA suppliers in Shenzhen: PCBasic, PCBONLINE, Shennan Circuits, Suntak Technology and Kingford. It will evaluate their engineering strength, delivery time and speed, quality, and whether they are suitable for prototype PCB assembly or future expansion to mass production.

Meanwhile, this article also shows you why Shenzhen remains the global center of electronics manufacturing and how you should choose the most suitable PCBA manufacturer to accelerate the progress of your project.

The greatest advantage of Shenzhen is its speed. The industrial chain here is highly concentrated, the types of suppliers are diverse, and the manufacturing experience is mature. Therefore, making hardware prototypes in Shenzhen is often faster, more cost-effective, and it is also easier to smoothly transition from prototype to mass production.

1. Complete Electronics Ecosystem in One City

There is almost no other city in the world like Shenzhen, where PCB manufacturers, component suppliers, SMT assembly houses, cable factories, mould factories and testing labs are all concentrated in the same city. This dense industrial environment enables your products to start production quickly.

Therefore, many international teams will come to Shenzhen for PCB assembly services, turnkey PCB assembly, and rapid iterations.

2. Unmatched Supplier Diversity

Whether you are a large company or a start-up team, you can find suitable partners in Shenzhen. Here, there are both large enterprise-level EMS providers and PCBA manufacturers specializing in small-batch and rapid trial production. Whatever type of service you need, there is a supplier that fits.

3. Rapid Innovation and Engineering Culture

Factories in Shenzhen are very familiar with the working fast. Unlike some traditional contract manufacturers that only like to handle a large number of stable orders, many suppliers in Shenzhen are better at handling high-mix, low-volume orders. For companies that need rapid updates and quick trial production, Shenzhen is the most suitable place.

How fast can quick-turn exactly be? In fact, it depends on the supplier's ability and the complexity of your project. In Shenzhen, the speed that can generally be achieved looks like this:

• 2-layer boards can be finished in as fast as 24 hours

• 4–8 layer boards usually take 48–72 hours

• HDI or complex stack-up boards take about 5–7 days

For SMT assembly and prototype PCB assembly:

• If components are ready, assembly can be done on the same day

• Turnkey builds usually take 24–72 hours

• More complex prototypes require 5–10 days

Fast speed also means that some problems may be encountered, such as the design not being fully suitable for manufacturing (not enough DFM), last-minute BOM changes, component shortages requiring substitutions, or tight tolerances and complex structures that easily lead to rework.

Therefore, it is very important to choose a PCBA manufacturer that is experienced, capable of conducting engineering audits, able to perform DFM inspections, and can stably provide PCB assembly services.

There are hundreds of suppliers in Shenzhen. To select a suitable PCB manufacturer or EMS provider, it is necessary to carefully evaluate from multiple aspects.

A strong quick-turn partner should support:

• Fine-pitch SMT assembly

• BGA, QFN, CSP packages

• Impedance-controlled PCBs

• High-layer-count fabrication

• Rigid, flex, and rigid-flex board types

These capabilities influence both speed and reliability.

For fast iteration, engineering responsiveness is essential. Look for suppliers who offer:

• DFM/DFT analysis

• PCB stack-up suggestions

• BOM optimization

• Quick resolution for design issues

This ensures your prototype PCB assembly avoids unnecessary delays.

Evaluate minimum order quantities, expedited service levels, and how quickly the supplier can:

• Start production

• Implement design changes

• Re-run prototypes

• Source replacement components

A reliable PCBA manufacturer should have:

• ISO-certified facilities

• AOI/SPI/X-ray inspection

• MES traceability

• IPC-A-610 trained operators

• Consistent quality across rapid builds

Even for small batches, proper quality control prevents costly debugging loops.

Pricing varies depending on:

• NRE setup fees

• Stencil charges

• Turnkey PCB assembly vs. consigned

• Lead time requirements

• Component availability

The goal is to balance speed with long-term scalability.

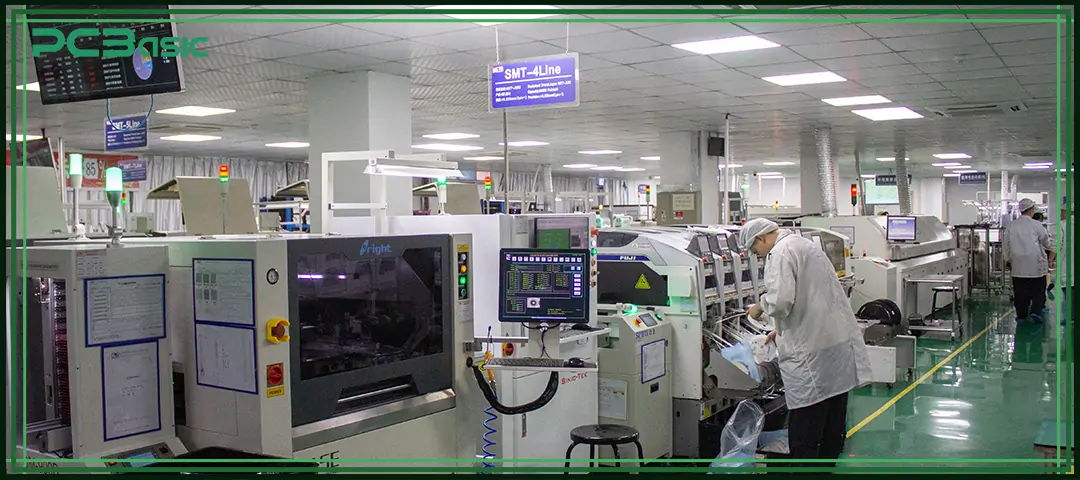

PCBasic is a PCBA manufacturer located in Shenzhen and founded in 2011. After more than 10 years of development, it has built a highly digitalized and automated electronics manufacturing system. With mature processes, rapid engineering feedback and stable manufacturing capabilities, PCBasic performs exceptionally well in quick-turn PCB assembly and scalable mass production, and is a trusted partner for many overseas hardware teams.

PCBasic offers a complete one-stop process: PCB fabrication + SMT assembly + BOM sourcing. Customers only need to submit the documents, and the subsequent procurement, board manufacturing, SMT, and testing will all be handled by PCBasic, which saves time and effort.

The engineering team of PCBasic will conduct multiple checks on the design before production, such as manufacturability (DFM), testability (DFT), stack-up suggestions, and footprint compatibility, helping customers identify problems in advance and increase the success rate of the first sample.

The factory uses MES to control the entire production process, from IQC, SPI, AOI, first article inspection, to X-Ray, FCT, QA, all of which are recorded and traceable. This makes the quality control more transparent and ensures that rapid prototyping can still maintain stable quality.

PCBasic is very familiar with multi-variety and small-batch orders, which is also the most common requirement for many hardware teams in the early stage. It can not only quickly initiate orders but also gradually expand production as the project progresses.

PCBasic has long served customers in:

• IoT

• Industrial control

• Robotics

• Medical electronics

• EV/BMS battery systems

• Power and communication devices

This multi-industry experience helps reduce customer trial-and-error and speeds up development.

PCBasic can achieve the fastest 24-hour quick-turn PCB assembly, and is very friendly to small-batch demands. It supports No MOQ and is particularly suitable for start-up companies and teams that need frequent version updates.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

• Teams needing fast prototype PCB assembly

• Projects expected to scale from small batch to larger volumes

• Teams that revise designs frequently and need fast re-runs

• Projects requiring stable quality and full traceability

PCBONLINE is renowned for its "high speed" and is particularly adept at handling various complex PCB technologies. For engineering teams that require advanced stacked structures, HDI, radio frequency (RF), or high-speed signal designs, PCBONLINE is a highly competitive supplier.

Highlights

• PCB fabrication available in as fast as 8 hours

• Strong capability in HDI, high-frequency laminates, and multilayers

• Reliable PCB assembly services including BGA and micro-pitch packages

• Component sourcing strategies designed to reduce BOM cost

Shennan Circuit (SCC) is one of the largest and most technologically advanced EMS providers and PCB manufacturers in China, serving the global automotive, aerospace, communication and server industries.

• World-class automated production

• High-end PCB, IC substrate, and advanced PCBA capabilities

• Robust NPI and engineering validation support

• Extremely stable quality suitable for mission-critical devices

Suntak is a well-known PCB manufacturer specializing in medium and large-scale PCB production. It has multiple factories and possesses a strong global supply capacity.

Highlights

• Huge production capacity suited for mass-market products

• Experience across smartphones, automotive, industrial, and communications electronics

• Competitive pricing and consistent quality for volume orders

Kingford offers complete PCB assembly services, covering SMT assembly, DIP, functional testing, box-build and other services. It is a convenient and worry-free one-stop EMS provider.

Highlights

• Fast prototype PCB assembly

• Engineering support for multi-technology assemblies

• End-to-end electronics manufacturing, including enclosure assembly and wiring

• Serves automotive, industrial automation, power electronics, medical, and smart home sectors

Shenzhen remains the world's most powerful center for PCB assembly, electronics manufacturing and rapid hardware development. Whether you need prototype PCB assembly, full turnkey PCB assembly, high-reliability SMT assembly, or a reliable PCBA manufacturer that can support scalable mass production, you can always find the supplier that best suits your needs in Shenzhen.

PCBasic delivers smart-factory quality and fast NPI.

PCBONLINE excels in ultra-fast advanced prototypes.

Shennan Circuits supports enterprise-grade reliability.

Suntak offers huge production capacity.

Kingford provides full-product EMS and rapid prototypes.

As long as you evaluate from aspects such as technical capabilities, engineering support, quality systems and delivery speed, you can find the most suitable partner and accelerate your hardware innovation cycle.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.