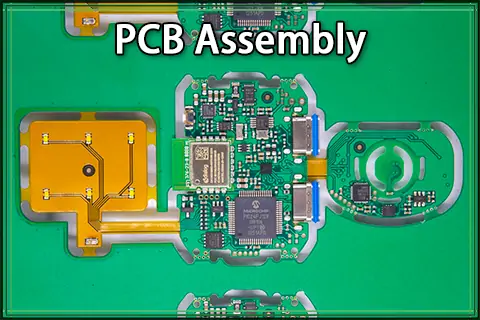

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top 5 PCBA Manufacturers with Flying Probe Testers in China

What is the most important thing when choosing the PCB assembly manufacturer? For enterprises pursuing high-reliability and medium and small batch production, high-quality circuit board assembly is undoubtedly the primary factor. In the current highly competitive China’s PCBA market, PCB assembly companies with advanced inspection capabilities have more advantages, especially those capable of conducting flying probe testing.

Especially in the prototyping circuit board assembly stage, flying probe testing, with its characteristics of no fixture and being fast and flexible, is widely applied in the PCB assembly manufacturing process. Compared with traditional ICT, flying probe testing is more suitable for rapid verification of designs. Especially in projects with medium and low-volume production and frequent design changes, flying probe testers provide higher test coverage and cost performance. It is an important means for modern PCB assembly companies to enhance their competitiveness.

This article will introduce 5 leading PCB assembly companies in China, which are equipped with advanced flying probe testers. One-stop electronic manufacturing solutions can be provided from prototype PCB assembly to mass production.

Flying Probe Testing (FPT) is an advanced electrical testing technique that detects short circuits, open circuits, resistance matching, component polarity and impedance changes in PCBA without the need for test fixtures. It is especially suitable for low-volume PCB assembly, high-density interconnect (HDI) PCBs, and complex circuit board assembly.

ICT testing (In-Circuit Testing) is a commonly used traditional method in PCBA testing. It requires a dedicated test fixture that checks soldering and component issues by simultaneously contacting a large number of test points on the PCB. Although ICT has a fast detection speed and is suitable for mass production, the production cost of fixtures is high and the lead time is long, making it inefficient for small-batch or frequently design-changing projects. This is also the key point that flying probe vs ICT is often discussed.

Let’s compare the two testing methods in a chart:

|

Feature |

Flying Probe Testing |

ICT Testing |

|

Test Fixture |

No fixture required |

Requires a custom fixture |

|

Setup Time |

Very low |

High |

|

Cost (NRE) |

Minimal to none |

High for small batches |

|

Test Speed |

Slower than ICT for large volumes |

Faster for high-volume testing |

|

Flexibility |

High – easily reprogrammed for design changes |

Low – limited by physical fixture constraints |

|

Application |

Prototype, low-mid volume, complex boards |

High-volume, mature designs |

If you are looking for a PCBA manufacturer in China with flying probe testing capabilities, here are 5 top PCB assembly companies that excel in quality control and precision inspection.

PCBasic is a leading multi-variety, low-volume PCBA manufacturer in China, specialized in high-quality board assembly. To ensure the high reliability of PCB prototype fabrication service and mass production, PCBasic introduced advanced flying probe testers last year.

Since the introduction of flying probe testers, the production quality and efficiency in PCBasic have been greatly improved. First of all, the flying probe tester can provide high-precision detection, especially suitable for BGA, CSP, POP packaging and other complex PCB design.

Then, like ICT, flying probe testing does not require specialized fixtures, which makes it particularly suitable for prototype PCB assembly and small batch production, significantly reducing test costs and improving overall production efficiency.

Flying probe testing is widely used, covering a number of industries such as automotive electronics, medical equipment, industrial control and aerospace PCB. It is suitable for areas with high requirements for accuracy and reliability. With its advanced technical capabilities, PCBasic is able to meet the diverse testing needs of various industries, ensuring high-quality, reliable PCBA production for every project.

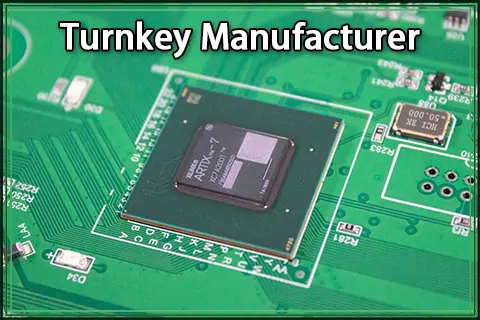

Foxconn is the world's top electronics manufacturing service provider (EMS), known for its high-precision PCB manufacturing and assembly. In order to ensure that every PCB and PCBA meets strict industry standards, Foxconn uses a variety of advanced testing methods such as flying probe testing, ICT online testing and functional testing to improve product quality and accuracy.

A significant advantage of Foxconn's flying probe testing is its automated AI defect analysis technology. This technology can quickly and accurately identify defects, significantly improving inspection efficiency. The flying probe testing is particularly suitable for areas such as 5G, Internet of Things (IoT), and automotive electronics, where high speed, low latency performance is required.

In addition, Foxconn also has a strong PCB assembly and manufacturing capacity, which can provide large-scale PCBA production to meet the needs of enterprises for high efficiency and mass production. With these cutting-edge technologies, Foxconn is ideally suited for companies that require efficient, large-scale PCBA production, ensuring a smooth transition from prototype to volume production.

Overall, Foxconn offers a comprehensive PCB manufacturing and assembly solution through advanced testing and automation technology, and if you need efficient, high-volume production and strict requirements for precision, Foxconn is your good choice.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Shenzhen Kaifa Technology is also a leading PCB assembly company in China, focusing on providing customers with high quality prototype PCB assembly and high reliability PCBA manufacturing. With its advanced flying probe testing technology, Kaifa Technology is able to quickly inspect multi-layer PCBs to ensure product accuracy and reliability.

At the same time, Kaifa's flying probe testing technology combines ICT to greatly improve the flexibility of testing. This combination of technologies not only improves inspection efficiency but also enables efficient quality control at different production stages and on different types of PCBs, ensuring that each board complies with strict industry standards.

Whether in rapid iterative prototype production or in serial manufacturing requiring high reliability, Kaifa Technology is able to meet your various needs.

Jabil is able to offer a full range of PCB Assembly services, including PCB Prototype Fabrication Service and PCBA China. Through flying probe testing, Jabil ensures that every piece of product achieves a 100% pass rate, helping customers guarantee excellent performance of products in terms of quality and performance.

Jabil's testing capability is one of its core competencies in the industry. The manufacturer supports multi-layer PCB assembly manufacturing, which is able to meet the manufacturing needs of a variety of complex circuits. Jabil's testing technology is used in a wide range of fields, including automotive electronics, defense and industrial electronics. These industries place high demands on reliability and performance, and Jabil's advanced manufacturing and testing technology ensures that it can provide customers with high-quality PCB assembly solutions that meet stringent standards.

Luxshare Precision is one of the core suppliers of Apple, Tesla and other world-famous enterprises, with its excellent technology and innovation capabilities, to provide high-precision circuit board assembly services. Its flying probe testing technology ensures that every circuit board meets stringent quality standards, especially for consumer electronics and high-frequency applications.

Luxshare Precision 's sophisticated flying probe testing technology supports prototype PCB assembly, enabling customers to perform accurate testing and validation during the rapid prototyping phase, thus accelerating product development and iteration. This technology not only improves test efficiency, but also enhances the adaptability of complex boards, especially in the high-density BGA and Fine Pitch PCB assembly, showing strong performance.

In general, with its advanced flying probe testing technology and high-precision manufacturing capabilities, Luxshare Precision has become the preferred partner of many world-renowned companies, providing a full range of PCB assembly services to meet the needs of high-precision and high-density products.

The top 5 PCBA manufacturers with flying probe testers in China are listed above. PCBasic is suitable for a variety of small-batch orders, while another 4 manufacturers accept large-volume PCB assembly. If you are looking for a reliable Chinese PCBA manufacturer, they may be a trusted partner for you.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.