Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Complete Guide to PCB Assembly (PCBA) in Modern Electronics

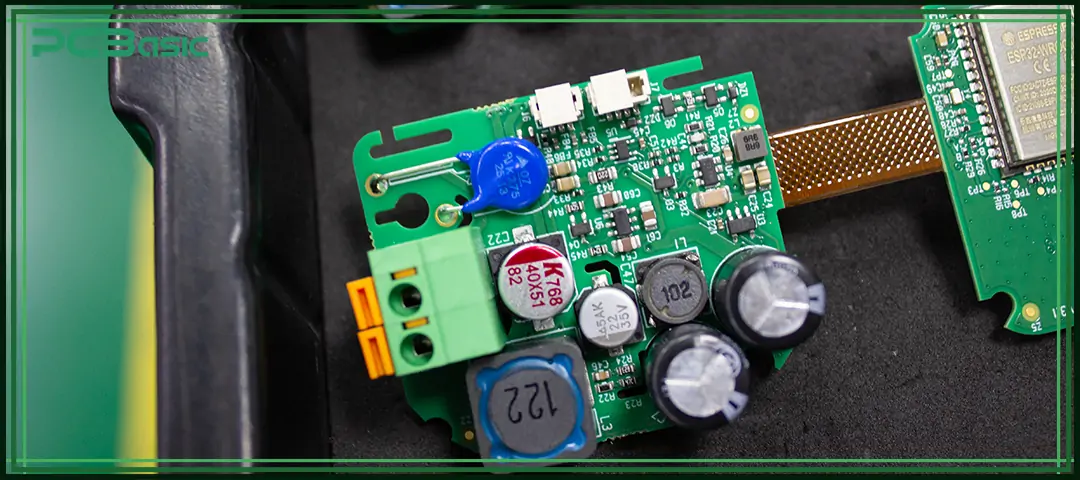

Printed Circuit Board Assembly (PCBA) is the key process to bring circuit boards to life. It turns an ordinary copper-clad board into the core part of electronic products. In simple terms, PCB manufacturing and assembly are the processes of transforming circuit designs into a physical device that can function properly. It combines PCB fabrication and assembly, component mounting and soldering together to form a highly automated production process.

Today's PCB assembly services are not just simple soldering, but a complete set of digital production systems. Modern PCB manufacturing assembly lines will use MES and ERP systems to manage production, and combine 3D AOI, X-ray inspection and precise reflow soldering processes to ensure that each printed circuit board assembly complies with international quality standards such as ISO 9001, IATF 16949, IPC-A-610.

This guide will take you to have a comprehensive understanding of the circuit board assembly process - from design file preparation and PCB board assembly techniques to inspection, testing, and final packaging. You will clearly see how PCBasic, a professional PCB assembly manufacturer, turns circuit designs into truly functional electronic products, helping you understand that efficient, automated and high-quality electronic assembly services are the core force of modern technological manufacturing.

Printed Circuit Board Assembly refers to the process of mounting, soldering and testing various electronic components on a bare circuit board to produce a functional electronic product.

In simple terms:

PCB + electronic components + soldering = PCBA

A PCB is a flat board made of fiberglass (FR-4), copper foil and insulating materials, which is used to carry electronic components and provide electrical connections between them. When components such as resistors, capacitors, IC chips and connectors are mounted and soldered, it becomes an assembled PCB that can drive electronic products to operate.

PCB assembly manufacturers generally adopt advanced electronic assembly services, covering the entire process of PCB fabrication and assembly. This can ensure that each PCBA board meets the standards in terms of electrical performance, mechanical strength and environmental reliability.

Unlike PCB fabrication, which only produces empty boards, PCB assembly services also include steps such as component placement, soldering, inspection and functional testing. It is a crucial step in transforming a circuit design into truly functional electronic hardware.

According to different circuit designs, layer counts and component types, circuit board assembly can be divided into various forms. The main types are as follows:

|

Assembly Type |

Description |

Typical Application |

|

Single-sided SMT Assembly |

All SMD components mounted on one side of the PCB. |

LED lighting, power modules |

|

Double-sided SMT Assembly |

SMD components mounted on both sides, enabling higher circuit density. |

IoT devices, smartphones, wearables |

|

Mixed Assembly (SMT + THT) |

Combination of surface-mount and through-hole components; may appear on same or opposite sides. |

Automotive, industrial control, and medical devices |

|

Full THT Assembly |

All components are through-hole and wave-soldered or hand-soldered. |

Power supplies, connectors, transformers |

At present, most PCB assembly companies prefer to use SMT PCB assembly to achieve high-density circuit design. Through-hole assembly is usually used for large-sized components with high requirements for heat dissipation or mechanical strength, such as connectors and transformers.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Before carrying out PCB board assembly, file preparation is very crucial. At this stage, the main focus is to confirm whether the design can be manufactured, whether the components can be purchased, and whether the process is feasible.

PCB assembly companies usually require several key documents before production begins, including Gerber Files, BOM (Bill of Materials), CPL or PnP File, assembly drawings, notes and testing files

Complete and accurate files help reduce rework and speed up the PCB board assembly process.

Before PCB assembly, engineers perform Design for Manufacturability (DFM) and Design for Assembly (DFA) checks to find potential issues such as:

• Incorrect pad spacing or trace width

• Missing polarity or reference marks

• Improper component height or test point layout

• Obsolete or unavailable components

A good DFM review helps detect problems early and ensures smooth production for any circuit board assembly.

After the files are approved, PCB assembly manufacturers verify all materials and components:

• Use only authorized parts to avoid counterfeits

• Check the Moisture Sensitivity Level (MSL) of ICs and BGAs

Confirm storage conditions, shelf life, and traceability labels

This ensures every PCBA board meets the same reliability and quality standards.

After the data is confirmed, the production team will program the pick-and-place machine and the inspection equipment. Modern PCB manufacturing assembly lines achieve automated assembly through CAD automatic import, and the mounting speed can reach more than 50,000 pieces per hour.

SMT PCB assembly is the core technology of modern electronic manufacturing. It can directly mount components onto the PCB surface without drilling holes for each pin, achieving miniaturization, high speed and automated assembly.

The solder paste is accurately applied to the PCB pads through an SMT stencil printing machine to prepare for the subsequent mounting. The amount of solder paste must be precise - too much may cause short circuits, and too little can lead to bridging or weak joints. Each SMT line of PCBasic is equipped with a 3D solder paste inspection (SPI) system to ensure correct thickness and position.

The high-speed pick-and-place machine takes parts from the material tape and precisely places them in the solder paste position. Small components are assembled by high-speed machines, while large ICs and connectors are mounted by general-purpose machines.

The completed PCB board assembly enters the reflow oven. The solder paste is melted through controlled heating to form a firm connection with the pad.

After soldering, the circuit board undergoes automatic optical inspection (AOI) to check for issues such as missed soldering, misalignment, or solder defects. The discovered defects will be immediately repaired at this stage to ensure that the SMT PCB assembly meets the factory standards.

Although most PCB assembly services nowadays adopt SMT PCB assembly technology, through-hole assembly is still very important. It is suitable for components that require a stronger mechanical fixing force or can carry large currents, such as connectors, transformers and power modules.

In through-hole soldering, the pins of the components are inserted into pre-drilled holes on the PCB and then connected to the copper pads with solder. This step can be done manually or automatically using wave soldering.

• Component Preparation and Insertion – The component leads are formed, trimmed, and inserted into the holes.

• Flux Application – Flux is applied to clean the surface and prevent oxidation during soldering.

• Preheating – The PCB is gradually heated to prevent thermal shock.

• Solder Wave – The board passes over a wave of molten solder, and all leads are soldered at once.

• Cooling – The solder cools and solidifies, creating strong joints.

Wave soldering is often used for large-sized or highly reliable devices. When the space on the board is limited, PCBasic can also adopt selective soldering.

As a high-standard, strict PCB assembly manufacturer, PCBasic has established a strict inspection system to ensure that products leave the factory without defects. Quality control is an important stage to ensure that the PCBA board complies with international standards such as IPC-A-610 and ISO before shipment.

Key Inspection Methods

• SPI (Solder Paste Inspection): Measures paste volume and alignment before placement.

• AOI (Automated Optical Inspection): Detects solder bridges, missing parts, and polarity issues.

• X-ray Inspection: Essential for hidden joints like BGA and QFN packages.

• Manual Microscopy: Human verification for complex or irregular components.

The data collected from these detection systems can achieve full traceability of PCB manufacturing and assembly. PCBasic has its self-developed MES (Manufacturing Execution System), which can achieve real-time process monitoring and data-based quality management.

After assembly is completed, the circuit board will undergo various electrical tests to verify its performance and reliability. PCBasic will adopt different testing methods according to the batch size and complexity of the products:

Checks electrical continuity, resistance, and component functionality on every circuit.

Ideal for prototypes or low-volume builds; flexible, non-invasive, and fast.

Simulates real-world operation to confirm that the PCB board assembly behaves as expected.

Used for automotive, aerospace, and medical electronics—PCBs run under high temperature or stress to expose early failures.

Verifies signals on inaccessible pins of microprocessors and FPGAs.

These tests are a crucial stage in the printed circuit board assembly services, ensuring that each PCBA board can work stably and reliably before entering the final product.

Even a well-soldered assembled PCB board requires perfect post-processing. Cleaning, conformal coating and final assembly are important steps to ensure the long-term stable operation of the product.

The function of cleaning is to remove the residual flux, dust or other contaminants after soldering. If these residues remain on the circuit board, they may cause corrosion, leakage or even short circuits.

In PCB manufacturing and assembly, common cleaning methods include deionized water washing, solvent-based spray cleaning, and ultrasonic cleaning.

When circuit boards are used in environments with high humidity, a lot of dust or exposure, PCB assembly manufacturers usually apply a conformal coating.

The coating materials include acrylic, silicone and polyurethane. Conformal coating can effectively prevent moisture, dust, salt spray or chemical substances from eroding the circuit.

After cleaning and coating, the circuit board will enter the final assembly stage. PCB assembly companies will check whether the solder joints are good and the component orientation is correct to ensure there are no assembly errors. Afterwards, the circuit board will be packaged in ESD-safe materials and labeled to prevent static damage during transportation.

After these steps, the entire PCB manufacturing assembly process is considered to be over. In this way, the circuit boards received by customers can be directly used for mass production, which is stable, safe and reliable.

The complete PCB board assembly process - including SMT PCB assembly, through-hole assembly, testing and inspection - is at the core of every high-quality electronic product. From solder paste printing, reflow soldering, to automated inspection, every step ensures the accuracy and reliability of the product.

Choosing an experienced PCB assembly manufacturer can make your project more efficient and stable, and you can enjoy:

High-speed automated production lines, international quality certifications (ISO9001, IATF16949, ISO13485), digital traceability systems (MES+ERP), and flexible production capabilities from prototype to batch production.

PCBasic has a complete capability in PCB manufacturing and assembly and provides one-stop electronic assembly services, covering SMT assembly, through-hole soldering and functional testing. Whether it's a prototype or a large order, PCBasic can efficiently implement your design with high speed, high quality and high reliability.

Contact PCBasic immediately to experience reliable PCB assembly services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.