Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top Flex Circuit Manufacturer Guide: Choosing the Best for Your

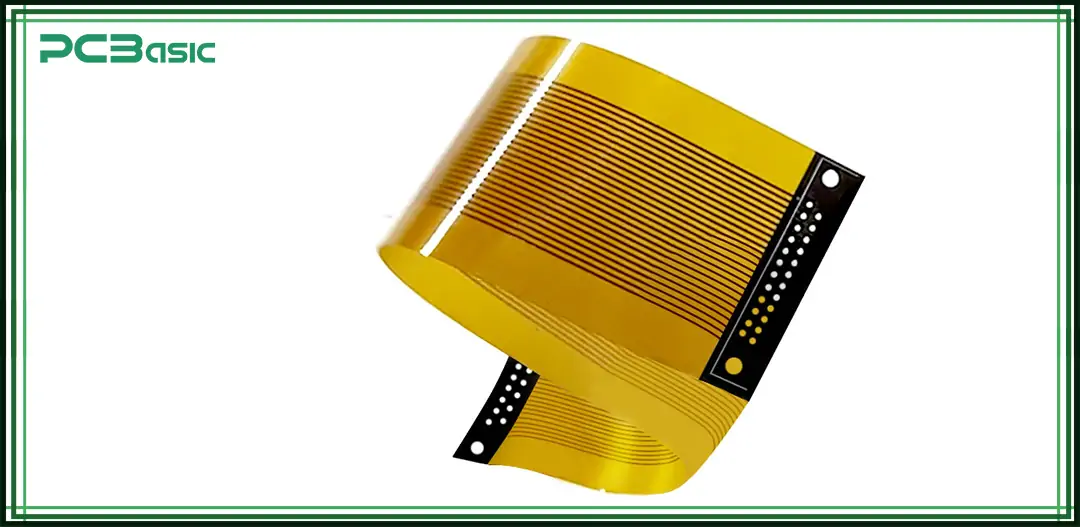

Flexible PCBs are of great significance in today's electronic products. They are used in medical devices, smartphones, automotive systems, and aerospace equipment. Flexible circuit boards can be bent, take up less space and have a more reliable structure. This makes them highly suitable for small and high-performance products.

Choosing a reliable flex circuit manufacturer is crucial to the success of the product. Professional flexible PCB manufacturers can offer high-quality production, material support and rapid delivery. Whether you are building a prototype or starting full production, the right flex circuit board supplier affects both performance and cost.

This guide will introduce the basic knowledge of flexible printed circuits, their main applications, and how to choose a reliable, flexible circuit board manufacturer.

A flex circuit, also known as a flexible printed circuit board, is a special type of circuit board. It is made of a soft plastic material that can be bent, usually polyimide. Unlike ordinary rigid circuit boards, flexible circuit boards are not hard or stiff. It can be bent, twisted and even folded. This makes it very useful in small devices or parts that need to be moved.

A flexible PCB consists of several important parts:

• Flexible substrate: the bottom layer. It provides strength and insulation while allowing the circuit board to bend without breaking.

• Copper conductor: the part used for conducting electricity. It forms the circuit paths or traces on the board.

• Adhesive or coverlay: applied on top of the copper. It protects the circuit from damage and also helps the circuit board remain insulated.

There are several different types of flexible PCBs, each used for different requirements:

• Single-sided flex circuit: has only one layer of copper and is the simplest type.

• Double-sided flexible PCB: has two layers of copper, which are connected by small holes called through vias.

• Multilayer flexible PCBs: have three or more copper layers and are suitable for more complex circuit designs.

• Rigid-flex PCBs: combine the rigid part and the flexible part. One part of the board can be bent while the other part remains stiff. This design is applicable to specific equipment structures.

Many engineers like to use flexible PCBs in their designs. This is because flexible circuit boards can save space, and they are lighter than rigid boards and more capable of withstanding bending and vibration. This makes them highly reliable in harsh environments or scenarios with moving parts.

Flexible printed circuit boards are widely used in many industries. They are used in products such as mobile phones, medical devices, cars and aircraft. Often, ordinary rigid boards are too large or too fragile to be used. Therefore, engineers often choose flexible PCBs as substitutes.

Flexible printed circuit boards are electronic components with very wide applications. Because it can be bent, save space and is very reliable, it is used in many industries. Many flexible circuit manufacturers provide services for the following industries:

1. Consumer Electronics

Flexible PCB boards are widely used in mobile phones, tablet computers, digital cameras and various wearable devices. These products are usually very small and the interior space is very tight. The use of flexible circuit boards can help save space and enhance the reliability of equipment. For instance, the screen ribbon cable in a mobile phone uses a flexible circuit.

2. Automotive Electronic Systems

In modern vehicles, flexible PCBs are increasingly used. They are used in infotainment systems (such as central control screens), rearview cameras, sensors and engine control modules. Because cars operate in environments with high temperatures, vibration, and dust, flexible circuit boards must be used to ensure safety and stability. Reliable flexible circuit manufacturers will specifically design these circuit boards to meet the challenges of the automotive environment.

3. Medical Devices

Many medical devices are flexible PCBs, such as pacemakers, hearing aids, and various diagnostic devices. The advantage of using flexible circuit boards is that they can be made very small and can also adapt to the curved space inside the human body. The manufacturers that produce these circuit boards must comply with the strict quality and hygiene standards of the medical industry. Professional flexible circuit board manufacturers can ensure that these products are both safe and reliable.

4. Aerospace and Defense

Flexible printed circuit boards are also widely used in airplanes, satellites and military communication equipment. Because these devices not only need to be light but also capable of working in extreme environments, such as high temperatures, low temperatures, or strong vibrations. These devices have very high requirements for electronic systems and must use flexible circuit boards that have undergone strict testing. Only experienced flexible circuit manufacturers can meet these demanding standards.

An experienced flexible circuit manufacturer will follow a very clear and step-by-step process when making flexible PCBs. This can ensure that every stage of the flex PCB manufacturing meets the quality requirements. The following is a detailed description of the entire process:

1. Substrate Preparation

The first step in making flexible circuit boards is to select the appropriate materials. The commonly used material is polyimide. After selecting the materials, it is necessary to clean and pre-treat the surface of the materials first. This step is to ensure that the copper foil can be firmly adhered to the substrate.

2. Copper Lamination

Next, a very thin layer of copper foil needs to be adhered to the substrate. This layer of copper will become the path used for conducting electricity in the circuit, that is, the channel through which the current flows. This step is the key to forming the conductive structure of the flexible circuit board.

3. Imaging and Etching

This step is to make the circuit pattern. First, apply a layer of photoresist on the surface of the copper foil. Then a photomask is used to expose the desired circuit pattern. After exposure, the copper without patterns is etched away, leaving the circuit traces we need. These traces are the circuit layout on the flexible printed circuit board.

4. Drilling and Plating

Some flexible PCBs are multilayered, and different layers need to be connected to each other. Drilling is necessary at this time. Drilling can be done by laser or mechanical tools. Then electroplate a layer of copper into the hole to connect the upper and lower layers. This step enables multilayer flexible PCBs to conduct electricity between each other.

5. Coverlay Lamination

After the circuit is completed, a protective film, also known as a coverlay or solder mask, should be added. It will be laminated onto the surface of the board, playing a role in protecting the circuit and preventing short circuits. This step is also a very important stage in the manufacturing of flexible PCBs. Without a protective layer, the circuit is very easy to be damaged.

6. Surface Finishing and Electrical Testing

In order to make the board easier to solder, surface finish is also required, such as ENIG or OSP. Next, the circuit needs to be tested to see if there is any open or short circuit. Outstanding flexible PCB manufacturers will also conduct AOI and impedance tests to ensure that the products are fully qualified.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Choosing the right flexible circuit board manufacturer is not just about comparing prices. What truly matters is whether the manufacturer has experience, technology, service, and quality assurance. Below are the key points to consider when selecting an excellent flex circuit manufacturer:

1. Experience in Flexible PCB Manufacturing

A good flex circuit manufacturer should have many years of experience in flexible PCB design, prototyping, and mass production. They should be capable of handling different types of flexible circuit boards and have successful case studies to show. If they have passed industry certifications such as IPC or ISO, that’s even more reliable.

2. Familiarity with Various Materials

Different projects have different material requirements. A professional flexible PCB manufacturer can offer a variety of material options, such as different polyimide thicknesses, copper weights, and dielectric properties. They understand how these materials perform and can help you choose the right ones based on your application.

3. In-House Flex PCB Assembly Capabilities

Some manufacturers only make the bare boards and don’t handle assembly. If they can provide one-stop flexible PCB assembly services, communication becomes easier and delivery times are shorter. Such flex circuit manufacturers can help you save both time and cost.

4. Industry Certifications

Top flexible circuit board manufacturers usually meet international standards, such as IPC-6013 (flex circuit standard), ISO 9001 (quality management), and IATF 16949 (automotive standard). These certifications show that their production processes are well-managed and their quality is reliable.

5. Rapid Prototyping Services

Many projects require the quick development of prototypes. In these cases, time is very important. An excellent flexible PCB manufacturer should be able to offer quick turn flex PCB services to help customers verify their designs quickly.

6. Design for Manufacturability (DFM) Support

During the design phase, engineers may not fully understand the manufacturing limits of the factory. A professional flex circuit board manufacturer will provide DFM (Design for Manufacturability) support early on. They will offer suggestions on layout, stack-up, and material selection to make the product easier to produce and more reliable.

In conclusion, a truly outstanding flexible PCB manufacturer not only has the technical capabilities and equipment but also provides full support from design to delivery. A partner like this ensures that your product can be successfully mass-produced and perform reliably over the long term.

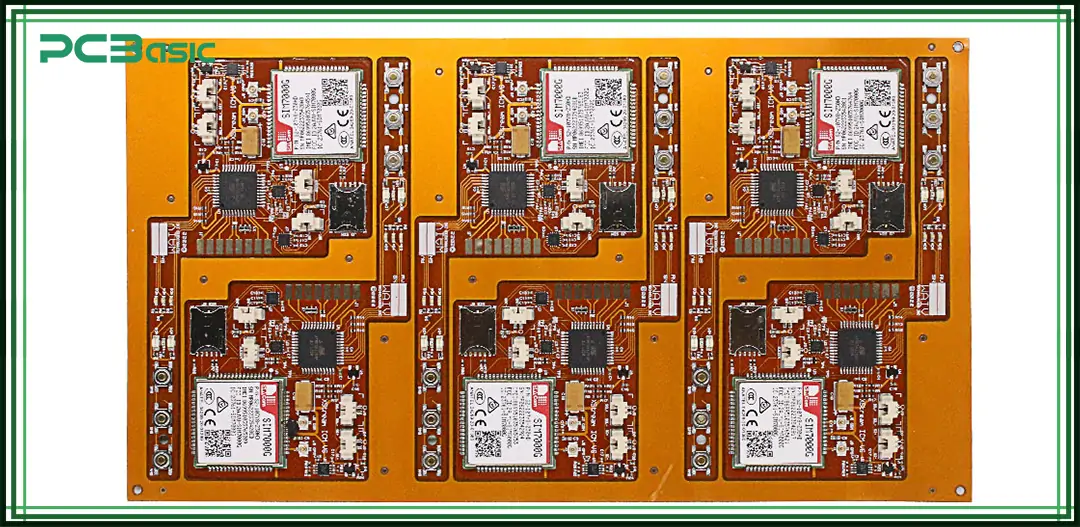

Among many flex circuit manufacturers, PCBasic stands out with strong engineering skills, smart manufacturing systems, and strict quality control. It is a reliable partner for flexible PCB manufacturing.

Strong R&D and Project Management

PCBasic has a team with over 10 years of experience in PCB design and project management. It also works with PhD teams from top universities to improve and develop new flexible circuit board technologies.

Flexible Production and Full Support

PCBasic runs a small-batch quick-turn factory in Shenzhen and a high-volume factory in Huizhou. This setup supports both quick turn flex PCB production and large-scale orders. PCBasic also has its own stencil factory, fixture production center, and CNC precision equipment for one-stop service.

Fast Delivery and Material Supply System

PCBasic has a smart warehouse for electronic components. It uses only original, genuine parts. The company also offers one-click BOM import and online quoting. Stencils can be delivered in as fast as 1 hour.

Certifications and Quality Control

PCBasic is a certified high-tech enterprise. It meets ISO 13485, IATF 16949, ISO 9001, ISO 14001, and UL standards. It is also an IPC member and holds over 20 patents for quality and production systems. All flexible printed circuit boards are made to IPC Class 2/3 standards for high reliability.

Trusted by Global Customers Across Many Industries

PCBasic serves customers in automotive, medical, industrial control, and consumer electronics. It always delivers flex PCB solutions that are cost-effective, fast, and reliable.

Whether you need a prototype, custom design, or high-volume production, PCBasic is ready to provide high-quality and efficient flex circuit board manufacturing. It is a long-term partner you can trust.

With electronic products constantly tending towards miniaturization and dynamism, flexible printed circuit boards have become an indispensable core technology. They can bend and adapt to complex structures, bringing brand-new design possibilities to all walks of life.

However, the success of the project largely depends on which flexible circuit manufacturer is chosen. The ideal partner should not only have manufacturing capabilities but also be able to provide engineering support, customized services, and rapid prototyping. PCBasic excels in these aspects and is a brand that you can cooperate with for a long time in the field of flexible PCB manufacturing.

If you need to customize flexible PCBs, please contact PCBasic immediately to obtain professional support and rapid delivery services from the world's leading flexible circuit manufacturers.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.