Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: Your Trusted Electronic PCB Assembly Provider

In the electronics manufacturing industry, electronic PCB assembly is a key phase in the product from design to final application. Whether it's consumer electronics, medical devices, or industrial control systems, a reliable PCB assembly manufacturer is critical to ensuring product quality and performance.

PCBasic has more than 10 years of printed circuit board assembly experience. It has advanced PCBA manufacturing processes and global supply chain management capabilities, providing customers with efficient, accurate and reliable electronic assembly services.

Electronic PCB Assembly, also known as printed circuit board assembly (PCBA), is the process of assembling and soldering electronic components to a bare PCB to build a complete and functioning electronic circuit. The process involves several key steps, including the precise placement of electronic components, soldering connections, and final quality checks to ensure that the board is operating reliably according to design specifications.

In the PCBA manufacturing process, different types of electronic components require different assembly methods, so as to ensure the stability of electrical connections, mechanical strength, and production efficiency. There are three main electronic assembly technologies.

• Surface Mount Technology, SMT

SMT is the most common technology used in modern electronic PCB assembly. It is suitable for electronic products with small size, light weight and high-density integration. In the SMT process, electronic components are precisely placed on the pad on the PCB surface by an automatic mounter, and the components are soldered and fixed by reflow soldering. This method has the characteristics of high speed, high precision and high degree of automation, and is very suitable for large-scale production.

• Through-Hole Technology, THT

THT is a traditional but still widely used method of electronic PCB assembly. It is mainly suitable for electronic components that require stronger mechanical fixation and high current carrying capacity, such as connectors and large-size electrolytic capacitors. In the THT process, the pins of the electronic components need to pass through pre-drilled holes on the PCB and be connected by wave soldering or hand soldering. This method is especially suitable for industrial control equipment, power modules, and electronic products that need to withstand high mechanical stress.

• Hybrid Technology Assembly

However, the design of modern electronic products often combines SMT and THT technologies to take into account high-density integration and mechanical strength requirements. For example, in the assembly of a printed circuit board, small components with high precision can be assembled by SMT, while components with high power or mechanical strength requirements are assembled by THT technology. This hybrid assembly method is commonly used in automotive electronics, medical equipment, and high-reliability industrial products to ensure their long-term stable operation.

PCBasic is committed to providing comprehensive electronic assembly services to customers worldwide. It has years of industry experience, advanced production equipment and a professional technical team. PCBasic is able to ensure that every project complies with strict industry standards and meets the individual needs of customers.

It offers turnkey PCB Assembly solutions that cover the complete process from PCB design, component sourcing, PCBA manufacturing to testing and packaging. This seamless solution helps customers streamline production processes, reduce costs and shorten project cycles, especially for innovative electronics projects that require fast response times.

PCBasic has two professional PCBA factories in Shenzhen and Huizhou, which can flexibly respond to production needs of different scales:

• Shenzhen factory: Focus on small-batch prototype PCBA and fast production, to meet customer needs for urgent orders, complex prototyping and diversified projects.

• Huizhou factory: Mainly responsible for mass production, with the help of automated production lines and

intelligent manufacturing technology, to achieve efficient and stable mass production.

PCBasic's electronic PCB assembly solutions are used in a wide range of industries, covering a wide range of electronic products from consumer electronics to high-end aerospace equipment.

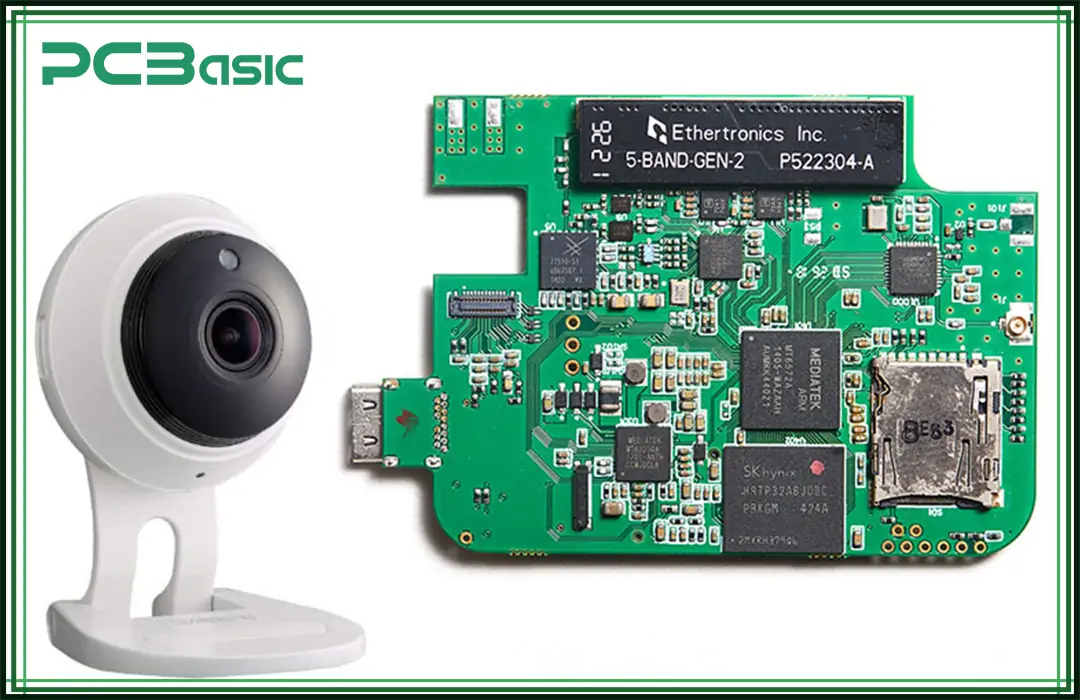

1. Consumer Electronics PCB Assembly

In the rapidly evolving consumer electronics market, products often require compact designs, multifunctionality, and stable performance. PCBasic's advanced SMT technology and strict quality control ensure that every PCB meets precision and reliability requirements.

Application Examples:

• Smartphones,

tablets, and other portable devices

• Smart

home products such as smart speakers, cameras, and thermostats

• Wearable

devices like smartwatches and health monitors

2. Medical Electronics PCB Assembly

Medical devices demand exceptional reliability and stability. PCBasic’s ISO13485 certification for medical device quality management ensures that every medical PCB performs optimally and consistently.

Application Examples:

• Heart

rate monitors, blood pressure monitors, and other portable health devices

• CT

scanners, MRI machines, and other medical imaging equipment

• Laboratory

instruments and patient monitoring systems

3. Automotive Electronics PCB Assembly

Automotive electronics require robust designs to withstand high temperatures, vibrations, and demanding environmental conditions. PCBasic's manufacturing process follows the IATF 16949 automotive quality management system, ensuring maximum safety and reliability.

Application Examples:

• ADAS

(Advanced Driver Assistance Systems) modules

• Electric

vehicle (EV) battery management systems (BMS)

• In-vehicle

infotainment systems and electronic control units (ECUs)

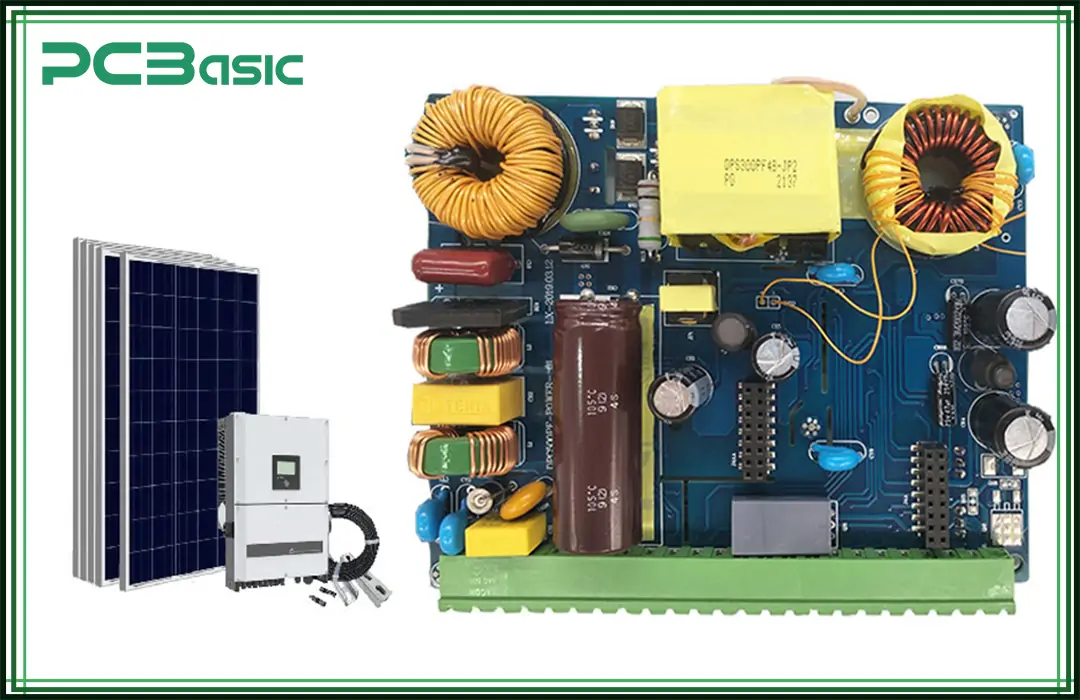

4. Industrial Control PCB Assembly

Industrial control equipment demands stable PCB performance, strong interference resistance, and extended operational lifespan. PCBasic applies advanced THT (Through-Hole Technology) and hybrid assembly techniques to ensure reliability in harsh environments.

Application Examples:

• PLC

(Programmable Logic Controller)

• Inverters,

sensor control modules

• Automation

equipment and robotic control systems

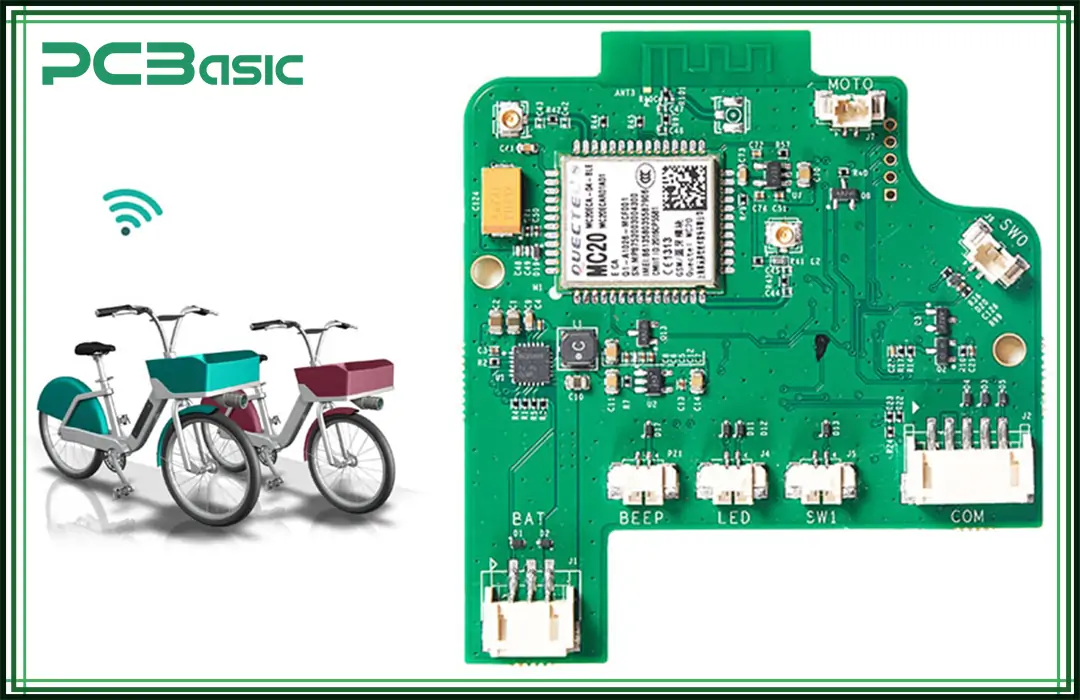

5. Communication Equipment PCB Assembly

In the fast-growing communication industry, maintaining signal integrity and electromagnetic compatibility is crucial. PCBasic has extensive experience in assembling high-frequency and high-speed PCBs to meet the rigorous demands of 5G and fiber optic communication systems.

Application Examples:

• 5G

base stations and wireless network equipment

• Optical

fiber communication devices and data center servers

• Radio

communication systems and satellite communication modules

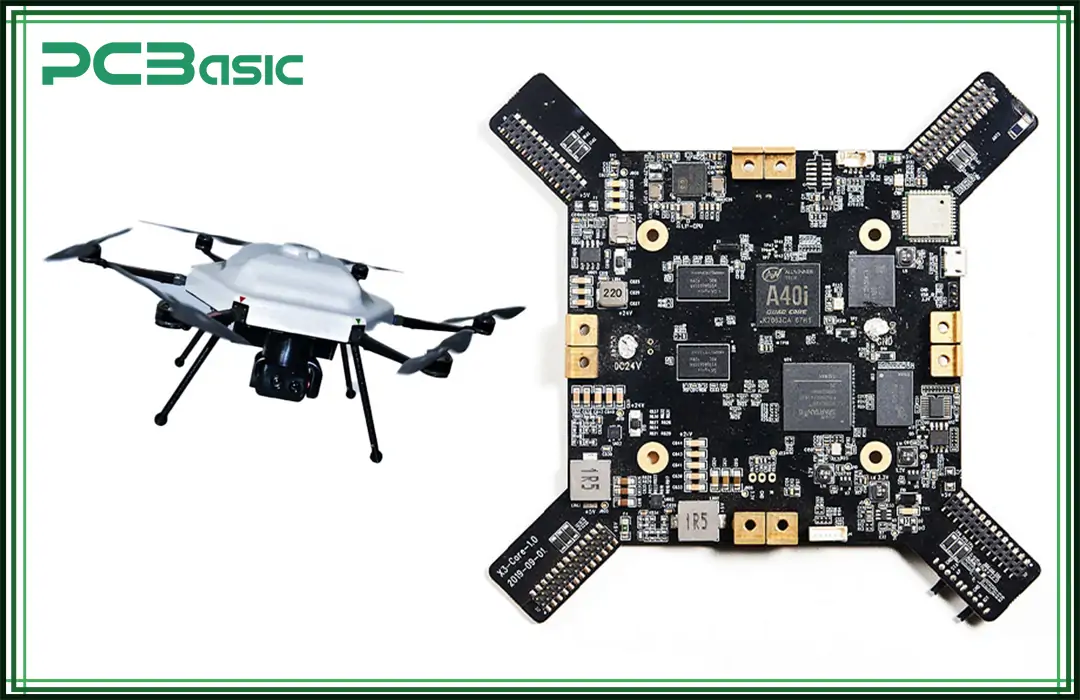

6. Military and Aerospace PCB Assembly

Military and aerospace equipment require extremely high reliability, security, and durability. With strict production processes, precise quality control, and advanced testing equipment, PCBasic ensures that every PCB meets the demanding standards of these high-end applications.

Application Examples:

• Radar

system electronic modules

• Satellite

communication equipment and navigation systems

• Military

electronics and tactical control systems

PCBasic stands out as a trusted PCB assembly manufacturer due to its extensive experience and innovative approach. Here are some reasons why you should choose PCBasic for your electronic PCB assembly needs:

• Experienced Team: PCBasic boasts a team with over 10 years of experience in PCB design and project management, ensuring that every project is handled with expertise.

• Collaboration with Academia: PCBasic collaborates with PhD teams from multiple universities, fostering industry-academia research that keeps its PCBA manufacturing processes at the forefront of technology.

• State-of-the-Art Facilities: With self-operated stencil and fixture factories, PCBasic ensures rapid stencil delivery and precision CNC parts processing.

• Intelligent Warehouse: The company's intelligent electronic components central warehouse guarantees an original and genuine parts supply, reducing the risk of component errors.

• Certifications and Awards: PCBasic is certified by ISO13485, IATF 16949, ISO9001, ISO14001, and UL, and has been awarded over 20 patents for quality inspection and production management systems.

In conclusion, PCBasic is your trusted partner for all electronic PCB assembly needs. With its comprehensive PCB assembly services, cutting-edge technology, and commitment to quality, PCBasic ensures that your electronic assembly projects are completed efficiently and effectively.

Whether you require turnkey PCB assembly solutions or customized PCBA manufacturing services, PCBasic is the ideal choice for transforming your electronic designs into reliable, high-performance products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.