Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Contract Manufacturing Services | PCBasic

In today's highly competitive global market, enterprises must constantly innovate while ensuring fast time-to-market and effective cost control. Building an in-house factory means investing a large amount of money in equipment, skilled personnel, and a long-term supply chain and production management. For many companies, such a model is costly, risky and difficult to sustain in the long term. Therefore, more and more enterprises have begun to choose "contract manufacturing services" as the main model of production.

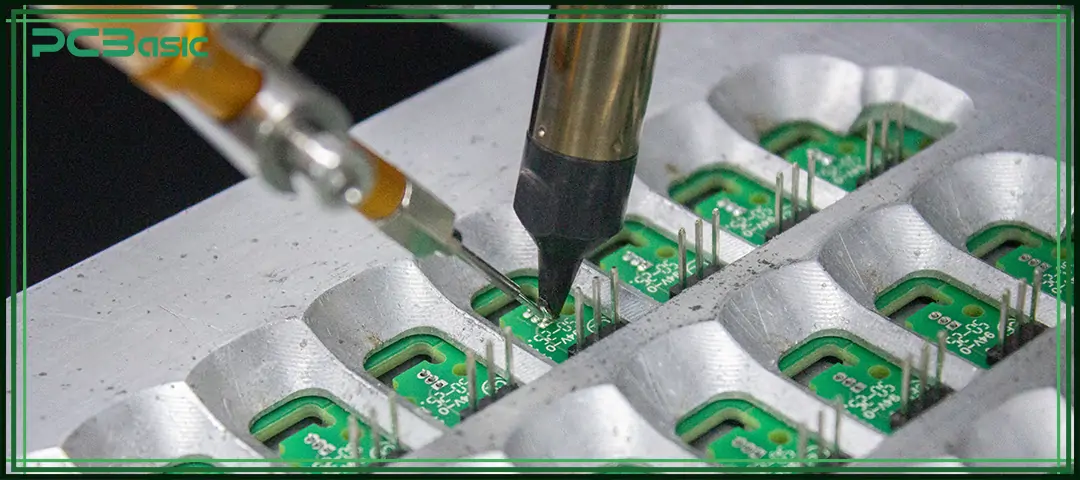

PCBasic is dedicated to providing stable and efficient contract manufacturing solutions for electronic products and PCB assembly. By cooperating with this professional contract manufacturer, enterprises can focus more on product design, brand promotion and market development, while entrusting the complex production work to experienced manufacturing teams. Whether it is a start-up company that has just launched a new product or a mature enterprise that needs flexible expansion capacity, contract manufacturing outsourcing is an effective choice.

This article will introduce contract manufacturing services from a practical perspective, including its basic concepts, contract terms, service types, production processes and main advantages. It also shows how PCBasic provides reliable one-stop electronic manufacturing and full contract manufacturing services for global customers.

Contract manufacturing services refer to a cooperative model in which an enterprise outsources to a third-party manufacturer to complete the production process of its products. The hiring company (commonly known as OEM) provides the product design, technical specifications and performance requirements, while the contract manufacturer is responsible for the specific production work, including manufacturing, assembly, testing, and sometimes also covering packaging and logistics.

In the contract manufacturing industry, related services usually include the following areas:

• Product design and engineering support

• Component sourcing and supply chain management

• Manufacturing and assembly

• Quality inspection and testing

• Packaging and global shipping

Unlike general outsourcing, contract manufacturing focuses on the production and manufacturing of physical products. This makes contract manufacturing companies an important bridge connecting technological innovation and large-scale production. Enterprises can use advanced production equipment, professional engineering teams and mature quality management systems without building their own factories.

In the electronics industry, contract assembly services and EMS (electronic manufacturing services) play a crucial role in the process of transforming PCB designs into final electronic products.

A successful contract manufacturing services partnership depends on a clear and specific agreement. The function of the contract is to clearly define in advance what each party should do, what standards they should meet, and how to handle any problems that arise, so as to avoid misunderstandings later on. Generally, a complete agreement will include the following points:

The agreement specifies inspection criteria, testing requirements, and acceptable defect rates to ensure consistent results.

Volume commitments, batch sizes, and scalability options are defined to match business needs.

Timelines for prototyping, pilot runs, and mass production are clearly stated.

Industry standards such as ISO 9001, ISO 13485, and IATF 16949 are often required in regulated sectors.

Functional testing, traceability records, and technical documentation are included.

Non-disclosure agreements and IP clauses protect product designs and proprietary processes.

Terms for payment, penalties, and dispute resolution are defined.

Through these agreements, contract manufacturing outsourcing can have a production cooperation model with rules, processes and controllable risks rather than a risk-driven decision.

Contract manufacturing services come in various forms, and different types are suitable for enterprises of different scales and needs. Enterprises can choose the most suitable cooperation model based on their product characteristics and production goals.

In this model, the manufacturer is responsible for producing finished products and selling them under the client's own brand. The manufacturer is mainly responsible for the technical and production processes, while the customer is responsible for sales and marketing. This approach is often used for consumer goods and standardized products.

In this approach, contract manufacturers produce only a single component or module, which is then assembled into a complete machine by the customer or other suppliers. This model is often adopted in the electronics, automotive and industrial equipment industries.

In this model, the manufacturer is only responsible for a certain step in the production process, such as soldering, molding or machining. Such subcontractors act as specialized process partners in the supply chain.

This approach is also known as full-service contract manufacturing. From design support to final delivery, it is completed by the same manufacturer and is suitable for enterprises that hope to have the entire production process uniformly managed by a single partner.

The enterprise uses the factory buildings and equipment provided by the manufacturer, but arranges its own personnel to carry out production operations. This approach can rapidly expand production capacity without a large investment in equipment funds.

Electronic contract manufacturing services mainly include PCB assembly, component sourcing, testing, and box-build assembly. EMS service providers can support the entire process of products from prototyping to mass production.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Although the specific details of each project are different, the basic workflow of most contract manufacturing companies is relatively similar.

First, the product design will be reviewed, and manufacturability design (DFM) will be evaluated. Engineers will check whether the design is suitable for production, helping to reduce costs, improve product stability, and ensure a smoother manufacturing process at the same time. Before mass production, prototypes are usually made and tested first.

After the design is confirmed, the factory will produce the required molds and tooling fixtures. Then, small-scale trial production will be carried out to check if the products meet the quality requirements. Only after confirming that there are no issues will mass production start.

After the product is assembled, it will undergo inspection and functional testing, such as AOI, X-ray, ICT and FCT, to ensure the reliable performance of the product. Then, complete the packaging and labeling work according to the customer's requirements.

Under the full-service contract manufacturing model, a single partner is responsible for all stages from design to delivery, making the entire production process more efficient and consistent.

Choosing contract manufacturing services can significantly reduce operating costs. Enterprises do not need to purchase expensive equipment by themselves or form large-scale production teams, thus saving a large amount of funds.

After outsourcing manufacturing, the internal team of the enterprise can focus on more important tasks such as research and development (R&D), marketing and customer management.

Professional contract manufacturers have mature production processes and experience, which can shorten the product development and production cycle and bring products to market more quickly.

Enterprises can increase or decrease production at any time according to market demand without having to invest a large amount of money in building new production lines or purchasing equipment.

Contract manufacturing companies with certification systems adopt standardized production processes and comply with relevant regulatory requirements, which can ensure stable and reliable product quality.

Contract manufacturing is widely used by:

• Startups and small businesses

• Companies launching new products

• Firms lacking manufacturing expertise

• Large enterprises seeking efficiency and scalability

Industries that rely heavily on the contract manufacturing industry include electronics, medical devices, aerospace, automotive, robotics, and consumer products.

PCBasic is a provider of contract manufacturing services specializing in the electronics field. Our core capabilities include:

• PCB fabrication and multilayer PCB manufacturing

• SMT and DIP PCB assembly (PCBA)

• Component sourcing and BOM management

• Functional testing (AOI, X-ray, ICT, FCT)

• Programming and firmware loading

• Box-build and final product assembly

• Packaging and global logistics

We support customers at every production stage:

• Prototype and NPI (New Product Introduction)

• Low-volume and small-batch production

• High-volume mass manufacturing

As a professional contract manufacturer, PCBasic strictly implements quality management systems such as ISO 9001, ISO 13485 and IATF 16949. Through the MES + ERP digital management system, the entire production process can be traced and managed transparently.

PCBasic serves industries including:

• Consumer electronics

• Medical devices

• Automotive electronics

• Industrial control

• IoT and communication equipment

• AI and computing hardware

By providing stable and reliable contract assembly services and integrated EMS solutions, PCBasic helps customers reduce costs, improve product quality, and accelerate the time to market for products.

In today's manufacturing environment, contract manufacturing services have become an important means for enterprises to enhance their competitiveness. Through contract manufacturing outsourcing, enterprises can reduce costs, accelerate the time to market for products, and flexibly expand production scale without investing in a large amount of infrastructure.

Understanding different types of contract manufacturing models and production processes can help enterprises choose suitable partners. Whether it is component production, turnkey solutions, or manufacturing services for electronic products, choosing the right supplier is the key to long-term success.

PCBasic, as a professional contract manufacturing company, provides customers with reliable, high-quality and scalable electronic manufacturing solutions. It is a reliable partner in the contract manufacturing industry.

1: What are contract manufacturing services?

Contract manufacturing services refer to outsourcing product production to a third-party manufacturer. The customer provides the design and requirements, while the contract manufacturer handles manufacturing, assembly, testing, and sometimes packaging and logistics.

2: What industries use contract manufacturing the most?

The contract manufacturing industry is widely used in electronics, medical devices, automotive, industrial control, IoT, and consumer electronics due to its cost efficiency and scalability.

3: What is the difference between contract manufacturing and outsourcing?

Outsourcing covers many business functions, such as IT or customer service, while contract manufacturing focuses specifically on producing physical products and related contract assembly services.

4: Why do companies choose contract manufacturing outsourcing?

Companies choose contract manufacturing outsourcing to reduce costs, speed up production, improve quality, and scale manufacturing without investing in their own factories or equipment.

5: How does PCBasic support electronics contract manufacturing?

PCBasic provides one-stop contract manufacturing services for electronics, including PCB fabrication, PCBA, component sourcing, testing, box-build assembly, and global delivery with certified quality systems.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.