Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Refrigerator PCB: A Complete Guide

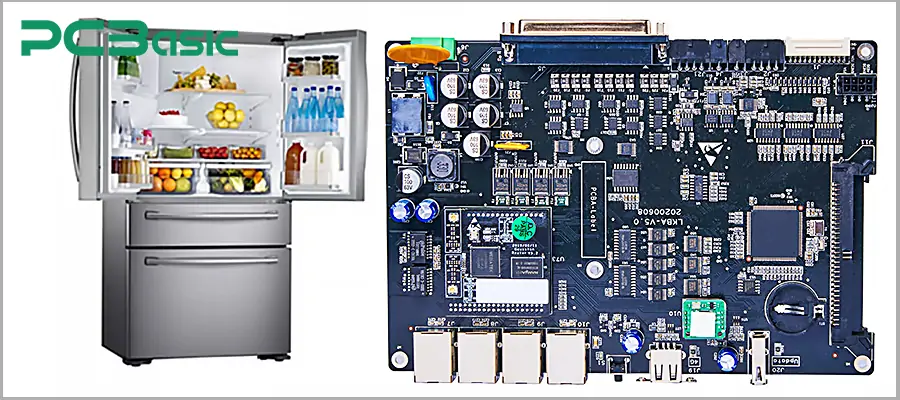

In the context of modern home appliance intelligence, the functions of refrigerators are no longer limited to cooling and preservation. Nowadays, refrigerators are equipped with touch panels, variable-frequency compressors, multi-zone management, and even support Wi-Fi remote control. All these functions would not be possible without the role of the refrigerator circuit board.

Whether it is a basic single-door refrigerator or a high-end model with an intelligent control module, a PCB in the refrigerator plays the role of the command center. It controls the compressor, fan, electric heater, and user interface and other functional components. It is the key component that ensures the stable, efficient operation and timely response of the entire system. Therefore, it is very necessary to understand the relevant knowledge of the refrigerator PCB. If you want to deeply understand what a PCB is in a refrigerator, or are facing the practical problem of replacing the faulty refrigerator PCB, our article will provide you with comprehensive technical references.

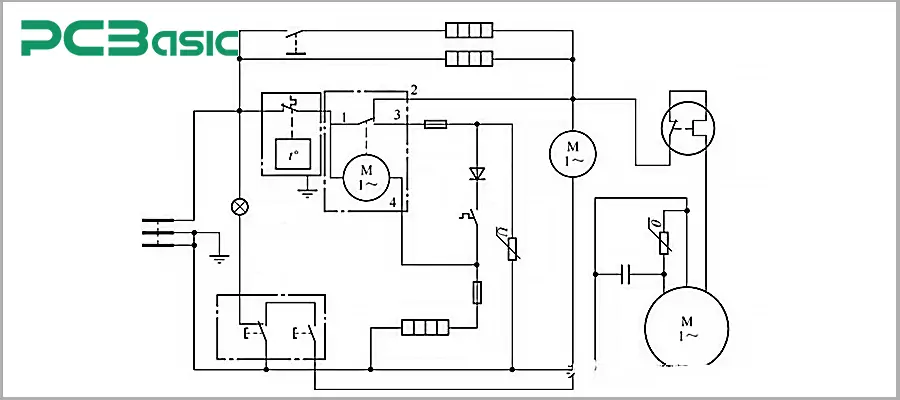

The refrigerator PCB, also known as the main printed circuit board, the refrigerator control board, or simply the fridge PCB, is the main control unit inside the refrigerator that manages and coordinates all electrical and electronic functions. It is usually located on the back of the refrigerator or behind the control panel. Through it, we can integrate various sensors, relays, motors, and user interface components into a unified and controlled system. It continuously receives data from sensors throughout the refrigerator, such as:

Temperature sensors in the refrigerator and freezer compartment

Defrost sensors on the evaporator

Refrigerator door control switch

Humidity sensors, current monitoring module, etc.

These signals are input into the main control chip (such as an MCU or an embedded controller), and after being processed by the program logic, control instructions will be generated, which in turn will drive the related functional modules. The core modules related to the PCB control of the refrigerator include:

Temperature regulation: The main control board reads data from temperature sensors such as thermistors to decide whether to start the compressor and adjust the fan speed to maintain stable temperatures in the refrigeration and freezing areas.

Compressor management: Based on the set temperature and actual detection results, it sends signals to start or stop the compressor. At the same time, an internal start delay mechanism is included to prevent frequent compressor startups and stoppages from causing losses.

Defrost control: The refrigerator circuit board will perform defrosting procedures at regular intervals or upon sensor triggers to ensure refrigeration efficiency.

Fan control: The PCB will control multiple fans (such as condenser fans and evaporator fans) based on the operating status and temperature zone requirements to achieve uniform distribution of cold air within the refrigerator.

User interface management: It manages human-machine interaction modules such as display panels, LED lights, touch or button inputs.

In this section, we will introduce the internal structure and key components of the refrigerator PCB to you.

A typical refrigerator PCB board is usually composed of 1 to 4 conductive layers. Basic models of refrigerators mostly use single-sided FR-4 boards, while high-end smart refrigerators may adopt multi-layer high-density interconnect boards. Generally speaking, a refrigerator PCB typically includes the following main functional layers:

Top layer (component side): installs core components such as microcontrollers, connectors, and relays.

Internal layers (specific to multi-layer PCBs): used for power layers, ground layers, signal routing, and electromagnetic shielding.

Bottom layer (solder side): arranges secondary components and surface mount devices (SMDs).

In addition, refrigerator PCBs are usually equipped with moisture-proof, mold-proof, and anti-static coatings to ensure the stability of the circuit board in complex environments. Reasonable layout and layering design can effectively reduce electromagnetic interference to the PCB and improve the reliability of signal transmission.

The function of the PCB ultimately depends on the electronic components installed on these layers. Common key components on the refrigerator circuit board include:

Microcontroller Unit (MCU): The microcontroller unit can be regarded as the "brain" of the entire refrigerator PCB. In most cases, it is installed on the top layer. Its responsibility is to collect and process signals from various sensors, and then, based on the preset program logic, send control instructions to the compressor, fan, heater, and other execution modules. The MCU is the decisive factor for the operation strategy and working state of the refrigerator. Its stability directly affects the reliability of the entire refrigerator control board.

Relays: A relay is a switching device that operates based on the principles of electromagnetism. It controls the start and stop of high-power components (such as compressors, defrost heaters, and evaporator fans, etc.). Due to the need to handle high currents, they are usually placed in the area close to the power conversion circuits. This layout not only enhances safety but also helps to reduce electromagnetic interference.

Sensors: Sensors are the foundation for the intelligent control of refrigerators, serving as the "nerve endings" that allow the refrigerator to perceive its external and internal conditions. They are connected to the MCU via analog or digital signals and continuously monitor the operating status. Common sensors include thermistors (for temperature detection), humidity sensors (for regulating the humidity inside the refrigerator), and door switch sensors (for detecting whether the door is closed). These seemingly simple functions form the basis for the precise regulation and energy-saving operation of smart refrigerators.

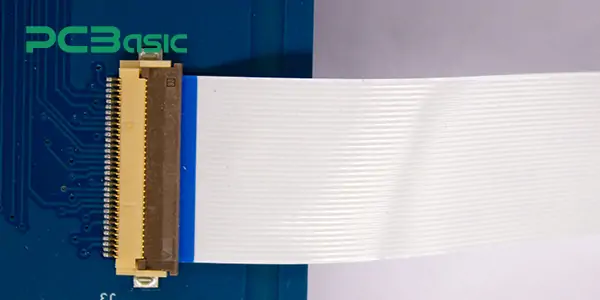

Connectors: The connectors are used to connect the refrigerator board with other functional modules of the refrigerator, such as motors, lighting lamps, user operation panels, etc. A reasonable layout of connectors not only optimizes the signal and power transmission, but also supports modular maintenance. Thus, when the repairer replaces the refrigerator PCB board or other components, they only need to remove and plug in the corresponding interfaces. This method greatly enhances efficiency.

Power Conversion Circuitry: The power conversion circuitry is responsible for converting the input AC power from the mains supply into the required DC power for multiple components, providing power to different elements. It is usually composed of components such as rectifiers, switching power supplies, EMI filters, capacitors, and inductors. An efficient and stable power system can protect the precision electronic components on the PCB in the refrigerator from damage caused by voltage fluctuations.

LEDs & Display Drivers: Nowadays, refrigerators often come equipped with LED displays or touch panels for displaying temperature, operating status, and intelligent function menus. These LED and display driver circuits may be directly integrated on the main control board or connected through cables to an independent user interface (UI) board.

The reasonable layout and high-quality components ensure that the refrigerator operates stably and energy-efficiently in various complex environments.

There are many factors influencing the price of PCB in refrigerators. In terms of design complexity, the basic analog refrigerator circuit board has a relatively lower price; while the intelligent refrigerator control board that incorporates microcontrollers, inverter control, Wi-Fi connection and multi-zone management is much more costly. Generally speaking, the more complex the design, the higher the price of the circuit board.

The compatibility between the brand and model also affects the price of the refrigerator PCB. For instance, some refrigerator PCB boards must match specific brands and models, and naturally, the price will be higher. The following table shows the reference range of the prices of some mainstream brands' PCBs in refrigerators that we have surveyed.

|

Brand |

Price Range (USD) |

Advantages |

|

Samsung refrigerator PCB board |

$50 – $150 |

Mature design with good compatibility; |

|

LG refrigerator PCB board |

$55 – $370 |

High durability for original boards; |

|

Godrej refrigerator PCB board |

$30 – $90 |

Budget-friendly; |

|

Whirlpool refrigerator PCB board |

$50 – $140 |

a good balance between cost and performance; |

Of course, manufacturing quality and certification are also major factors affecting the refrigerator PCB. High-end refrigerator boards often use high-quality FR-4 or halogen-free materials, are equipped with gold-plated connectors, and are coated with moisture-proof, dust-proof, and anti-corrosion three-in-one paint. Although this design, which complies with RoHS or UL and other certification standards, is more costly, it has better long-term reliability in humid and high-temperature kitchen environments.

When problems such as the refrigerator's inability to cool, the buttons not responding, or the complete failure to start the refrigerator occur, how should we solve them? First, we should conduct a fault investigation. After confirming that the problem is indeed caused by the damage or failure of the PCB, then follow the steps below to replace it.

The first step is to prepare the appropriate tools.

Screwdrivers - Cross and flat-head screwdrivers, suitable for the type of screws used in the refrigerator

Multimeter - To test the connectivity and voltage before and after the replacement

Anti-static wrist strap - To prevent static discharge from damaging the refrigerator PCB board

Protective gloves - To protect the hands and increase grip strength

Camera or mobile phone - To take photos of the wiring for reference during reinstallation

User manual or repair guide - To obtain the specific disassembly and assembly methods for the model

After all the tools are ready, you can start the disassembly, replacement, and assembly. Before disassembling and repairing, make sure to cut off the power supply of the refrigerator and, if possible, disconnect the water inlet pipe.

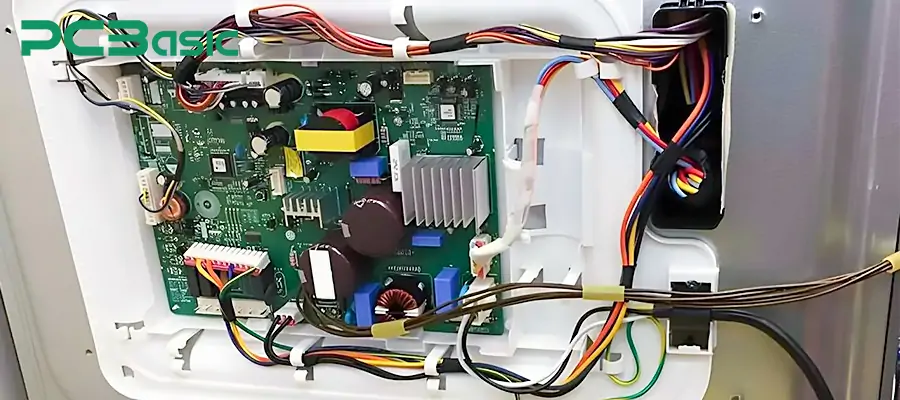

First, we need to locate the position of the PCB in the refrigerator. Usually, it is located behind the maintenance panel on the back of the refrigerator. However, there is also a possibility that it is inside the top control panel. We can quickly confirm the exact location by referring to the refrigerator's maintenance manual.

Next, access the area where the PCB is located. Remove the screws that fix the maintenance panel, then gently remove the panel and expose the refrigerator control board. (Note: You can store the screws together to avoid losing them)

Then, use a camera to take clear photos of the wiring to ensure accurate connection of each wire during reinstallation. Start disconnecting the wires, carefully remove all the wire bundles on the PCB. If you encounter interfaces with snap-on clips, gently press the clip before pulling out.

Remove the faulty PCB again. (When removing, only hold the edges of the PCB and move it to avoid touching the components.) Then install the new board. Place the new refrigerator PCB in its original position and fix it with screws to ensure the position is accurate and secure.

After the installation is completed, reconnect the wires in the order shown in the reference photo. Finally, reassemble the refrigerator, reinstall the maintenance panel and tighten the screws, and clean up the surrounding dust and debris.

Note: Installation is not the end.

After installation, multiple tests need to be conducted. First, perform an electrical check to confirm if the compressor starts; then conduct a function test to ensure the display, buttons, and temperature adjustment functions are normal; subsequently, perform a refrigeration verification by checking if the internal temperature reaches the set value after several hours; finally, conduct a 24-hour observation to continuously monitor for one day to ensure stable operation and no abnormal noise or fault codes. Once all are fine, it indicates that the refrigerator PCB replacement was successful.

PCBasic is a globally trusted partner. As a professional refrigerator PCB manufacturer, PCBasic has advanced production lines and mature assembly processes, and is capable of providing stable and reliable refrigerator PCBs for various models of refrigerators. They are well aware of the importance of refrigerator PCB prices to customers, and therefore, while ensuring quality, always maintain competitive prices.

By choosing PCBasic, you will receive:

ISO-certified manufacturing quality

Support for multiple models

Competitive prices

Fast delivery and global distribution

Whether you need large-scale mass production or small-batch supply, PCBasic is your reliable expert in refrigerator PCB (refrigerator PCB) production and assembly.

The refrigerator PCB is the core of the refrigerator, managing various intelligent functions such as cooling, defrosting, and temperature control. With the continuous development of refrigerator technology, the refrigerator PCB motherboard has integrated more functions, including Internet of Things connection, adaptive energy consumption management, and more advanced fault diagnosis functions.

If you need high-quality, durable, and cost-effective refrigerator circuit board solutions, you can collaborate with experienced manufacturers like PCBasic.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.