Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Aerospace PCB Assembly | A Comprehensive Guide

In high-tech equipment such as aircraft, satellites and spacecraft, the reliability of electronic systems determines the success or failure of the entire mission. Among these systems, the highly complex and demanding aerospace PCB assembly has a significant impact on the quality of the equipment. Unlike ordinary consumer electronic products, PCBs for the aerospace industry need to operate continuously and stably in extreme environments, such as low pressure and cold temperatures at high altitudes, strong radiation in space, as well as severe mechanical shock and vibration. These aerospace PCBs must undergo special design and a strict assembly process to ensure normal operation even in extreme environments.

This article will help you gain a comprehensive understanding of aerospace PCB assembly, including its applications, industry standards for material selection and manufacturing, as well as the aerospace PCB assembly process. Meanwhile, this article also introduces you to a reliable aerospace PCB manufacturer and professional electronic assembly contract manufacturer located in Shenzhen, China.

Aerospace PCBs are a type of highly reliable printed circuit board specially designed for aircraft, satellites, and various systems entering space. These aerospace PCBs need to operate stably for a long time in extreme environments, withstanding high stress, strong electromagnetic interference (EMI), sudden temperature changes and continuous mechanical vibrations.

Aerospace PCB assembly is a specialized assembly process for these high-performance circuit boards, including precise component soldering, lamination, testing and final integration to ensure that the circuit boards achieve the highest reliability and safety in aerospace missions.

Compared with the PCBs of ordinary consumer electronic products, aerospace PCB assembly has higher technical requirements at every stage:

• Higher-quality materials: High-performance substrates such as Polyimide, high-frequency copper-clad laminates (like Rogers), and metal core boards are usually selected to ensure high-temperature resistance, radiation resistance, and low dielectric loss.

• Stricter tolerance control: In terms of drilling sizes, trace widths, and interlayer alignment, tolerance control is precise to the micron level to ensure signal integrity and mechanical reliability.

• More advanced reliability testing: It not only includes conventional AOI (Automatic Optical Inspection) and X-Ray inspection, but also requires thermal cycling testing, vibration testing, damp heat testing and high-acceleration life testing (HALT).

• Strict traceability and documentation: From raw material batches, production process parameters to each inspection record, all must be fully archived to meet the quality management requirements of the aerospace industry.

• Comply with global aerospace PCB design standards: Such as IPC-A-610 Class 3, AS9100, MIL-PRF-31032, NASA-STD-8739.1, etc., to ensure that the products meet the internationally recognized safety and performance standards.

The strict production and assembly process ensures that aerospace PCB assembly can work stably for a long time in extreme tasks such as space launches, long-term orbital operations or high-intensity flights without any functional failures.

Aerospace PCB applications are widely distributed in civil and military aviation, defense systems, and various aerospace technology fields. They are indispensable core electronic foundations in all modern aerospace equipment. Aerospace PCBs are like nerve centers, responsible for organically connecting various sensors, control units and communication systems to ensure that the aircraft can operate stably, safely and efficiently in all kinds of environments.

In aircraft, spacecraft and various space mission equipment, aerospace PCB assembly is widely used in navigation, communication, power supply, propulsion control, as well as environmental and safety systems.

Aerospace PCBs provide stable and electromagnetic interference (EMI) resistant signal processing for GPS positioning, radar detection, autonomous driving, flight attitude control, etc. At the same time, they also ensure that satellite communications, air-to-ground data links, airborne radio and space station communications do not distort during long-distance transmission.

Additionally, reliable aerospace PCB assemblies provide a stable power supply for voltage regulation, power conversion and distribution systems. They can achieve precise control of fuel injection, turbine speed regulation and other high-temperature and high-vibration environments in jet or rocket engines. Aerospace PCBs have been operating stably for a long time in safety systems such as fire alarm, oxygen control, cabin pressure monitoring, gas detection and temperature and humidity regulation.

Whether cruising at an altitude of 35,000 feet or on spacecraft orbiting the Earth, aerospace PCB applications must ensure extremely high reliability, fault tolerance and long-term stability to cope with the rapidly changing and extreme operating environment.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Aerospace missions often operate in high-risk, high-load and extreme environments, and any minor design or manufacturing defect cannot be ignored. Therefore, PCBs for the aerospace industry must strictly follow internationally accepted norms and standards during the design stage. Every stage, from circuit design, material selection, to production and manufacturing, must comply with the requirements of the aerospace PCB design standards.

The main standards include:

• IPC-A-610 Class 3: It is the highest-level standard for the acceptability of electronic assembly, applicable to electronic products with extremely high requirements for performance and reliability. It has clear restrictions on soldering quality, component placement accuracy, and cosmetic defects, etc.

• AS9100: Aerospace quality management system standard, covering quality management throughout the entire process, including design, manufacturing, inspection and delivery, ensuring the stability of aerospace PCB assembly products in long-term operation and complex environments.

• MIL-PRF-31032: This is a performance specification for high-reliability PCBs in the US military, which has strict requirements for mechanical strength, environmental adaptability and electrical performance, and is suitable for high-intensity missions such as fighter jets, missiles and spacecraft.

• NASA-STD-8739.1: The electrical connection standard for soldering formulated by NASA of the United States provides detailed regulations on soldering processes, solder joint quality and inspection methods, ensuring that aerospace PCBs can still operate normally under vacuum, strong radiation and extreme temperature variations.

• IPC-2221 and IPC-6012: They are general design guidelines and qualification standards for rigid PCBs, which make unified requirements for materials, routing, stacking structure and reliability testing, etc., and are important components of the aerospace PCB design standards system.

These standards are not only product technical specifications, but also fundamental guarantees to ensure that aerospace PCB manufacturers produce reliable and safe products.

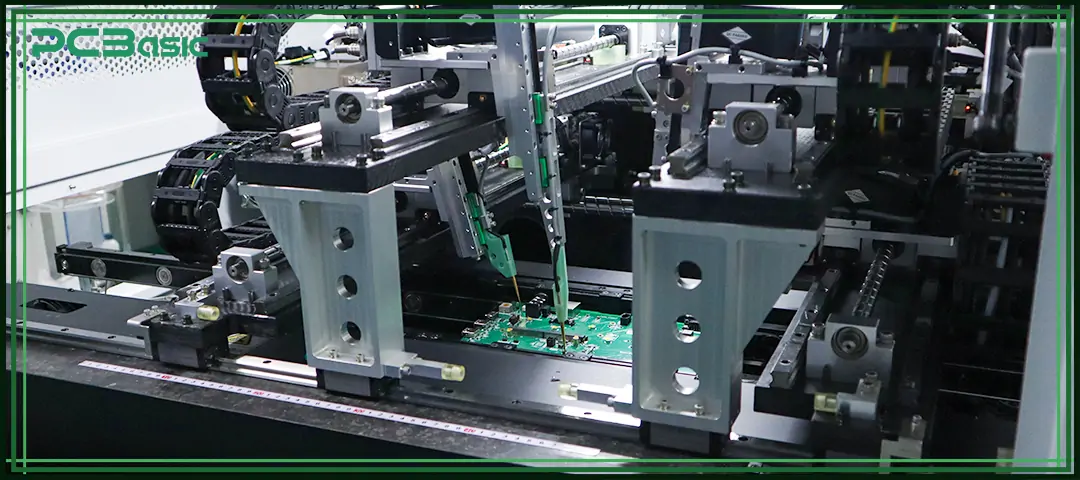

In the aerospace PCB assembly stage, a combination of SMT (Surface Mount Technology) and THT (Through-Hole Insertion Technology) is usually adopted:

Surface Mount Technology Assembly

SMT is the most commonly used method in aerospace PCB assembly, suitable for mounting small-sized and high-precision surface mount components (SMD).

First, use a laser-cut stainless steel stencil to precisely print solder paste onto the PCB pads. This step determines the strength of the subsequent soldering and the quality of the solder joints.

Through high-speed automatic placement machines, components such as resistors, capacitors, diodes, and IC chips are precisely placed onto the positions coated with solder paste. The placement tolerance must be controlled within the micrometer level to meet the precision requirements of the aerospace PCB design standards.

The PCB with components already assembled is sent into the reflow oven. According to the set temperature curves of heating, soaking, reflow and cooling, the solder paste melts and firmly adheres to the pads, thereby fixing the components.

Remove residual flux from the soldering process as required to prevent corrosion of the solder joints or impact on electrical insulation performance.

THT is mainly used for mounting large-sized or pin-type components that require higher mechanical strength, and is widely applied in connectors, high-power devices and some key components in PCBs for aerospace components.

Manually or automatically insert leads of through-hole components into the pre-drilled through holes in the PCB, ensuring that the lead positions are precisely aligned with the hole positions.

For mass production, wave soldering is often used to solder a large number of leads at once. For components in special positions or with higher requirements for soldering quality, manual, precise soldering is carried out by skilled technicians.

After soldering is completed, excess component leads are trimmed, the solder joints are cleaned to ensure a strong bonding, a clean appearance and no extra metal shavings.

In the production of aerospace PCB assembly, testing, and quality control are indispensable processes. To ensure reliability, each PCB must undergo a complete and rigorous inspection process before delivery to verify whether it can work stably for a long time in aerospace missions.

The first is automatic optical inspection (AOI), which checks the shape of solder joints, whether component positions are accurate, whether there are any missed parts, and whether the polarity direction is correct through high-definition cameras and image recognition.

Subsequently, X-ray Inspection is used to check the quality of the bottom solder joints of BGA, QFN, etc., and problems such as voids, short circuits, cold solder joints, and inner layer defects that are difficult to detect with the naked eye are found.

Flying Probe Testing and In-Circuit Testing (ICT) can be used to verify circuit continuity and measure resistance, capacitance, and polarity, ensuring that electrical performance meets design specifications.

Functional testing (FCT) involves running the entire PCB in a simulated actual working environment to confirm whether its signal processing, power output, and interface response functions are normal.

Some aerospace PCBs also undergo environmental stress screening (ESS), subjecting the PCBs to harsh environmental tests such as thermal cycling, vibration and humidity.

In addition, burn-in testing allows the PCB to run at high temperatures for a long time to detect potential early failures in advance. And Hi-Pot testing is conducted to verify insulation performance and dielectric strength, preventing breakdown under high voltage conditions.

PCBasic is a company dedicated to the manufacturing and assembly of precision and highly reliable circuit boards. Its business covers the entire process, including SMT assembly, THT insertion, mixed assembly and test and verification. With advanced production and testing equipment, a strict quality management system and an experienced engineering team, PCBasic has provided customized PCB and PCBA solutions for multiple fields such as industrial control, medical electronics, automotive electronics and aerospace.

• Extensive Experience: Long-term supplier of PCBA products for critical systems such as avionics, satellite communications, and flight control, PCBasic has a deep understanding of industry requirements.

• Strict Standards: The production process of PCBasic complies with the AS9100 aerospace quality system, IPC-A-610 Class 3 high reliability standard, and meets the RoHS/REACH environmental protection regulations.

• Advanced Testing: Equipped with AOI automatic optical inspection, X-ray inspection, ESS environmental stress screening and functional testing, PCBasic ensures that each circuit board can still work stably in harsh environments

• Comprehensive Services: From design review, prototyping to mass production and after-sales support, the entire process is covered to meet the needs of customers at different stages

• Strong Environmental Adaptability: Products can withstand high and low temperature shock, vibration and impact, ensuring long-term reliable operation

PCBasic, supported by authoritative certifications, advanced manufacturing and profound industry experience, delivers high-performance PCBA that operates stably even in the most demanding environments.

In the aerospace and defense fields, electronic devices must not make any mistakes. Therefore, in the design of aerospace PCB assembly, it must be more reliable, safer and more durable. From military drones, commercial aircraft to satellites, the demand for precision, durable and mission-critical electronic equipment is higher than ever before.

Choose an aerospace PCB manufacturer like PCBasic to deliver your products faster, safer and more reassuring.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.