Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

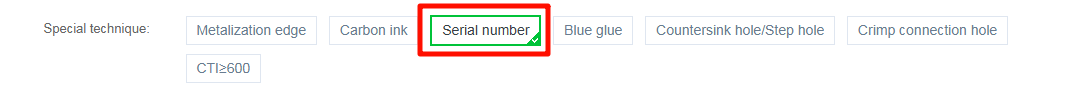

As electronic products continue to evolve in complexity and variety, the ability to track each PCB throughout production, inspection, and maintenance has become increasingly vital. In this context, assigning a unique serial number to every PCB serves as an efficient management and traceability tool. PCBasic provides the option to add serial numbers to your PCBs, allowing you to choose whether to accept or not accept non-consecutive numbering.

The main purpose of a serial number for quality traceability is to achieve complete product tracking. With a unique serial number on each PCB, manufacturers can precisely trace critical information such as the production process, material batch, operator, and inspection record. When a product issue occurs, the serial number enables rapid identification of the root cause, ensuring timely resolution and minimizing losses.

Serial numbers play an important role in optimizing production management. By recording each PCB’s serial number, manufacturers can better control production batches, identify abnormalities during production, and make timely corrections in later stages. This is particularly crucial in large-scale production, improving overall efficiency and consistency.

Serial numbers enhance after-sales support efficiency. When customers report issues, the technical support team can use the serial number to locate the corresponding production data and provide accurate troubleshooting. Serial numbers can also help verify warranty validity and product authenticity.

In warehouse and logistics operations, serial numbers help distinguish between different production batches and prevent mix-ups. During storage, shipping, and inventory management, serial numbers enable efficient tracking, ensuring every board is correctly managed.

In real production, PCBasic typically uses the following methods to apply serial numbers to PCBs:

1. For serial numbers that accept non-consecutive numbering and use solid fonts, a text printer can directly print them in one step.

2. For serial numbers that do not accept non-consecutive numbering and use solid fonts, about 80% can be printed using a text printer, while the remaining 20% require manual printing (applicable to single-piece orders only).

3. In other special cases, manual screen printing is required for all serial numbers, which is not recommended due to high production costs and low efficiency.

PCBasic strictly follows the customer’s required serial number coding format. However, the most common styles of PCB serial number coding include:

1. Simple Numeric Sequence

A pure numerical format such as “00001,” “00002,” etc. This is straightforward but may lead to longer serial numbers as production volume increases.

2. Alphanumeric Combination

Combines letters and numbers, for example, “PCB00123” or “AB1001.” This method is often used to indicate PCB type, version, or product category.

3. Date Coding

Incorporates the production date into the serial number, such as “20231001-001,” meaning the first PCB produced on October 1, 2023. This helps track production time and batches.

4. Batch Number Coding

Includes batch information, for example, “L23-B01456,” where “L23” indicates the batch and “B01456” represents the specific PCB serial number. This format is suitable for mass production and facilitates traceability.

5. QR Code/Barcode Coding

Generates a unique QR code or barcode that includes both letters and numbers, enabling automated scanning and data management. QR codes can also embed detailed information like manufacturer, date, and batch.

6. Mixed Coding

Combines multiple elements such as date, batch number, and production line—for example, “23A-09-00123-P1,” where “23A” indicates the production batch, “09” is the month, “00123” is the serial number, and “P1” represents the line number.

7. ECO (Engineering Change Order) Version Number Coding

When PCBs go through multiple design revisions, the serial number may include an ECO version, such as “00123-ECO3,” indicating that this is the version corresponding to the third engineering change.

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.