Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

In PCB design, screws are often used for mechanical fixation. Sometimes, the screw heads need to be flush with the PCB surface or slightly embedded. To achieve this effect, engineers will design special holes on the circuit board, such as counterbore holes and countersink holes. These holes allow different types of screws to be firmly fastened, while enhancing the functionality and appearance of the circuit board.

A counterbore hole is a cylindrical recess with a flat bottom, usually enlarged from the basis of the original pilot hole. It is often used in situations where the head of the socket head cap screws needs to be recessed or flush with the PCB surface.

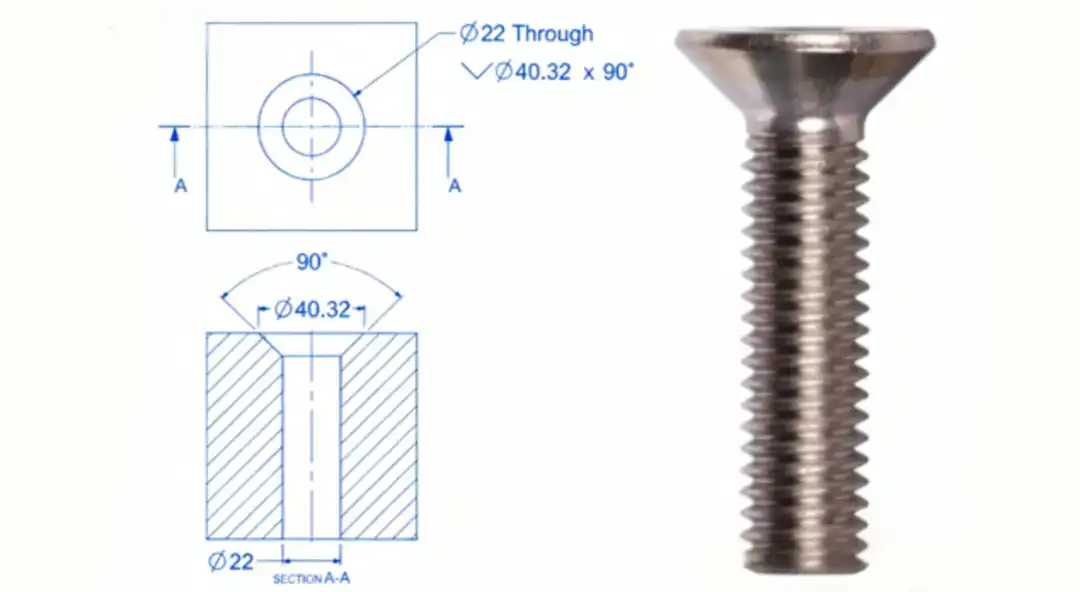

A countersink hole is a recess that is cut into the PCB laminate to accommodate screw heads or bolts with bevels. It enables the screw head to be flush with or slightly lower than the PCB surface, thus keeping the board surface neat and smooth.

In simple terms, the main difference between a counterbore and a countersink lies in the geometry of the hole: the former is a flat-bottomed structure, while the latter is a conical structure.

To correctly manufacture counterbore holes and countersink holes, the corresponding detailed parameters must be provided in the PCB design file.

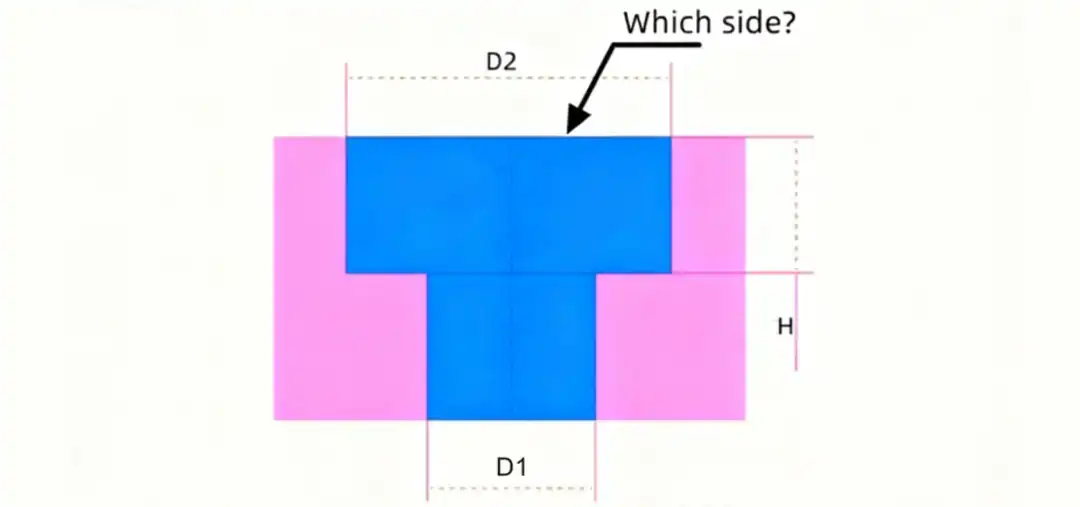

1. Counterbore

• Pilot hole diameter (D1)

• Counterbore hole diameter (D2)

• Depth of the counterbore (H)

• Hole attribute: PTH or NPTH

• Side of the counterbore hole (Top or Bottom)

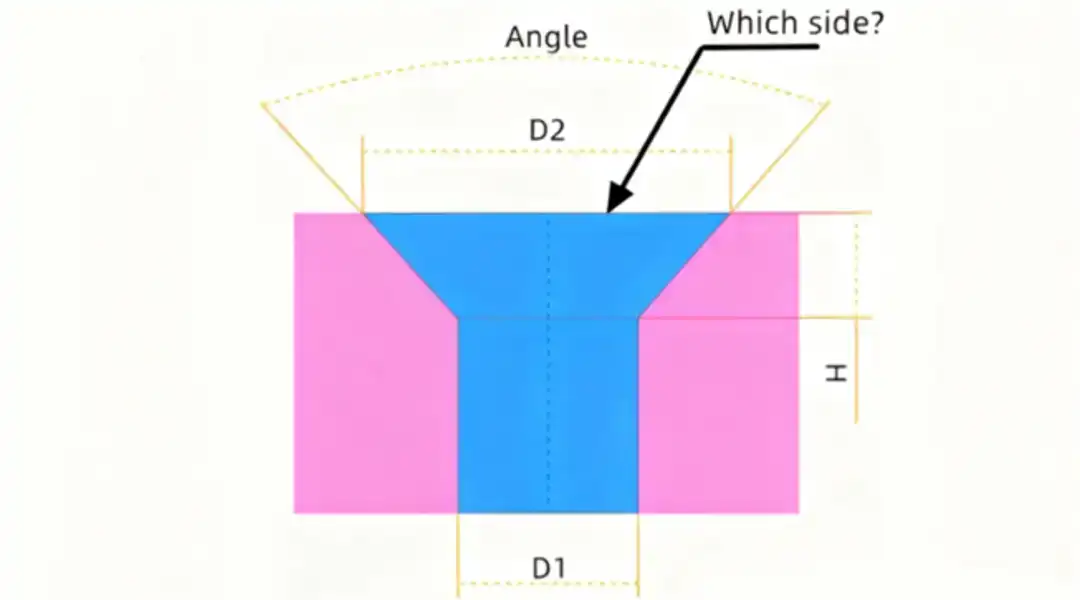

2. Countersink

• Pilot hole diameter (D1)

• Countersink hole diameter (D2)

• Countersink depth (H) or angle

• Hole attribute: PTH or NPTH

• Side of the countersink hole (Top or Bottom)

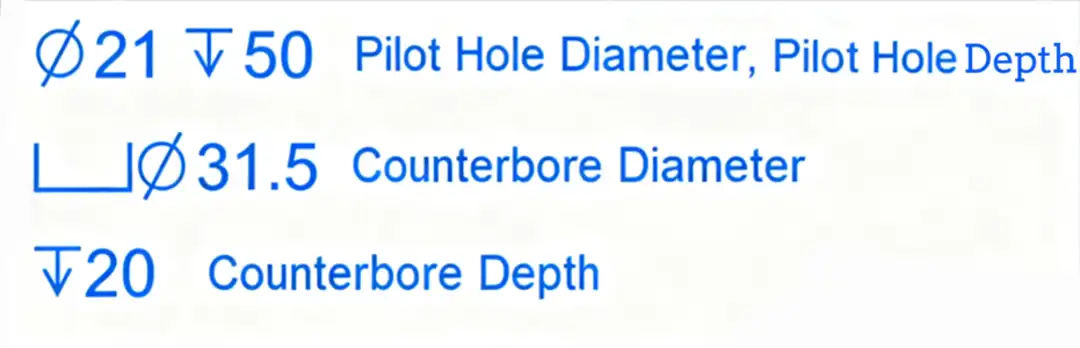

In engineering and PCB design drawings, counterbores and countersinks are distinguished by different standard symbols for easy identification

• The symbol for a counterbore hole is "⌴".

• The symbol for a countersink hole is "⌵".

These standardized symbols enable designers and manufacturers to quickly distinguish between flat-bottom holes (countersunk holes) and conical holes (countersunk holes).

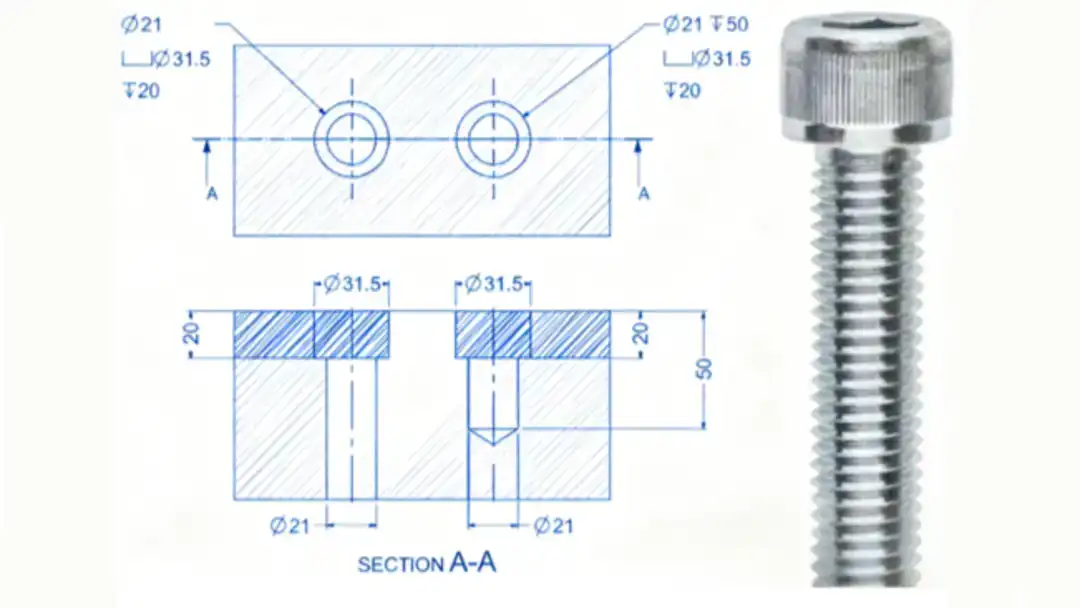

In PCB or mechanical engineering drawings, counterbore vs countersink is usually represented by dimensional notations and symbols.

First, drill a pilot hole (a hole with a smaller diameter), and then process a larger counterbore hole on it.

The typical notation format is:

⌀D1 ⌴ ⌀D2 × H

This marking method is typically used in situations such as M20 hex socket bolts with standard clearance fits.

For the countersink hole, the approach is similar to that of the countersink hole. The difference is that its upper part is a conical structure and is represented by the countersink hole symbol on the drawing:

⌀D1 ⌵ ⌀D2 × 90°

In the drawing, the sectional view below the dimension will show the depth and angle of the hole, helping to understand more clearly the difference between countersink and counterbore holes, as well as the actual drilling method.

In mechanical and PCB design, it is crucial to understand counterbore vs. countersink. Both have the function of making the screw head flush with the surface or slightly embedded, but their structures and uses are different:

• When using flat-head screws, countersink holes should be adopted. These holes are conical in shape and are suitable for the screw head to adhere to the surface.

• When using socket-head screws, counterbore holes should be adopted. These holes have a flat-bottom structure, allowing the screw heads to be fully recessed.

Correctly marking the counterbore hole symbol and the countersink hole symbol in the design drawing can not only ensure the processing accuracy and smooth assembly, but also ensure that the final product meets the design requirements.

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.